2 Alginate & Gypsum

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

45 Terms

why are mounted diagnostic casts on an articulator important?

complement tool in addition to clinical exam

legal proof of pt’s current occlusion

allow clinician to

modify occlusal pre-treatment plan prior to establish definitive Tx plan

evaluate occlusion in centric and eccentric positions

determine inter-arch distance, teeth vs alveolar ridge

make alteration without pt being there physically

what materials are most commonly used to make impressions?

Hydrocolloids and synthetic elastomeric polymers

what is alginate made from?

cell wall constituents of brown algae (chemistry involves salt of alginic acid Na or Ca alginate)

what can be evaluated with casts of the mouth?

relative alignement between maxillary/mandibular arches

occlusal relationship

fabrication of restoration and prostheses

The impression material is usually carried to the mouth by means of …?

a tray (plastic or metal; pre-fabricated or individual)

what are desireable qualities to consider when picking impression materials?

Pleasant odor, taste, and color

Absence of toxic or irritant constituents Adequate shelf life

Economic

Easy to use

Good setting characteristicsSatisfactory consistency and texture

Readily wets oral tissues

Resistance to permanent distortion

Adequate strength

Dimensional stability over temperature and humidity normally found in clinical and laboratory setting

Compatibility with cast and die materials

Accuracy in clinical use

Readily disinfected without loss of accuracy

No release of gas during the setting of the impression or cast and die materials

what are different types of impression materials?

Alginate hydrocolloid (A.K.A. irreversible hydrocolloid)

Agar hydrocolloid (A.K.A. reversible hydrocolloid)

Elastomeric materials

Zinc oxide-eugenol materials

Gypsum

Compound impression materials

what are the most widely used impression material in dentistry?

Alginates

what are some advantages of alginate hydrocolloids?

hydrophilic

accurate if handled properly

inexpensive

easy manipulation

pleasant taste

able to displace blood and body fluids

easily pourable

can use with stock trays

what are some disadvantages of alginate hydrocolloids?

dimensionally unstable (syneresis vs imbibition)

low tear resistance

must be poured immediately

limited detail reproduction

can only be used for a single cast

incompatible w epoxy resin die materials

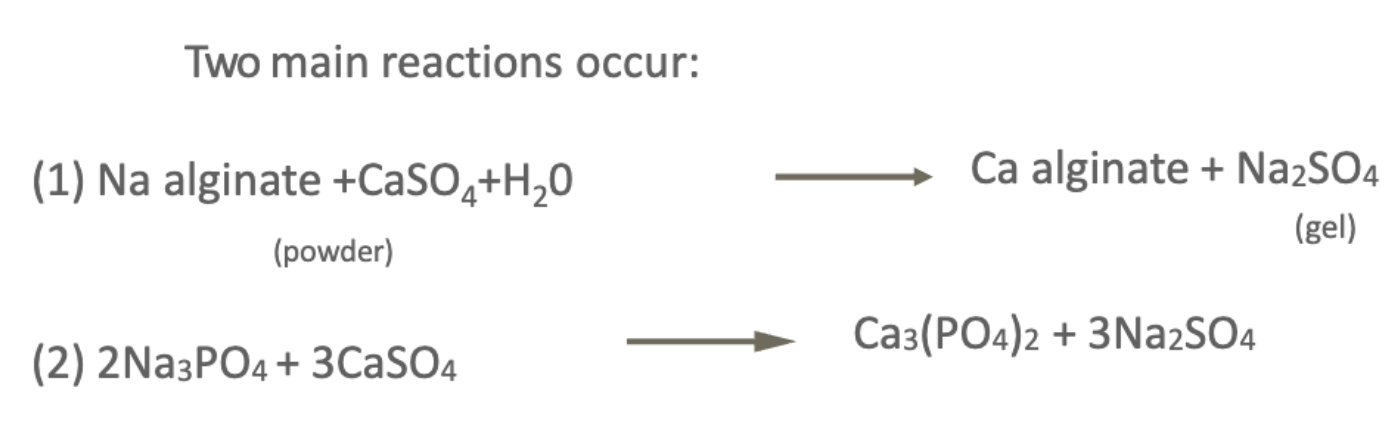

what 2 main chemical reactions occur when alginate hydrocolloid powder is mixed with water to obtain a paste?

