(2) Sludge Treatment (Anaerobic Stabilization to the end)

1/37

Earn XP

Description and Tags

(Anaerobic Stabilization to the end pg. 13-20)

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

38 Terms

anaerobic digester

Most important factors effecting the performance of ___

SRT

HRT

Temp

pH

toxic materials

Standard (Low) Rate Process

what type of anaerobic digestion process

does not employ sludge mixing/ heating

SRT - 30-60 days

high rate process

what type of anaerobic digestion process

w/ mixing and heating

SRT - 15-20 days

2 digesters operating in series separate the functions of fermentation and solid-liq separation and residual gas extraction

Primary Digester

Kind of Anaerobic Digester

to increase the reaction rate, reactor is;

covered

heated

mixed

35C sludge

Secondary Digester

Kind of Anaerobic Digester

not mixed/ heated

used

storage of gas

concentrating of sludge by settling

gas is high enough in CH4 to be used as a fuel and is usually used to heat the primary digester

Anaerobic Digester Gas Production

810 to 1120L of digester gas/ kg volatile solids

65-69% methane

31-35% CO2

if more than 35% CO2 there is something w the digestion

Egg-shaped digester

Digester

first installed in Germany 1950s

American Digester

shallow cylindrical vessel w moderate floor and roof slopes

Conventional German Digester

deep cylindrical tank w steeply sloped top and bottom cones

aerobic digestion

used to sltabilize;

primary sludge

secondary sludge

combination

process converts organic sludge to CO2, NH3, H2O

bacteria

lack of organic matter leads to the death of __

CO2

organic matter is consumed by bacteria and converts it into __

Conventional

Type of Aerobic Digestion

concentration VSS influent - 3% max for RT of 15-20 days

by batch (mostly), semi batch, continuous basis

Activated sludge - SRT 15-20 days

Primary & Activated Sludge - SRT 20-25 days

Conventional batch basis

The way of Conventional Aerobic Digester introduces the sludge

digester is filler w raw sludge and aerated for 2-3 weeks then stopped

Conventional semi batch basis

The way of Conventional Aerobic Digester introduces the sludge

raw sludge is added every couple of days

supernatant is decanted periodically

settled solids are held long time before removing

Conventional Aeration period

200 to 300C-days

multiplying digester’s temp in C by the sludge age

AutoThermal Thermophilic Aerobic Digestion (ATAD)

Type of Aerobic Digestion

variation of both conventional and high purity oxygen aerobic digestion

reqs

insulated reactors 120-140F

aerators

foam controllers

sludge

70% removal rate of the biodegradable organics at 3-4 days

Biofilter

ATAD Challenge - odor control

High Purity Oxygen Aerobic Digestion

Type of Aerobic Digestion

used in lieu of air

applicable in cold weather

costing disadvantage

cryophilic aerobic digestion

Type of Aerobic Digestion

ow temp - less than 20C

sludge age increase = operating temp increase

Composting

biological degradable to a stable end product

microorganisms involved are

bacteria - meso and thermophilic

actinomycetes

fungi

20-30% of volatile solids converted to CO2

Water at temp in the pasteurization of 50-70C

optimum moisture content is 50-60%

40C at least 5 days

Composting PSRP Req

min temp & days

55C at least 3 days

Composting PFRP Req

min temp & days

Agitated Composting

Principal Method of Composting examples are;

window composting

in vessel composting

Static Composting

Principal Method of Composting examples are;

static aerated pile composting

Sludge conditioning

to improve its dewatering characteristics

2 methods

adding chemicals

heat treatment

Sludge Dewatering

physical unit operation used to reduce moisture content of sludge and biosolids by subjecting it to vacuum, pressure, drying

