Firearms and Toolmarks- Final Exam

1/82

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

83 Terms

What can function testing include?

Determining if the firearm is in mechanical operating condition

Testing firing

Determining if safety features are functioning properly

Testing scenarios for accidental discharge

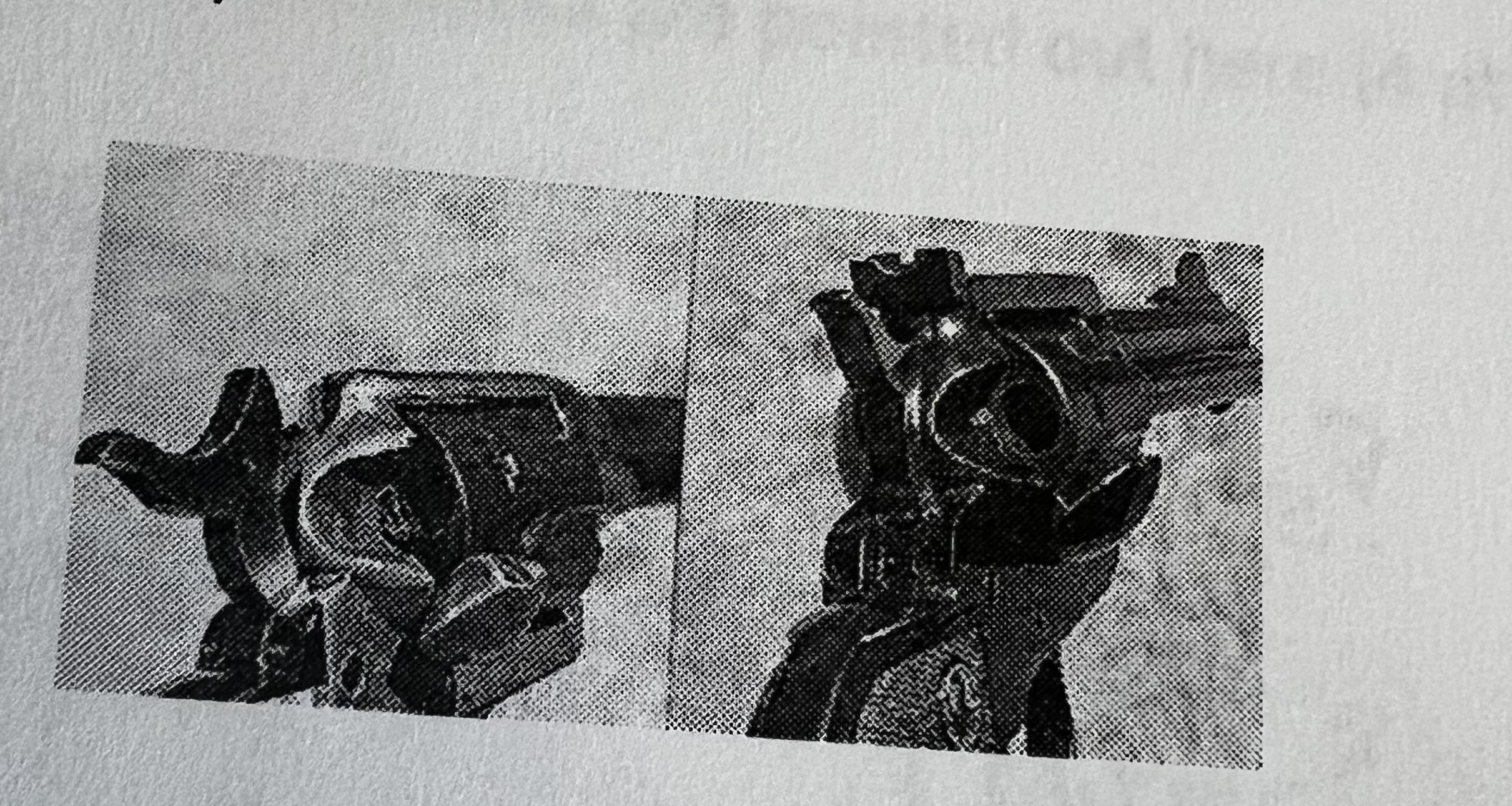

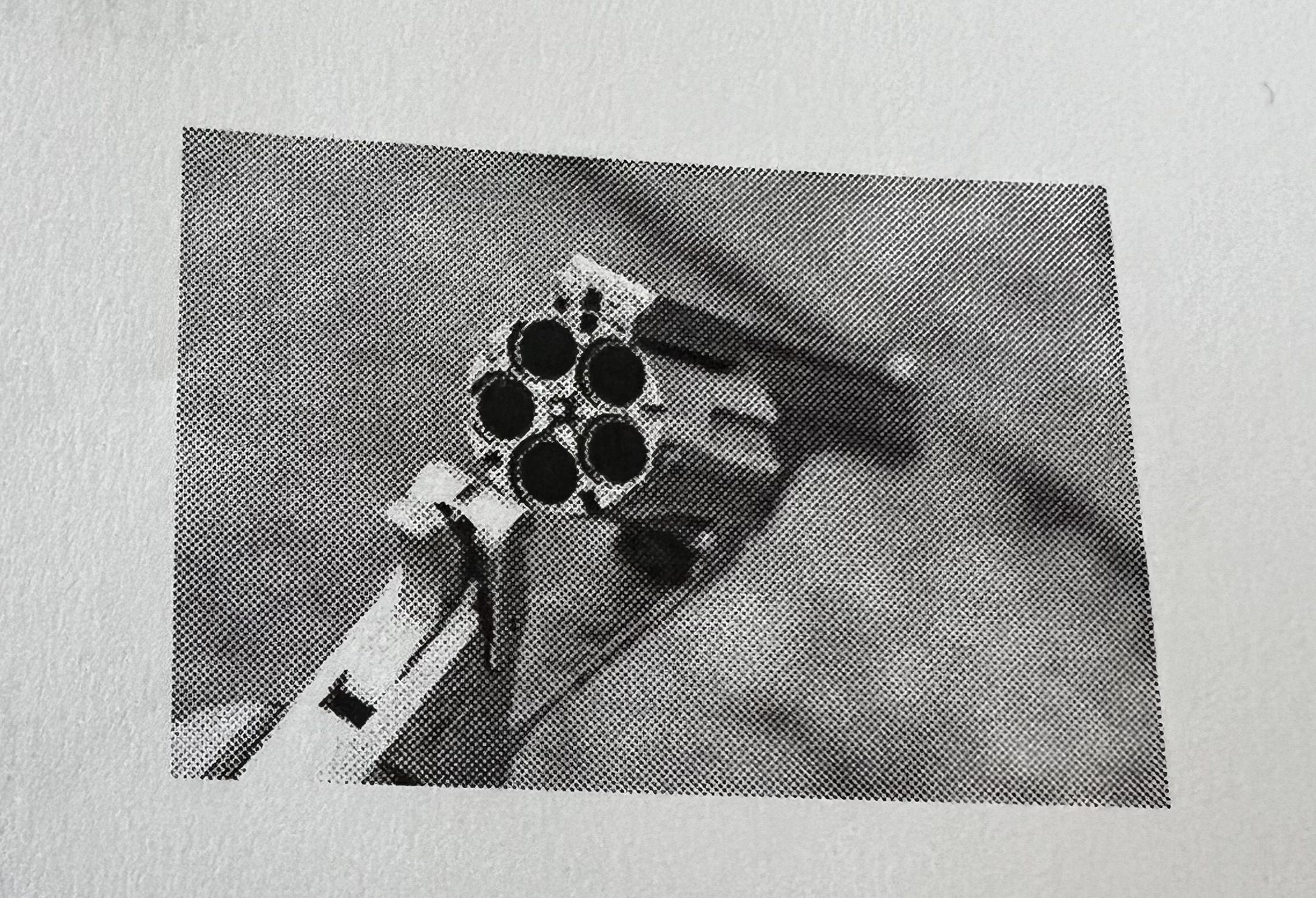

Types of revolvers

Double-Action

Single-Action

Top-Break

Single-Action

Action requiring the manual cocking of the firing mechanism

Double-Action

Action in which a single pull of the trigger cocks and releases the firing mechanism

