WGU C215 Operations Management PVDC Final

1/145

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

146 Terms

Which definition is used for quality, evaluates how well a product performs its intended function?

Fitness for use

14 points for quality improvement

Which total quality management (TQM) process was developed to stress management's responsibility for quality?

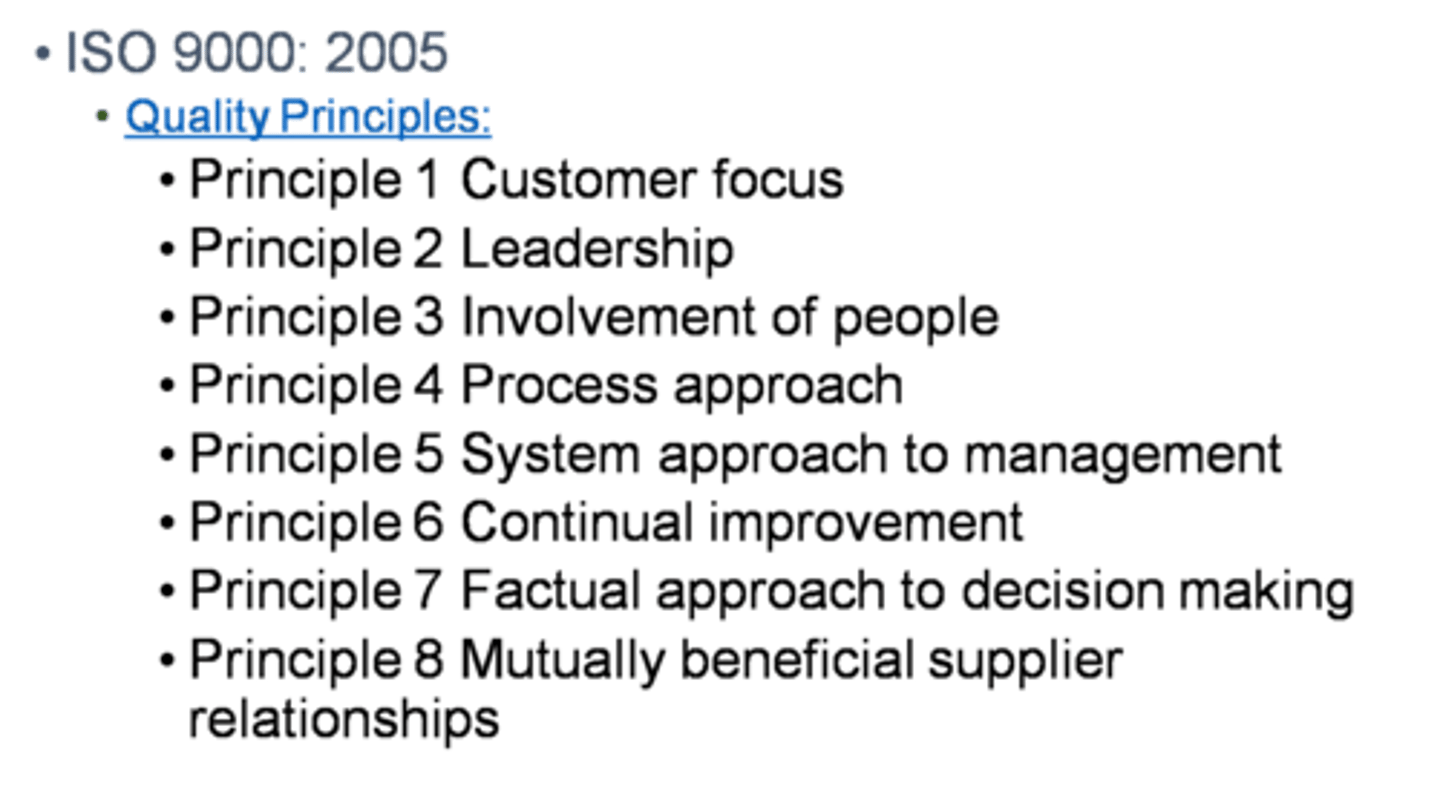

ISO 9000

Set of international standards on quality management and quality assurance, critical to international business

-TQM process consists of 13 published standards and guidelines

-Like when joint commission shows up at the hospitals

Checklist

A list of common defects and the number of observed occurrences of these defects.

