Mech Test 3

5.0(5)

Card Sorting

1/143

Earn XP

Description and Tags

Last updated 5:11 PM on 4/4/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

144 Terms

1

New cards

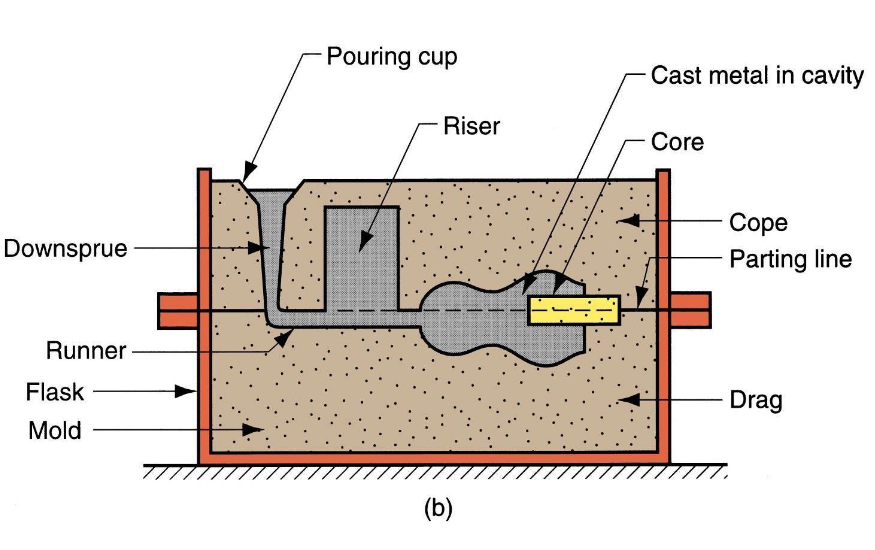

Sand casting mold

purple is gate

2

New cards

Quiz 8 (26)

Quiz 8 (26)

3

New cards

Which of the following is NOT one of the usual objectives of heat treatment?

increase recrystallization temperature

4

New cards

Of the following quenching media, which one produces the most rapid cooling rate:

brine

5

New cards

On which one of the following metals is the treatment called austenitizing performed:

copper alloys

6

New cards

The treatment in which the brittleness of martensite is reduced is called which one of the following:

tempering

7

New cards

The Jominy end-quench test is designed to indicate which one of the following:

hardenability

8

New cards

In precipitation hardening, the hardening and strengthening of the metal occurs in which one of the following steps:

aging

9

New cards

Which one of the following surface hardening treatments is the most common?

carburizing

10

New cards

Which of the following is not a selective surface hardening method?

austenitizing

11

New cards

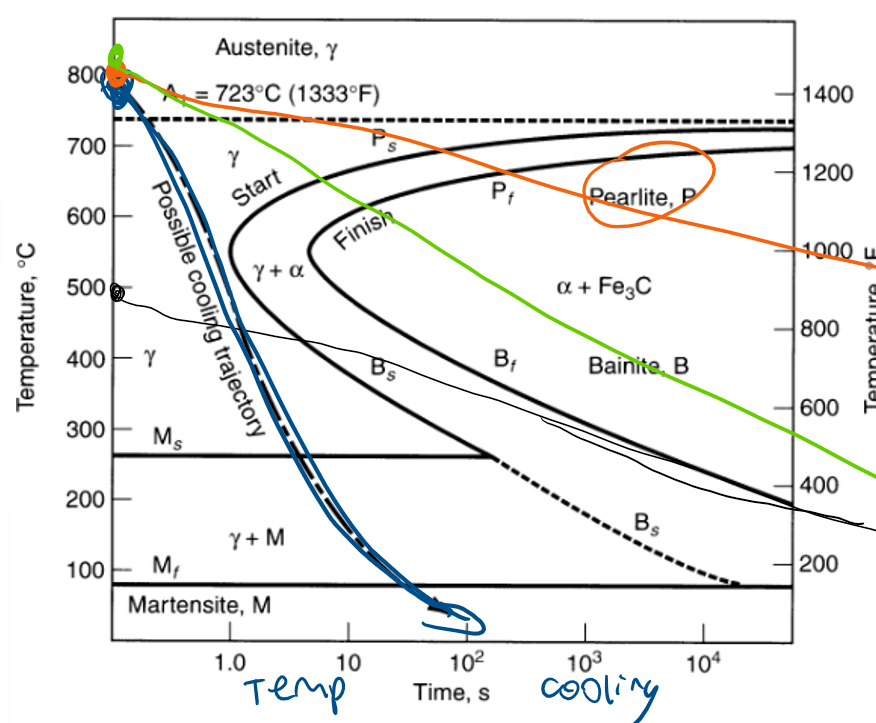

Assignment 7 (10,11)

Assignment 7 (10,11)

12

New cards

Identify some of the important advantages of shape-casting processes.

