Operations Management Final

0.0(0)

Card Sorting

1/110

There's no tags or description

Looks like no tags are added yet.

Last updated 2:38 PM on 4/27/23

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

111 Terms

1

New cards

Critical Path

longest path from start to finish

2

New cards

ES

Earliest start time = max\[EF times of all activities immediately preceding activity\]

3

New cards

LS

Latest start time = LF – t

4

New cards

EF

Earliest finish time = ES + t

5

New cards

LF

Latest finish time = min\[LS times of all activities immediately following activity\]

6

New cards

Slack

subtraction of either LatestStart - EarliestStart or LatestFinish - EarliestFinish

7

New cards

Process

turning inputs into outputs

8

New cards

Backward integration

owning and controlling entities upstream (earlier on in the chain → strawberry farms, dairy farms)

9

New cards

Forward Integration

owning and controlling entities downstream (closer to the consumer → food trucks, deli restaurants)

10

New cards

4 Costs of Quality

External failure, Internal failure, Appraisal, Prevention

11

New cards

Causes of Variation: Common Causes

(completely unavoidable)

* purely random; unidentifiable factors

* e.g. diameter varies by 0.0001 in.

* purely random; unidentifiable factors

* e.g. diameter varies by 0.0001 in.

12

New cards

Causes of Variation: Assignable Causes

(the real reason why; to investigate)

* Variation-causing factors that can be identified

* e.g. poorly trained employee

* Variation-causing factors that can be identified

* e.g. poorly trained employee

13

New cards

Types of Variable Charts (continuous numerical data)

R-charts, xbar-charts

14

New cards

Types of Attribute Charts (discrete numerical data)

p-charts, c-charts

15

New cards

Variables (to measure performance)

weight, length, volume, or time

16

New cards

Variable Data Examples

How long did the customer wait? What was diameter of the pizza? Temp of food? Weight of chicken?

17

New cards

Attributes (to measure performance)

yes-no counts (yes, defect or no defect)

18

New cards

Attribute Data Examples

Food sent back to kitchen? Bill correct or not? Did food leave the kitchen < 147 degrees? Was the pizza larger than 12 in?

19

New cards

SPC

Statistical Process Control

20

New cards

Step 1: Calculating X-bar & R-Chart UCL & LCL

within each sample (will either be by row or by column), calculate the range and the average

21

New cards

Step 2: Calculating X-bar & R-Chart UCL & LCL

then calculate the average of all sample ranges and averages to compute x-bar and R-bar

22

New cards

Step 3: Calculating X-bar & R-Chart UCL & LCL

based on n (aka sample size), identify A2, D3, D4 values on the chart to be used in the formulas

23

New cards

What makes a process out of control

* run = is when you have 5 consecutive sample points either to the upperside or lowerside of your nominal value

* reached past UCL or LCL

* reached past UCL or LCL

24

New cards

Using Control Charts for Process Improvement

Sample the process

Find the assignable cause

Eliminate the problem

Repeat the cycle

Find the assignable cause

Eliminate the problem

Repeat the cycle

25

New cards

Variable charts involve ____ measurements

precise

26

New cards

Attribute charts involve measuring by ____

counting the # of defects

27

New cards

R-bar & X-bar charts _____

have to be done together

28

New cards

p-charts & c-charts _____

are less expensive $$$ than other charts

29

New cards

p-bar =

total defectives / total observations

30

New cards

c-chart UCL & LCL steps

1. calculate average number of defects per item (total defects observed / total # of observed items) = c-bar

2. take c-bar + z (whatever sigma, ex 3) \* sqrt c-bar = UCL

3. take c-bar - z (whatever sigma, ex 3) \* sqrt c-bar = LCL

31

New cards

What makes c-Charts different?

c-Charts: defects on __**one unit**__ (e.g. how many scratches are on one piece of plexiglass (c = 4)