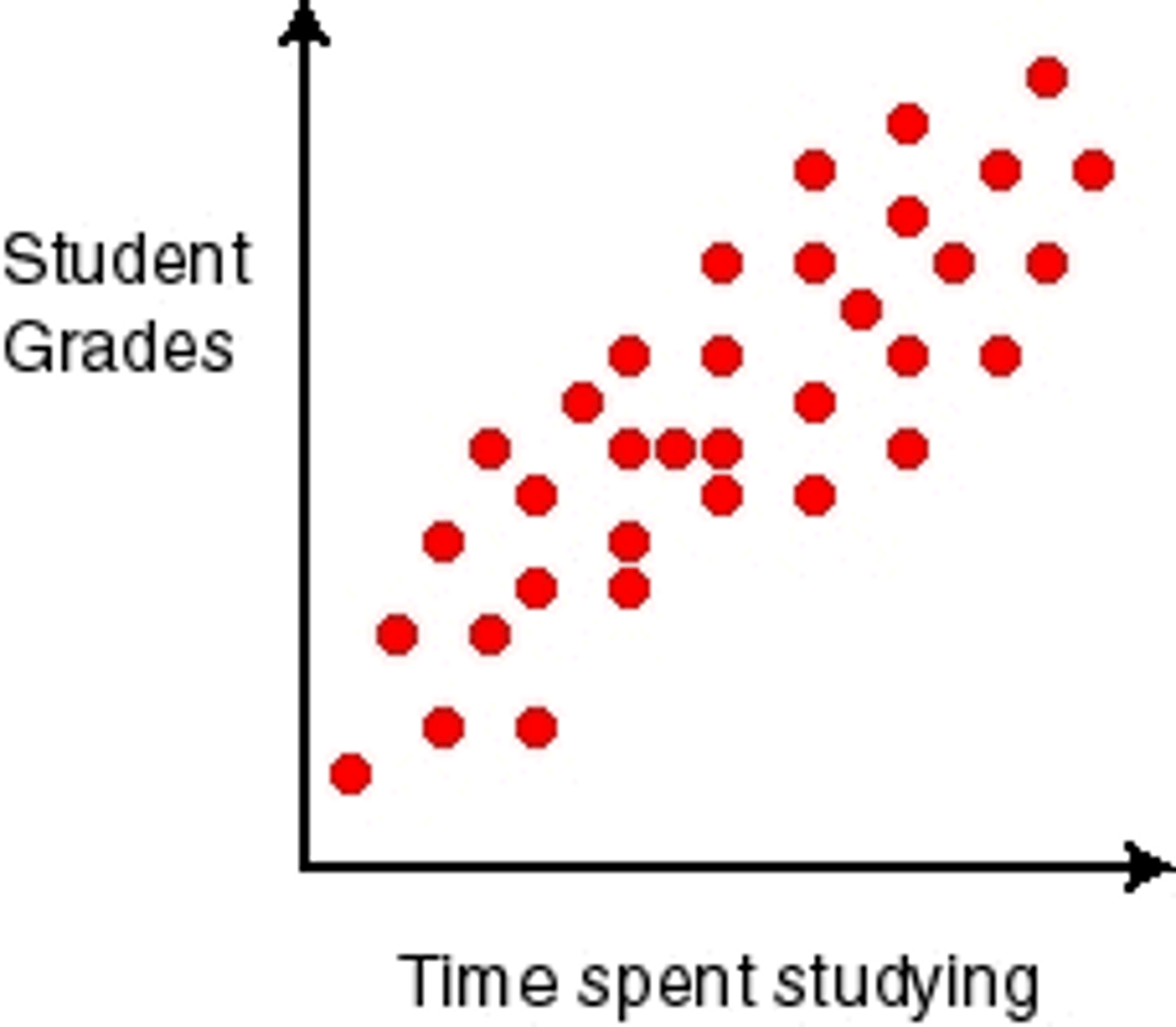

scatter diagram

a plot of two variables showing whether they are related

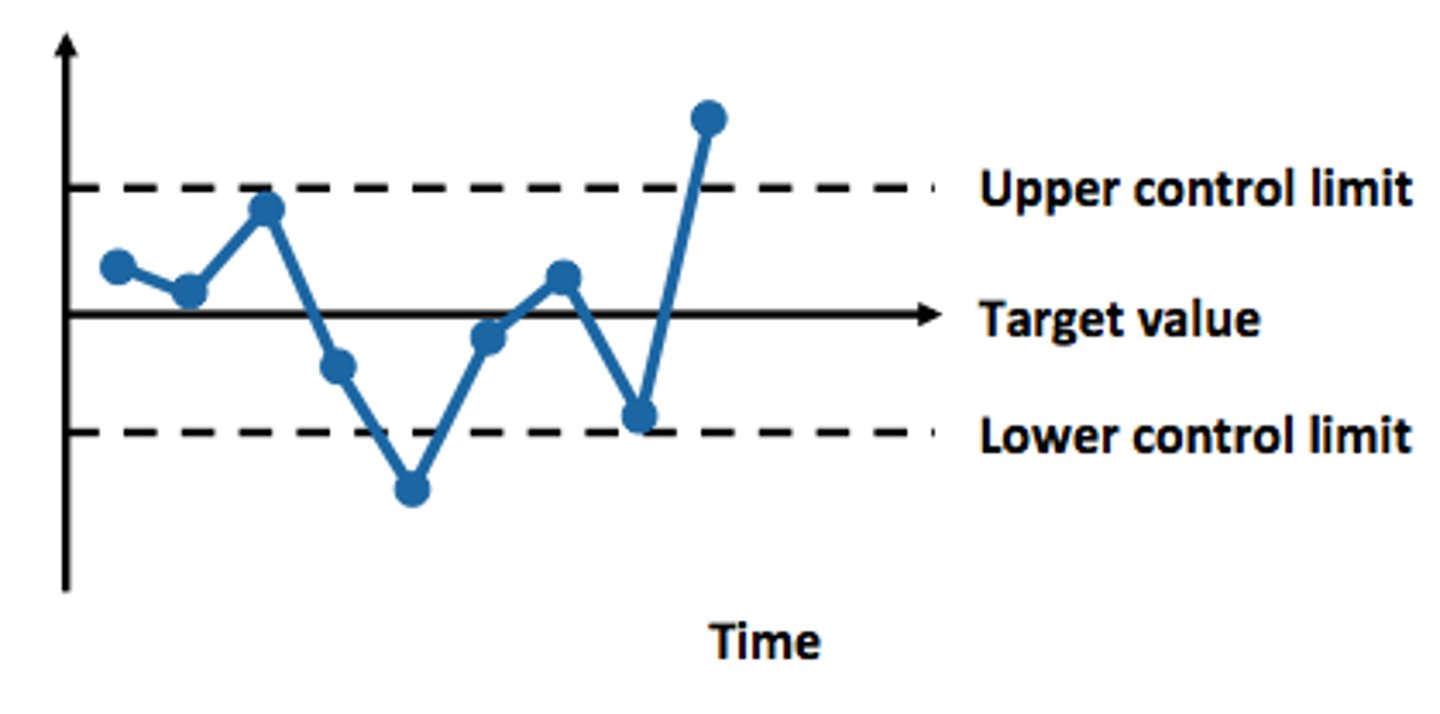

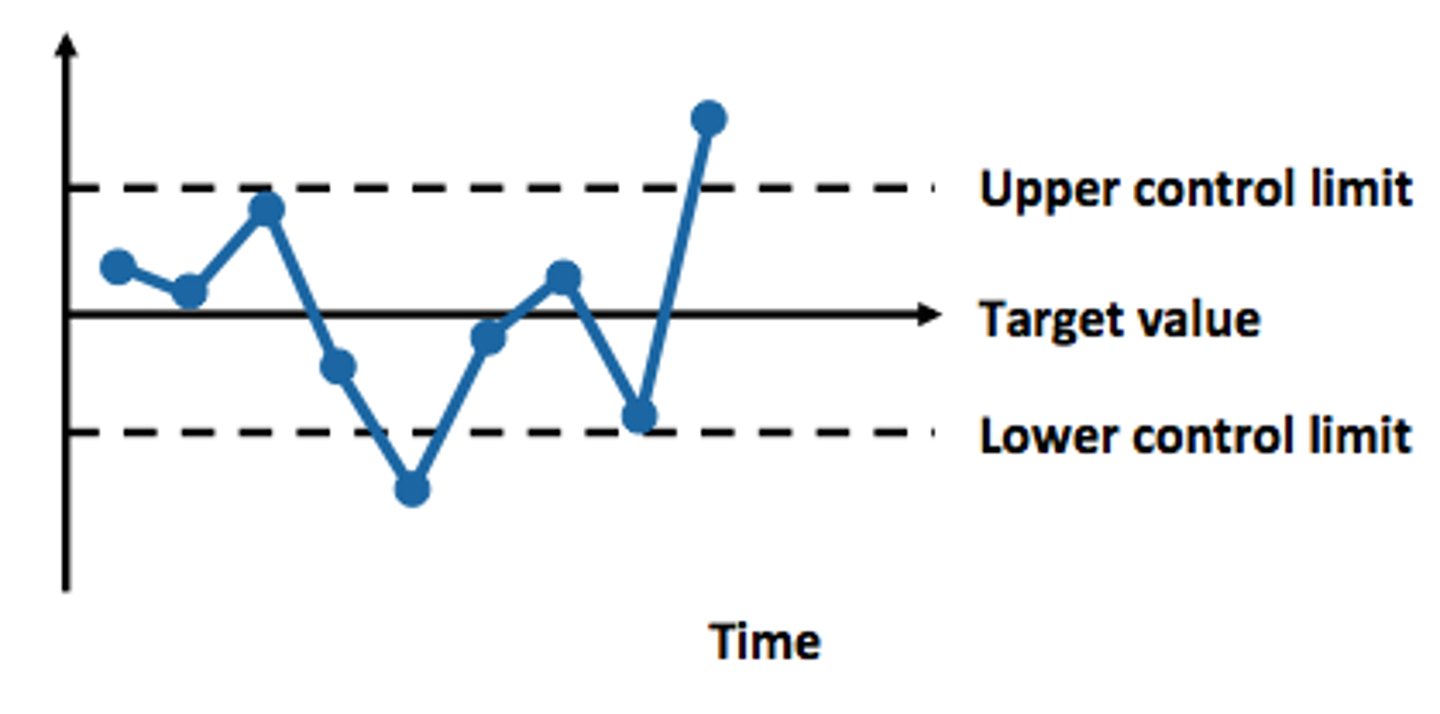

Control Chart

A graph that shows whether a sample of data falls within the common or normal range of variation.

mean

A statistical measure of central tendency, or average, based on dividing a total by the number of individual cases.

assignable causes of variation

-Causes can be identified and eliminated

-e.g. poor employee training, worn tool, machine needing repair

common causes or random

Stuff you cannot identify

-Random causes that we cannot identify, unavoidable

Cpk measures

How close one is to a target and how consistent one is with the average performance.

-How closely it measures

Six Sigma

Technical tolls and people involvement

The empirical rule, 3 standard deviations. This is 3 sigma's.

