Fundamentals of Welding 2

1/59

Earn XP

Description and Tags

More in-depth description of welding process from fundamental 1

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

60 Terms

Brief Description of Arc Welding

A pool of molten metal is formed near electrode tip, as the electrode moves along the joint, molden weld pool solidifies in its wake.

Problems with manual welding

weld joint quality, productivity

Two types of Arc Welding Electrodes

Consumable: consumed during welding process, nonconsumable: not consumed during welding process

Types of consumable electrodes

Welding rods, weld wire continuously fed from spools with long lengths of wire

Nonconsumable electrodes

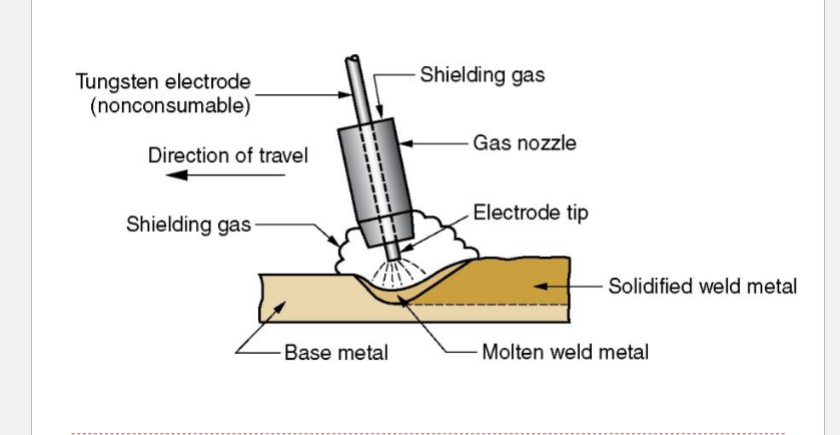

made with tungsten which resists melting, gradually depleted during welding (vaporizing), filler metal must be supplied by separate wire feed into weld pool

Arc Shielding

At high temps in AW, metals are chemically reactive to oxygen, nitrogen and hydrogen in air.

Arc Shielding is accomplished by…

shielding gases, flux

What is Flux?

A substance that prevents formation of oxides and other contaminants in welding, or dissolves them and facilitates removal

Flux Application methods

Pouring granular flux onto welding operation, covering electrode with flux, tubular electrode where flux is contained in core and released during consumption

Power Sources in Arc Welding

AC/DC, AC machines are less expensive but restricted to ferrous metals, DC can be used for all metals and is better for arc control

What are the Four Consumable Electrode AW Processes?

Shielded Metal, Gas Metal, Flux-Cored, Submerged

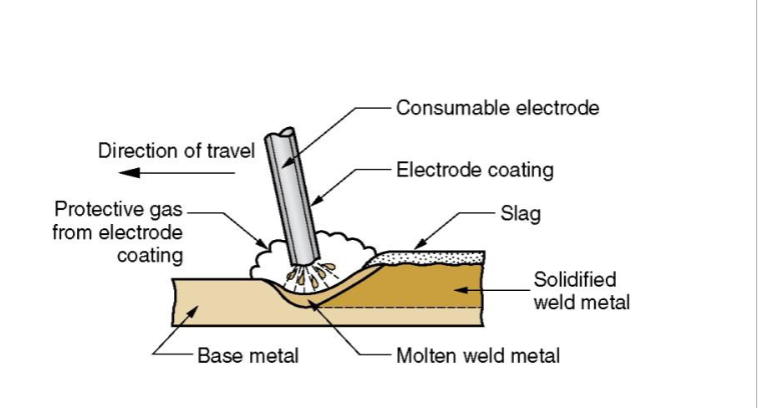

Shielded Metal Arc Welding (SMAW)

Uses a consumable electrode consisting of a filler metal rod coated with chemical that provide flux and shielding

What process is this?