Advantages include (1) complex part geometries are possible; (2) some casting operations are net shape processes, meaning that no further manufacturing operations are needed to accomplish the final part geometry; (3) very large parts are possible; (4) casting is applicable to any metal that can be melted; and (5) some casting processes are suited to mass production.

13

New cards

What are some of the limitations and disadvantages of casting?

Disadvantages include (1) limitations on mechanical strength properties; (2) porosity; (3) poor dimensional accuracy; (4) safety hazards due to handling of hot metals; and (5) environmental problems.

14

New cards

What is a factory that performs casting operations usually called

A foundry

15

New cards

What is the difference between an open mold and a closed mold

An open mold is open to the atmosphere at the top; it is an open container in the desired shape which must be flat at the top. A closed mold has a cavity that is entirely enclosed by the mold, with a passageway (called the gating system) leading from the outside into the cavity. Molten metal is poured into this gating system to fill the mold.

16

New cards

Which casting process is the most important commercially?

Sand casting is the most important casting process

17

New cards

What is the difference between a pattern and a core in sand molding?

The pattern determines the external shape of the cast part, while a core determines its internal geometry if the casting includes a cavity.

18

New cards

How does solidification of alloys differ from solidification of pure metals?

Pure metals solidify at a single temperature equal to the melting point. Most alloys (exceptions are eutectic alloys) start to solidify at the liquidus and complete solidification occurs at the solidus, where the liquidus is a higher temperature than the solidus

19

New cards

What is a eutectic alloy?

A eutectic alloy is a particular composition in an alloy system for which the solidus and liquidus temperatures are equal. The temperature is called the eutectic temperature. Hence, solidification occurs at a single temperature, rather than over a temperature range.

20

New cards

What is the relationship known as Chvorinov's rule in casting?

. Chvorinov's rule is summarized: *TTS* = *Cm*(*V*/*A*)2, where *TTS* = total solidification time, *Cm* = mold constant, *V* = volume of casting, and *A* = surface area of casting.

21

New cards

Identify the three sources of contraction in a metal casting after pouring.

The three contractions occur due to (1) contraction of the molten metal after pouring, (2) solidification shrinkage during transformation of state from liquid to solid, and (3) thermal contraction in the solid state.

22

New cards

Name the two basic categories of casting processes.

The two categories are (1) expendable mold processes, and (2) permanent mold processes.

23

New cards

There are various types of patterns used in sand casting. What is the difference between a split pattern and a match plate pattern?

A split pattern is a pattern that consists of two pieces; a match‑plate pattern consists of the two split patterns attached to opposite sides of a plate.

24

New cards

What is a chaplet?

Chaplets are metal supports of various designs used to hold the core in place in the sand mold.

25

New cards

What properties determine the quality of a sand mold for sand casting?

The usual properties are (1) strength ‑ ability to maintain shape in the face of the flowing metal, (2) permeability ‑ ability of the mold to allow hot air and gases to escape from the cavity, (3) thermal stability ‑ ability to resist cracking and buckling when in contact with the molten metal, (4) collapsibility ‑ ability of the mold to give way during shrinkage of the solidified casting, and (5) reusability ‑ can the sand be reused to make other molds?

26

New cards

What are the most common metals used in die casting?

Common die-casting metals include zinc, tin, lead, aluminum, brass, and magnesium.

27

New cards

What is flash in die casting?

Flash is a thin portion of metal at the exterior of a casting that results from molten metal being squeezed into the spaces between the die halves of the mold at the parting line, or into the clearances around the cores and ejector pins.

28

New cards

What is the difference between true centrifugal casting and semicentrifugal casting?

In true centrifugal casting, a tubular mold is used and a tubular part is produced. In semicentrifugal casting, the shape is solid; an example is a railway wheel. The mold is rotated so that centrifugal force is used to distribute the molten metal to the exterior of the mold so that the density of the final metal is greater at the outer sections.

29

New cards

What is a cupola?

A cupola is a vertical cylindrical furnace equipped with a tapping spout near its base. Cupolas are used for melting cast irons.

30

New cards

What are some of the operations required in sand casting after the casting is removed from the mold?

