(1-2) Extractive Metallurgy | Hydrometallurgy

1/55

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

56 Terms

HYDROMETALLURGY

selective reaction of valuable metals using aqueous reagents.

PYROMETALLURGY

involves heat

ELECTROMETALLURGY

electrolysis is used

LAW OF CONSERVATION OF ELEMENTS

The quantity of element is neither decreased nor increased

BLACK BOX REACTION

Steady-state assumption

Time is not a factor

What comes in also comes out

PRINCIPLES OF COMBINING VOLUMES

Atoms combine to form molecule

Expressed by the product of atomic weight and small whole

LAW OF COMBINING VOLUMES

When gases react, the volume consumed and produced

GAY-LUSSAC’S LAW

Fixed amount of gas

Pressure is proportional to temperature (k)

GAY-LUSSAC’S LAW (formula)

P1/T1 = P2/T2

CHARLES’ LAW

• Volume is proportional to temperature

CHARLES’ LAW (formula)

V1/T1 = V2/T2

BOYLE’S LAW

Pressure and volume are inversely proportional

High pressure, Low Volume

Low Pressure, High Volume

BOYLE’S LAW (formula)

P1V1 = P2V2

IDEAL GAS LAW

The state of an ideal gas is determined by the macroscopic and microscopic parameters like pressure, volume, temperature.

IDEAL GAS LAW (formula)

PV = nRT

COMBINED GAS LAW

Pressure is inversely proportional to volume, or higher volume equals lower pressure

Pressure is directly proportional to temperature, or higher temperature equals higher pressure.

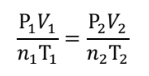

COMBINED GAS LAW (formula)

P1V1/n1T1 = P2V2/n2T2

HYDROMETALLURGY

involves chemical reactions carried out in aqueous solutions

To recover metals from low-grade ores

Form high-grade concentrates that are roasted

Preliminary operation to mineral processing

ADVANTAGES OF HYDROMETALLURGY (3)

Mineral Beneficiations (optional)

Roasting (optional)

Leaching

Solid-liquid separation

Metal recovery

Solid/waste treatment

GENERAL STEPS IN HYDROMETALLURGY (6)

MINERAL BENEFICIATION

Control the fineness of the feed material

ROASTING

Conversion of valuable minerals into soluble forms

LEACHING

To dissolve the valuable mineral/metal into the liquor

SOLID-LIQUID SEPARATION

Separation of leach liquor from undissolved residue

METAL RECOVERY

Final extraction of metal from the solution

SOLID/WASTER TREATMENT

Neutralization for recycling or prior to disposal

LEACHING

Selective dissolution of the valuable metal in the suitable reagent or leachant (usually sulfuric acid)

Process of dissolving in a suitable reagent or leachant

LIXIVIANTS

Liquid or reagent used to selectively extract metals

water

acids

bases

aqueous salts

Common Lixiviants (4)

Readily available in quantity

Relatively cheap

Does not react unduly with gangue minerals

Non-corrosive

Amenability of regeneration/recycling

Requirements of Lixiviants (5)

DUMP LEACHING

HEAD LEACHING

IN-SITU LEACHING

VAT/PERCOLATION LEACHING

PRESSURE LEACHING

5 DIFFERENT LEACHING METHODS

DUMP LEACHING

Actual ore in the specific part of the site

Feed of lixiviant is downward

PREGNANT LEACH SOLUTION

term given for the product of dump leaching

HEAP LEACHING

We construct reaps

Lixiviant are sprinkled from the top-most part

Inclined position

IN-SITU LEACHING

“In-place” leaching

On site or in site leaching

VAT/PERCOLATION LEACHING

Composed of series of tanks

Ore is fed on every tanks

Lixiviant is fed on the side

PRESSURE LEACHING

Uses autoclase

Big tanks

High pressure at 10 atm

ION EXCHANGE

SOLVENT EXTRACTION

ADSORPTION

3 Methods of Solution Purification/Concentration

ION EXCHANGE

Exchange of ions in a polymeric resin with significant ions present in solution

Functionalized resin

SORPTION

ELUTION

2 Methods of Ion Exchange

SORPTION

Resin is contained in a column

ELLUTION

Retained ions are displaced from resin

We feed eluant (organic) for metals to leave the resin

SOLVENT EXTRACTION

Involved a distributive reaction wherein metals is allowed to partition

Uses solvents to extract metals

Organic solution

ADSORPTION

Activated carbon – most important

Adherence to the surface of another particle

CARBON-IN-PULP

Leaching → Adsorption

cyanidation leaching first and then adding the activated carbon in the slurry

CARBON-IN-LEACH

simultaneously leaching and adsorbing

activated carbon is added to the leaching tank, the leaching and adsorption are carried out at the same time

METAL SEPARATION AND RECOVERY

Also known as metal winning

Final step of hydrometallurgy

Precipitation

Electrometallurgy

Methods of Metal Winning (2)

PRECIPITATION

Formation of a solid product from solution as a result of addition of a reagent

Single-replacement method

Metal is recovered as salt or oxide

ELECTROMETALLURGY

Also known as Also known as ELECTROWINNING

Recovery and purification of metals using electrode position of metals at a cathode

Employs redox reaction

ELECTROREFINING

Improves the purity of metal

Copper Leaching

Bacterial Leaching

Solvent Extraction

Gold Leaching

Cyanidation

Adsorption

Cobalt

HPAL

Moa-Bay Process

Aluminum

Bayer Process

Hydrometallurgical Processes

Bacterial Leaching

Solvent Extraction

Hydrometallurgical Process in Copper Leaching

Cyanidation

Adsorption

Hydrometallurgical Process in Gold Leaching

High Pressure Acid Leaching (HPAL)

Moa-Bay Process

Hydrometallurgical Process in Cobalt Extraction

Bayer Process

Hydrometallurgical Process in Aluminum Extraction