Defects, Deterioration and Shrinkage of Wood

1/21

Earn XP

Description and Tags

codes and specs 3434

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

22 Terms

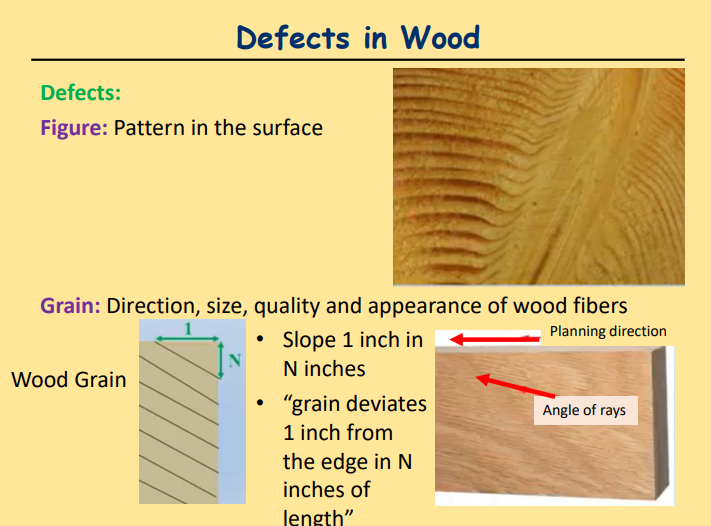

Defects

Pattern in the surface

Grain

Direction, size, quality and appearance of wood fibers

Defects in Wood 1

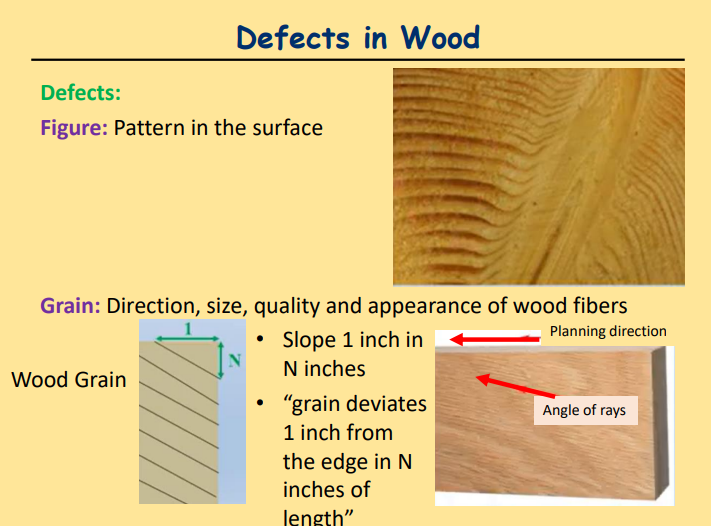

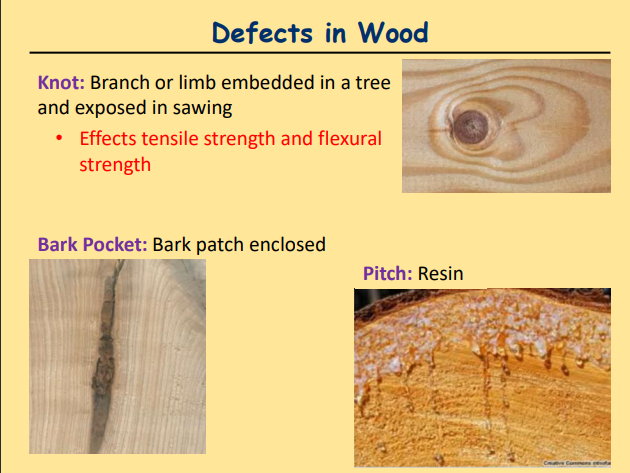

Knot: Branch or limb embedded in a tree

and exposed in sawing

• Effects tensile strength and flexural

strength

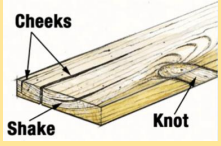

Shake

Separation of wood between and parallel to the grain

Check

Lengthwise separation of wood

Wane

Lack of wood in the corners

Dry Shrinkage

Uneven drying creates cracks

Warping

bow, warping, cup, crook, twist, kink

Shrinkage

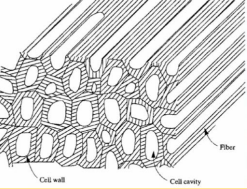

• Wood absorbs moisture when it contacts water: Volume

increases until it reaches FSP

• FSP: Moisture content when the cell walls are saturated and

the cell cavities are empty

• As water is lost in the cell cavity: No dimensional change

• As water is lost in the cell wall: Dimensions of wood will

decrease causing shrinkage

• Moisture content below FSP

• On average there is a 12% decrease in volume when going

from FSP to a moisture content of 0%

Shrinkage

• Wood absorbs moisture when it

contacts water: Volume increases

until it reaches FSP

• FSP: Moisture content when

the cell walls are saturated and

the cell cavities are empty

Factors Influencing Shrinkage

• Species

• Cell wall thickness

• Cell arrangement

• Sapwood/Heartwood

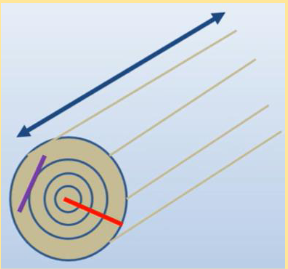

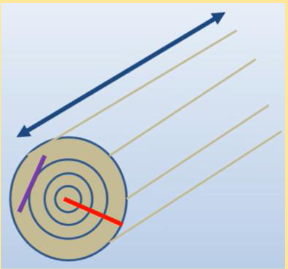

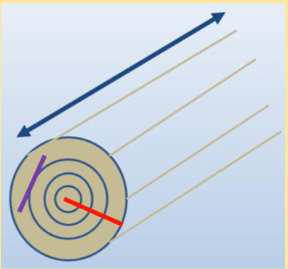

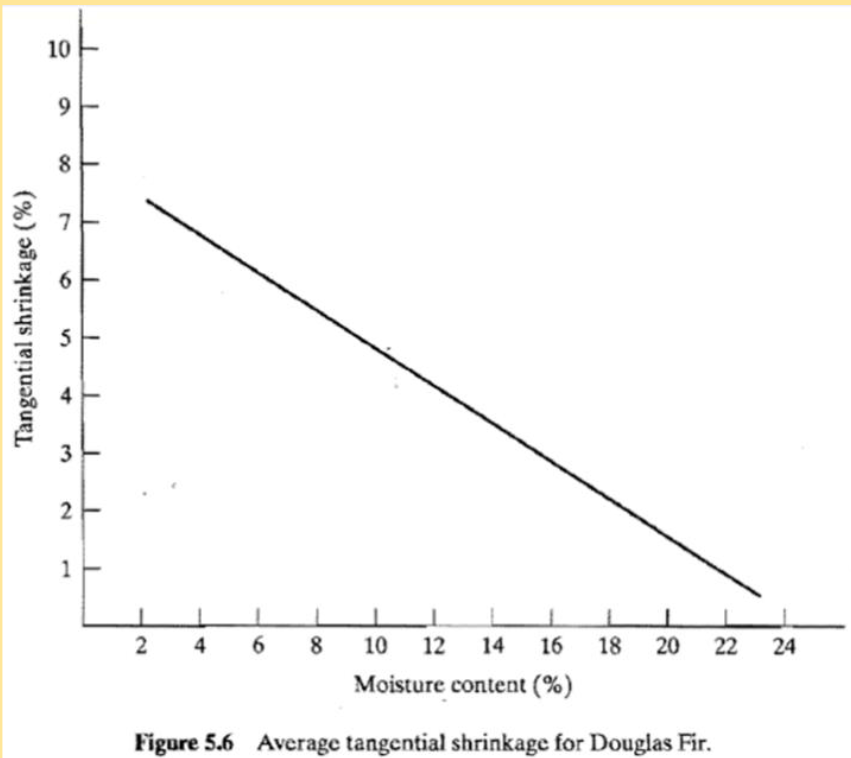

Tangential Shrinkage

Plane tangent to the