The operations include (1) trimming, in which the sprues, runners, risers, and flash are removed, (2) core removal, (3) surface cleaning, (4) inspection, (5) repair if needed, (6) heat treatment, and (7) machining

31

New cards

What are some of the general defects encountered in casting processes? Name and briefly describe three.

General defects include: (1) misruns, in which the casting solidifies before filling the mold cavity; (2) cold shuts, in which two portions of metal flow together but there is lack of fusion at the joint; (3) cold shots, where solid globules of cast metal become entrapped in the casting; (4) shrinkage cavity, which is a depression on the casting surface or an internal void in the casting caused by solidification shrinkage; (5) microporosity, which is a network of small voids throughout the casting caused by localized solidification shrinkage; and (6) hot tearing, which is a crack in the casting caused by a mold that does not yield to the metal during the early stages of solidification shrinkage.

32

New cards

Quiz 7 (18,19)

Quiz 7 (18,19)

33

New cards

A circular sheet metal slug produced in a hole punching operation will have the same diameter as which of the following:

the die opening

34

New cards

Most sheet metalworking operations are performed as which of the following:

cold working

35

New cards

Sheet metal bending does NOT involve which of the following stresses and strains:

shear

36

New cards

Springback in a sheet metal bending operation is the result of which one of the following:

elastic recovery of the metal

37

New cards

The cutting force in a sheet metal blanking operation depends on which mechanical property of the metal (one correct answer):

shear strength

38

New cards

The maximum possible draft in a rolling operation depends on which of the following parameters:

coefficient of friction between roll and work

39

New cards

The starting workpiece in steel hot rolling of plate and sheet stock is which of the following (one best answer):

slab

40

New cards

Which of the following bulk deformation processes is involved in the production of nails for lumber construction:

bar and wire drawing

41

New cards

Which of the following is classified as a forging operation:

coining

42

New cards

Which of the following stress or strength parameters is used in the computation of the maximum force in a forging operation (one best answer):

final flow stress

43

New cards

Assignment 8 (26)

Assignment 8 (26)

44

New cards

Why are metals heat treated?

Metals are heat-treated to effect metallurgical changes that beneficially alter properties.

45

New cards

Identify the important reasons why metals are annealed.

The purposes of annealing include (1) to control properties, (2) to reduce brittleness and improve toughness, (3) to recrystallize cold‑worked metals, and (4) to relieve stresses from prior metalworking. At least 3 out of the four

46

New cards

What is the most important heat treatment for hardening steels?

The most important heat treatment for steels is martensite formation by heating steel into the austenite region and quenching.

47

New cards

What is the mechanism by which carbon strengthens steel during heat treatment?

When steel containing carbon is heat-treated, martensite is formed which is a hard and brittle non-equilibrium phase of steel. The extreme hardness of martensite results from the lattice strain created by carbon atoms trapped in the body-centered tetragonal structure, thus providing a barrier to slip.

48

New cards

What information is conveyed by the TTT curve?

The time-temperature-transformation (TTT) curve indicates what phases in the iron‑carbon phase diagram will be produced under various conditions of cooling

49

New cards

What function is served by tempering?

Tempering involves heating and soaking of martensite for about one hour at a temperature below the austenitizing region, followed by slow cooling to reduce brittleness, relieve stresses, and increase toughness and ductility.

50

New cards

Define hardenability

Hardenability is the relative capacity of a steel to be hardened by transformation to martensite.

51

New cards

Name some of the elements that have the greatest effect on the hardenability of steel.

Important hardenability elements are chromium, manganese, molybdenum, and nickel *at least two.*

52

New cards

Indicate how the hardenability alloying elements in steel affect the TTT curve.

The hardenability alloying elements operate by pushing the nose of the TTT curve to the right, thereby permitting slower cooling rates for conversion of austenite to martensite

53

New cards

Define precipitation hardening.

Precipitation hardening is a heat treatment in which very fine particles (precipitates) are formed so that dislocation movement is blocked and the metal is thus strengthened and hardened.

54

New cards

How does carburizing work?

Carburizing adds carbon to the surface of low‑C steel, thereby transforming the surface into high‑C steel for greater hardening potential.

55

New cards

Identify the selective surface-hardening methods.

The selective surface-hardening methods include flame hardening, induction hardening, high‑frequency (HF) resistance heating, electron beam (EB) heating, and laser beam (LB) heating.3 out of 5.