Top-Break

Two safeties that may be on a revolver

Hammer Block

Transfer Bar

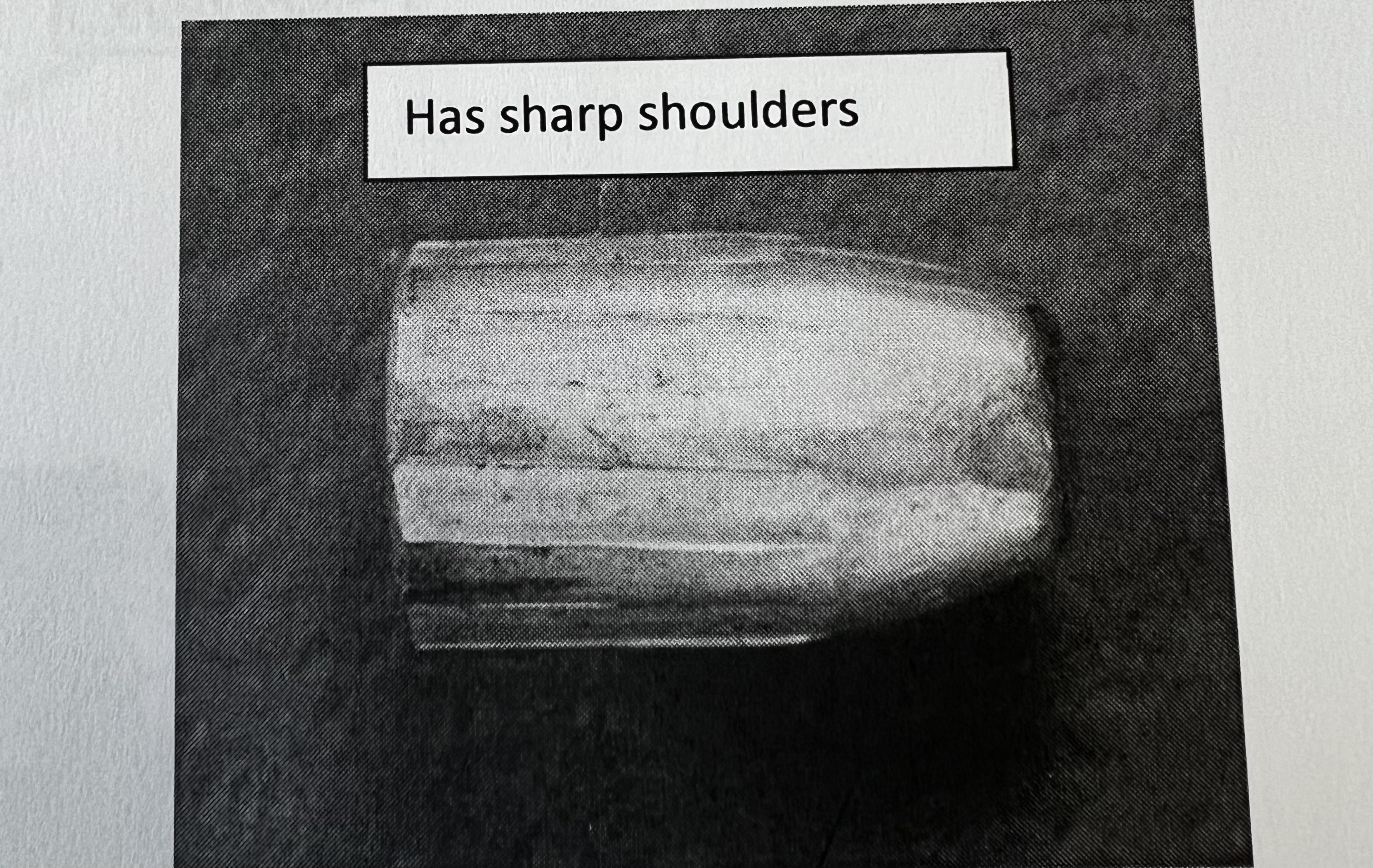

Conventional

Rifling with sharp, defined edges between that land and groove

Polygonal

Rifling in which lands and grooves have a rounded profile

General Rifling Characteristics (GRC)

Number of lands and grooves

Width of lands and grooves

Direction of twist

Caliber

Hybrid

design that incorporates aspects of both single action and double action

Two types of firing mechanisms for pistols

Hammer Fired

Striker Fired

Blowback

mechanism has the barrel of the firearm fixed to the frame and the weight of the slide and tension on the recoil spring keeps the breech closed during firing

Recoil

mechanism is the barrel of the firearm no fixed to the frame and the slide and barrel travel/lock together for a portion of the recoil

Gas-operated

mechanism uses the propellant gases to unlock the breech and complete the cycle of extracting and ejecting

Three safeties that may be on a pistol

Key Lock

Disconnect

Manual grip safety

Accidental

discharge typically involves the discharge of a firearm without the trigger being pulled