Shielded Metal Arc Welding (SMAW)

Welding Stick in SMAW

Composition of filler metal usually close to base metal, clamped to in electrode holder connected to power source, coating: powdered cellulose mixed with oxides and carbonates

Disadvantages in SMAW

Sticks must be periodically changed, high current levels may melt coating prematurely

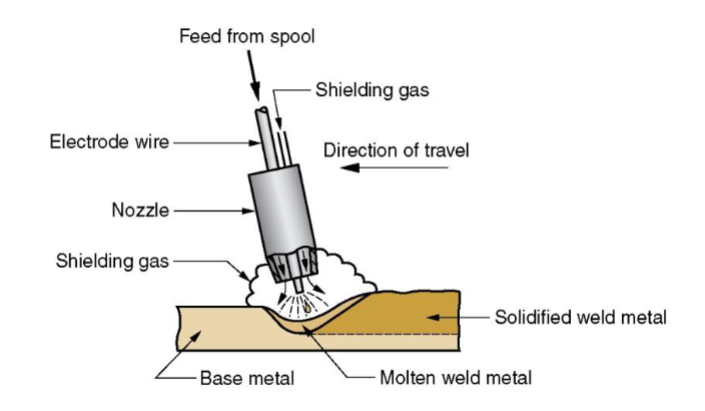

What is Gas Metal Arc Welding (GMAW)?

Uses a consumable bare metal wire as electrode with shielding by flooding arc with a gas.

What process is this?

Gas Metal Arc Welding (GMAW)

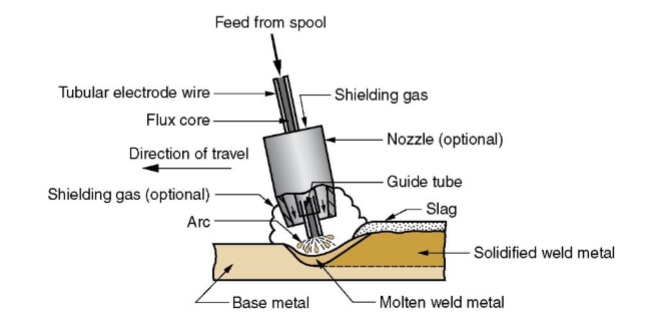

Flux-Cored Arc Welding (FCAW)

Adaption of shielded metal arc welding to overcome limitations of stick electrodes

Two Types of FCAW

Self-shielded (core includes compounds that produce shielding gases), Gas-shielded (uses externally applied shielding gases)

What process is this?

Flux-Cred Arc Welding (FCAW)

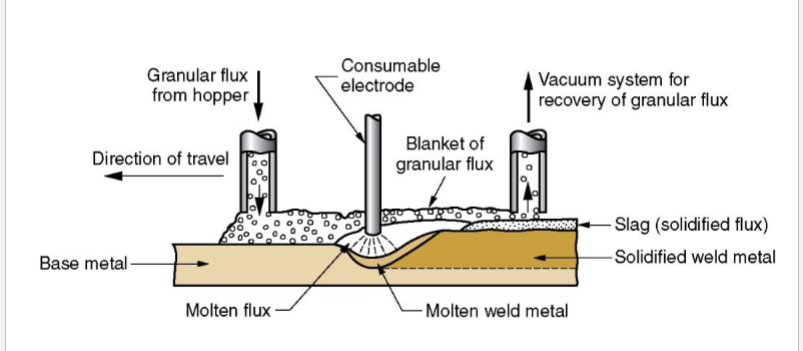

Submerged Arc Welding (SAW)

Uses a continuous, consumable bare wire electrode with arc shielding by a cover of granular flux

What process is this?

Submerged Arc Welding (SAW)

SAW Applications

Steel fabrication of structural shapes, seams for large diameter pipes, tanks and pressure vessels, welded components for heavy machinery

Gas Tungsten Arc Welding (GTAW)

Uses a nonconsumable tungsten electrode and an inert gas for arc shielding

What process is this?

Gas Tungsten Arc Welding

Advantages of GTAW

High quality welds, no spatter, little or no post-weld cleaning

GTAW Disadvantages

Slower and more costly than consumable electrode

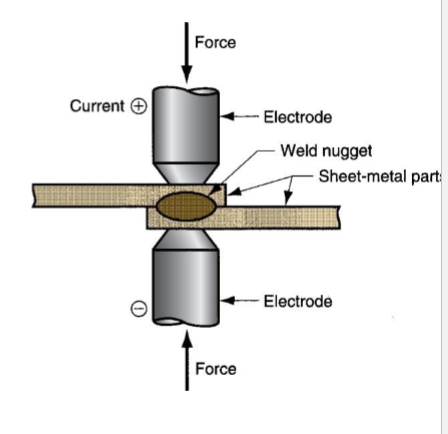

Resistance Welding (RW)

A group of fusion welding processes that use a combination of heat and pressure to accomplish coalescence

What Process is this?

