DDS LEC - Solid Dosage Forms: Tablets Part II

1/37

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

38 Terms

Quality Standards & Compendial Requirements

Tests performed in intermediate and finished products before and after the manufacturing process in order to comply with the specifications

Routinely run to monitor the process from powder to granules up to its compression

Monitored every step so if there’s a problem in terms of the granulation, it can be addressed immediately

Also performed during product development

Used for Process Validation

Compendial Standards

Pharmaceutical standards in a compendium

Process Validation

A small-scale test run of the procedures and processes, making sure that before the upscale or the manufacturing scale production, the process meets the specifications

In Process Quality Control Tests ((IPQC Tests)

Tests done for intermediate testing

Finished Product Quality Control Tests (FPQC Tests)

Tests done for finished product testing

Particle Size Distribution

Can also be called Grain-size Distribution

Represents the relative proportions of different particle or grain sizes in a sample

Can be performed using a sieve with various sieve numbers, microscope methods, or using a RO-TAP Mechanical Sieve Shaker

Ideal Tablet

Composed of:

80% Good

20% Fine Granules

Bulk Density

Ratio of the mass to the volume of the untapped powder sample

It describes the packing of particles or granules

Dictates how much space is needed for the powder or granules to be safely stored

Tapped Density

Ratio of the mass of the powder to the volume occupied after it has been tapped for a definite number

Method I

Commonly used method

Method using Graduated cylinder in Bulk and Tap Density Tester

Method II

Method using Volumeter

Method III

Method using Vessel

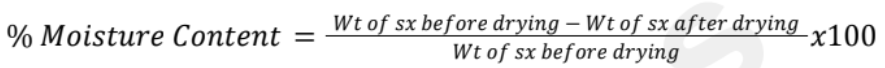

Moisture Content

Presence of water in a product

2-3% moisture content before starting compression when the tablet undergoes wet granulation

Directly measure the moisture content of a sample by using the Loss On Drying (LOD) technique

If there is excessive moisture, granules will stick to the dye cavity

Will not result in a 1 solid tablet because of sticking

If done manually, done in a drying oven with a balance to determine the initial and final weight of the sample and using a simple mathematical calculation to determine the moisture content

Tablet Hardness

Determines the quality of tablet in terms of rigidity and resistance to chipping or breakage during transport and storage

Stokes-Monsanto Tablet Hardness Tester

If not available, use Rule of Thumb

Stokes-Monsanto Tablet Hardness Tester

Spring gauge and screw mechanism

Place the tablet upright

Screw clockwise

Continue screwing until a crack forms

Not the reading - Tablet Hardness

Uncoated, Oral Tablet Acceptable Hardness Range

4-10 kg

Sublingual, Chewable Acceptable Hardness Range

2-3 kg

Buccal Tablets Acceptable Hardness Range

10 kg

Sustained Release Acceptable Hardness Range

10-20 kg

Rule of Thumb

Used if Stokes-Monsanto Tablet Hardness Tester is not available

Place the tablet in between the 2nd and 3rd finger

Let it fall to the floor and the tablet should not break

Tablet Weight

Establish how many granules are placed in the die cavity and it should be uniform

Quantity of fill in the die of the tablet press

USP Weight Variation Test - determination of dosage form uniformity

Minimum of 10 tabs are weighed individually, and the average is calculated

The tablets are assayed to determine homogeneity of drug distribution

Maximum % Weight Variation Allowed for <130 mg

± 10%

Maximum % Weight Variation Allowed for 130 mg to 324 mg

± 7.5%

Maximum % Weight Variation Allowed for >324 mg

± 5%

Tablet Thickness

Non-official test for tablets

In-house specification sample (within the manufacturing company): ± 5%

Can give an idea in terms of the disintegration and dissolution profile

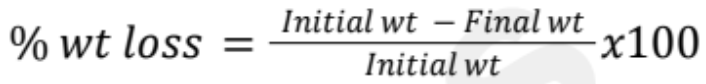

Tablet Friability Test

Tests the durability of tablets during packaging processes

Makes use of a tumbling apparatus where tablets are exposed to rolling and repeated shocks from free fall within the transparent synthetic polymer with polished internal surface drum

Condition: 100 revolutions

Speed: 25 ± 1 revolution per minute (4 minutes)

Criteria: Weight loss should not be more than 1%

Rotates clockwise and drops the tablets and will continuously repeat

Twice

In case of cracked, cleaved, or broken tablets present, repeat the test _____.

% Weight Loss Formula

Disintegration Test

Measures the ability of a tablet to break apart into smaller particles or granules to allow the active drug to be absorbed into the body

1 tab is placed per cylinder, then a disk is placed in top of the tablet to prevent the tablet from floating

Condition:

Volume: 900 mL distilled water (or whatever is specified)

Temperature: 37 ± 2°C - body temp

Sample: 6 tablets

Time:

Uncoated or Plain Tablets: 30 mins

Delayed-Release Tablets: 60 mins

Criteria:

All tablets should have disintegrated completely

If 1 or 2 tablets fail, repeat the test on 12 additional tablets (repeat test twice)

Time for Uncoated or Plain Tablets in Disintegration Test

30 minutes

Time for Delayed-Release Tablets in Disintegration Test

60 minutes

Dissolution Test

Process by which solid substances enters in a solvent to yield a solution

From powders, after disintegration, the drug is slowly dissolved or when it is present in the solution, it can be concluded that it is now ready for absorption

Type of Apparatus:

Apparatus I - Rotating Basket

Apparatus II - Rotating Paddle

Apparatus III - Reciprocating Cylinder

Apparatus IV - Flow-Through Cell

Apparatus V - Paddle Over Disk

Apparatus VI - Rotating Cylinder

Apparatus VII - Reciprocating Holder

Importance:

Guides formulation and product development

Product monitoring

Ensures consistent bioequivalence characteristics from batch to batch

In-Vitro

Establishes the amount of drug released

In-Vivo

Establishes the amount of drug absorbed

Quadrant 1

High Solubility

High Permeability

Fast to dissolve, Fast to be absorbed by the body for its therapeutic effect

Quadrant 2

Low Solubility

High Permeability

Slow to dissolve, Fast to be absorbed by the body for its therapeutic effect

Quadrant 3

High Solubility

Low Permeability

Fast to dissolve, Slow to be absorbed by the body for its therapeutic effect

Quadrant 4

Low Solubility

Low Permeability

Show to dissolve, Slow to be absorbed by the body for its therapeutic effect