6 sigmas and you are almost at 100%

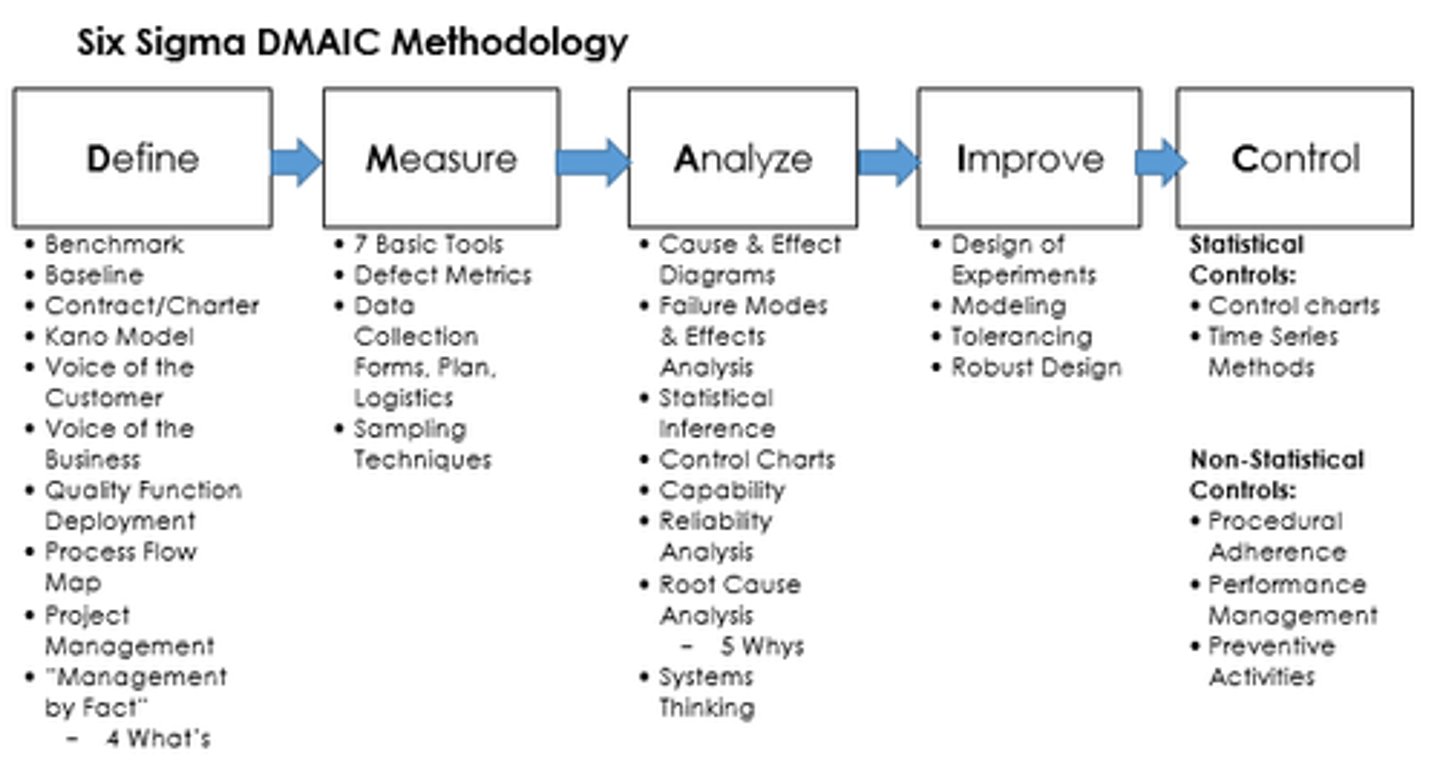

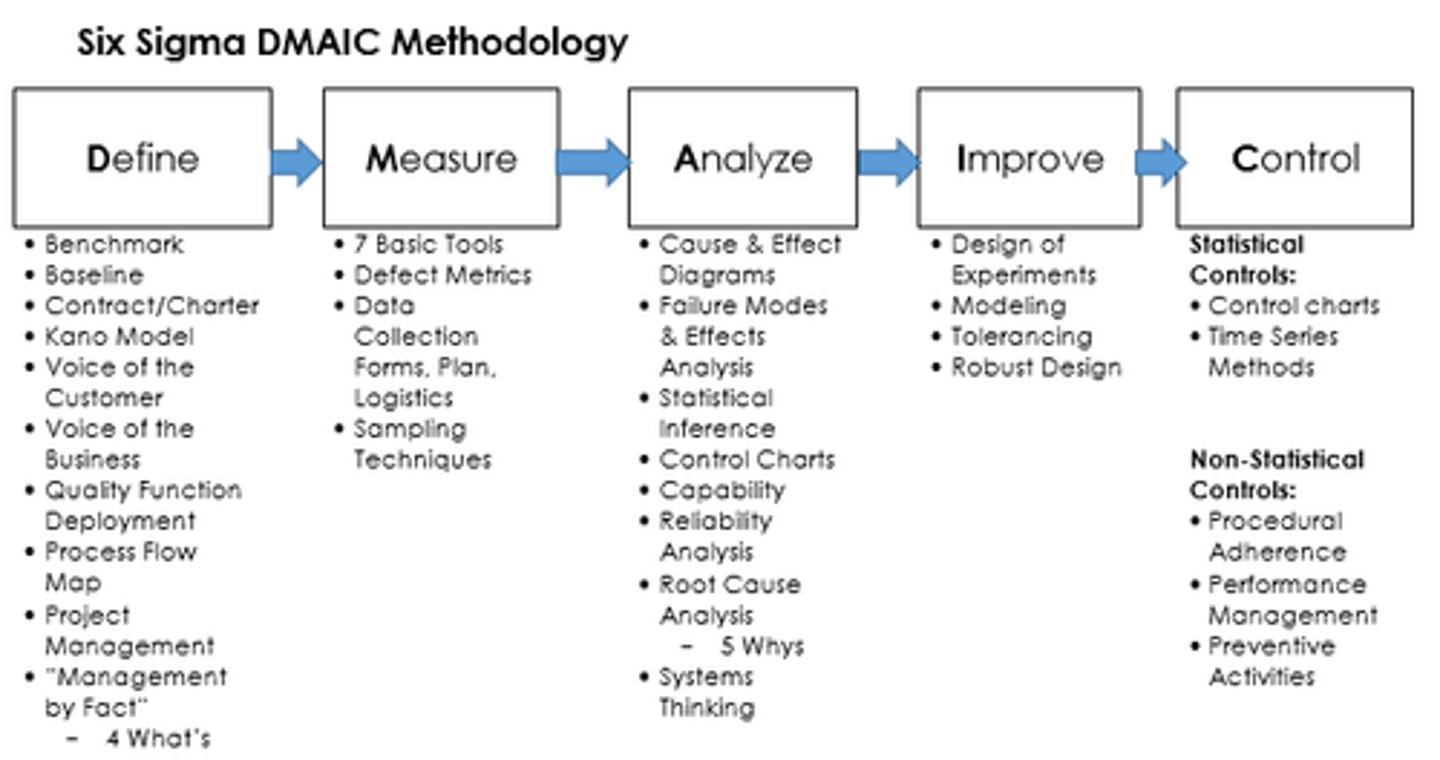

DMAIC

DMAIC (Define, Measure, Analyze, Improve, Control)

a six sigma process that outlines the steps that should be followed to improve an existing business process

define stage

includes the voice of the customer and value stream

Job Design

It does not have anything to do with people.

-The process by which managers decide how to divide tasks into specific jobs

waiting time

-Screen patients and fast track those with minor ailments

-amount of time a process has been waiting in the ready queue

Service location decisions

-proximity to customers

-Quality of life issues

proximity to customers

-key factor of a location analysis for a service company

-if you need to have a car repaired, you wont drive too far.