Cake

the dewatered solids coming out from a dewatering device

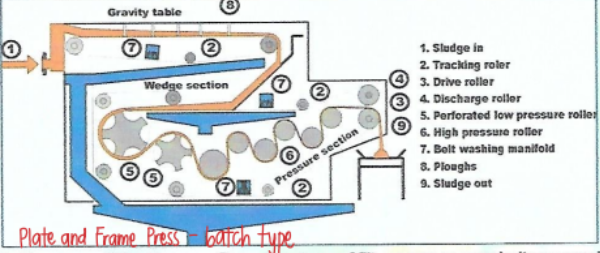

Belt Filter Press

Device used in sludge dewatering

continuously feed sludge dewatering device

involve

chemical conditioning

gravity drainage

mechanically applied pressure

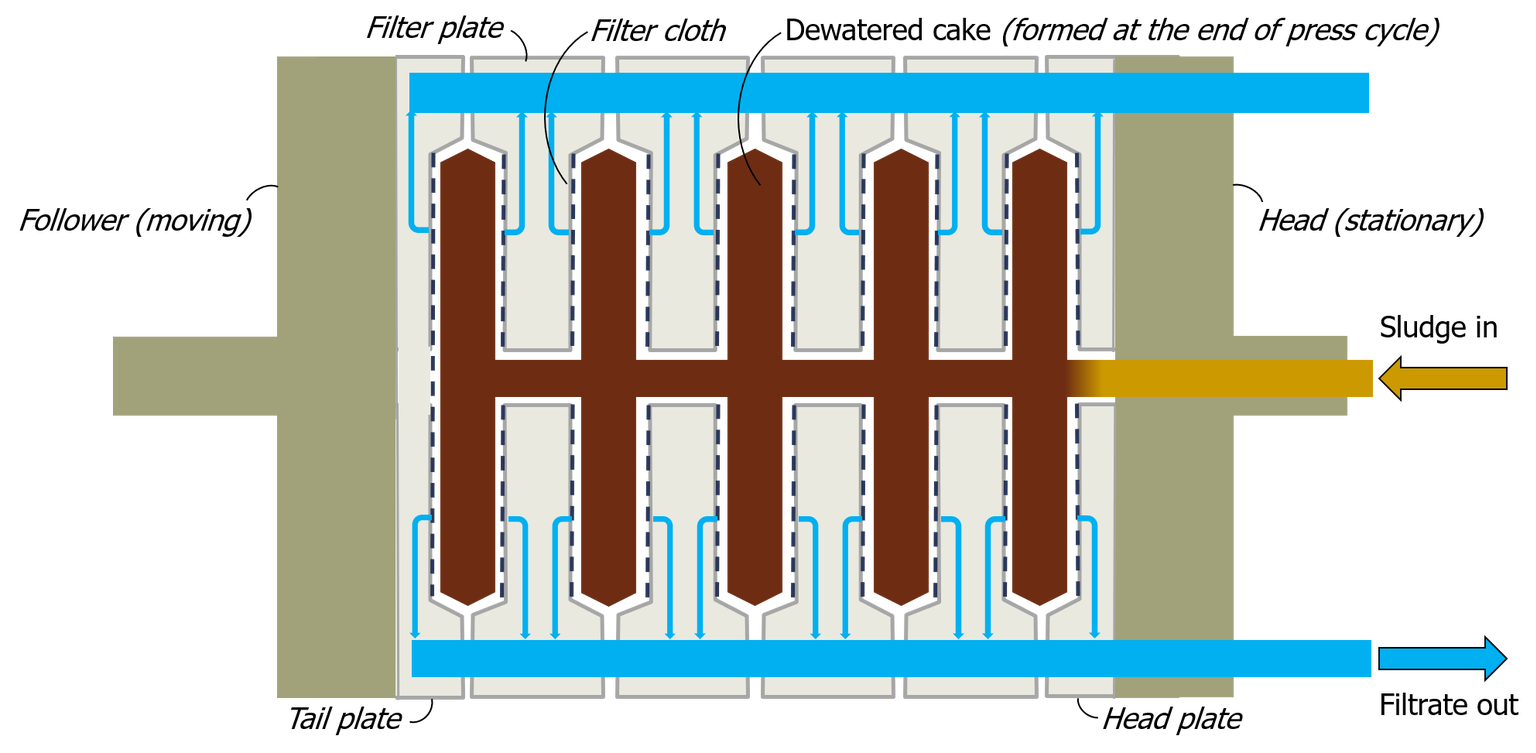

Pressure Filter Press

Device used in sludge dewatering

req lower polymer input due to higher pressure and finer cloths

sludge is pumped into the press at pressured up to 225 psi for less than 2hrs

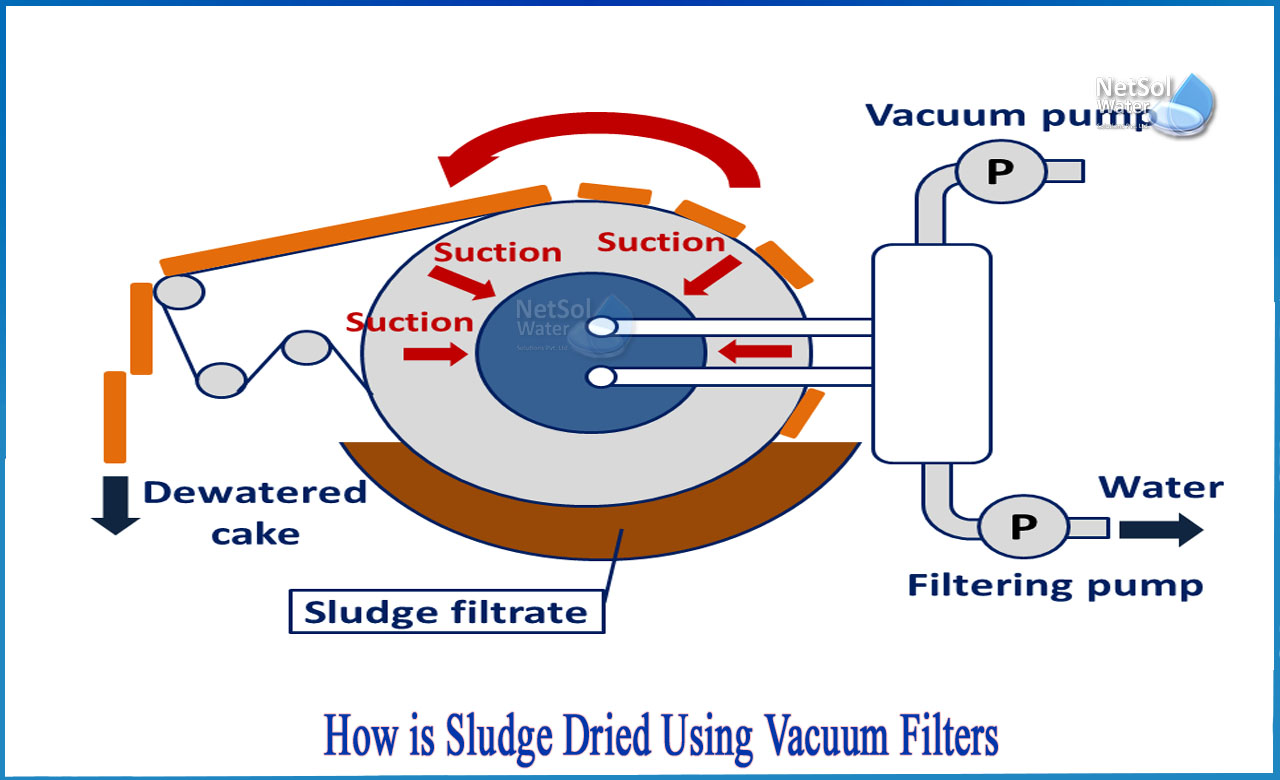

vacuum filters

Device used in sludge dewatering

used for almost 7 decades

drum is partly submerged 20-40% in a vat containing sludge

small plants

35h operation / week

larger plants

16-20hrs operation/ day

optimum solids content for filtration is about 6-8%

chemical conditioners

ferric chloride

lime

polymers

Centrifuge

Device used in sludge dewatering

used in solid bowl decanter

w/o chemical conditioner - 50-80% solids capture

