Industrial Processes

1/4

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

5 Terms

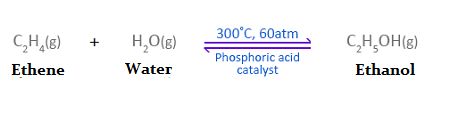

What are the industrial conditions for the production of ethanol?

A pressure of 60-70atm

A temperature of 300°C

A phosphoric acid catalyst

Why is the temperature 300°C?

The reaction is exothermic so lower temperature favour the forward reaction and it means a better yield

However, low temperatures mean a slower rate of reaction so 300°C is a compromise between maximum yield and a faster reaction

Why is the pressure 60-70atm?

Higher pressure favours the forward reaction and increases the yield so 60-70atm is used

Higher pressure also means higher rate of reaction, so ideally you would want an even higher pressure but it’s expensive to produce as you would need stronger pipes and containers

60-70atm is a compromise between max yield and minimum expense

What do you do to save money and raw materials in the production of ethanol?

Only a small proportion of ethene reacted each time

So, the unreacted ethene is separated and recycled back into the reactor

Thanks to this, around 95% of ethene is eventually converted to ethanol

What are the industrial conditions for the production of methanol?

Pressure of 50-100atm

Temperature of 250°C

Catalyst of a mixture of copper, zinc oxide and aluminium oxide