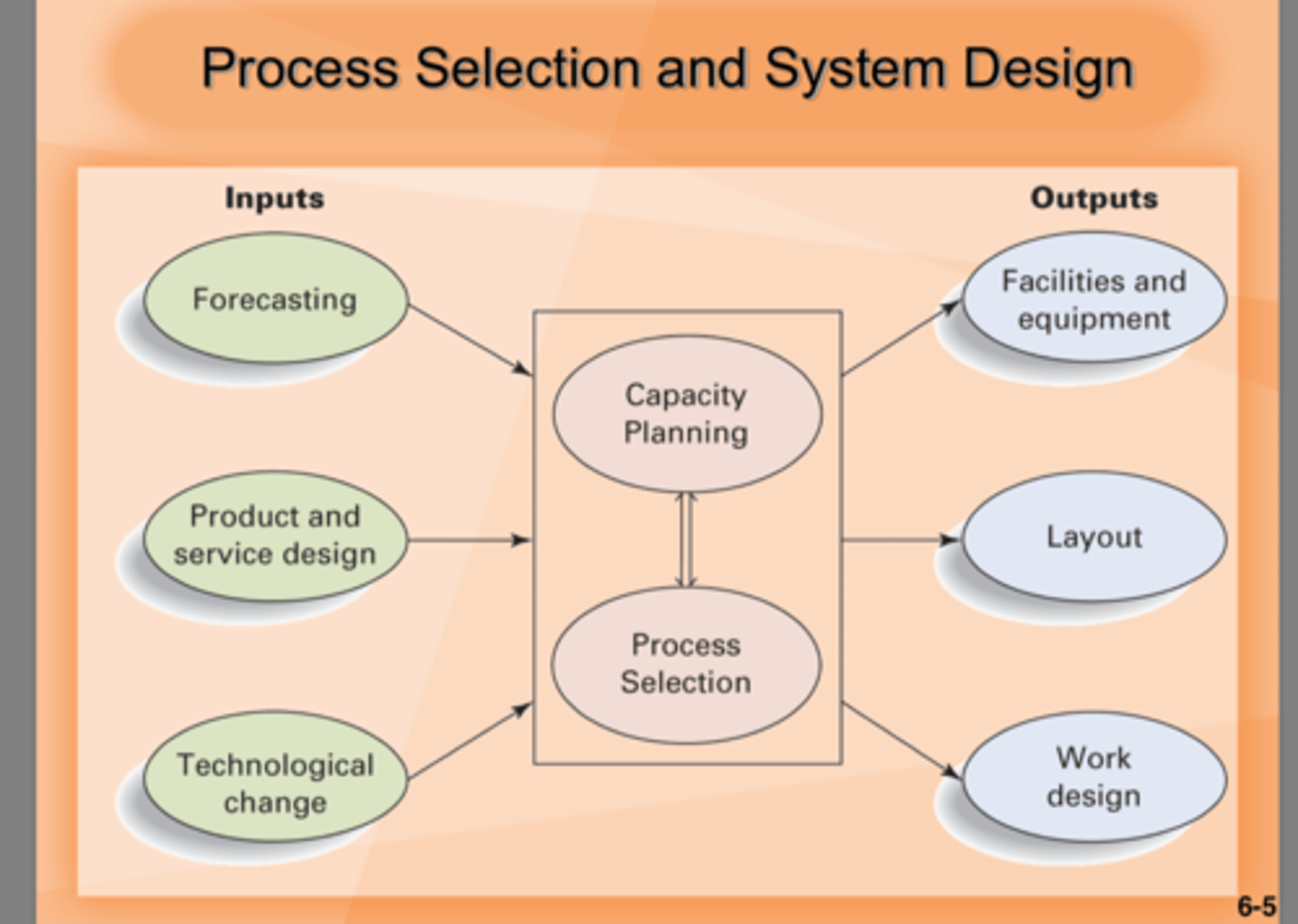

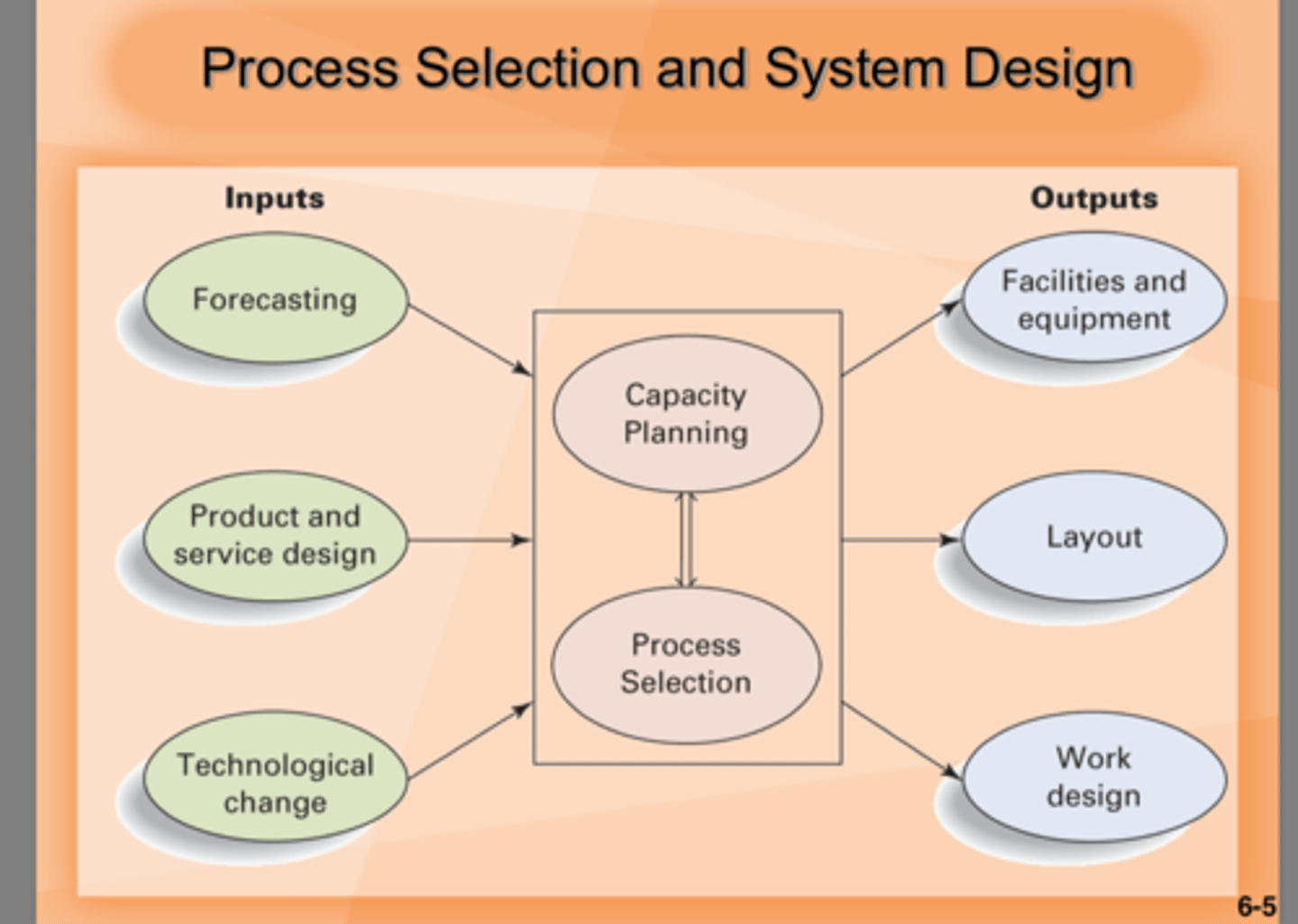

Capacity Planning

Hospital- Capacity is beds and output is the patients. If you have 1 pt for 2 days and one for 3 days. The output is how many patients and not how many beds we have.

capacity utilization

are you using more workers and what are your resources? Measures how much of the available capacity is actually being used. Measures effectiveness.

Capacity Focus

facilities that are small, specialized, and focused on a narrow set of objectives.

effective capacity

capacity measurement at the best operating level

when the average unit cost is minimized

center of gravity approach

an approach for locating a single facility that minimizes the distance to existing facilities.

-use the breakeven analysis -how many units needed to manufacture to breakeven.

break-even analysis

the process of determining the number of units a firm must sell to cover all costs. Considers fixed costs, variable costs.eg Fed EX is in Tennessee so it will be in the middle

