MSSC - Quality Practices & Measurement

0.0(0)

Card Sorting

1/277

Earn XP

Description and Tags

Study Analytics

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

278 Terms

1

New cards

Which type of feature is parallel to the surface being dimensioned?

Dimension line

2

New cards

The three standard views of an object are \__________.

Top, front, right side

3

New cards

Which type of lines are used to show the counterbored hole in the part?

Hidden lines

4

New cards

The number of views in a drawing \__________.

Is the fewest number that shows all of the features and dimensions

5

New cards

Which of the following steps is NOT used in the glass box method?

Rotate object in glass box.

6

New cards

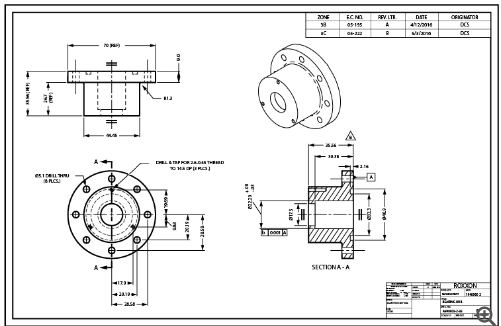

What type of drawing is shown?

Multiview

7

New cards

The dimensions of raw material supplied by metal suppliers are described by the \__________.

Stock size

8

New cards

Which of these requires a computer?

CAD

9

New cards

An isometric drawing is a type of \__________.

Pictorial drawing

10

New cards

Dimensions are used to specify the \__________ and location of the features of an object.

Size

11

New cards

What feature in the figure shown is a Chamfer?

D

12

New cards

A \__________ dimension is described in inches per foot.

Shaft taper

13

New cards

What is the order of precedence of lines in a drawing?

Object, Hidden, Center

14

New cards

Which of the following is not one of the six rules for dimensioning an object?

Dimension hidden lines

15

New cards

Engineers sometimes use a \__________ to measure angles on a drawing.

Protractor

16

New cards

There are 60 minutes of arc in one \__________.

Degree

17

New cards

In manufacturing, a blueprint is also called what?

A technical drawing

18

New cards

The distance across the flats of the hex head shown in the part drawing is \__________ inches.

2 ¼

19

New cards

The length of the part shown in the drawing is \__________ inches.

9 ¾

20

New cards

Which type best describes the line indicated in the graphic?

Object Line

21

New cards

Which of the following bolts is a grade 2?

A

22

New cards

The hole shown in the graphic is a \__________ hole.

Counterbore

23

New cards

What are the two types of assembly drawings?

Exploded and basic

24

New cards

A sectional view \__________.

All of the above

25

New cards

Which of the following is not used to specify a threaded fastener?

Minor diameter

26

New cards

Two types of threads are \__________.

Internal and external

27

New cards

In the assembly drawing shown, part 3 screws into part \__________.

4

28

New cards

The material that will be used to create the gear is indicated in the part drawing's title block to be \__________.

Cast iron

29

New cards

In a threaded fastener assembly what is designed to protect the threads?

Shank

30

New cards

Manufacturing workers can use a calibrated torque wrench to \__________.

Measure the proper amount of torque

31

New cards

The part of a drawing that indicates that the drawing has the most up to date information on it is \__________.

Drawing revision level

32

New cards

What type hole is shown in the figure?

Counterbored

33

New cards

The minor diameter of a screw thread is measured at the \__________.

Root of screw thread

34

New cards

Section lines in a sectional view are \__________.

All of the above

35

New cards

To establish on a drawing that 1/4 inch equals 1 inch, the designer would write \__________.

1/4\=1

36

New cards

Metals treated by \__________ processes become soft.

Annealing

37

New cards

Where would you look in a title block to see if there has been changes?

Revision number

38

New cards

Section lines on a blueprint indicate \__________.

A surface that has been cut

39

New cards

A screw with fine thread is represented on a drawing with what designation?

UNF

40

New cards

What is the depth of the countersink in the image?

0.12 inches

41

New cards

What is placed at the arrowheads of the cutting plane line to identify the cutting plane with the proper sectional view?

Capital letter

42

New cards

Assembly drawings rely on reference letters or numbers to \__________.

Identify the individual parts

43

New cards

If a feature on a drawing is drawn 3 inches long and the scale is 1:4, what is the actual dimension on the object?

12"

44

New cards

The specifications for the length of produced parts is 5.146 inches with a tolerance of ± 0.005. Is a part that has been produced at 5.140 inches out of spec?

Yes, it is out of spec

45

New cards

Which dimension on a production drawing has the most accuracy?

The one with the most "tolerance" decimal places

46

New cards

A datum feature symbol can be connected to \__________.

Any of the above

47

New cards

The graphic shown is an example of \__________ dimensioning.

Baseline

48

New cards

If 4 percent of 1200 production pieces are out of spec, how many are out of spec?

48

49

New cards

A part measuring 2.54 inches is out of spec if the specification is \__________.

2.00 ± .53

50

New cards

A running fit is also called a(n) \__________.

Sliding fit

51

New cards

Form, profile, orientation, location and runout are shown by \__________.

GD&T

52

New cards

If a drawing shows a part with a diameter of 1.275 ± .003, what is the minimum and maximum size allowed?