Unintentional

discharge involved the trigger being pulled without the intent to fire

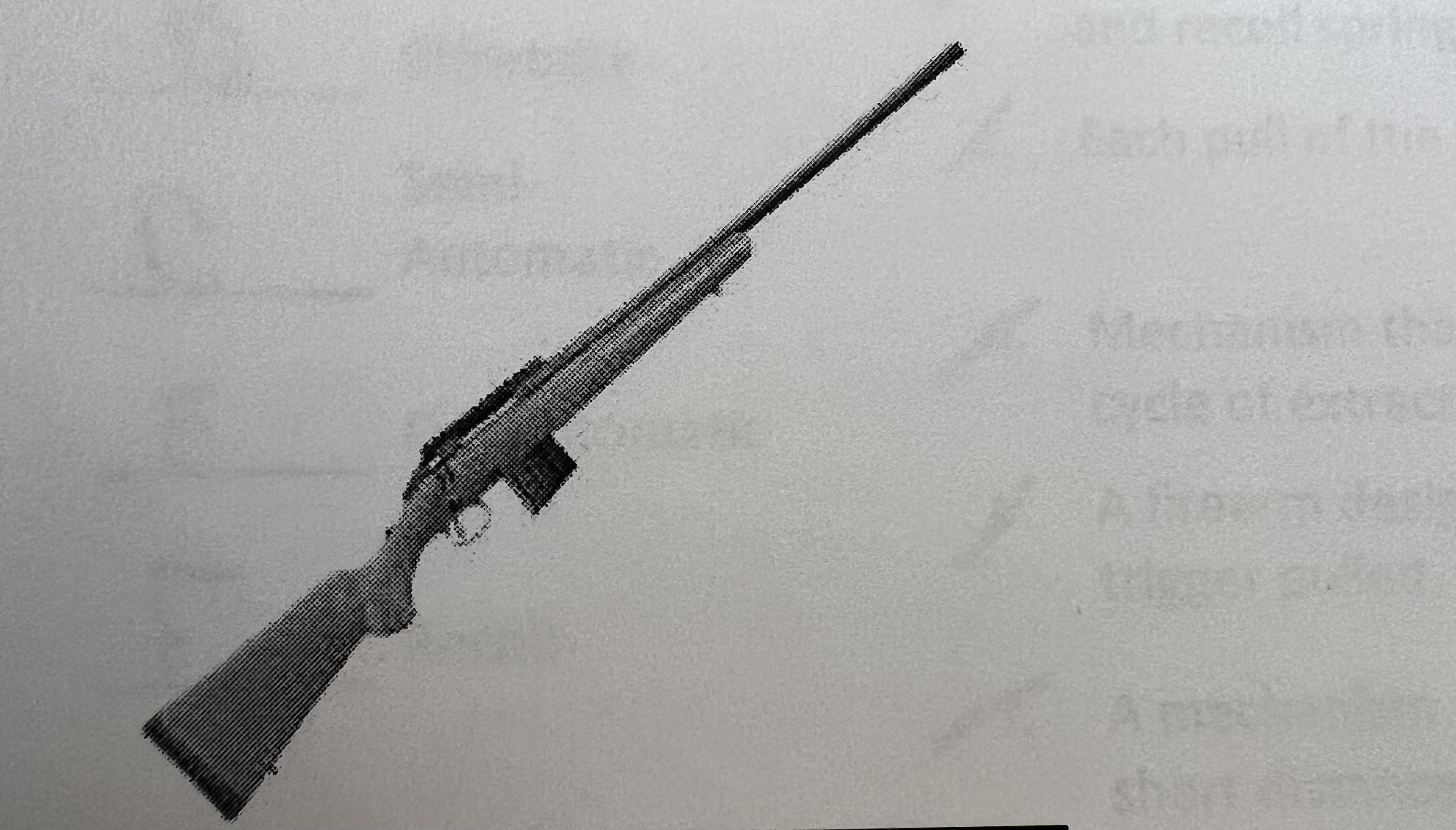

Semiautomatic

action in which each pull of the trigger results in a complete firing cycle

Automatic

firearm design that feeds cartridges, fires, extracts, and ejects cartridge cases as long as the trigger is fully depressed and there are cartridges in the feed system

Two types of rifles

Gas-operated

Lever action

Direct impingement

Gas is bled rearward to cycle the action in a rifle

Indirect impingement

Gas moves a piston, piston cycles the action in a rifle

Two common safety features on a rifle

cross bolt safety

disconnector

Military versions of the AR-type rifle may have a selector switch to choose between….

Semiautomatic

Automatic fire

Burst mode

Safe mode

AR-type rifles have what types of cartridges?

223 Remington/5.56 × 45 mm

AK-type and SKS-type rifles have what types of cartridges?

7.62 × 39 mm

Two types of shotguns

Slide-Action

Break open

Two common safety features on a shotgun

Trigger Safety

Lever Safety

True or False: 10 gauge has a smaller barrel diameter than 28 gauge

False

Choke

interior constriction at or near the muzzle end of a shotgun barrel bore to control shot dispersion

Rifles and Shotguns are….

Single Action

Breechface

area of a firearm that supports the head during firing

Firing pin aperture

opening in the firearm slide where the firing pin comes through

Shear

Types of marks produced when the firearm unlocks and scrapes the cartridge case across the surface of the breech face

