Casting Processes and their Advantages/Disadvantages

1/46

Earn XP

Description and Tags

Slides 61-113

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

47 Terms

Expendable-mold Processes

Economic disadvantage because a new mold is needed for every cast

shell molding

expanded-polystyrene process

investment casting

plaster-mold and ceramic-mold casting

Permanent Mold Processes

Mold is removed and reused several times

Die Casting

Hot Chamber Die Casting

Cold-chamber die casting

Squeeze Casting

Semisolid Metal Casting

Centrifugal Casting

Shell Molding

Casting process in which the mold is a thin shell of sand held together by a thermosetting resin

Final sand mold prepared for casting

Advantages of Shell Molding

Smoother cavity surface permits easier flow of molten metal and better surface finish

Good dimensional accuracy

Mold collapsibility minimizes cracks in casting

Can be mechanized for mass production

Disadvantages of Shell molding

More expensive metal pattern

difficult to justify for small quantities

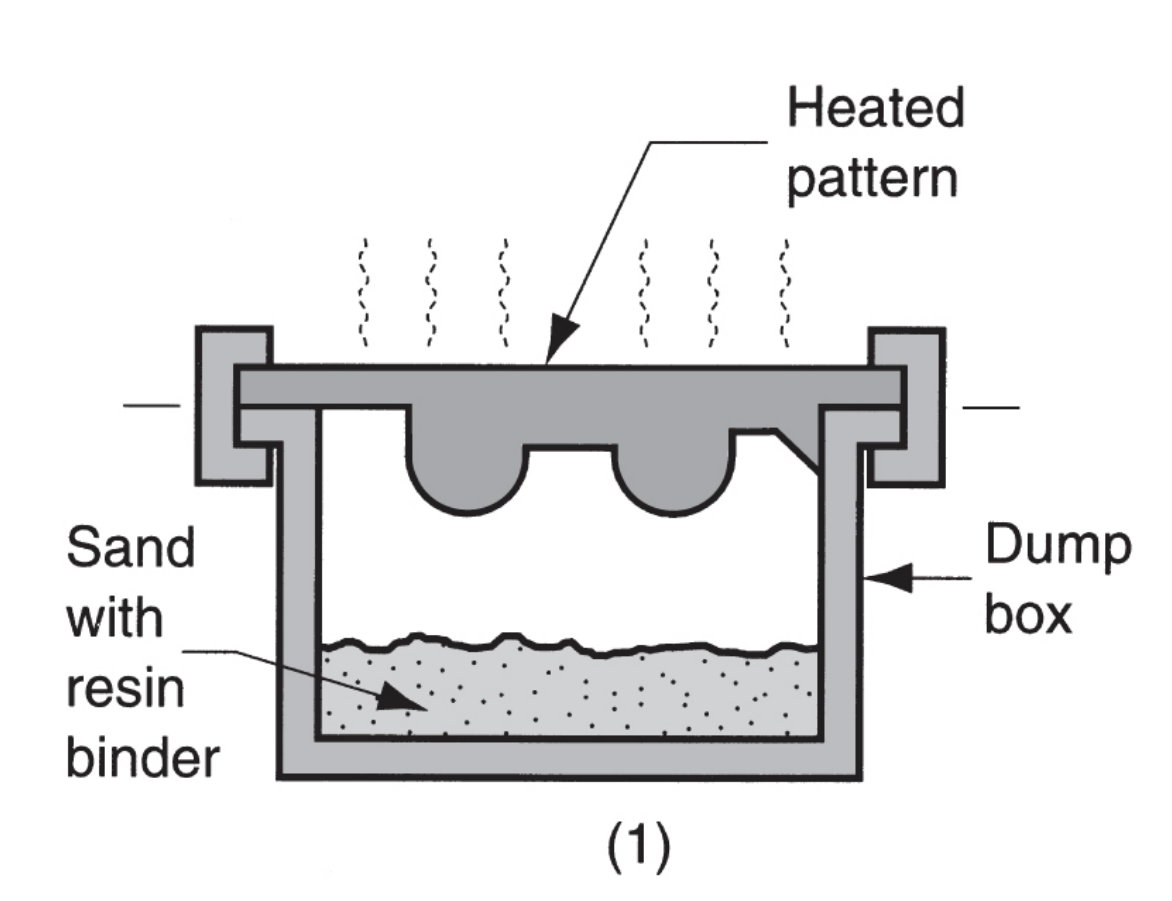

Steps in Shell Molding

Metal pattern is heated and placed over a box of sand mixed with TS resin

Box is inverted causing sand to fall and cure on the heated pattern

Box is flipped back so uncured sand falls off the pattern

Sand shell is heated in an oven to finish curing, and then it is stripped from the pattern

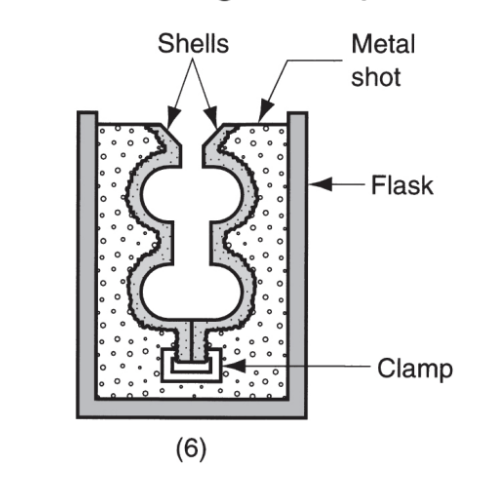

two halves of the shell are assembled and supported by sand in a box, pouring commences

Expanded Polystyrene Processes

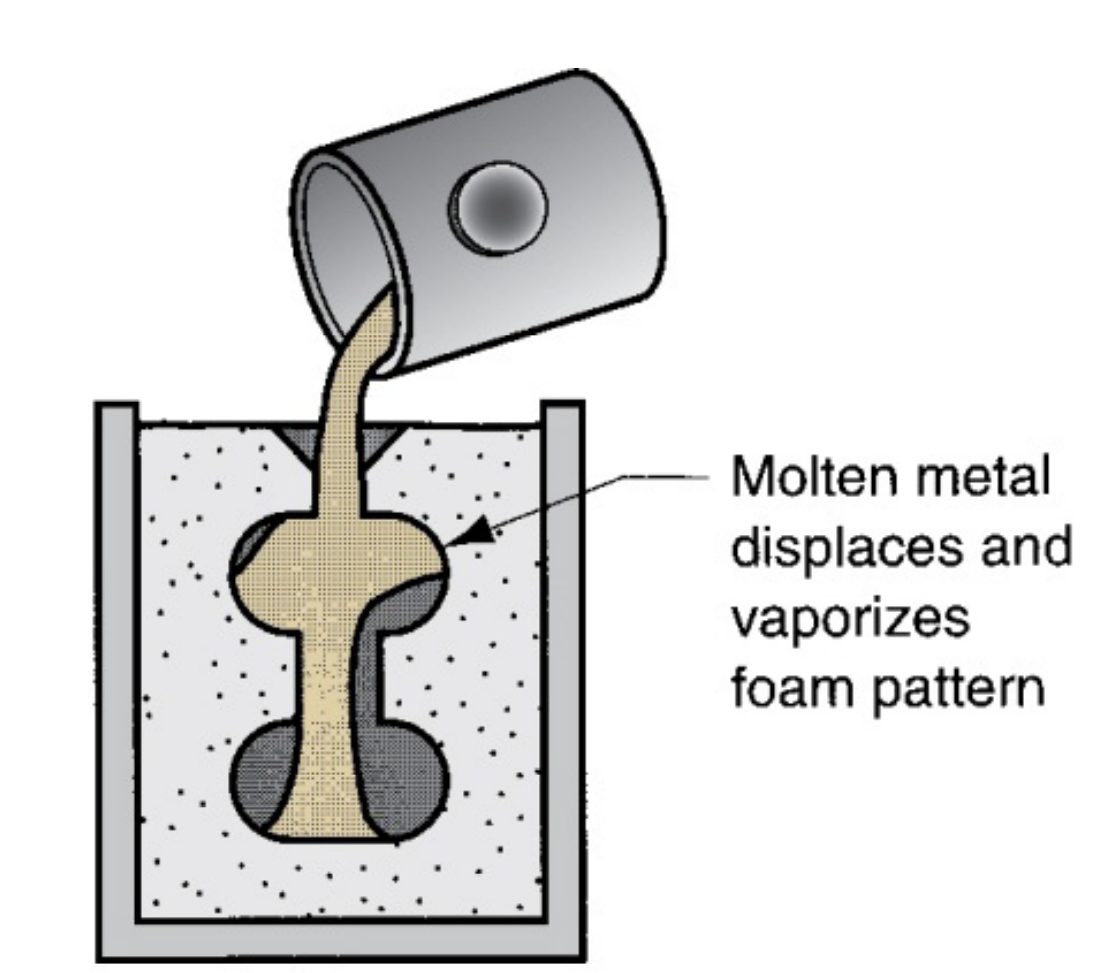

uses a mold of sand packed around a polystyrene foam pattern, the foam vaporizes when molten metal is poured