1.272, 1.278

53

New cards

The equipment at a workstation is supposed to produce parts at 2.593, per the part drawing, and has a spec limit of ± 0.004. Is a part that has been produced at 2.590 out of spec?

No, it is within spec

54

New cards

A part measuring 44.85 mm in a process with a tolerance of 45mm ± .28 is considered \__________.

**In spec (within the tolerance range)**

55

New cards

Datums are a point of reference to establish \__________.

Job tasks

56

New cards

The maximum material condition for the part shown is \__________.

15.75

57

New cards

The least material condition for the part shown is \__________.

0.75

58

New cards

Geometric Dimensioning and Tolerancing uses \__________ to represent features and tolerances.

Symbols

59

New cards

Examples of \__________ tolerance describe the form and orientation of a part.

Profile

60

New cards

Which of the following part lengths is out of spec if the specification calls for a part length of 3.202 (± 0.003)?

3.197

61

New cards

Length, width, height, diameter, and hole diameter are all examples of \__________.

Features of size

62

New cards

The tolerance for a geometric feature can be easily identified by reading the \__________.

Feature control frame

63

New cards

The term \__________ refers to a physical portion of a part.

Feature

64

New cards

A letter with a box around it is a standard notation symbol used to indicate a(n) \__________.

Datum feature

65

New cards

GD&T \__________.

Allows certain tolerances on part features to be increased

66

New cards

Which of the following is a feature control frame typically used to identify?

Extension lines

67

New cards

A \__________ is a theoretically perfect line, point or plane that is located by a similar feature of the part.

Datum

68

New cards

Dimensional measurement determines physical dimensions such as \__________.

Width, height, and depth

69

New cards

The measurement of a 5.000 inch part, with an instrument having \__________ accuracy, should range from 4.998

5.002 inches.

70

New cards

Convert 650 millimeters to inches (1mm \= 0.0394 inches).

25.61

71

New cards

One inch is equal to \__________.

25.4 mm

72

New cards

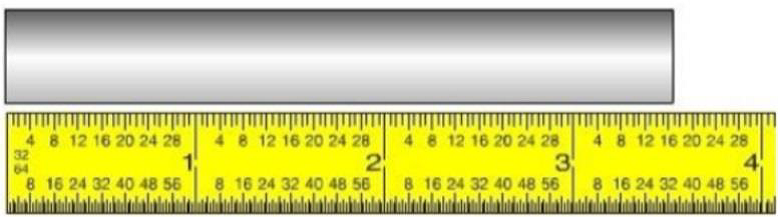

What is the measurement shown on the rule?

3 17/32 inch

73

New cards

10 inches is the same length as \__________ mm.

254

74

New cards

The first step in dimensional measuring is to align the end of the rule where the zero is located with one edge of the dimension you want to measure. This edge is called the \__________.

Reference point

75

New cards

A common decimal inch rule graduation is in \__________.

50ths

76

New cards

Two systems of dimensional measurement used in manufacturing are the SI Metric System and the \__________.

US customary system

77

New cards

Flatness is an important geometric feature of what measurement component?

Reference plane

78

New cards

What value is shown on the gauge?

56 psi

79

New cards

Resolution is sometimes called \__________.

Discrimination

80

New cards

A tape measure is flexible so that \__________.

It can be easily stored

81

New cards

A \__________ has its graduations engraved so that they can not be rubbed off.

Machinist's rule

82

New cards

The conversion of 3

3/8 inches to decimal inches is \__________.

83

New cards

A common fractional inch rule graduation is in \__________.

32nds

84

New cards

You have designed a part that has a length of 1.125 inches. Your supervisor requests that you reduce its length by 1/16 of an inch, what will be its final length?

1.0625 inches

85

New cards

\__________ error comes from either built

in sources or calibration.

86

New cards

From a 2 ft x 3 ft piece of stock, theoretically how many 1 ft x 1.5 ft pieces can be cut?

4

87

New cards

The work measured with a tape measure requires \__________ than that of work measured with a machinist's rule.

Less precise graduations

88

New cards

A scale typically found on a machinist rule is \__________.

1/16

89

New cards

The typical accuracy of a modern dial caliper is about \__________.

0.001 inches

90

New cards

The reading on the 3

4 inch micrometer indicates a measurement of \__________ inches.

91

New cards

The width of the plate being measured in the image using a metric micrometer is \__________.

6.89 mm

92

New cards

The digital caliper's \__________ houses the digital display.

Carriage

93

New cards

What is 1 /1000 inches in decimal?

0.001

94

New cards

A typical dial caliper can be used to measure dimensions to the nearest \__________ inches.

0.001

95

New cards

Calibration means to \__________.

Adjust a device to a standard

96

New cards

A micrometer increments how far for each complete rotation of its thimble?

0.025

97

New cards

The two outside jaws of a \__________ are only used to measure the outside dimensions of parts.

Digital and dial caliper

98

New cards

The measuring tool shown is a \__________.

Depth micrometer

99

New cards

A vernier micrometer is \__________ as accurate as a caliper.

10 times

100

New cards

A measurement made with a precision measurement tool can be as precise as \__________.

0.001 inches