Class Characteristics of Breechface Mark

Parallel

Circular

Arched

Granular

Cross-Hatched

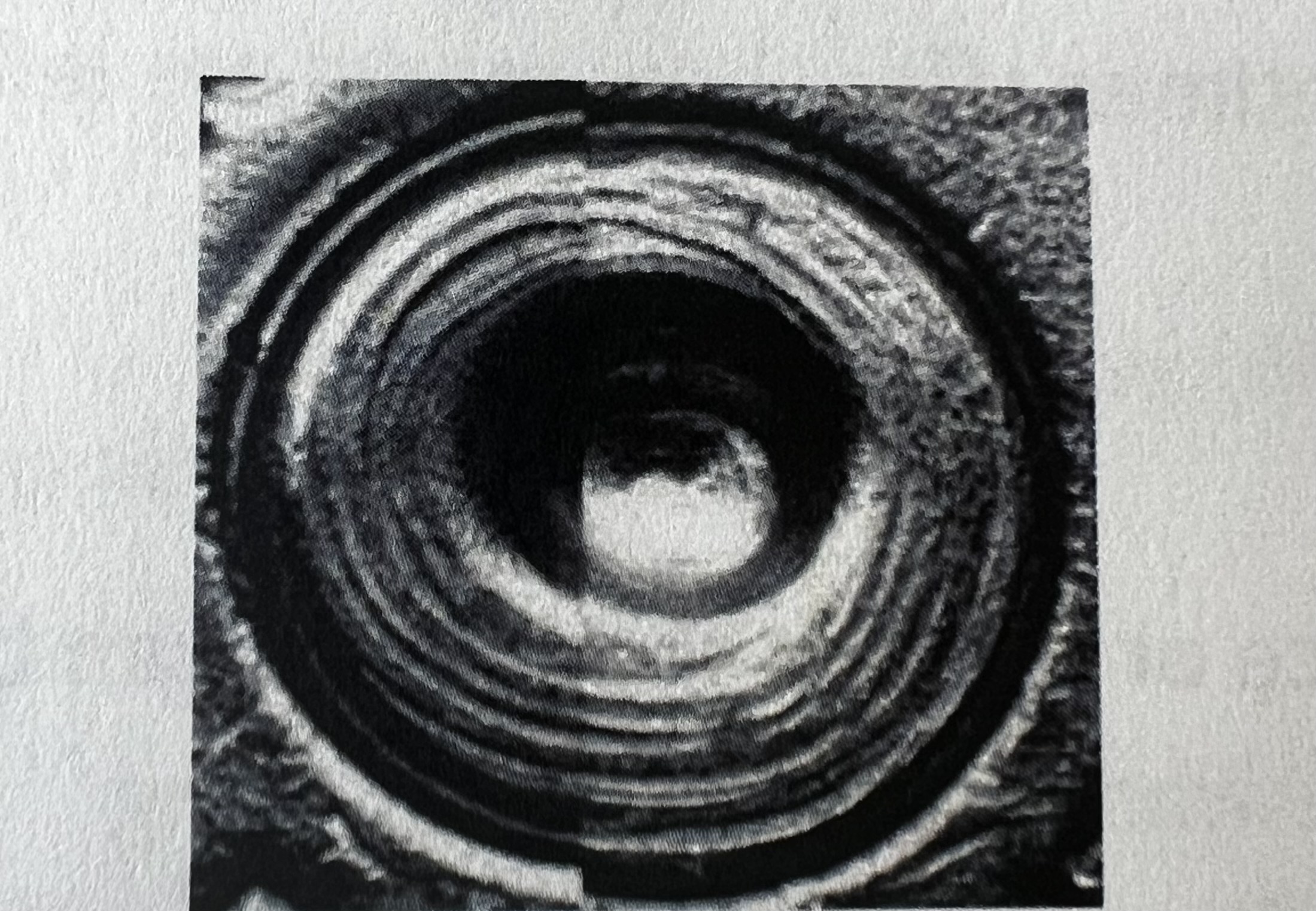

Parallel Breechface Mark

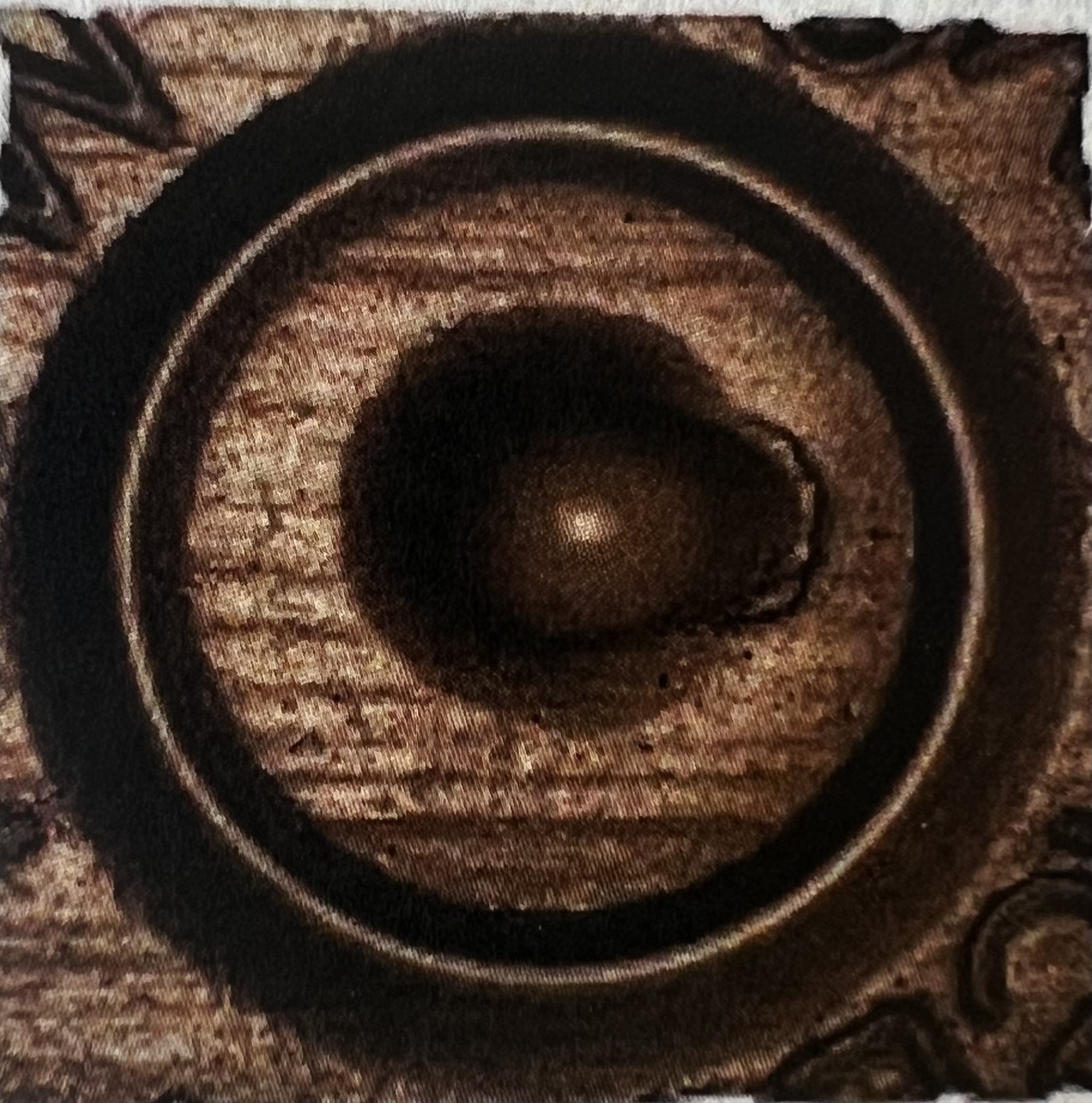

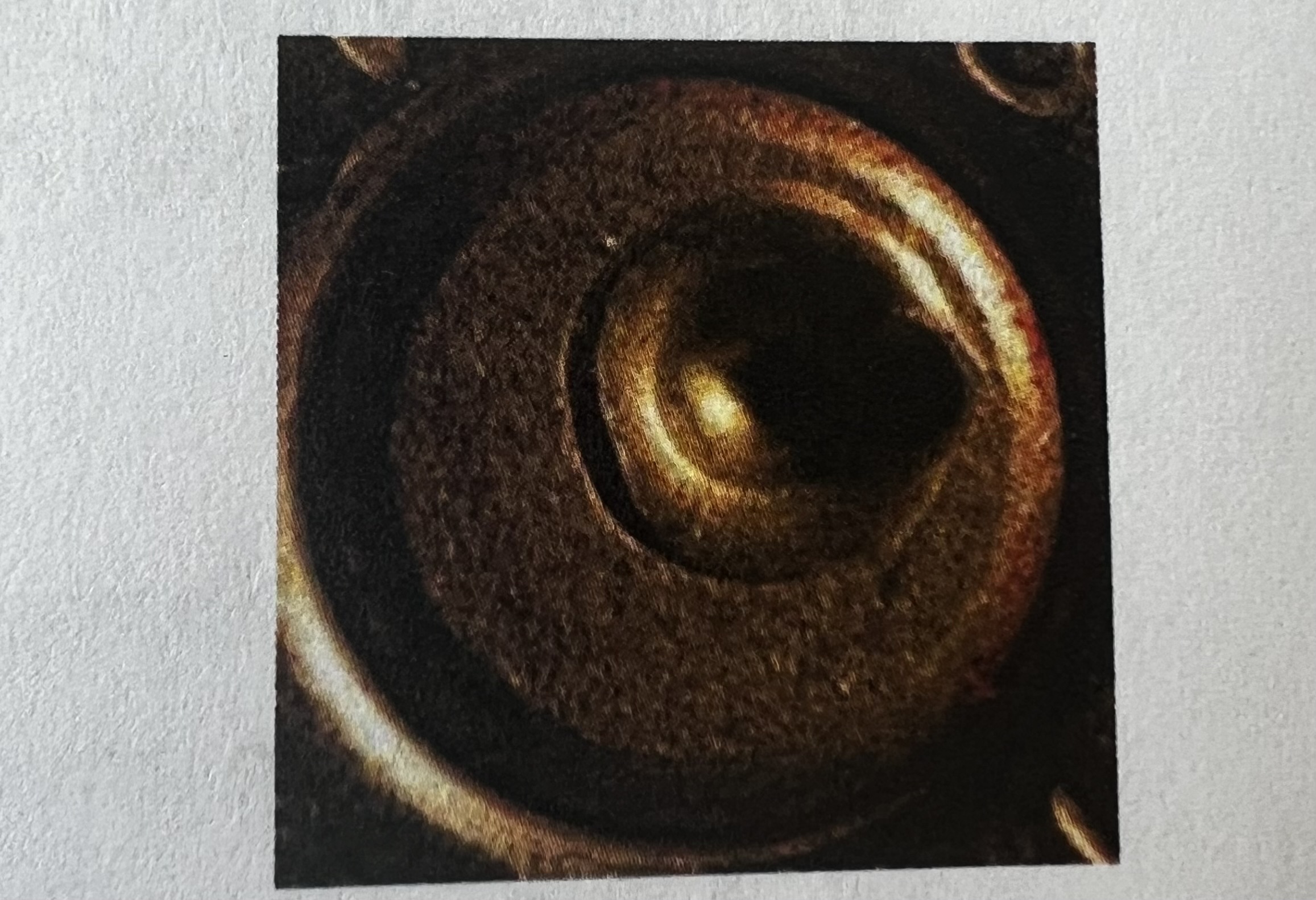

Circular Breechface Mark

Arched Breechface Mark

Granular Breechface Mark

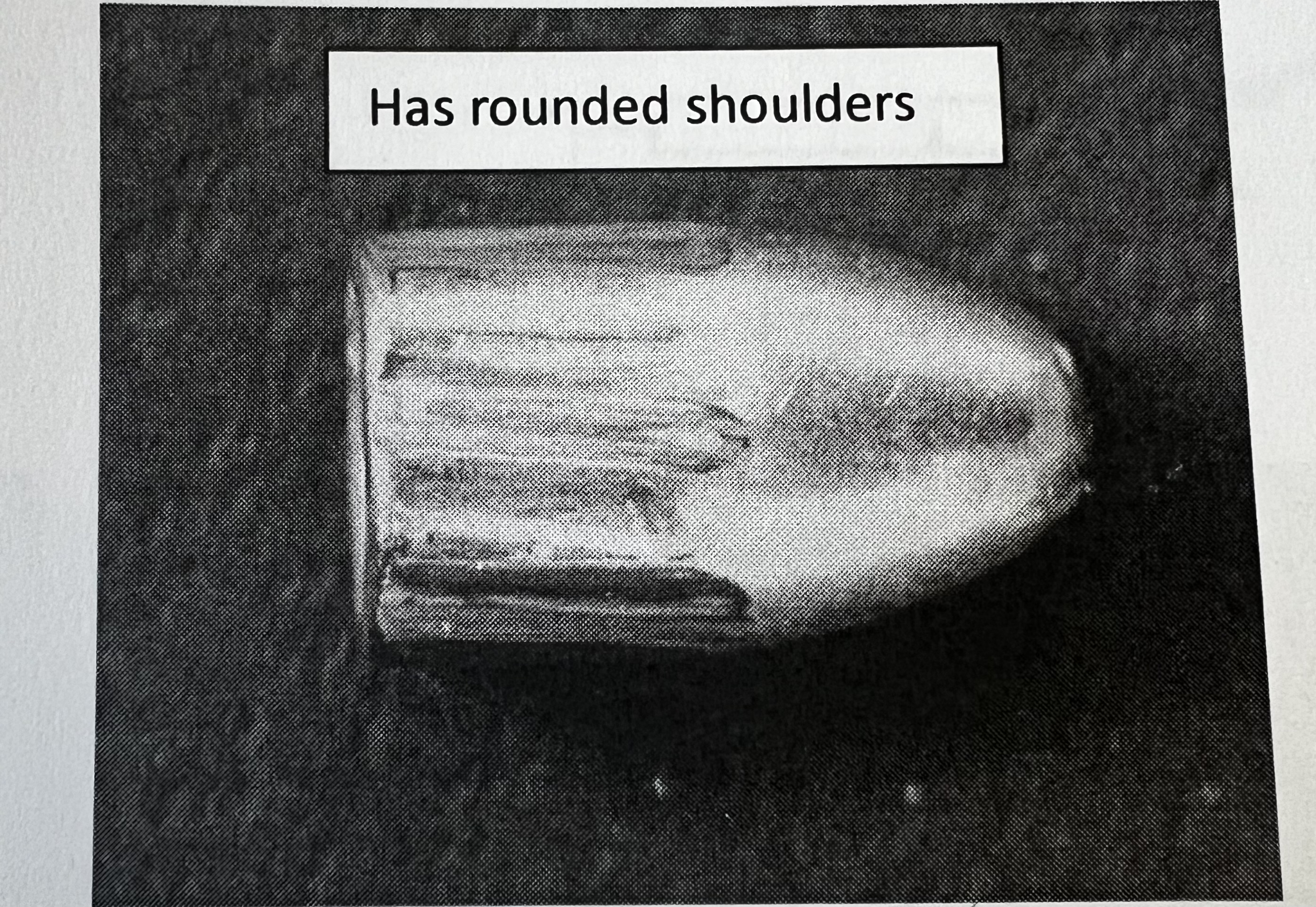

Hemispherical Firing Pin Mark

Rectangular Firing Pin Mark

Elliptical Firing Pin Mark

Circular Firing Pin Mark

D-shaped Firing Pin Mark

Two marks that can be created on a cartridge of a firearm without it being fired

Extractor

Ejector

Reproducibility

the appearance of the same marks in repeated test samples describes what concept?

What are some reasons that some features might not reproduce over all samples?

Different cartridge materials

Different projectile weights

