Transformers

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

18 Terms

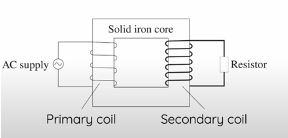

Transformer

a device that transfers electric energy from one alternating current circuit to one or more other circuits, either increasing or decreasing the voltage through the process of electromagnetic induction

Structure

A primary coil – the coil that is connected to the AC power supply

A secondary coil – the coil that is experiencing the change in flux

A transformer core, generally made from soft iron connecting the two coils

Ferromagnetic = it amplifies the magnetic field of the primary coil

Has increased magnetic permeability compared to air = magnetic field lines prefer to flow through the core, allowing it to be directed towards the secondary coil.

How transformers work

The primary coil is connected to an AC power supply

AC power supply changes the direction of current and its magnitude → does NOT work for DC current, since it has the primary solenoid creates a constant current (unless switch opens/closes), thus a constant B field, so there is no change in flux or EMF induced in the secondary

Its graph of current over time generally shows a sinusoidal wave

The current generates a magnetic field in the coil, but its strength changes sinusoidally along with the current

The magnetic flux produced by the primary coil is transmitted through the iron core into the secondary coil

The secondary coil experiences a change in flux and according to Faraday’s law this induces an EMF (electromotive force)

Since the circuit is closed, an induced current flows to create a magnetic field in the direction opposing the change in flux according to Lenz’s law.

The current and the emf of the primary and secondary coils are out of phase. → since EMF is the NEGATIVE DERIVATIVE of flux (current + flux max for primary = min emf and current in secondary)

Purpose

to change the voltage (emf) during transmission of electrical energy

Step up transformer = Increases the voltage in the second coil, decreased current

When Ns < Np → decrease the number of turns in secondary coil

Step down transformer = Decreases the voltage in the second coil, increased current

When Ns > Np → increase the number of turns in secondary coil

Ideal transformers follow the ratios (no power loss, so 100% efficient)

Vp Ip=Vs Is

Vp/Vs = Np/Ns = Is/Ip

Transformers in reality

Power is loss since energy is transformed into other forms:

Power in primary > Power in secondary

Energy lost = Pprimary - Psecondary

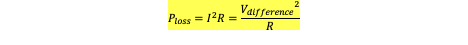

Ploss = I²R = Vdrop²/R

Transformer efficiency – the percentage of power transferred from the primary coil to the secondary coil

Efficiency= (Psecondary/Pprimary) ×100

Limitations/power loss caused by

generation of eddy currents in core

incomplete flux linkage

Resistive heat production

hysteresis (not in syllabus)

Incomplete flux linkage

Occurs when not all the magnetic field lines generated by the AC current in the primary coil are transferred to the secondary coil

∴ the full change in flux is not experienced by 2nd coil

∴ not all the electrical energy from the 1st coil is transferred to the 2nd coil

Iron core improves the transmission of magnetic flux, but some is not transmitted → voltage in secondary coil is lower than calculated by Np/Ns= Vp/Vs)

The core naturally contains some magnetic reluctance that opposes the flow of the magnetic flux → contribute to incomplete flux linkage

Generally, the stray field (lines that go outside of the solenoid) are not transmitted

Solutions for Incomplete flux linkage

SOLUTION 1: Decrease the length of the path between the two coils

•Coils are further apart = more flux can be lost or opposed by the core

Achieved by coiling the secondary coils over the primary coils around the same limb and separating the coils using an insulating layer / put one coil inside the other

Reducing the distance decreases magnetic reluctance, improving flux linkage

SOLUTION 2: Change the shape of the core

Toroidal (circular/donut)

Continuous magnetic path = more uniform magnetic field = Highest efficiency due to lower flux leakage

Square

Sharper corners = less uniform magnetic field = Lower efficiency due to higher leakage flux

SOLUTION 3: Decrease air gaps in the core

Air gaps decrease permeability of a transformer and increase the magnetic reluctance, reducing its ability to redirect the magnetic field and increasing the opposition to flux, causing more flux to be lost along the way

Resistive heat production

Occurs when electrical energy is lost as heat by the system due to resistance → IN COILS

Primary and secondary coils have electrical resistance (ohms)

When there is resistance, then electrical energy is converted to heat when current travels through = electrons collide with particles of material, so their kinetic energy is transferred to heat

When heat increases, this further increases resistance, causing a runaway effect →THERMAL RUNAWAY

Solutions for Resistive heat production

SOLUTION: Reduce heat lost due to the resistance, by changing the factors that influence it

→ If R decreases, then Ploss = I²R will decrease as well

Use a different coil material with lower resistivity copper is universally accepted standard for manufacturing wires due to its cheapness, durability, high conductivity

e.g. Silver: BUT very expensive and highly reactive (corrodes easily)

e.g. superconductors - “substance that offers no resistance to the electric current when it becomes colder than a critical temperature”

The critical temperature needs to be constant for it to function as desired, which can be impractical and require expensive materials

e.g Aluminium = 1.2 K = approx -273°C

Increase the cross-sectional area of the wire in the coil

Lower the temperature by… to reduce the runaway effect of heat and resistance

e.g. Implement internal fans and vents in the transformer to ensure adequate ventilation

e.g. Adding heat sink blades to increase surface area to allow for better heat dissipation

e.g. Make a black transformer case, so that the heat produced can be efficiently absorbed and re-radiated to the environment = why most small transformer-rectifier units are black.