Does not need to be opened into cope and drag sections

A.K.A. lost-foam process, lost pattern process, evaporative-foam process, and full-mold process

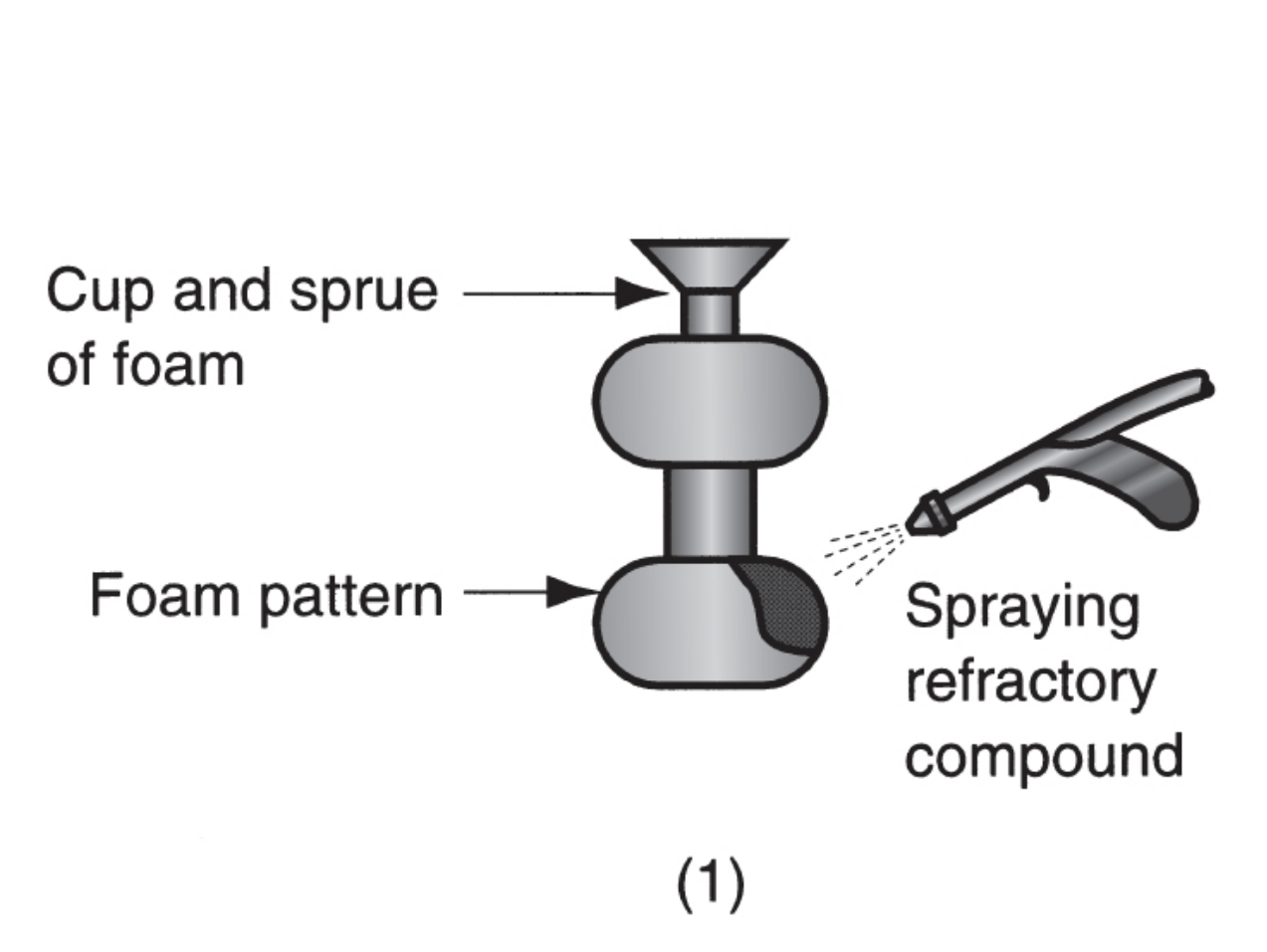

Steps in Polystyrene Process

polystyrene foam pattern is coated with refractory compound

Foam pattern is placed in a mold box and sand is placed around it

Molten metal is poured into the part of the mold that has the pouring cup and sprue

As the metal enters the mold the polystyrene foam is vaporized

Advantages of expanded polystyrene process

Pattern does not need to be removed from the mold

simplifies and expedites mold making because two halves are not required

Disadvantages of expanded polystyrene processes

New pattern needed for every casting

Economic justification for the process is dependent on the price of producing patterns

Applications of expanded polystyrene

mass production of automobile engines

Automated and integrated manufacturing systems can be used to mold the patterns and then feed them to a casting operation

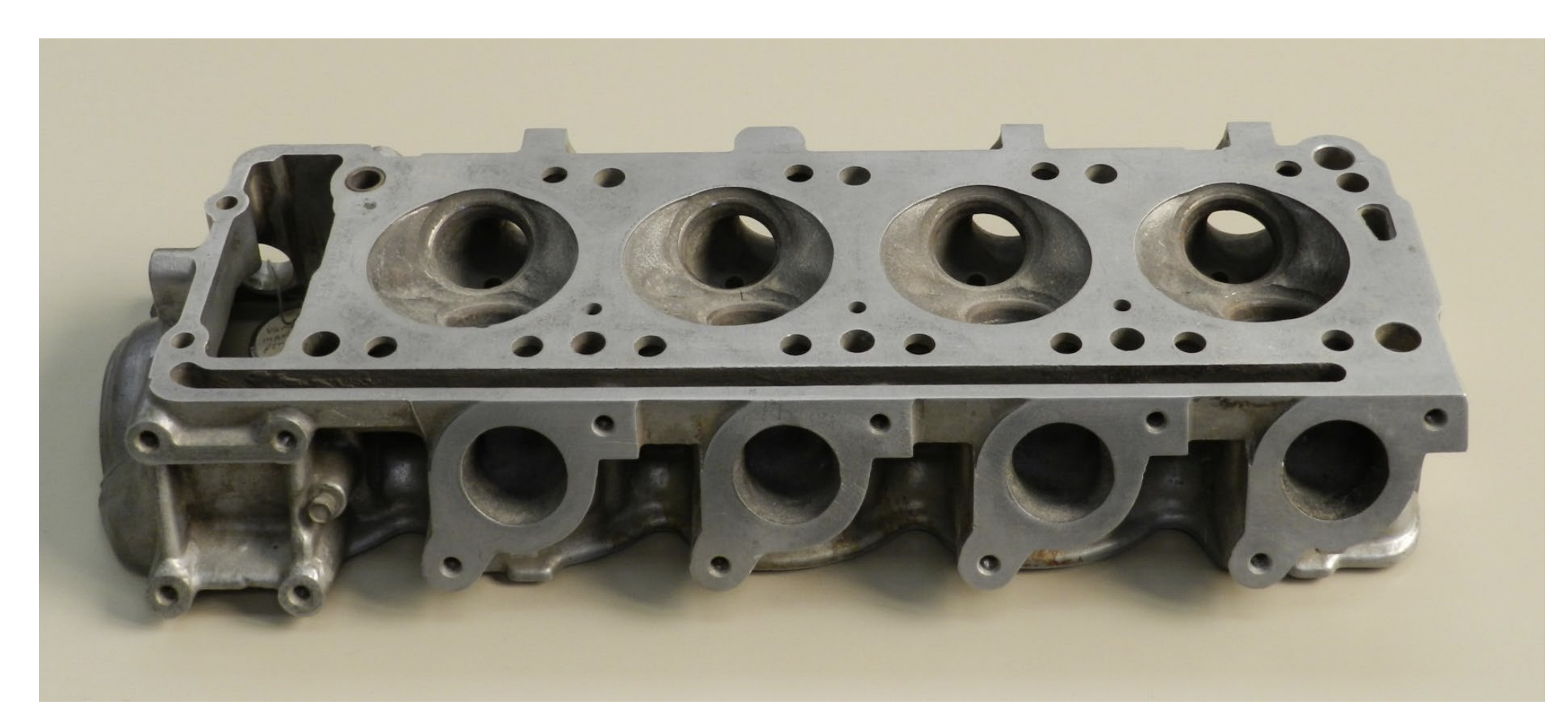

aluminum engine head from expanded polystyrene process

Investment Casting (Lost Wax Process)