32

New cards

Six Sigma Quality: DMAIC Cycle

D - Define

M - Measure

A - Analyze

I - Improve

C - Control

\

M - Measure

A - Analyze

I - Improve

C - Control

\

33

New cards

WBS stands for ____

Work Breakdown Structure

34

New cards

5 Steps to Planning Projects

1. Define work breakdown structure

2. Diagram the network

3. Develop the schedule

4. Analyze cost-time trade-offs

5. Assess risks

35

New cards

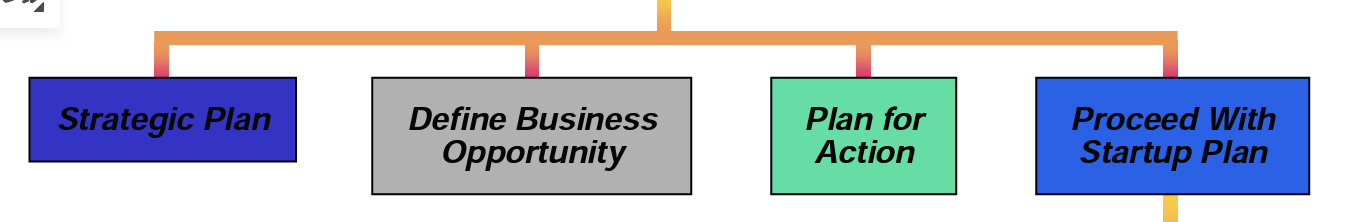

WBS First Level (after starting a business)

\

36

New cards

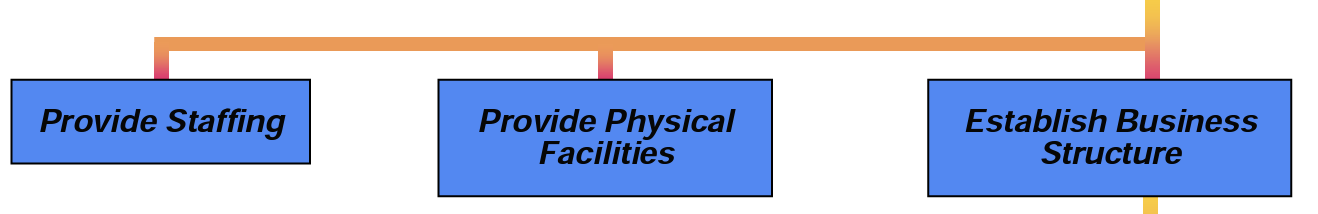

WBS Second Level

37

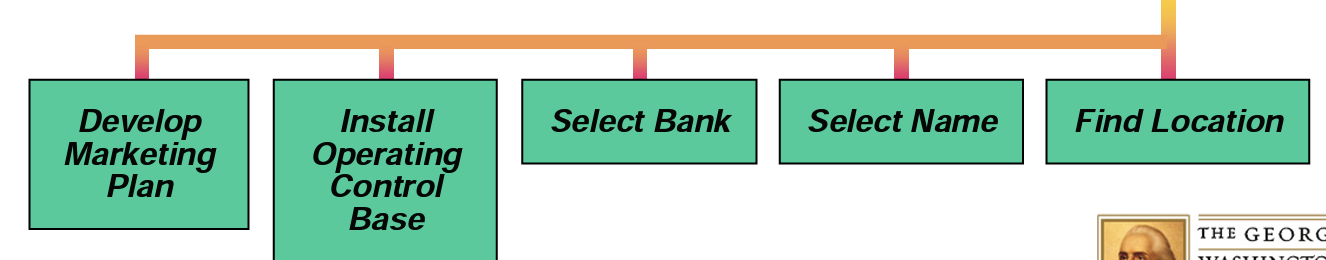

New cards

WBS Third Level

38

New cards

AON stands for

Activity-on-Node

39

New cards

EOQ (an Inventory Model) stands for ____

Economic Order Quantity

40

New cards

The Q System (an Inventory Model) is the _____

Continuous Review System

41

New cards

Aspects of the Continuous Review (Q) System

* constant lead times introduced now

* two models

* certain demand and uncertain demand

* Inventory position (IP) = OH (on hand inventory) + SR (scheduled receipts) - BO (backorders)

* two models

* certain demand and uncertain demand

* Inventory position (IP) = OH (on hand inventory) + SR (scheduled receipts) - BO (backorders)

42

New cards

Continuous Review → continuously checking IP after every withdrawal….

Rule:

* if IP > R do not place an order

* if IP

* if IP > R do not place an order

* if IP

43

New cards

The P System (an Inventory Model) is the _____

Periodic Review System

44

New cards

Aspects of Periodic Review (P) Systems

* Fixed interval reorder system (order once a week or month)

* Q may vary with each order

* IP reviewed periodically instead of continuously, new order after every review

* TBO (Time Between Orders) fixed at P

* Q may vary with each order

* IP reviewed periodically instead of continuously, new order after every review

* TBO (Time Between Orders) fixed at P

45

New cards

Periodic Review → Only check your inventory position after every P time periods…

Always place an order of size Qt = T - IPt

46

New cards

Comparatively, P Systems (single-bin system)

* convenient to administer

* orders may be combined

* IP only required at review

* orders may be combined

* IP only required at review

47

New cards

Comparatively, Q Systems (two-bin system)

* individual review frequencies

* possible quantity discounts

* lower, less-expensive safety stocks

* possible quantity discounts

* lower, less-expensive safety stocks

48

New cards

What is the average cost of inventory?