56

New cards

26 Prezi

26 Prezi

57

New cards

Austenizing

Gamma, rapid cooling, increase hardness and strength

58

New cards

tempering

500 C, air cooling, increase toughness

59

New cards

Annealing

gamma, slow furnace cooling, ductility

60

New cards

gamma, air cooling, most predictable uniform grain structure

normalizing

61

New cards

blue austenitizing, black tempering, orange annealing, green normalizing

Time-temperature-transformation curve

62

New cards

tensile strength and yield strength go up but area and elongation are reduced

If you add carbon in steel

63

New cards

for softer materials

Brinell

64

New cards

increase hardness.

Not a reason to anneal a metal

65

New cards

reduce brittleness, improve toughness, relieve stresses, recrystallize coldworked metals

Annealing will

66

New cards

Chapter 7 Ceramics Prezi

Chapter 7 Ceramics Prezi

67

New cards

Ceramic

An inorganic compound consisting of a metal or semi metal and one or more nonmetals

68

New cards

* Properties of ceramic materials

* High hardness, electrical and thermal insulating, chemical stability, and high melting temperatures

* Brittle, virtually no ductility-can cause problems in both processing and performance of ceramic products

* Some ceramics are translucent, window glass (based on silica) being the clearest example

* Brittle, virtually no ductility-can cause problems in both processing and performance of ceramic products

* Some ceramics are translucent, window glass (based on silica) being the clearest example

69

New cards

Density of ceramics

most ceramics are lighter than metals but heavier than polymers

70

New cards

Melting temperatures of ceramics

higher than for most metals

71

New cards

Electrical and thermal conductivities for ceramics

lower than for metals, but the range of values is greater, so some ceramics are insulators while others are conductive

72

New cards

Thermal expansion of ceramics

somewhat less than for metals, but effects are more damaging because of brittleness

73

New cards

Quiz 9 (7,8)

Quiz 9 (7,8)

74

New cards

Among the thermosetting polymers, the most widely used commercially is which one of the following:

phenolics

75

New cards

Glass products are based primarily on which one of the following minerals:

silica

76

New cards

Of the three polymer types, which one is the most important commercially:

thermoplastics

77

New cards

Synthetic diamonds date to:

1950s

78

New cards

The leading commercial synthetic rubber is which one of the following:

styrene-butadiene rubber

79

New cards

Which of the following ceramics are commonly used as abrasives in grinding wheels:

aluminum oxide

80

New cards

Which one of the following comes closest to expressing the chemical composition of clay:

Al2(Si2O5)(OH)4

81

New cards

Which one of the following is the chemical formula for the repeating unit in polyethylene:

C2H4

82

New cards

Which one of the following materials is closest to diamond in hardness:

cubic boron nitride

83

New cards

Which one of the three polymer types does not involve cross- linking:

thermoplastics

84

New cards

Quiz 10 (13)

Quiz 10 (13)

85

New cards

A thermoforming mold with a convex form is called which one of the following:

a positive mold

86

New cards

In rotational molding, centrifugal force is used to force the polymer melt against the surfaces of the mold cavity where solidification occurs:

false. It is the force of gravity in the doubly rotating mold that forces the polymer against the mold surfaces.

87

New cards

In which of the following property categories do plastic parts often compare favorably with metals:

impact resistance,

\

\

88

New cards

The function of the ejection system in injection molding is which one of the following:

separate the part from the cavity after molding

89

New cards

The parting line in injection molding is which one of the following:

where the two mold halves come together

90

New cards

The two principal components of an injection molding machine are which of the following:

clamping and injection units

91

New cards

Which of the following defects or problems is associated with injection molding:

\

\

flash

92

New cards

Which of the following is a section of a conventional extruder barrel for thermoplastics:

compression section

93

New cards

Which of the following processes are generally limited to thermoplastic polymers:

blow molding

94

New cards

Which of the following processes is associated with the production of plastic sheet and film:

blown-film extrusion process

95

New cards

Assignment 9 (7,8)

Assignment 9 (7,8)

96

New cards

What is a ceramic?

A ceramic is an inorganic compound, consisting of a metal (or semi-metal) and one or more non-metals.

97

New cards

What is the difference between the traditional ceramics and the new ceramics?

Traditional ceramics are based primarily on clay products (e.g., pottery, bricks) while new ceramics are more recently developed ceramics which are generally simpler in chemical composition (e.g., oxides, carbides).

98

New cards

What type of atomic bonding characterizes the ceramics?

Covalent and ionic bonding.

99

New cards

What is glazing, as applied to ceramics?

Glazing involves the application of a surface coating of oxides such as alumina and silica, usually to a porous ceramic product such as earthenware, to make the product more impervious to moisture and more attractive.

100

New cards

What is one of the important applications of titanium nitride, as mentioned in the text?

As a thin coating on cutting tools to prolong tool life.