Na3PO4 = retarder (delays reaction so we have more time to work w it)

CaSO4 = active ingredient

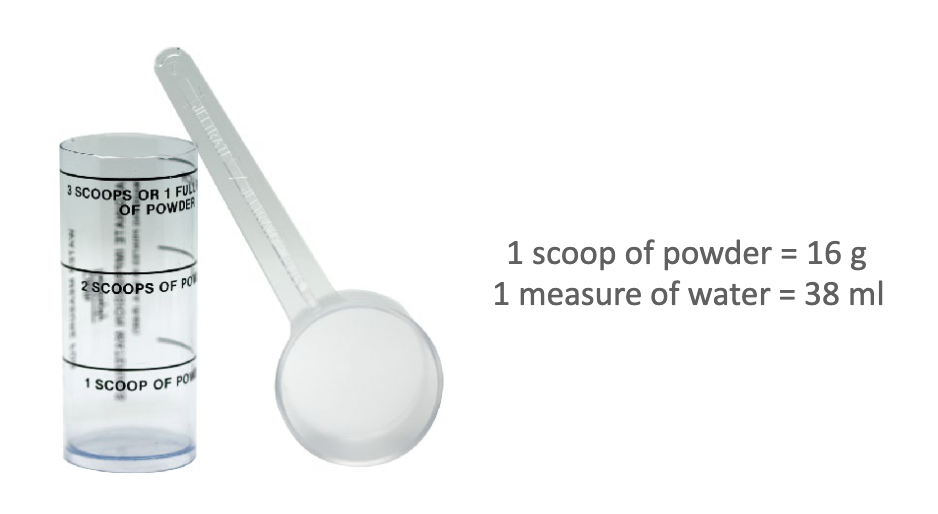

describe the process of mixing alginate and water.

powder lightly shaken for aeration

add water to mixing bowl first

1 scoop of powder used for 1 measure of water

1 minute of thorough mixing for regular setting

45 seconds for fast setting

set time = 3.5 minutes

1 scoop of alginate powder is __ g

16

1 measure of water is __ ml

38 ml

what happens if you use a lower water to powder ratio?

increased strength

increased tear strength

“better” consistency

decreased working time

decreased setting time

decreased flexibility

what happens if you use a higher water to powder ratio?

decreased strength

decreased tear strength

runny consistency

increased working time

increased setting time

increased flexibility

how does cold vs hot water affect alginate?

colder water increases working/setting times

t/f: Insufficient mixing results in a grainy mix and poor recording of details

true

Disinfection can be accomplished by immersion in …?

sodium hypochlorite or iodophors

If needed, impression can be stored in 100% humidity for __ minutes prior to pouring

30

Storage in either air (syneresis) or water (imbibition) results in significant dimensional change. what is syneresis? water is imbibition?

Syneresis: Loss of water due to dehydration that causes shrinkage

Imbibition: Tendency to absorb water that results in swelling

what are some common problems that are related to inadeqaute working or setting time?

temperature of mixing water (ideally 65-75 F)

incomplete spatulation

incorrect water-powder ratio

improper storage of alginate powder

what are some common problems that occur with impressions?

distortion

inadequate working/setting time

tearing

distortion can occur due to…?

movement of the tray during setting of the material

premature removal of impression

improper storage of impression after removal

length of time between impression making and pouring

Delayed cast separation

tearing can occur to impression due to…?

premature removal from the mouth

speed of impression removal

incorrect water-powder ratio

undercuts

not enough material

Consistency is related to what 3 factors?

(1) water-powder ratio,

(2) water temperature,

(3) spatulation

Porosity can be related to incorrect ________

spatulation

Poor stone surface is related to an extended period of contact between the set gypsum and the alginate (separation should occur between ___ minutes after pouring)

45 to 60

describe infection control guidlines for any impression

in operatory:

Rinse impression using cold running water to remove blood and debris

Rub impression using Cavi Wipe

Wrap it with Cavi-Wipe and place in plastic bag

in laboratory:

Place impression on a paper towel

Spray with Cavicide in 4th Fl Lab and leave it for 3 mins

Rinse impression using cold running water

Pour impression with Type III or IV dental stone

should alginate impressions be boxed?

no!