30-35% of product’s value (about 1/3)

49

New cards

Examples of Pressures for High Inventory

Customer Service/On-Time delivery, Quantity discounts, Transportation costs, Setup & Ordering costs, Supplier’s prices about to increase

50

New cards

Examples of Pressures for Low Inventory

Pilferage (stealing), Storage and handling costs, Obsolescence (becomes obsolete soon, short product lifetime), Interest or opportunity cost, Insurance on assets, End of year taxes

51

New cards

Is inventory bad?

Not necessarily

52

New cards

Physical Inventory

Raw materials, component parts, work in process (WIP), finished goods

53

New cards

Conceptual Inventory

1. Cycle Inventory

2. Safety Stock Inventory

3. Anticipation Inventory

4. Pipeline Inventory

54

New cards

EOQ Assumption: Demand rate is ____

constant

55

New cards

EOQ Assumption: No constraints on ____

lot size (Q) --- any size Q is possible!

56

New cards

EOQ Assumption: Only costs are _____

holding (storing an item) and ordering (administrative costs)

57

New cards

EOQ Assumption: Decisions for items are _____

independent (no correlation between different products; we’re just ordering final products)

58

New cards

EOQ Assumption: No uncertainty in _____

lead time or supply

59

New cards

Lead Time =

Time between placing an order and receiving it

60

New cards

Lot sizing

Two Decisions:

1. When to order?

2. How much to order?

1. When to order?

2. How much to order?

61

New cards

Cycle Inventory

saw-tooth diagram (max Q units, min 0 units)

62

New cards

Safety Stock Inventory

Protects against uncertainties in demand, lead time, and/or supply

* Operations not disrupted

* Avoid customer service problems

__**Place order earlier than needed**__

* Operations not disrupted

* Avoid customer service problems

__**Place order earlier than needed**__

63

New cards

Anticipation Inventory

* Absorbs uneven rates of demand

* Predictable, seasonal demand patterns

* Anticipating supplier strike

* Stockpile during low demand

* Predictable, seasonal demand patterns

* Anticipating supplier strike

* Stockpile during low demand

64

New cards

Pipeline Inventory

Inventory moving from point to point in material flow system

* eg parts traveling on trucks (inbound)

* eg materials moving between operations (within plant)

* eg finished goods shipped to distribution center (outbound)

* eg parts traveling on trucks (inbound)

* eg materials moving between operations (within plant)

* eg finished goods shipped to distribution center (outbound)

65

New cards

ABC Analysis

Classifying inventory to best manage it

Class A: 20% of the items make up 80% of the total dollar value (TVs in the back; protect them)

Class B: 30% of the items make up like 25%

Class C: 50% of the items make up like 5%

Class A: 20% of the items make up 80% of the total dollar value (TVs in the back; protect them)

Class B: 30% of the items make up like 25%

Class C: 50% of the items make up like 5%

66

New cards

Holding cost _____ as Lot Size (Q) increases

Holding cost increases

67

New cards

Ordering cost _____ as Lot Size (Q) increases

ordering cost decreases

68

New cards

Total cost ____ as Lot Size (Q) increases

Total cost decreases initially, then increases (like a Nike swoosh)

69

New cards

EOQ Variables are

D = Annual Demand

Q = Lot Size

S = Cost of Setup Ordering Cost (?)

H = Holding cost

Q = Lot Size

S = Cost of Setup Ordering Cost (?)

H = Holding cost

70

New cards

Aspects of a Push System

* Production trigger is based on forecasts or desired inventory levels

* No bounds on inventory

* No bounds on inventory

71

New cards

When to use a Push system?

* Example: Convenient store (inventory has built up; waiting for you to buy it, based off of forecasts)

* Long setups (spread the costs over the course of the setup) & Variety of products (will have to produce an array of colors in batches to offer customers)

* Long setups (spread the costs over the course of the setup) & Variety of products (will have to produce an array of colors in batches to offer customers)

72

New cards

Aspects of a Pull System

* Production trigger is actual consumption of inventory

* Imposes a bound on inventory

* Eg. Kanban

* Imposes a bound on inventory

* Eg. Kanban

73

New cards

When to use a Pull system?