Wax pattern is coated with a refractory material to make the mold, wax is then melted away prior to pouring metal

a high precision casting process that can produce castings with high accuracy and intricate details

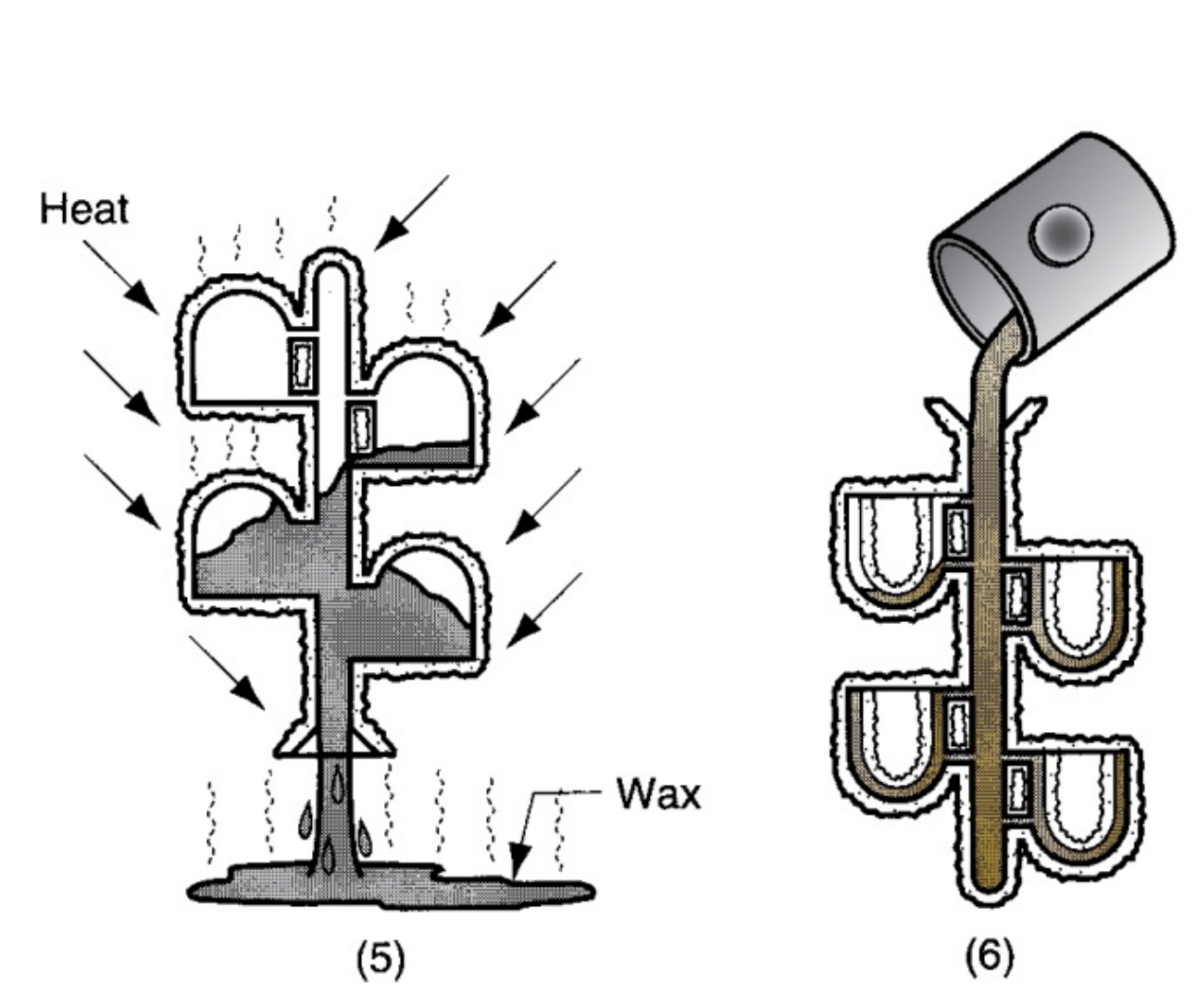

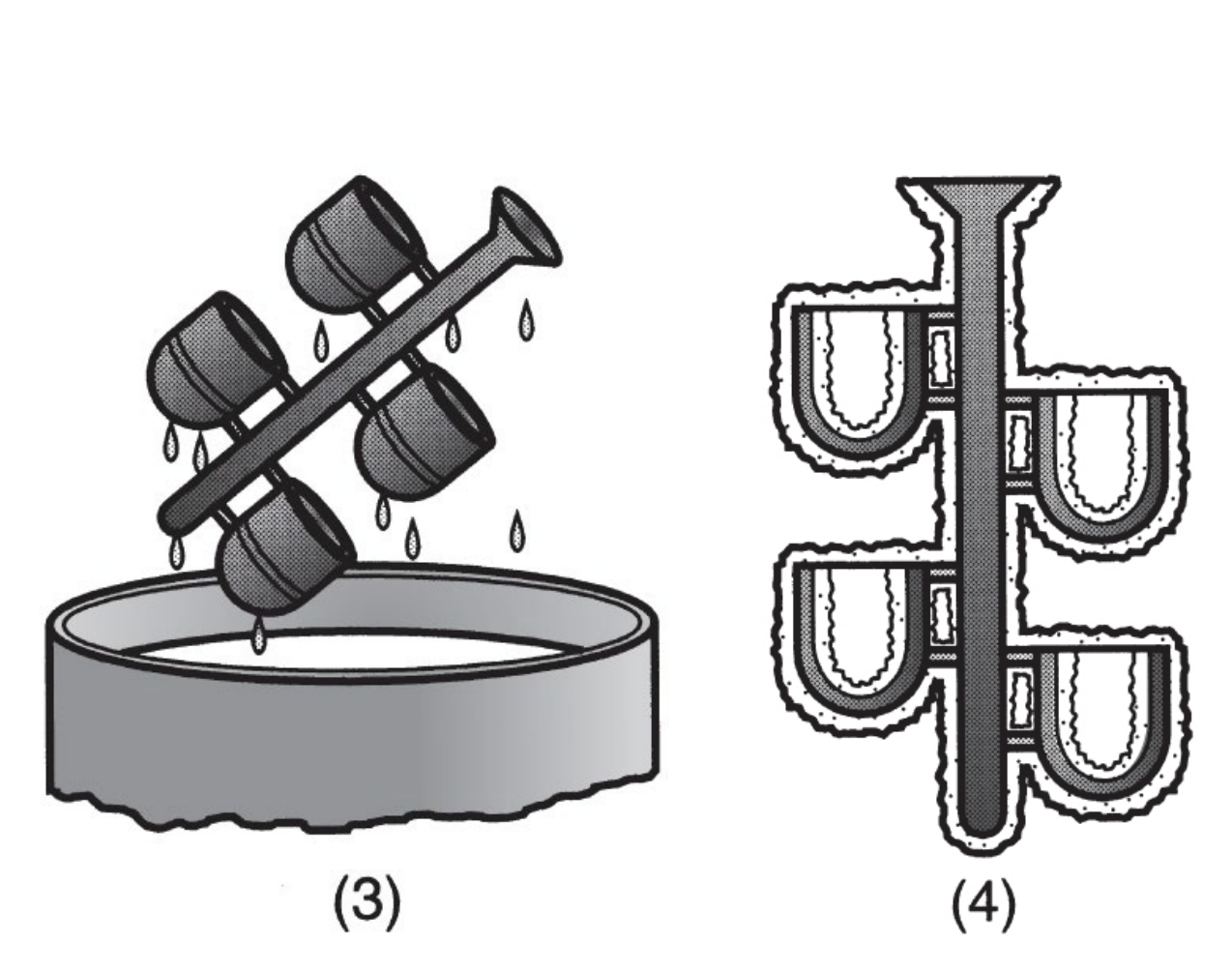

Steps in Investment Casting

Wax pattern produced

several patterns are attached to a sprue to create a pattern tree

Pattern tree coated in refractory material

full mold is made by sufficiently coating the pattern tree in refractory material to make it rigid