True or False: NIBIN digitally captures images of cartridge cases, searches them against other images in the database, and automatically makes a match of the identified cartridge cases

False

True or False: The way a gun is held when fired can sometimes affect how marks are left behind on cartridge components

True

Variations in mark reproducibility from force or angle in the firearm can be attributed to this:

large firearm tolerances (loose fit of parts)

Distance Determination

the process of determining the distance from the firearm, usually the muzzle, to the target based on patterns of gunpowder or gunshot residues deposited upon that target

Gunshot residues can include these two things

Lead

Nitrate

Gunshot residues are expelled from what areas of the firearm

Muzzle

Ejection Port

Cylinder Gap

Breech

Modified Griess Test

Chemical Testing for nitrate compounds

Sodium Rhodizonate Test

Chemical Testing for lead residues

How firearms should be packaged

Unload → Ziptie → Proper seal w/ initials → immobilize item

True or False: For guns in water, submit the firearms fully submerged in the water it was found in

True

Describe how to package tools for examination in the firearms fully submerged in the water it was found in

protect the working surface → under proper seal → and immobilize

Tool

an object used to gain mechanical advantage

factors that affect the production of toolmarks

Direction

Force

Rate of Speed

What general rifling characteristic is this?

Caliber

What general rifling characteristics is this?

Land

What general rifling characteristics is this?

Grooves

What general rifling characteristic is this?