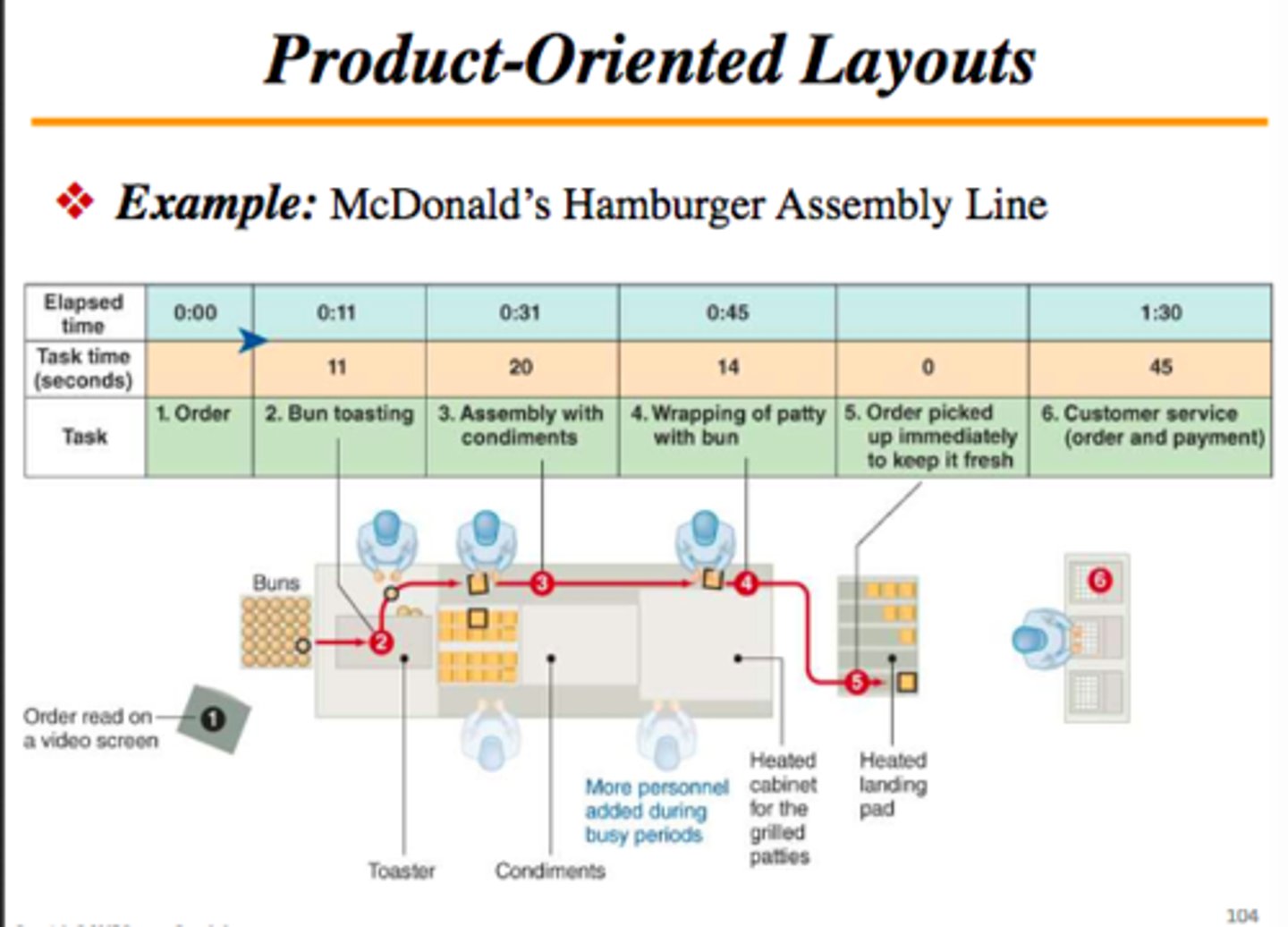

repetitive process

classic assembly line. A line process, a continuous process.

Project Process

make a one-at-a-time product exactly to customer specifications, expensive. Like an automobile collision shop that does body and engine repair as well as custom vehicle paint job.

Batch Process

a process in which goods or services are produced in groups (batches) and not in a continuous stream eg. auto shop offers body repair, engine repair, and custom vehicle paint options

Bottleneck in a flowchart

the longest part in the process eg manufacturing a car and the car needs to be painted or the time the cake in the oven.

compute process velocity

Throughput time/value-added time

-How fast we are going

Actual output/standard output

Which formula would indicate that a fast-food restaurant was performing at, above, or below its benchmark?

-We know how many burgers were making and what the standard is

output/input

productivity formula

Throughput time/value-added time

How long it takes from the raw materials to become finished goods.

Process

Each item goes through process

Which total quality management (TQM) process was developed to stress management's responsibility for quality?

14 points for quality improvement

Hybrid

any mix of elements from a product layout and a process layout, to gain the advantages of both eg group technology

standard time

Determines how long it takes a qualified operator to perform a duty of the job requirements under the assumption that the operator is working at a sustainable pace with the proper tools for the process.

-How long t takes somebody to finish the work

performance time

How long it actually took

observed time

Actual time

-The time measured from stopwatch

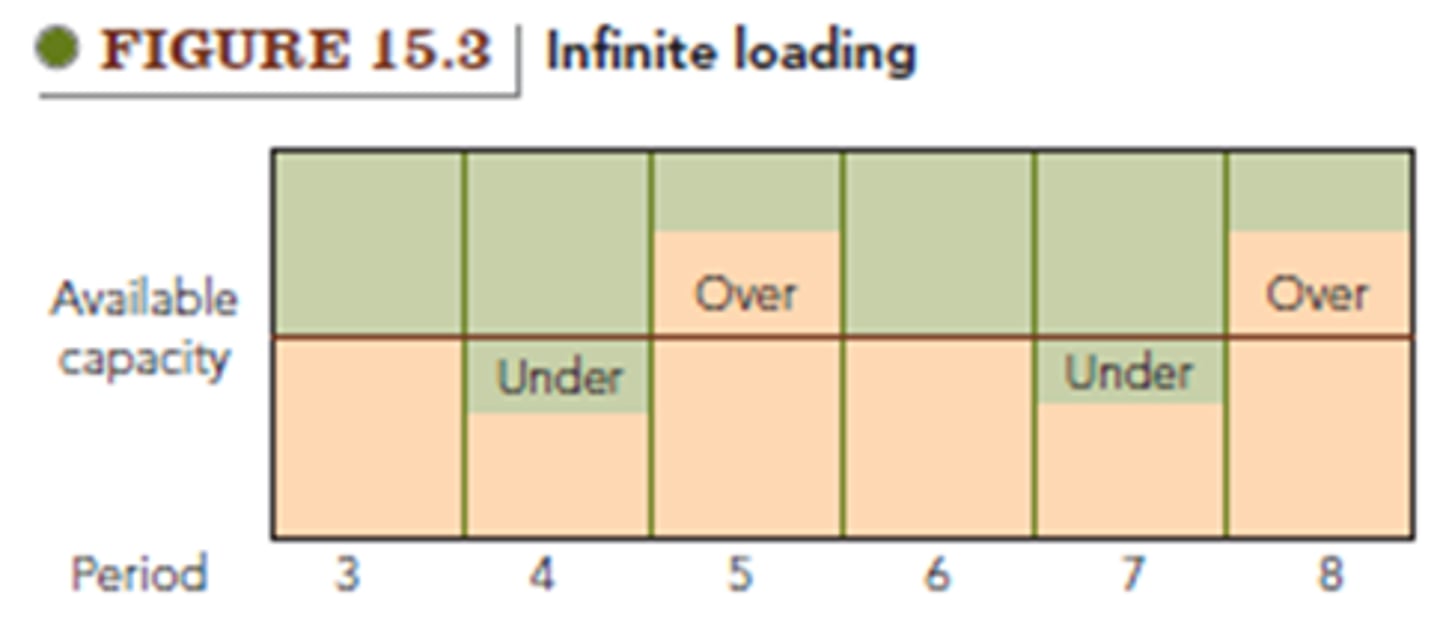

infinite loading

A scheduling approach that ignores capacity constraints.

-Working backwards

-ex Amazon doesn't have the computer you want but they have a network where they can send you to someone who can give it to you

finite loading

-Working forward.

-Jobs are assigned to work centers taking into account the work center capacity and job processing times.

-Have fixed capacity

-ex I go to a bike shop to buy a bike. They know what people will want. They offer repair, the can say I need this employee for repair shop. They have resources to manage

Backwards Scheduling

Begins with required delivery date and works in the reverse order to determine when each process step must be preformed.

Respect for people

A 3rd element element of JIT that considers human resources as an essential part of the JIT philosophy.