* Small setups & Few product lines

* Example: custom cakes

* Example: custom cakes

74

New cards

Kanban

Visual display to decrease throughput time e.g. must have 3 in your inbox, 0 in your outbox to start working (airplane example)

75

New cards

Idle time

sitting waiting for a unit

76

New cards

Cycle time

time in between finished goods getting off the assembly line

77

New cards

Supply Chain

Two or more parties linked by a flow of material, information, & money, often global in scope

78

New cards

Bullwhip

* order variation increases as you go upstream towards the supplier

* Supplier → M → R → Customer (looks like a bullwhip with the handle at the customer and the wavy end of variability is at the supplier)

* downstream is going → to the customer, upstream is going to the supplier

* Supplier → M → R → Customer (looks like a bullwhip with the handle at the customer and the wavy end of variability is at the supplier)

* downstream is going → to the customer, upstream is going to the supplier

79

New cards

Stockout

when you run out of a product, you will no longer be selling the product anymore

80

New cards

Backorder

Ran out of a product but eventually are going to fulfill the order

(cumulation of these would be a backlog)

(cumulation of these would be a backlog)

81

New cards

Center of Gravity

Determine x and y coordinates in the middle (may not be feasible right at this point but start there and go out)

x\* and y\*

example: where you pinpoint the starting point to the realtor

x\* and y\*

example: where you pinpoint the starting point to the realtor

82

New cards

Load-distance score

Select site that minimizes distances “loads” must travel

83

New cards

Horizontal Pattern of Demand

Data cluster about a horizontal line as time progresses

84

New cards

Trend Pattern of Demand

Data consistently increase or decrease

85

New cards

Seasonal Pattern of Demand

Data consistently show peaks and valleys

86

New cards

Cyclical Pattern of Demand

Data reveal gradual increases and decreases over extended periods

87

New cards

Time-Series Methods

1. Simple moving averages

2. Weighted moving averages

3. Exponential smoothing

88

New cards

Simple Moving Average

Simple;

Dt = actual demand in period t

n = total number of periods in the average

F t+1 = forecast for period t + 1

Dt = actual demand in period t

n = total number of periods in the average

F t+1 = forecast for period t + 1

89

New cards

Weighted Moving Average

* weights on historical demand (weight more recent demand more heavily, lowering

* more control

* Ft+1 = forecasted demand for period t + 1

* Dt = actual demand in period t

* Wi = assigned weight

* more control

* Ft+1 = forecasted demand for period t + 1

* Dt = actual demand in period t

* Wi = assigned weight

90

New cards

Exponential Smoothing

* forecasting software

* really strong results

* Ft+1 = forecasted demand for period t + 1

* Dt = actual demand in period t

* sigma = smoothing parameter

* really strong results

* Ft+1 = forecasted demand for period t + 1

* Dt = actual demand in period t

* sigma = smoothing parameter

91

New cards

Trend-Adjusted Exponential Smoothing

At = exponentially smoothed average of the series in period t

Tt = exponentially smoothed average of the trend in period t

sigma, Beta = smoothing parameters

Tt = exponentially smoothed average of the trend in period t

sigma, Beta = smoothing parameters

92

New cards

CFE

= Cumulative Forecast Error

*A measurement of the total forecast error that assesses the bias in a forecast.*

* if CFE is negative, we are overestimating

asses __**bias**__

*A measurement of the total forecast error that assesses the bias in a forecast.*

* if CFE is negative, we are overestimating

asses __**bias**__

93

New cards

MSE

= Mean Squared Error

* measure of variability

* Square Error = error ^2

*A measurement of the dispersion of forecast errors.*

* measure of variability

* Square Error = error ^2

*A measurement of the dispersion of forecast errors.*

94

New cards

Square Error

= error ^2

95

New cards

MAD

= Mean Absolute Deviation

* another indication of variability

* Absolute Error = ABS(Actual - Predicted)

A measurement of the dispersion of forecast errors.

* another indication of variability

* Absolute Error = ABS(Actual - Predicted)

A measurement of the dispersion of forecast errors.

96

New cards

Absolute Error

= ABS(Actual - Predicted)

97

New cards

MAPE

= Mean Absolute Percent Error

* average of the absolute percent errors; telling us amount of error relative to the size of demand

* Absolute % Error = (Absolute Error / ACTUAL DEMAND) \* 100%

* big deal to be off by 10 diamonds at a small jewelry store versus 10 cotton balls at a large manufacturing plant

* average of the absolute percent errors; telling us amount of error relative to the size of demand

* Absolute % Error = (Absolute Error / ACTUAL DEMAND) \* 100%

* big deal to be off by 10 diamonds at a small jewelry store versus 10 cotton balls at a large manufacturing plant

98

New cards

Absolute % Error

= (Absolute Error / ACTUAL DEMAND) \* 100%

99

New cards

Error

Difference between actual and predicted

100

New cards

Error relative to size of demand is related to _____

MAPE (Mean Absolute Percent Error)