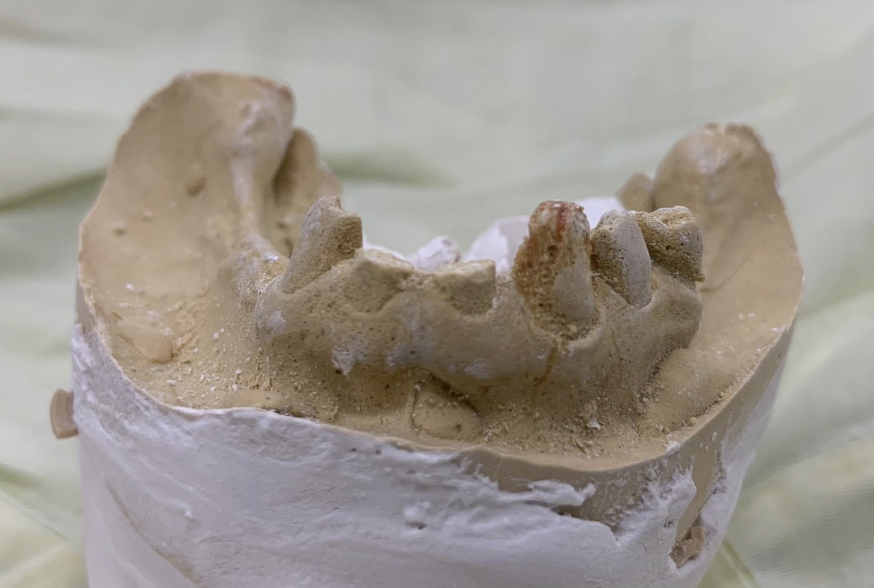

what happend?

left out too long

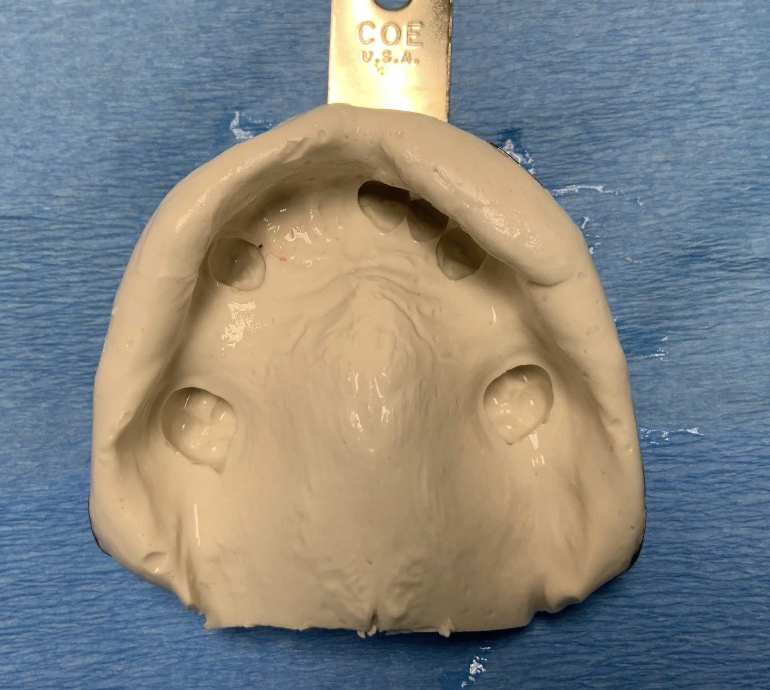

is this a good impression?

yes (9 out of 10)