Twist

two common causes of malfunctions

failure to load

failure to extract/eject

toolmark identification

the discipline of forensic science where the primary concern is to determine if a particular tools produced a tool mark

Tool

an object used to gain mechanical advantage, thought of as the harder of two objects

Subclass Characteristics

consistent among different items same tool in the same approximate state of wear

Striated Toolmark

tool is moved across the object (force and motion parallel to surface)

Impressed Toolmark

leaves an impression (force and motion perpendicular)

Microscopic Comparisons: Identification

Identified as produced by same tool

Microscopic Comparisons: Elimination

Eliminated by a particular tool

Eliminated by the same tool

Microscopic Comparisons: Inconclusive

not be identified or eliminated as having been produced by a particular tool

Microscopic Comparisons: Not suitable (unsuitable) for comparison

No microscopic markings present

Relative hardness between tool and surface too similar – marks not transferred from tool

Markings present are of poor quality and/or quantity

Tool may not produce suitable markings

Damaged after the mark was imparted (overlapping marks)

Blood and other body fluids can erode markings on metallic materials

Poor quality of a cast toolmark

Toolmark

Mark is produced when two objects come into forcible contact with one another- the softer surface receiving the mark

Tool Classification

Compression

Hammer

Punch

Stamp

Flat Action (Scraping)

Screwdriver

Chisel

Pry Bar

Slicing

Knife

Box Cutter

Axe

Gripping

Pipe Wrench

Groove and Joint Pliers

Pinching

Bolt Cutter

Diagonal Cutter

Shearing

Scissors

Tin Snips

Shears

Groove Joint Pliers

Gripping Tool

Class Characteristics include:

Jaw width

Jaw length

Teeth spacing

Jaw lip length

Number of teeth

Maximum opening

Improper Packaging

Plastic or paper bags

Unprotected edges

Preferred Packaging

Rigid boxes or container

Protect the edges and working surfaces of the tool

Consider trace evidence

AR-type rifle

AK-type rifle

Bolt-Action or Slide-Action Rifle

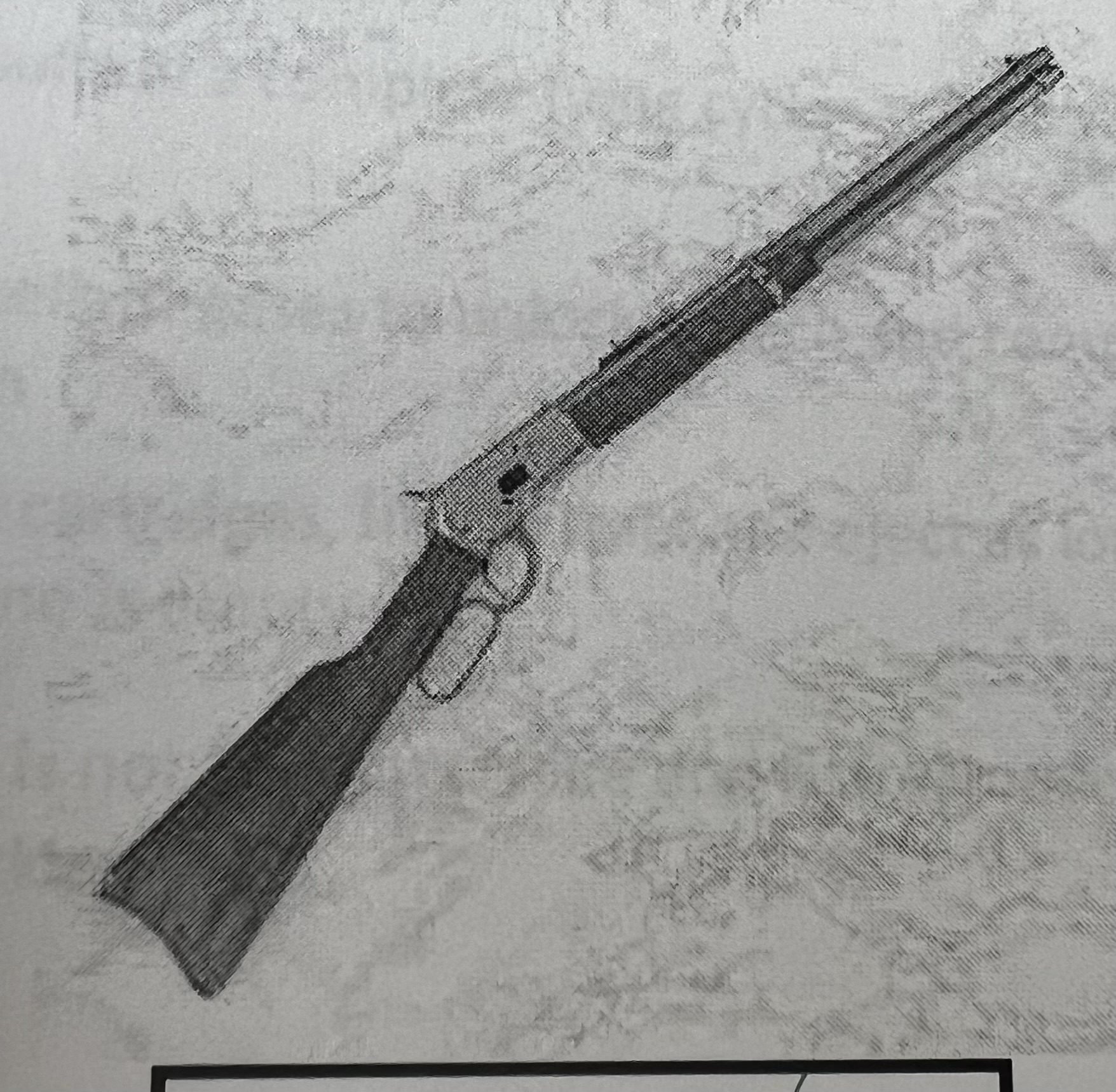

Lever-Action Rifle