Reducing waste is achieved

by Just in time and lean system

Lean Systems

systems that maximize productivity by reducing waste and delays. Not sacrificing productivity

-JIT is a part of lean system

-

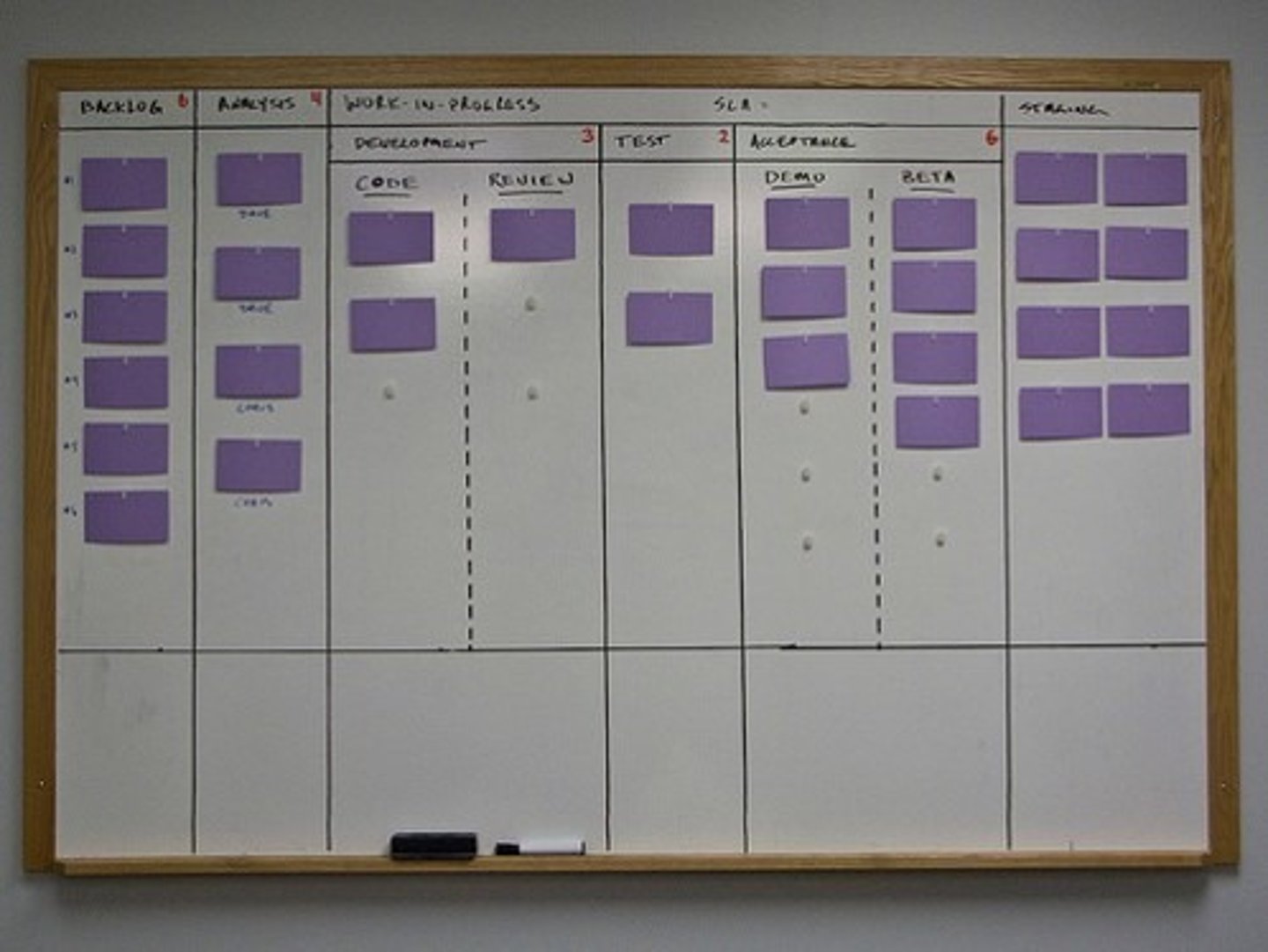

Kanban System

a pull system that uses cards to visually signal the need for inventory.

-Exact quantity that needs to be produced

-small lot and shorten manufacturing lead time

-forecast how much inventory your going to need

Which total quality management (TQM) process consists of 13 published standards and guidelines?

ISO 9000

ISO 9000

total quality management (TQM) process consists of 13 published standards and guidelines

A company manufactures shoes using a quality management system. The company needs to put a process in place to measure any defects. The company would like to measure the number of defects and observe the number of occurrences to isolate the particular defect.

Which quality tool should the company use to focus on correcting this particular issue?

checklist

Which quality control tool should be used to monitor the current status or end result of a process?

Flowchart

Which group of keywords or phrases describes the crucial role that marketing plays in the total quality management (TQM) process?

Review and recommend product changes, satisfy customers needs, open communication

What is the common theme in total quality management (TQM) across all functions in an organization?

To satisfy customer needs

Which concept of variation measures the central tendency of a set of data?

mean

What do assignable causes of variation indicate?

Equipment was found out of control

Which continuous improvement method does Cpk measure?

How close one is to a target and how consistent one is with the average performance

What are two important aspects of Six Sigma?

people involvement

technical tools

Which strategy is used by some emergency rooms to overcome customer frustrations about long waiting times?

Screen patients and fast-track those with minor ailments

Which two factors affect a service location decision?

Proximity to customers

Quality of life issues

Which is a key factor of a location analysis for a service company?

Proximity to customers

What helps an organization identify and plan the actions necessary to meet current and future customer demands?

capacity planning

Which capacity planning measurement tells how much capacity a company is using?

Capacity utilization

Design Capacity

The maximum output rate or service capacity an operation, process, or facility is designed for.

-the maximum designed service capacity or output rate.

Effective capacity

Design capacity minus allowances such as personal time and maintenance.

-Lower than design capacity.

-eg on the average, the bakery can make 20 custom cakes but during Christmas can do30 custom cakes

Capacity measurement at the best operating level

when the average unit cost is minimized

conducting a location analysis

-proximity to sources of supply

-site consideration

proximity to customers

major factor in the decision to locate a business near its primary market territory

Which two statements are true about effective capacity?

An effective capacity maintains a minimum output rate under normal conditions.

An effective capacity is lower than design capacity

When is capacity measurement at the best operating level?

When the average unit cost is minimized

Which two capacity measurement concepts should a firm consider when conducting a location analysis?

proximity to sources of supply

site considerations

What is a major factor in the decision to locate a business near its primary market territory?