growth rings

• Highest amount of shrinkage occurs on

this plane

• Approximately 1% volume decrease per

4% decrease in MC below the FSP

Radial Shrinkage

Occurs on the plane that

goes with the radius of the log

• = ½ x Tangential Shrinkage

Longitudinal Shrinkage

Occurs along the

longitudinal axis of the log

• Negligible

Shrinkage of Wood

• When differential shrinkage occurs between building parts

and aren’t accounted for properly:

• Affects plumbing, electrical, HVAC, finished surfaces

• Causes cracks in the wall

Seasoning:

The controlled drying of lumber

Methods:

• Air drying

• Kiln drying

Why?

• Increase strength

• Lower shrinkage in service

• Improve decay resistance

• Reduce the weight

• Needed to apply

preservative treatment

Treatment and Durability

Influential factors:

• Species

• Environment

• Seasoning

• Part of tree

• Sapwood: More susceptible to decay

• Heartwood: More durable

Use chemical treatments, coatings, seasoning, water proofing

Why? Wood decays if unprotected

Why? Insect/fungal attack

Ease of chemical treatment depends on:

• Density

• Wood structure

• Moisture content

• Dimensions

• Cell wall composition

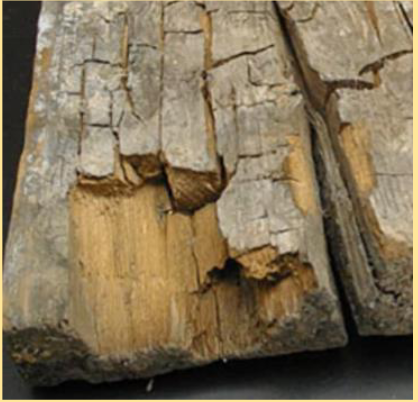

Decay:

Fungal attack

• Grows in cells

destroying lignin and

feeds on cell material

• Brittle failure

• Weakens wood

To grow, fungi need:

• Proper temperature

• MC > 19%

• Oxygen

• Food

Brown Rot

Fungus attacks cellulose

White Rot

Rot from cellulose and

lignin

Dry Rot

Attack part of wood which

gives it strength and stiffness

(spreads fast)

Wet Rot

Rot of wet lumber

Destruction

• Insects (Termites)

• Termites are the most common wood

eating insect

• Live in cellulose

• Dry wood (mostly in the south)

Use chemicals or

concrete foundation to

help reduce termites