Mold is inverted and heated to melt the wax and let it drip out of the mold

Mold is preheated and then filled with molten metal

Mold is broken away from finished casting and parts are separated from the sprue

One-piece compressor stator made by investment casting

Advantages of Investment Casting

Parts of great complexity can be made

Close dimensional control and surface finish

wax can be recovered for reuse

Net shape process - additional machining not usually required

Disadvantages of Investment Casting

Many processing steps

Relatively expensive process

Plaster mold casting

Similar to sand casting but the mold is made of plaster of paris

Plaster mold casting steps

plaster and water mixture poured over plastic or metal pattern and allowed to set

Wood is not typically used due to extended exposure to water

Plaster mixture flows around the pattern freely to capture all of the details

advantages of plaster mold casting

good accuracy and surface finish

capable of making thin cross sections

disadvantages of plaster mold casting

mold must be baked to remove moisture because moisture can cause problems in casting

mold strength is lost if over baked

plaster molds cannot withstand high temps, limited to lower melting point alloys

Ceramic Mold casting

similar to plaster but the mold is made of refractory ceramic material that can withstand higher temps than plaster

Applications and advantages of ceramic molding

Used to cast steels, irons, and other high temp alloys

Similar applications to plaster molding but with different metals

Has good dimensional accuracy and surface finish

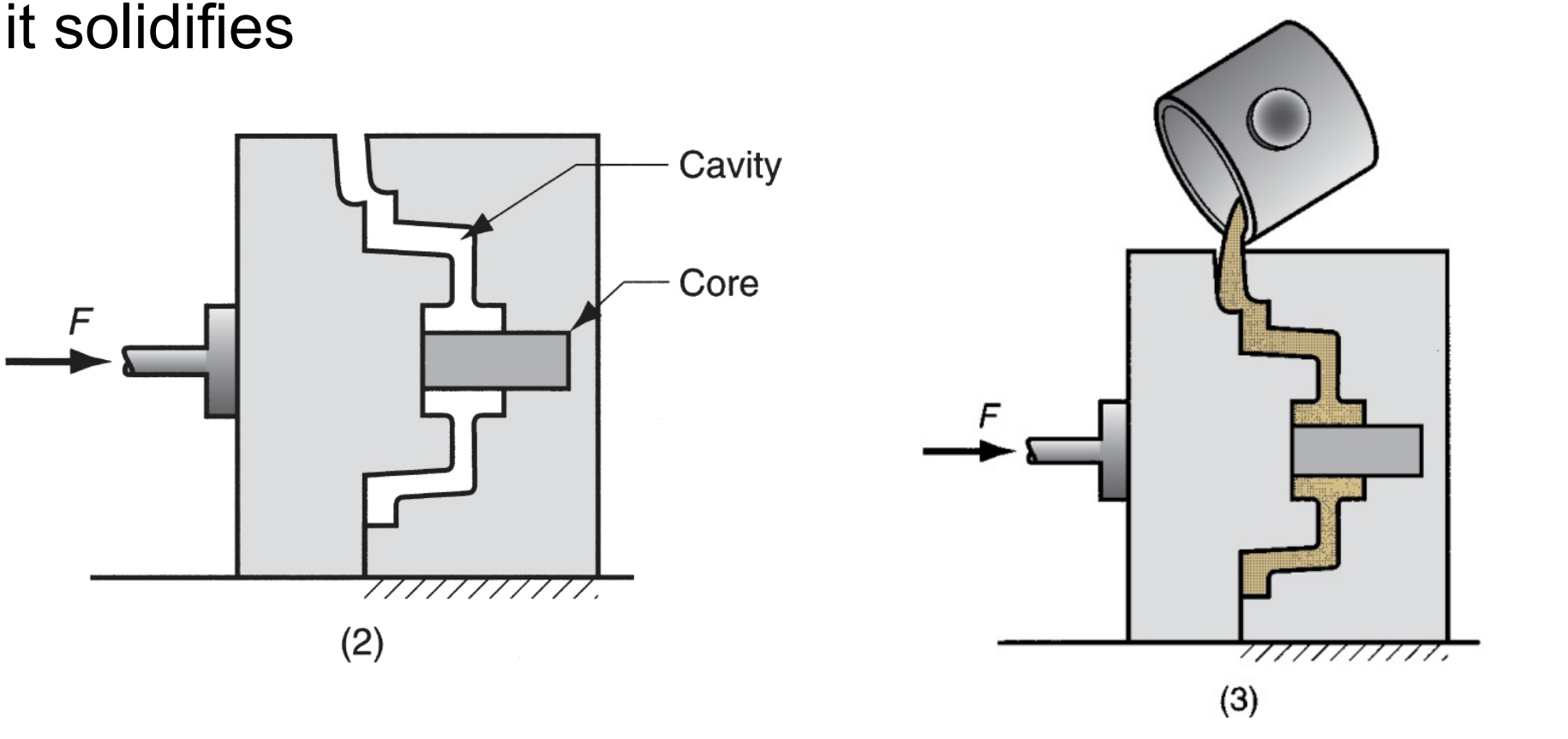

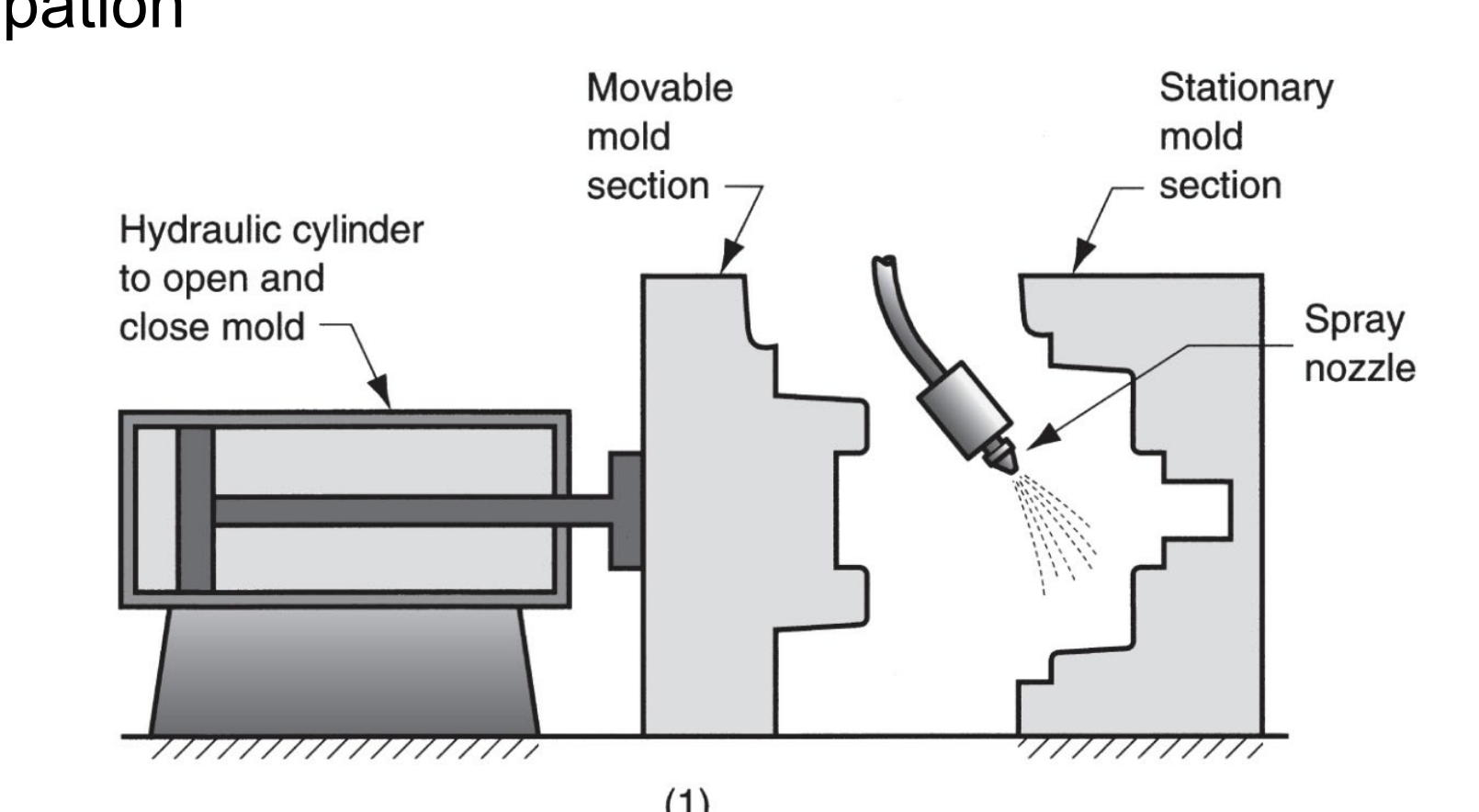

Basic Permanent mold process

metal mold constructed of two sections for easy and precise opening and closing

molds for lower temps made of cast iron or steel

molds used for casting steel MUST be made out of refractory material due to high pouring temps