proximity to customers

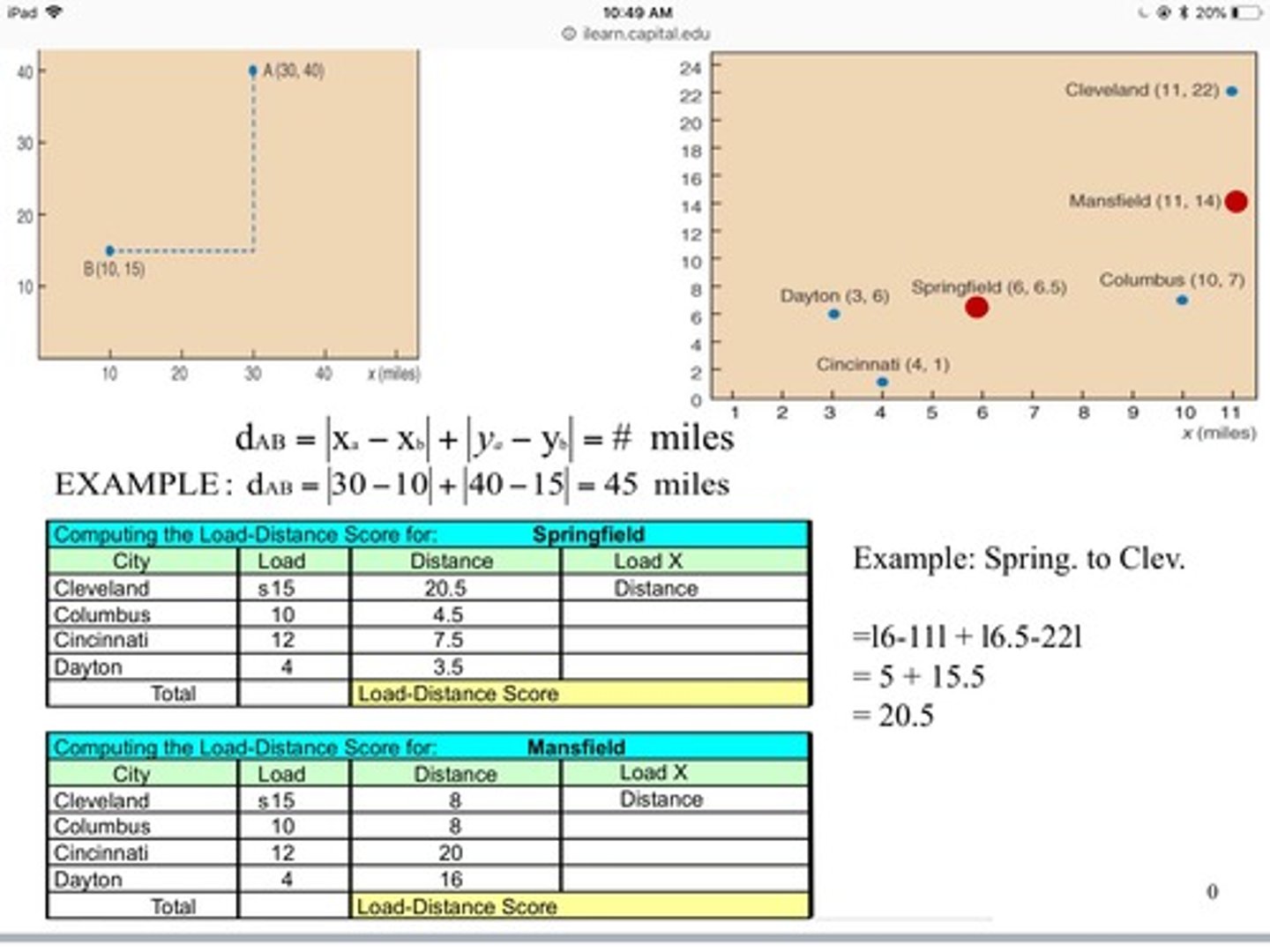

load-distance model

a model used in designing functional layouts where movement is minimized e.g. open a new distribution center location in order to minimize distribution costs

A manufacturing company decides to open a new distribution center location in order to minimize distribution costs to warehouses or stores.

What tool should the manufacturing company use to determine where the new distribution center should be located?

by using the load-distance model

Which two types of operations include repetitive processes?

continuous process

line process

A comprehensive automobile collision shop offers body and engine repair as well as custom vehicle paint options.

Which two operational processes would suit this shop?

batch process

project process

What is a bottleneck in a flowchart?

The longest task in the process

throughput time/value-added time

Which formula would compute process velocity?

Which formula would compute process velocity?

(Throughput time) / (Value Added Time)

Which formula would indicate that a fast-food restaurant was performing at, above, or below its benchmark?

actual output/standard output

process layout

similar equipment and functions are grouped together

In which organizational layout would one expect to see items arranged by type?

process

hybrid layout

any mix of elements from a product layout and a process layout, to gain the advantages of both eg group technology

Process Layout Advantages

-can handle a variety of processing requirements

-not particularly vulnerable to equipment failures

-general-purpose equipment is often less costly than the specialized equipment used in product layouts

-it is possible to use individual incentive plans

Product Layout Advantages

higher output rates, lower work-in-process inventories, less material handling, higher labor/equipment utilization, simple planning/control systems

group technology

challenges within one of the facilities:

-production qualities are low and only a small number of homes are built efficiently

-the facility space allows for low handling of materials

-there is limited space available for employees to operate

-hybrid layout

-is where you have a number of facilities and each facility is responsible for a particular process.

A construction company produces pre-fabricated homes. The manager has discovered the following challenges within one of the facilities:

-production qualities are low and only a small number of homes are built efficiently

-the facility space allows for low handling of materials

-there is limited space available for employees to operate

Which hybrid layout should be used to address the company's needs?

group technology

block plan

a plan that allocates space and indicates the placement of each operation. -would use an allocation process for space requirements in an industry scenario.

-A From to Matrix gives the number of trips between departments.

-Use Rectilinear distance

rectilinear distance

The shortest distance between two points measured by using only north-south and east-west movements

from-to matrix

A table that gives the number of trips or units of product moved between any pair of departments.

Which instrument would use an allocation process for space requirements in an industry scenario?

block plan

What would be an organizations next step after it has revised or implemented new operations?

-follow up to make sure the new operation resolves -----quality problems

Why is it beneficial for an organization to designate employees to communicate alternative ways to complete a job in a methods analysis?

they may have suggestions for improving the operation

Which factor determines how long it takes a qualified operator to perform a duty of the job requirements under the assumption that the operator is working at a sustainable pace with the proper tools for the process?

standard time

Which design work system minimizes repetitiveness in tasks by assigning employees the role of planning and scheduling?

job enrichment

labor specialization

The division of labor into specialized activities that allow individuals to be more productive. - acknowledges the benefits of employee proficiency?

Which work system acknowledges the benefits of employee proficiency?

labor specialization

forward scheduling

Starting an activity as soon as possible, regardless of its deadline.

Which term means to schedule a job that starts immediately, regardless of the due date?

forward scheduling

just-in-time (JIT) system

An inventory management and control system whose objective is to reduce waste throughout the production and delivery of a product or service; in manufacturing, also known as lean production or value-added manufacturing. Use a pull system

