PMCY 4510 -- Continuous Pharmaceutical Manufacturing (MS presentation -- for final)

1/11

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

12 Terms

Define “advanced manufacturing”

a collective term for new or innovatively applied medical product manufacturing technologies that can improve drug quality, address shortages of medicines, and speed time-to-market

What are the primary modes of operation for a chemical manufacturing process?

batch

continuous

others are specific to certain equipment and processes (biologics)

Define “batch manufacturing”

the raw material(s) is charged into the system at the beginning of the process, and the product is discharged all at once sometimes later

no ingredients cross the system boundaries between the time the raw material(s) is charged and the time the product is discharged

Define “continuous manufacturing”

a process in which material is continuously fed into and product continuously removed from the system, while the process flows through a series of integrated unit operations without interruption

Describe the core difference between batch and continuous manufacturing

The core difference is that batch manufacturing processes involve discrete charges of materials resulting in product discharge at intervals, while continuous manufacturing allows for uninterrupted flow of materials and products throughout the system.

batch manufacturing is like an oven when you’re baking a cake — you have to mix up each cake by itself and then put it in the oven, and then take out the first cake before you can bake the next one

continuous manufacturing is like a conveyer belt/assembly line — like parts moving along an assembly line where different actions are performed sequentially as the product progresses

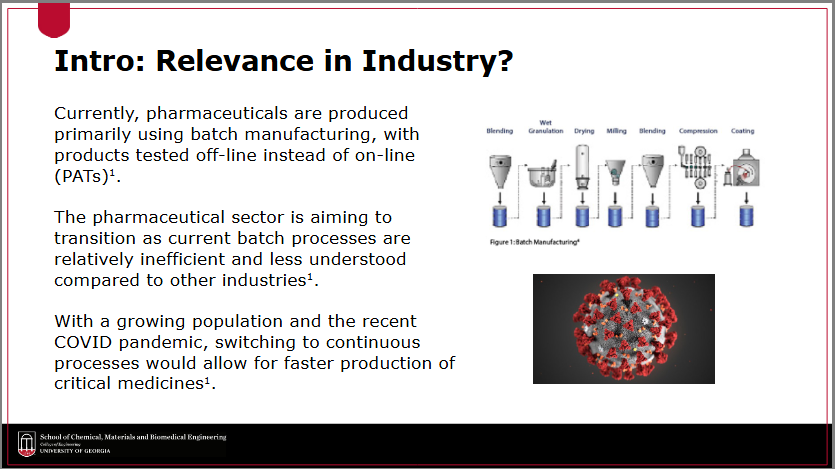

What are the current limitations with the batch manufacturing process?

products have to be tested off-line instead of on-line (making PAT not as accurate as desired)

batch processes are relatively inefficient and less understood compared to other industries

not as fast as continuous manufacturing

What are the benefits of continuous manufacturing?

increased production flexibility

don’t need to shut down in between batches for cleaning

scale of batches are more easily modified (can respond to demand surges faster)

change run-time or duplicating lines instead of recalibrating each piece of equipment

more efficient production

don’t have to wait for one process to finish to start another

reduces energy needs and overall waste

real-time monitoring of product quality (PATs)

in-line measurement allows for feedback control and reduces risk of faulty batches (issues are caught earlier)

cost savings

reduces labor and operational costs

waste is reduced by preventing off-spec production

fewer cleaning and changeover steps

What are the challenges/drawbacks of continuous manufacturing?

upfront costs

necessary equipment and infrastructure can be expensive

requires skilled workforce familiar with continuous systems

adoption of new statistical tools and models to optimize processes can be expensive to acquire and train on

process complexity

integration of multiple unit operations requires robust design

real-time analytics adds to already strenuous technical demands

regulatory concerns

What are examples of equipment incorporated in a continuous manufacturing process?

spray dryer

roller compactor

tablet press

distillation column

(T/F) There are dedicated sections in the Code of Federal Regulations (CFR) that exclusively govern continuous pharmacuetical manufacturing.

False

Which of the following is NOT a benefit of continuous pharmaceutical manufacturing?

A) reduced need for real-time monitoring

B) greater flexibility in production scale

C) faster response to demand changes

D) reduced cleaning and changeover steps

A — reduced need for real-time monitoring

What drug was the first to receive FDA approval for switching from batch to continuous manufacturing?

A) Lipitor

B) Orkambi

C) Prezista

D) Remdesivir

C — Prezista