Steps in permanent mold process

mold is pre-heated and coated for lubrication and heat dissipation

cores (if used) are inserted and mold is closed

molten metal is poured and solidifies

mold is opened and the casting removed

Advantages of permanent mold casting

good dimensional control and surface finish

rapid solidification from metal mold causes finer grain structure making the casting stronger

Limitations of permanent mold casting

generally limited to metals with lower melting points

cannot handle geometries as complex as the ones sand casting covers

high cost of mold

Applications for permanent mold casting

because of high mold cost it is best suited to mass production, and can be automated like that

typical parts : automotive pistons, pump bodies, and castings for aircraft/missiles

common metals : aluminum, magnesium, copper based alloys, cast iron

CANNOT be used for steels because of high pouring temps

Die Casting

molten metal is injected into mold cavity under high pressure

Pressure is maintained during solidification and then part is removed

molds = dies

Die casting machines

Designed to hold mold together while metal is forced into mold cavity

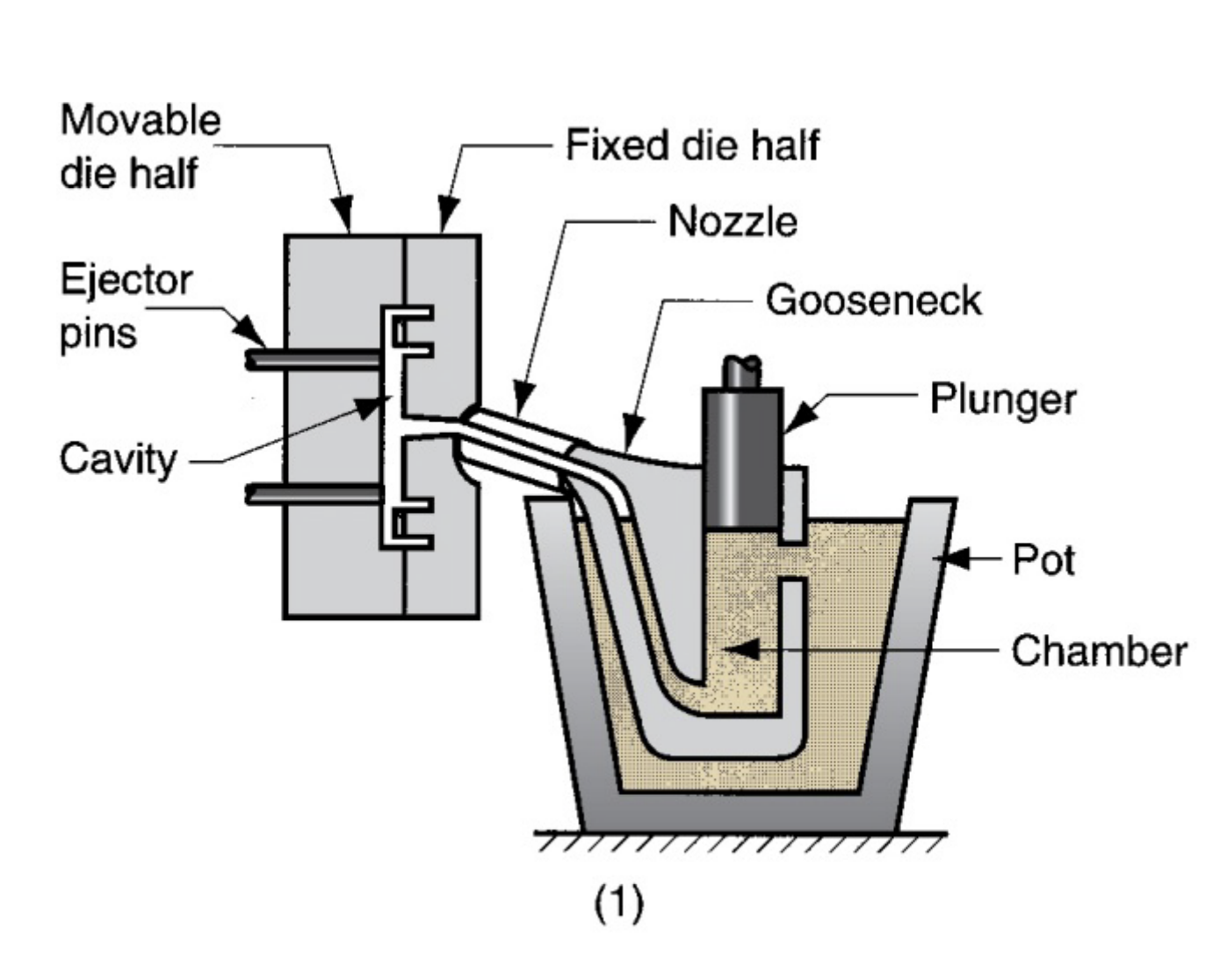

Hot Chamber machine

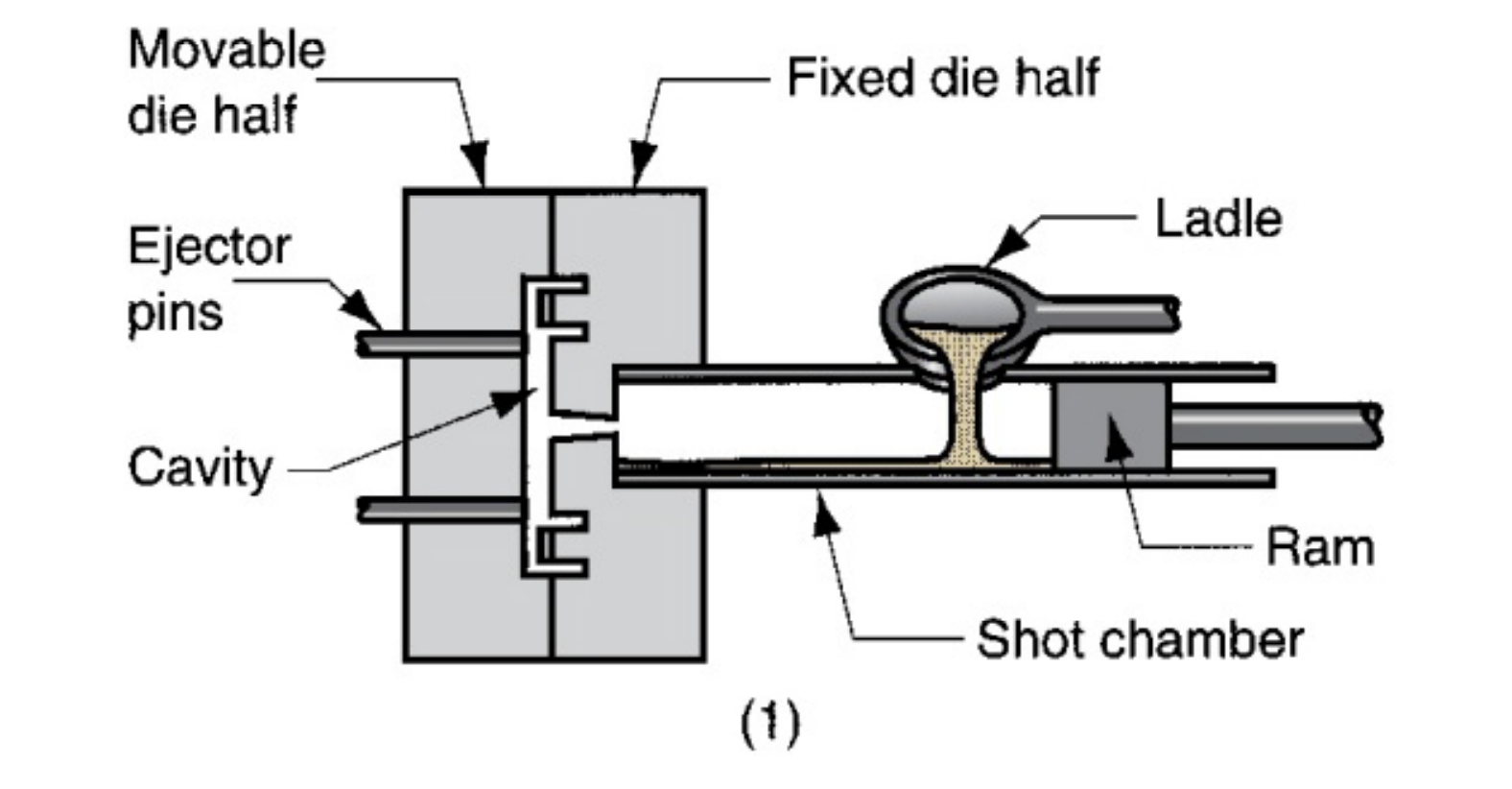

Cold Chamber machine

Hot Chamber Die Casting Machine

metal is melted in a container and a piston injects the metal under high pressure into the die

High production rates (500/hr)

limited to low melting point metals that do not attack plunger or other components

casting metals: zinc, tin, lead, magnesium

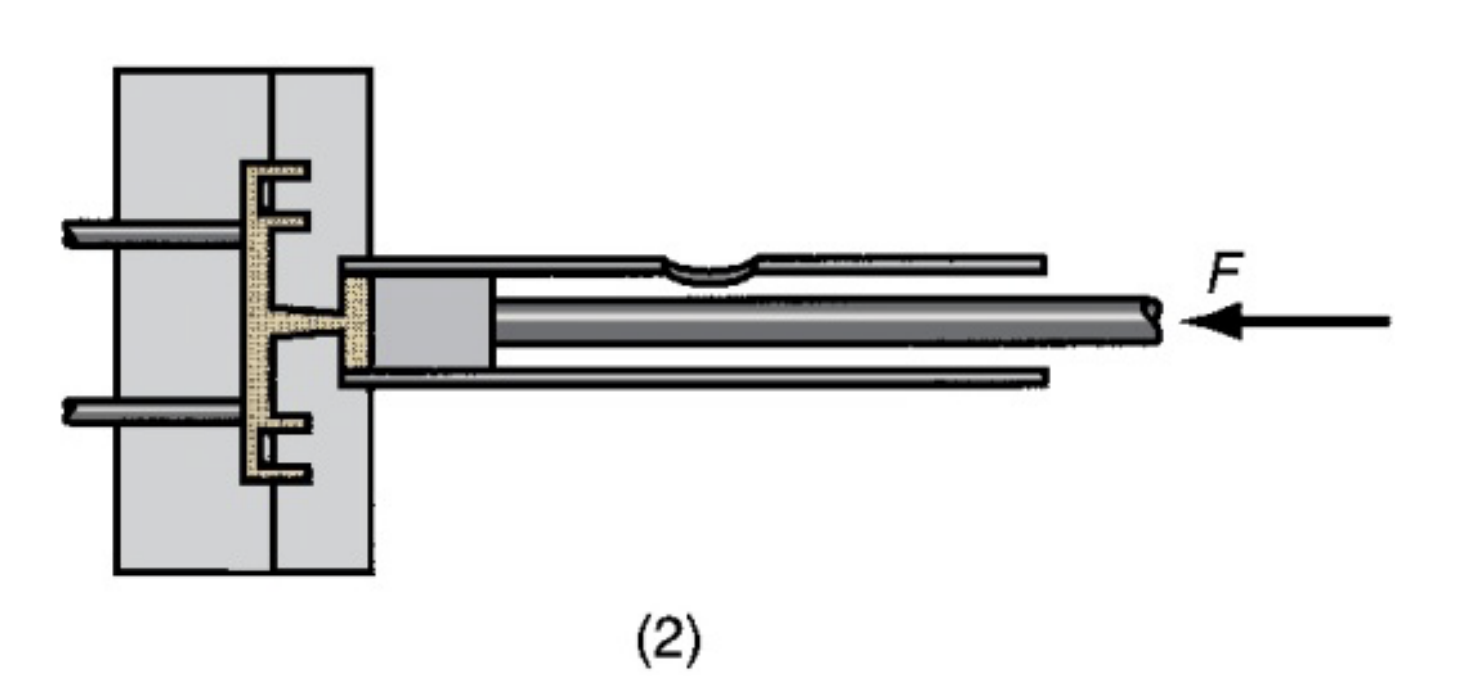

Cold Chamber Die Casting Machine

molten metal is poured into an unheated chamber from an external container, piston injects metal under high pressure

high production, but lower than HC because of pouring step

casting metals: aluminum, brass, and magnesium alloys

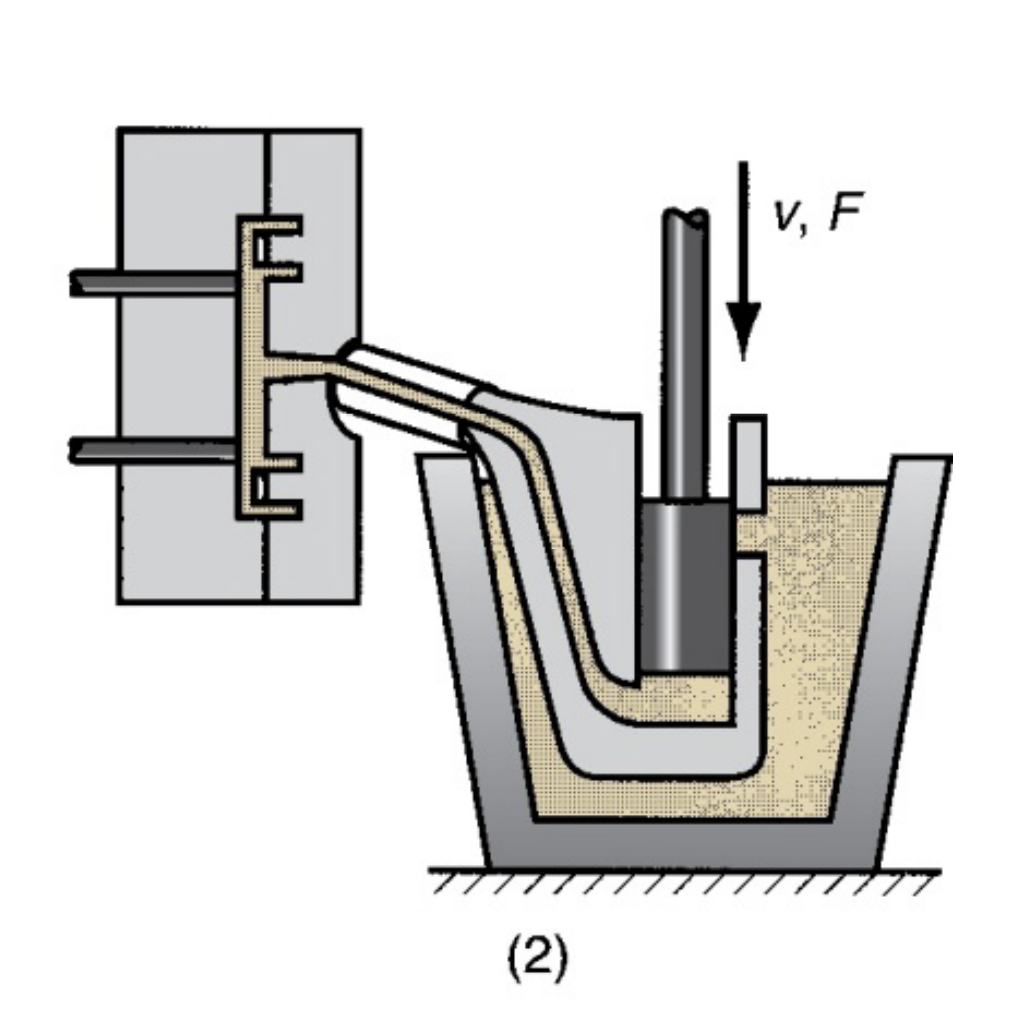

HC die casting cycle

die closed and plunger withdrawn molten metal flows into the chamber

Plunger forces metal in chamber to flow into die, maintaining pressure during cooling and solidification