basic element in the just in time (JIT) system are

1. TQM 2. JIT manufacturing 3. respect for people

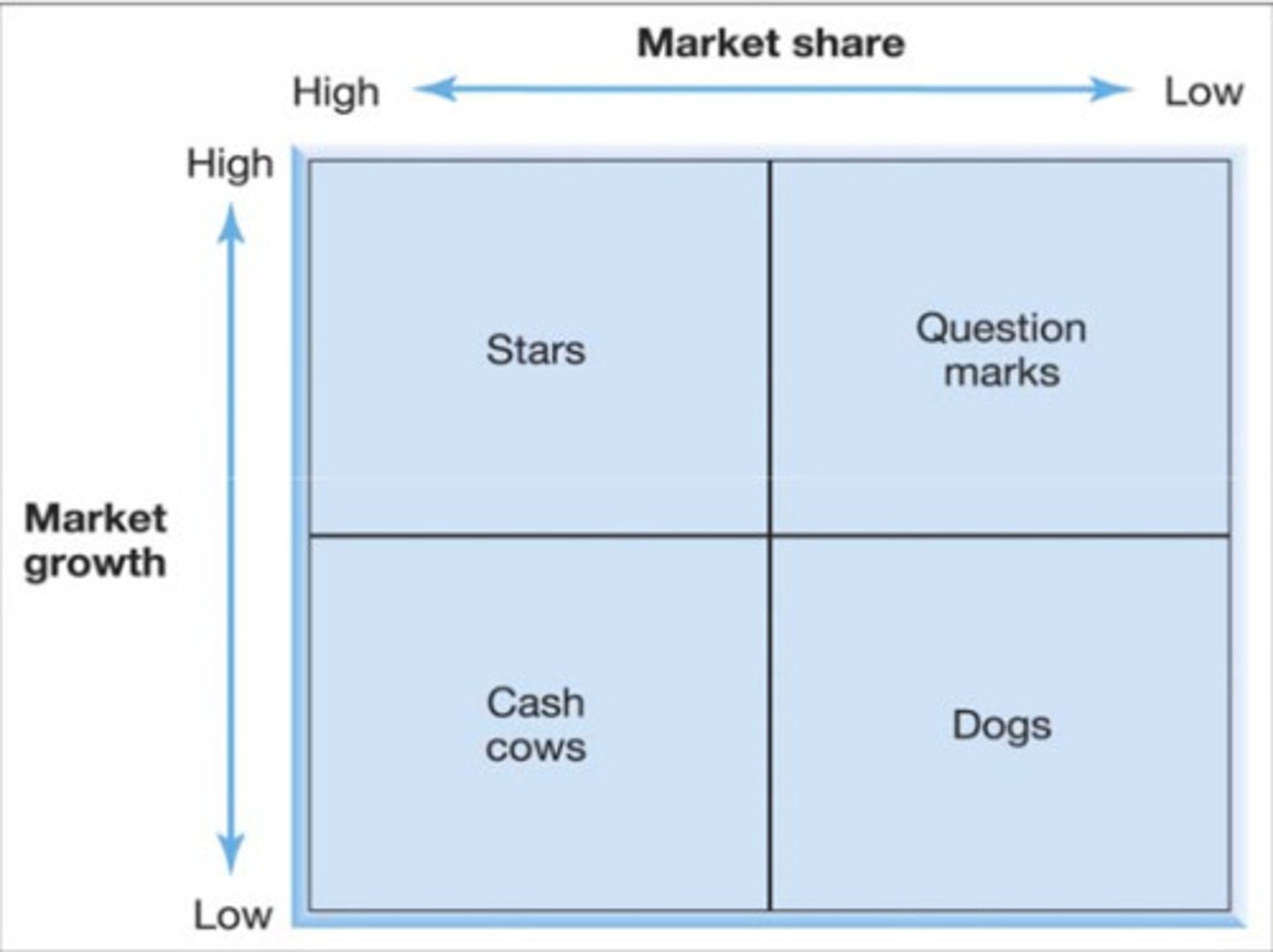

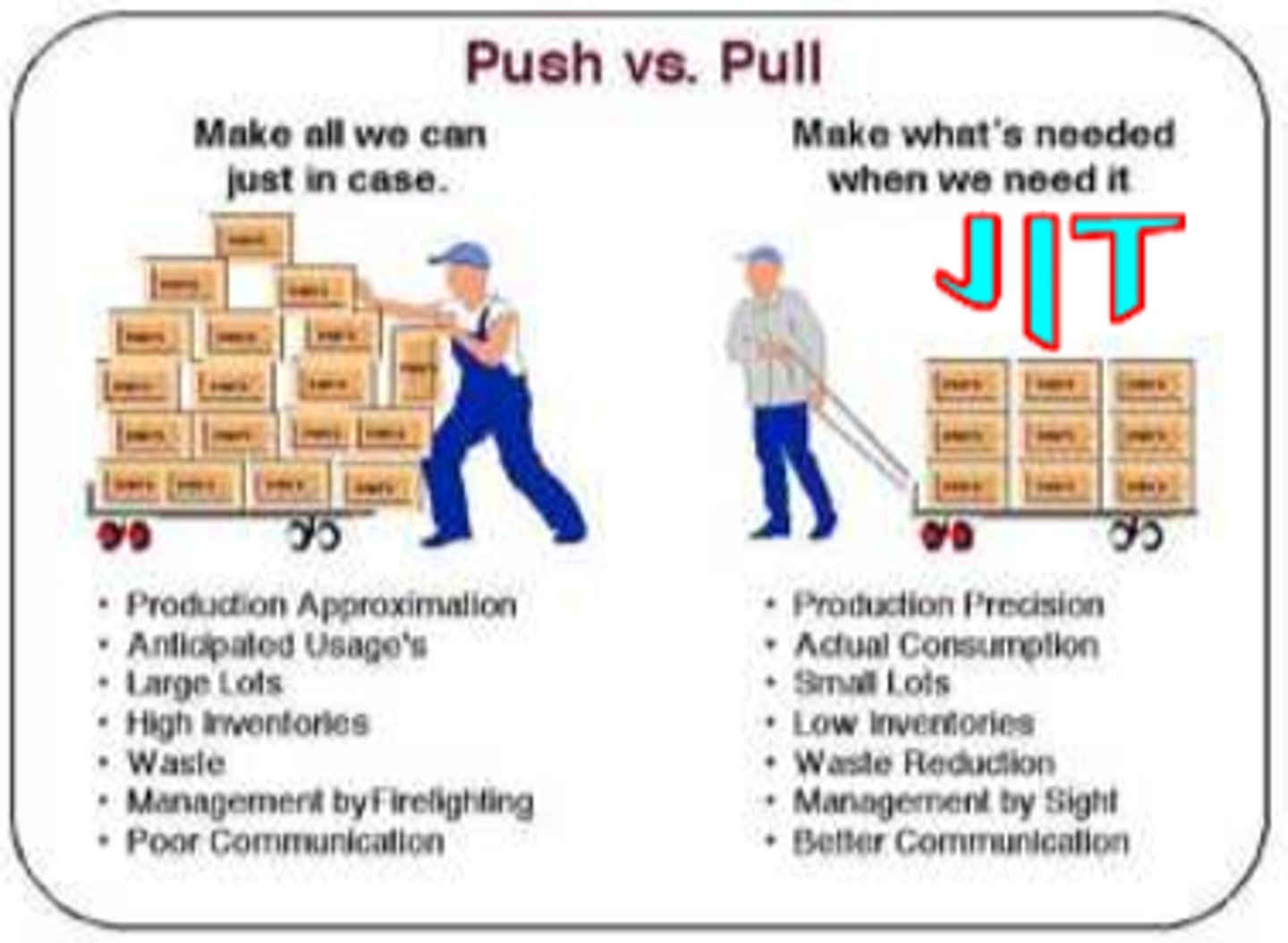

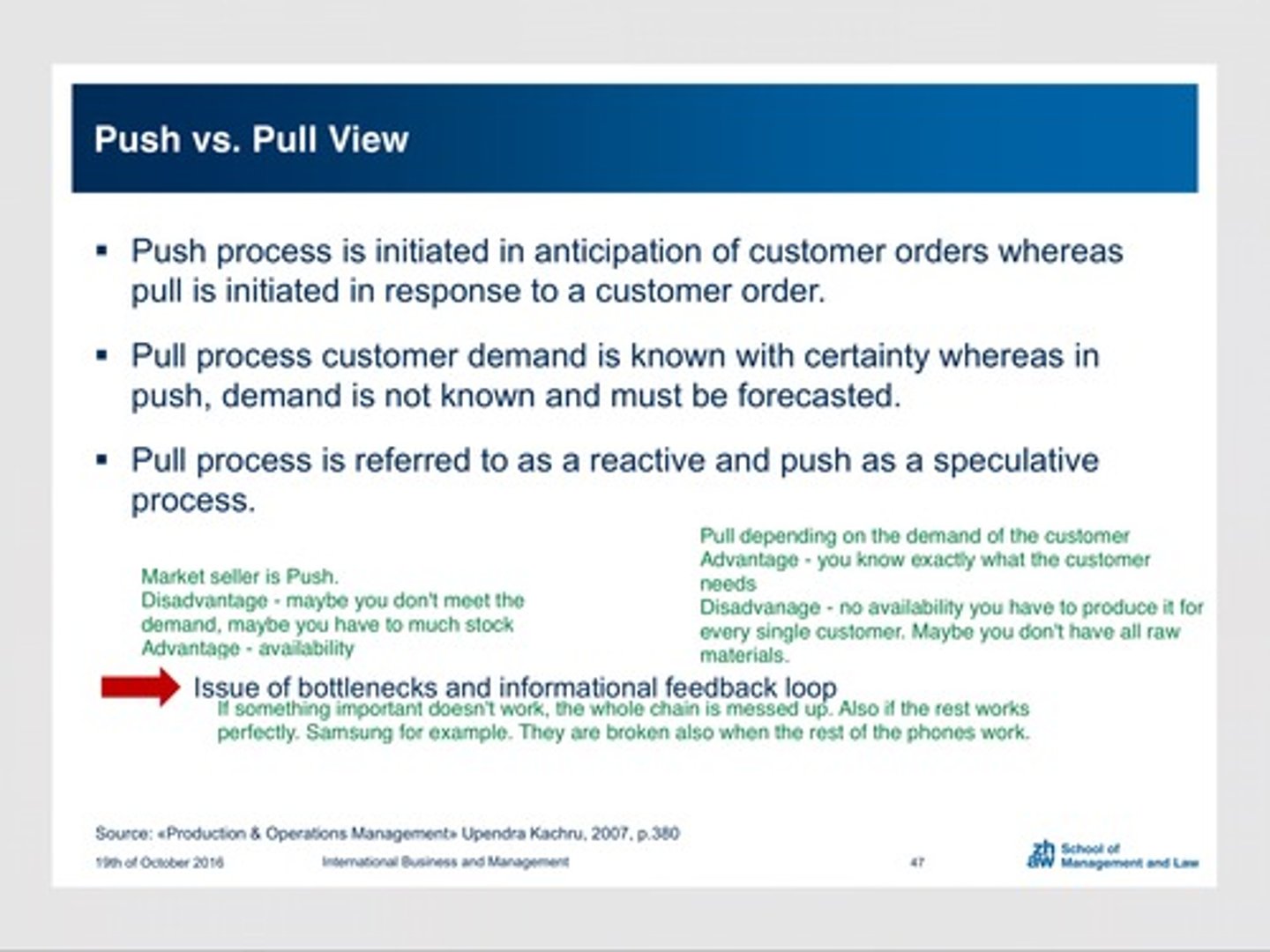

Push vs. Pull

Push: workflow idea that you make something even if no one is buying it

Pull: you use what you need but get enough just in time --> continuous work flow, Kanban system

What is the third basic element in the just in time (JIT) system if the first element is the total quality management (TQM) and the second is JIT manufacturing?

respect for people