w/ chemical conditioner - 80-95% solids capture

cake - 15-30% dry solids

Sludge Drying Bed

Device used in sludge dewatering

remove moisture by natural evaporation, gravity, most widely used in municipal in USA

Lagoon

Device/Location used in sludge dewatering

substitute for drying beds

not suitable for ;

untreated sludge

limed sludge

high strength supernatant

sludge drying - 18 months

clean and rested 6 months

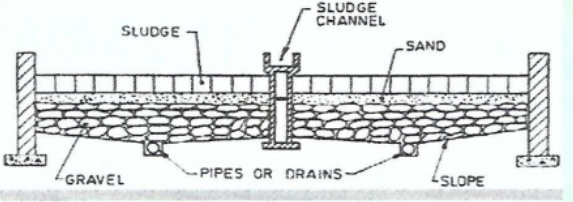

Sand Drying Bed

Type of Sludge Drying Bed

most cost effective

seepage and evaporation mechanism

sand content - 10-23cm

gravel layer - 20-50 cm

15cm deep dewatered sludge

Paved Drying Bed

Type of Sludge Drying Bed

consist of concrete and asphalt

slope 1.5%

artificial media drying bed

Type of Sludge Drying Bed

use of stainless-steel wedge wire

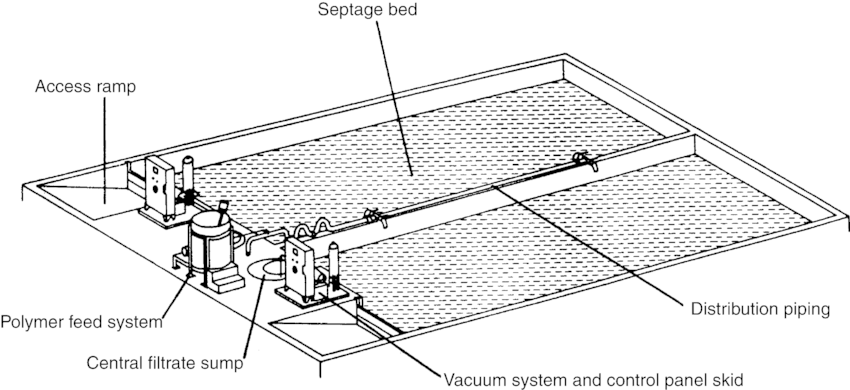

vacuum- assisted drying beds

Type of Sludge Drying Bed

consists of reinforced concrete ground slab, layer of supporting aggregate, rigid porous media plate on top