plunger is withdrawn, die is opened and casting ejected

CC Die Casting Cycle

with die closed and ram withdrawn molten metal is poured into the chamber

ram forces metal to flow into die maintaining pressure during cooling and solidification

ram is withdrawn die is opened and casting removed

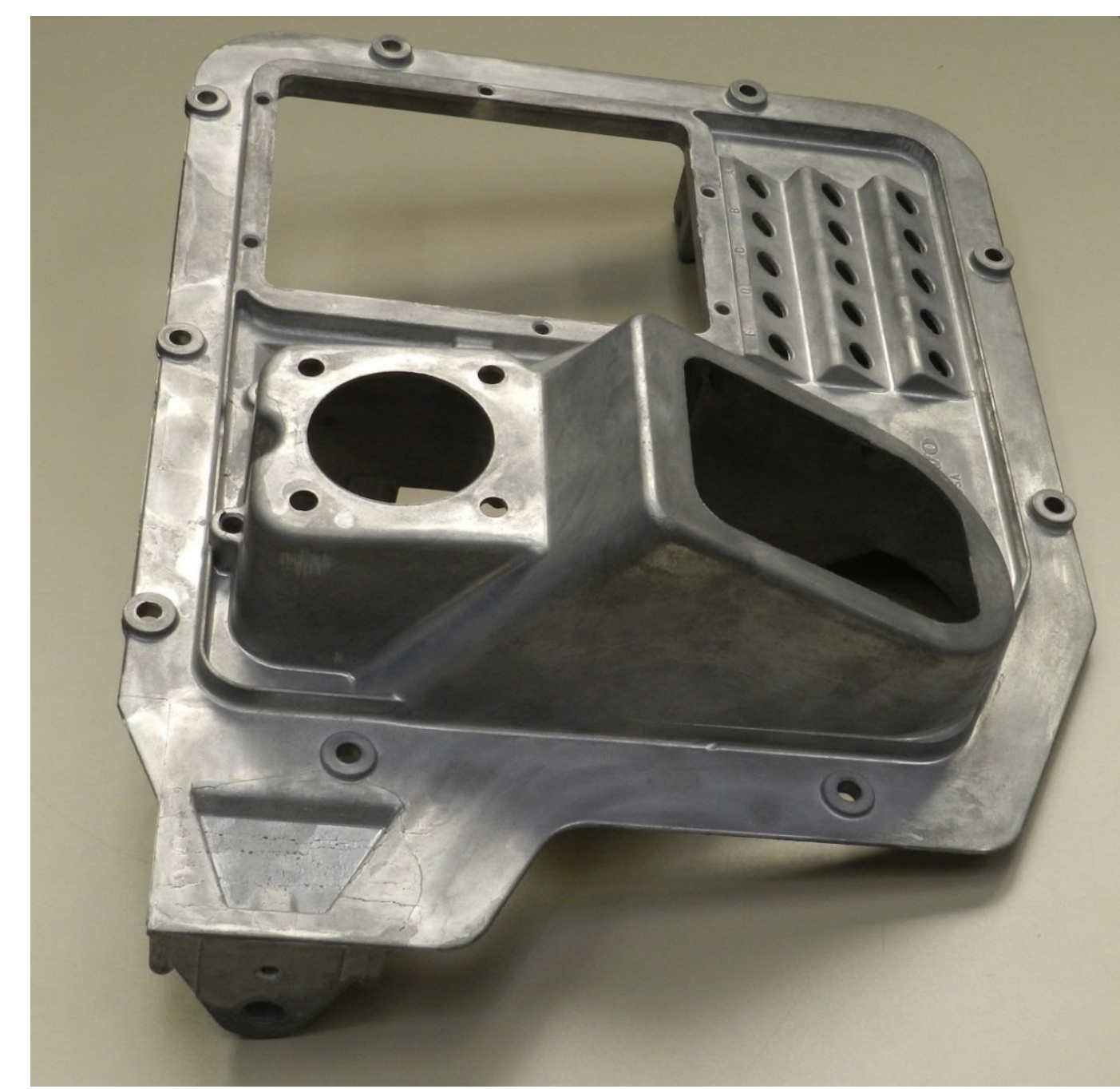

truck cab floor die casting

Die Casting advantages

economical for large production quantities

good accuracy and surface finish

thin sections feasible

rapid cooling = small grain sizes and stronger casting

Die casting disadvantages

generally limited to metals with low melting point

part geometry has to allow removing the die

Squeeze Casting

Combo of casting and forging in which molten metal is poured into a pre-heated lower die and the upper die is closed to create the mold cavity AFTER solidification begins

Semisolid Casting

Family of net shape and near net shape processes performed on metal alloys between liquidous and solidus temps

Mix of molten and solid metals during casting making it mushy

to flow properly the mixture needs solid metal globules (stir the mixture to prevent dendrite formation)

Semisolid casting advantages

complex part geometries

thin part walls possible

close tolerances

zero or low porosity, high strength of casting

Centrifugal Casting

family of processes where the mold is rotated at high speed so centrifugal force distributes molten metal to outer regions of die cavity