e.g. Oil cooling = absorbs heat generated and carries it away (high thermal conductivity)

Generation of eddy currents in the iron core

Eddies are electrical energy created by a change in flux, but dissipate energy in the form of heat

Since the soft iron core is an electrical conductor, it experiences a change in flux due to the AC power supplied to the primary coil

According to faraday’s law, this induces and emf in the core

This produces eddy currents that flow to oppose the change in flux (Lenz’s law)

Eddy currents convert the electrical energy into heat due to high electrical resistance of iron → not ideal since we want to maximise efficiency

Can determine the direction of eddy currents using right-hand grip rule

They circulate in a plane perpendicular to the plane of the primary coil

Result in heat loss of Ploss = I²R

Practical applications of eddy currents

Induction stove

There are electromagnetic coils under the stove connected to AC power source = change in flux = emf in the pan, which is a conductor = eddy currents produced = dissipate into heat = cook food

solutions for eddy currents in the core

SOLUTION: Minimise eddy currents by laminating the iron core

Lamination – separating layers of conductive material with insulating mate rial

Less area for eddy currents to form = less heat dissipated

Needs to be laminated in a specific way to effectively reduce eddies (perpendicular to the plane of the coil)

Vertical lamination: slicing the material in the opposite plane to the eddy currents = less area for eddies to form = makes them smaller

Horizontal lamination: slicing the material in the same plane to the eddy currents = area is not reduced = does not reduce the size of eddy currents

Hysteresis loss (not in syllabus)

Hysteresis - lagging of the magnetization of a ferromagnetic material, behind variations of the magnetizing field.

“loss is caused by the magnetism that remains in a material after the magnetising force has been removed” (Grant Transformers, 2024).

Energy lost as heat when the core is magnetised and demagnetised

Magnetic domains must realign when polarity of field changes = energy is consumed to change the domains of the core lost as heat due to the friction generated

Worsened by how transformers use AC current → domains are frequently realigning

SOLUTION: Make the core out of soft magnetic materials e.g. soft iron instead of hard iron

Consume less energy to realign domains when magnetisation is reversed

Reaches saturation magnetisation (the point where increasing the field doesn’t increase magnetisation of the material) with a relatively low magnetic field (Inoue & Kong, 2022)

They have more narrow magnetic hysteresis windows

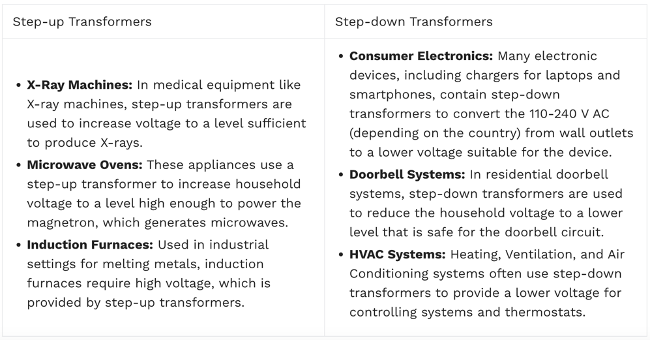

Other Applications of Step-up and Step-down transformers

Power transmission

Power stations produce electricity by burning coal, solar farms, wind farms, nuclear power stations

They need lots of land, can be dangerous, produce pollution, need to be located near fuel (coal, where there is lots of sun/wind) so are located relatively far from metropolitan areas

Thus, Power transmission occurs over long distances

Power loss during transmission

Power is lost during transmission from the station to homes

Due to resistive heat production, dependant on:

Magnitude of current

Resistance of power line

The long distance of power transmission results in a long conductor length: Since resistance, R=ρL/A → The resistance of the wire is very high

The power lost is observed as a voltage drop between the output and input

Use of step-up and step-down transformers in power transmission

We can reduce power loss by reducing the resistance (R)

increasing cross sectional area = expensive over long distances

Use materials that have better conductivity like gold or silver = very expensive

Decreasing the temperature = impractical since lines are exposed to the weather

But that is impractical, so we reduce the current instead, using transformers

Step-up transformers (increase voltage, decrease current) | To decrease the power lost during transmission

Step up transformers reduce power loss during transmission by decreasing the amount of current through the transmission line: Ploss=I²R

|

Step down transformers (decrease voltage, increase current) | To decrease the voltage as the current gets closer to where it will be used

|

Role of Insulators in Transmission wires

Transmission wires are insulated (using ceramic) from the supporting structures (made of metals)

Provide a safe distance between the conductors and supporting structures

Otherwise, current will flow through the structure into the earth (due to grounding)

Present danger of electrocution, and make transmission less efficient (due to loss of electrical energy)

Why do transformers need to be cooled

due to heat generated

Transformers get hot due to heat dissipated by eddy currents and copper losses due to the resistance in wires (+ hysteresis)

Too much heat can cause issues:

Insulation of coils could melt

Transformer could short circuit

Transformer could be destroyed/have its lifespan reduced → damages components

Poses a fire hazard

Further reduces efficiency