Resistance Welding

Components in Resistance Spot Welding

Parts to be welded, two opposing electrodes, means of applying pressure to squeeze parts between electrodes, power supply form which a controlled current can be applied for a specified time duration.

RW Advantages

No filler metal required, high production rates possible, lower operator skill level than for arc welding, good repeatability and reliability

RW Disadvantages

High initial equipment cost, limited to lap joints for most RW processes

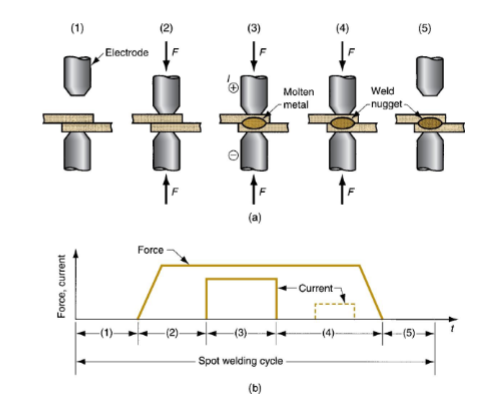

Resistance Spot Welding (RSW)

Process in which fusion of faying surfaces of a lap joint is achieved at one location by opposing electrodes. Used to join sheet metal parts.

List the 5 parts of the spot welding cycle

(1) parts inserted between electrodes, (2) electrodes close, (3) current on, (4) current off, (5) electrodes opened

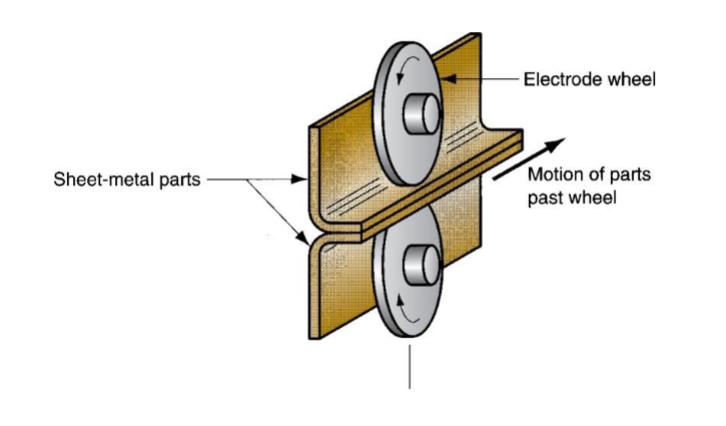

Resistance Seam Welding (RSEW)

Uses rotating wheel electrodes to produce a series of overlapping spot welds along lap joint and can produce air-tight joints

What process is this?

Resistance Seam Welding

Oxyfuel Gas Welding (OFW)

Group of fusion welding that burns various fuels mixed with oxygen. employes several types of gases, used in flame cutting torches to cut and separate metal plates and other parts

Oxyacetylene Welding (OAW)

Fusion welding performed by a high temperature flame from combustion of acetylene and oxygen, flame is directed by a welding torch, filler metal is sometimes added

What process is this?

Oxyacetylene Welding

Why acetylene and what are the two-stage reactions?

(C2H2) it is capable of higher temperatures than other fuels, first stage —> inner cone of flame, second stage —> outer envelope

Other Fusion welding processes that cannot be classified as arc, resistance or oxyfuel:

Electron beam, laser beam, electroslag, thermit

Electron Beam Welding (EBW)

fusion process in which heat for welding is provided by highly focused, high-intensity stream of electrons striking work surface,

Advantages of EBW

High-quality welds with deep and narrow profiles, limited heat affected zone, low thermal distortion, no flux of shielding gases needed

Disadvantages of EBW

High equipment cost, precise joint preparation and alignment required, vacuum chamber required, safety concern: EBW generates X-rays, vacuum chamber pumpdown time can be very long

Laser Beam Welding (LBW)

Fusion process in which coalescence is achieved by energy of a highly concentrated, coherent light beam focused on joint

Key comparisons of LBW and EBW

no vacuum chamber required for LBW, no X-rays emitted in LBW, Laser beams can be focused and directed by optical lenses and mirrors, LBW not capable of the deep welds and high depth-to-width ratios of EBW

Solid State Welding (SSW)

Coalescence of parts is achieved by pressure alone or heat and pressure, no filler metal is added, Each SSW process has its own way of creating a bond at the faying surfaces

SSW Advantages over FW Processes

If no melting —> no heat affected zone so metal around joint retain original properties, Many SSW processes produce welded joints that bond the entire contact interface between two parts rather than at distinct spots/seams, Some SSW can be used to bond dissimilar metals without concerns about relative melting points, thermal expansions and other problems that arise in FW.