true centrifugal casting

semicentrifugal casting

centrifuge casting

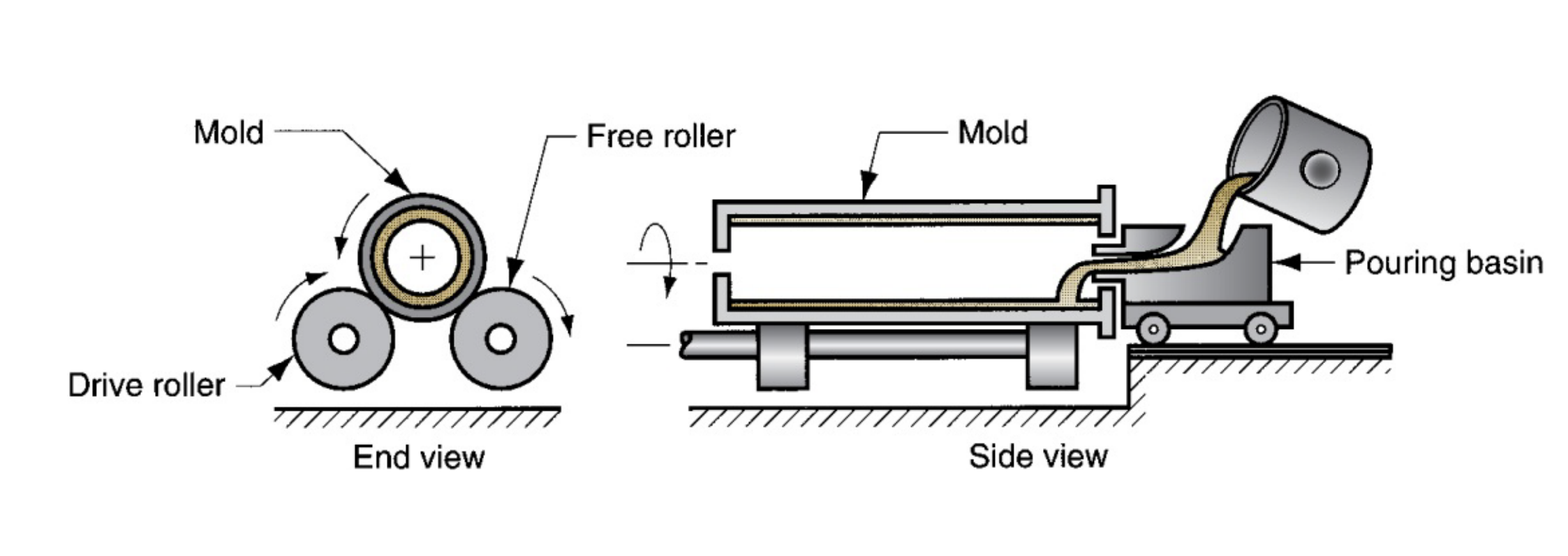

True centrifugal casting

molten metal is poured into rotating mold to make tubular part

parts: pipes, tubes, bushings, and rings

outside shape can be different but inside is ideally perfectly round

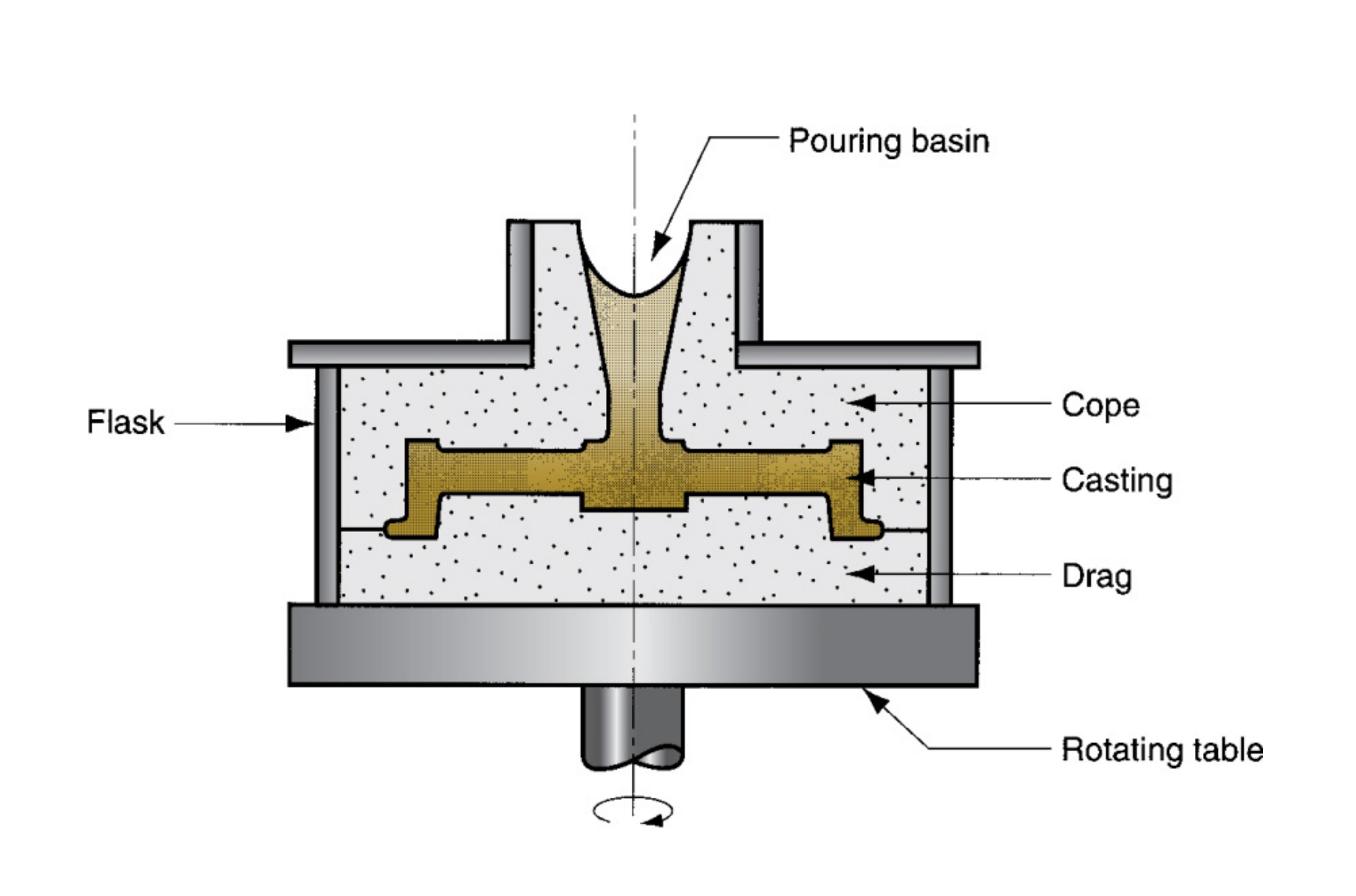

Semicentrifugal casting

centrifugal force is used to create solid casting instead of tube

use risers in the center and density of metal in final casting is greater in outer sections than at the center of rotation

Often used on parts where the center is machined away (eliminates the part where quality is worst)

Semicentrifugal casting

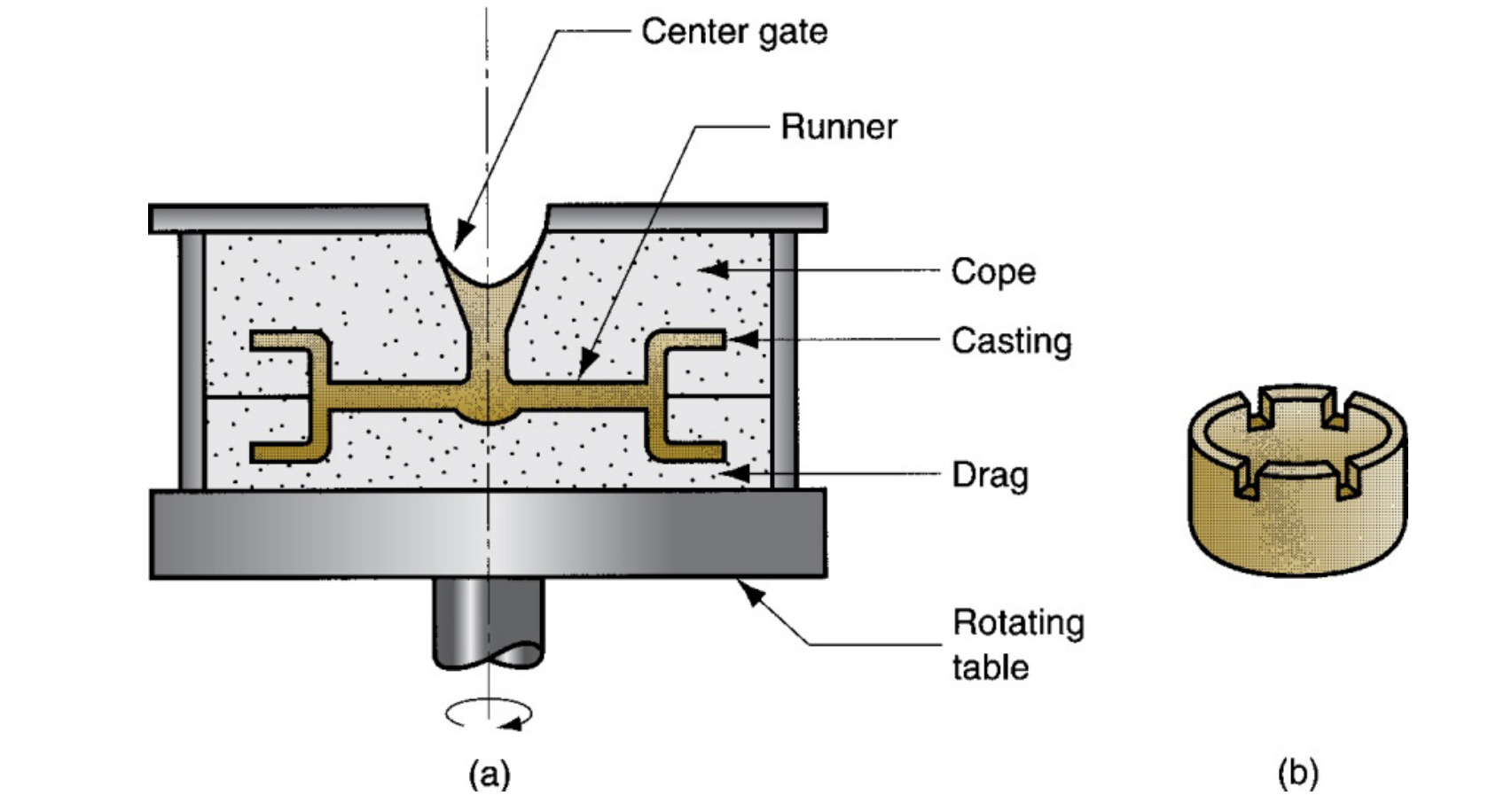

Centrifuge Casting

mold is created with part cavities located away from the axis of rotation

molten metal is distributed to those cavities via centrifugal forces

used for small parts, does not require radial symmetry

Centrifuge casting