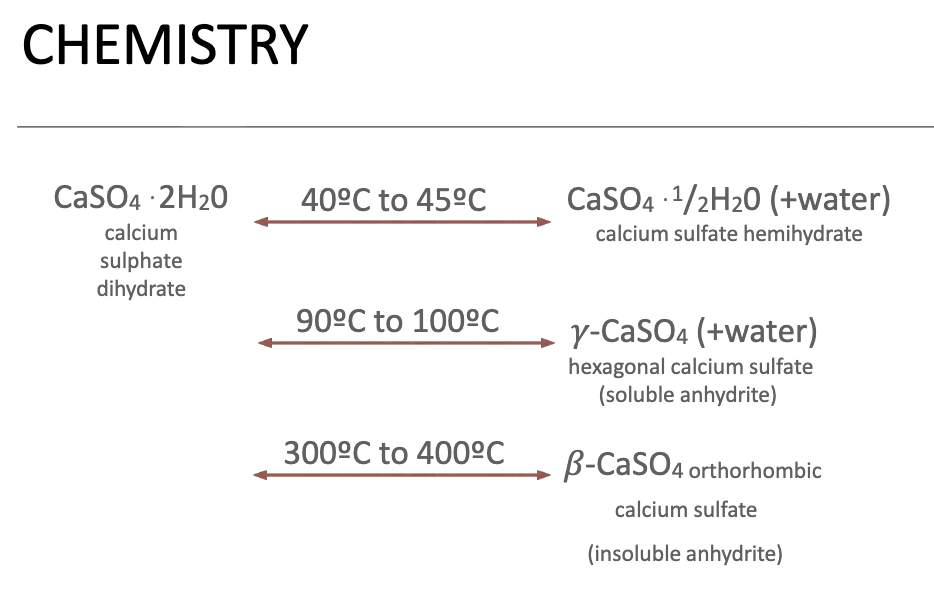

Gypsum products generally refer to the various forms of …?

calcium sulfate (hydrous and anhydrous)

gypsum products are manufactured by the calcination of …?

calcium sulfate dihydrate (CaSO 4 . 2H 2 0)

OR

calcining “synthetic” or “chemical” gypsum, a by-product of the manufacture of phosphoric acid

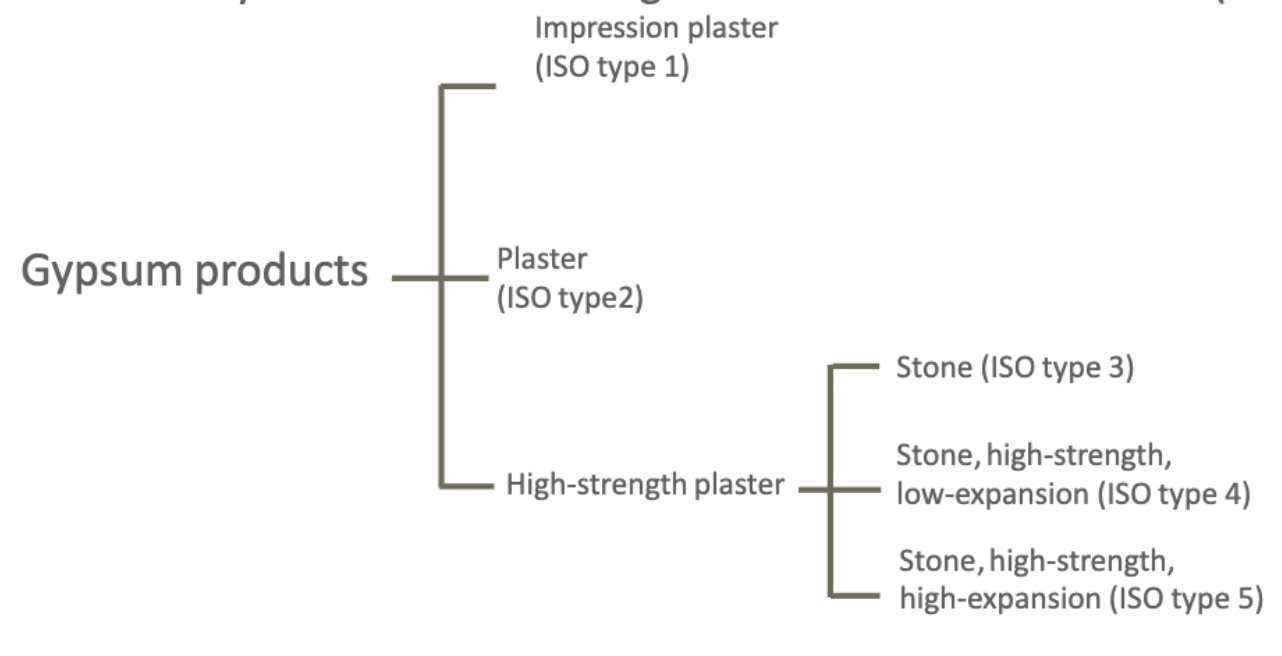

how are gypsum products classified?

by International Organization for Standardization (ISO)

Both plaster and stone are products of…?

partial dehydration of gypsum (Differences in properties result from differences in the physical nature of the powders)

Traditional hemihydrate plaster is produced by what process?

dry calcination (sometimes refer to Beta Hemihydrate)

Medium- and high- strength plasters (stones) manufactured by wet calcination have a stronger/weaker set mass (sometimes refer to Alpha Hemihydrate)

stronger

slide 61