Friction Welding (FW)

SSW process in which coalescence is achieved by frictional heat combined with pressure, no filler metal, flux or shielding gases used. Can be used to join dissimilar metals, Widely used commercial process amenable to automation and mass production

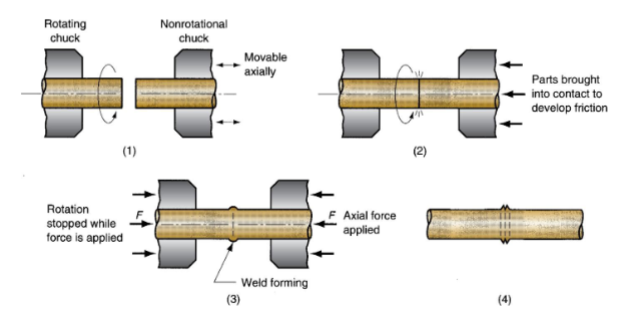

Describe the parts of this Friction Welding Process

(1) Rotating part, no contact (2) parts brought into contact to generate friction heat (3) rotation stopped and axial pressure applied and (4) weld created

Applications and Limitations of Friction Welding

Applications: shafts and tubular parts, Limitations: at least one of the parts must be rotational, flash must usualy be removed, upsetting reduces the part lengths

Friction Stir Welding (FSW)

SSW process in which rotating tool is fed along a joint line between two workpieces, generating friction heat and mechanically stirring the metal to form the weld seam

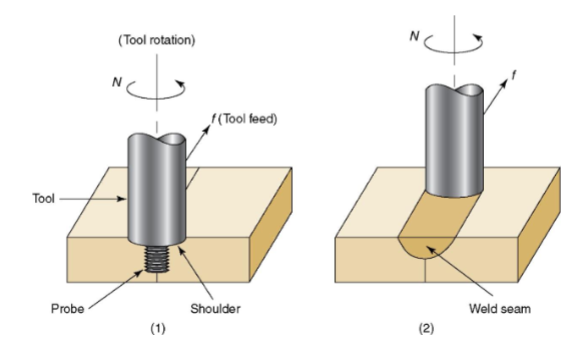

What process is this and what happens in each step?

Friction Stir Welding. (1) Rotating tool just before entering work, and (2) partially completed weld seam

Advantages of Friction Stir Welding

Good mechanical properties of weld joint, avoids toxic fumes, warping, and shielding issues, little distortion or shrinkage, good weld appearance

Disadvantages of Friction Stir Welding

An exit hole is produced when the tool is withdrawn, heavy duty clamping if parts is required

Weld Quality

Concerned with obtaining an acceptable weld joint that is strong and absent of defects, also concerned with the methods of inspecting and testing the joint to assure its quality

Residual Stresses and Distortion

Rapid heating and cooling in localized regions during FW result in thermal expansion and contraction that cause residual stresses. These stresses in turn, cause distortion and warpage.

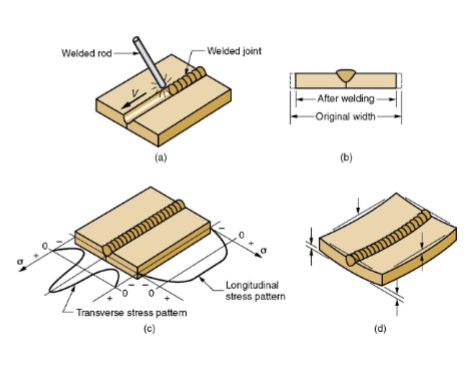

Name the Residual Stresses and Distortion in the four figures

(a) Butt welding, (b) shrinkage, (c ) residual stress patterns, (d) likely warping of weldment

Techniques to Minimize Warpage:

Welding fixtures to physically restrain parts, heat sinks to rapidly remove heat, tack welding at multiple points along joint to create a rigid structure prior to seam welding, selections of welding conditions to reduce warpage, preheating base parts, stress relief heat treatment, proper design of weldment

Welding Defects

Cracks, cavities, solid inclusions, imperfect shape or unacceptable contour, incomplete fusion, miscellaneous defects