Sludge Treatment (Sludge Infos, Thickening, Anaerobic Stabilization)

1/102

Earn XP

Description and Tags

(Sludge Infos, Thickening, Anaerobic Stabilization)

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

103 Terms

Sludge

refers to concentrating impurities into solid form and then separating these solids from the bulk liquid

quantity of sludge

higher the degree of wastewater

larger the?

Biosolid

end product of wastewater sludge treatment process

treated/ stabilized sludge

other term of biosolids

Webster Collegiate Dictionary

Define Biosolids

solid organic matter recovered from a sewage treatment process

McGraw Hill Dictionary of Scientific

Define Biosolids

biosolids as a recyclable, primarily organic solid material

screening

Description of Solids/ Sludge

all organic and inorganic materials large enough to be removed

Toxicity characteristic leaching procedure

A treatment for the materials coming from the preliminary tanks before treatment or disposal

grit

Description of Solids/ Sludge

heavier inorganic solids

scum/ grease

Description of Solids/ Sludge

floatable materials skimmed from the surface

primary sludge

Description of Solids/ Sludge

gray and slimy

extremely offensive odor

activated sludge

Description of Solids/ Sludge

brown flocculent appearance

septic tank

if the color is dark, sludge may be approaching a ?

under aeration

if the color is lighter than usual there may have been a?

good condition sludge

sludge inoffensive earthy odor

trickling filter sludge

Description of Solids/ Sludge

humus sludge

brownish

flocculent

inoffensive odor when fresh

aerobically digested biosolids

Description of Solids/ Sludge

brown to dark brown

flocculent appearance

not offensive odor - musty

dewater easily

twice of the CH4 gas produced

metal/ salts

Sludge from Chemical Precipitation

usually dark in color

What chemical is added to?

iron

Sludge from Chemical Precipitation

red color

What chemical is added to?

lime

Sludge from Chemical Precipitation

grayish brown

What chemical is added to?

chemical precipitation

Description of Solids/ Sludge

somewhat slimy, the hydrate of iron/ aluminum makes it gelatinous

sludge from tertiary (Advanced) treatment process

Description of Solids/ Sludge

depends on unit process

phosphorus

chemical sludge from ____ is difficult to handle and treat

Waste Activated Sludge

Description of Solids/ Sludge

Active Microbial mass

dark brown suspension

VSS 70-80%

Raw Sludge

Description of Solids/ Sludge

Other term form primary sludge

organic solids

grit inorganic fines

greasy

odorous slurry

PFRP - Process to Further Reduce Pathogens

test for class A

no pathogen related restriction for land application

PSRP - Process to Significantly Reduce Pathogens

test for Class B

reduce but do not eliminate pathogens

A

Primary Diseases for Class _

- reduce the pathogens in biosolids to below detectable levels

fecal coliform

salmonella sp.

bacteria

enteric viruses

parasites

viable helminth ova

B

Class _ reqs ensure that pathogens are reduced and unlikely to pose a threat to public health

3 MPN per 4g of dry solids

Class A

Salmonella sp. in biosolids must be less than __

1000

Class A

Fecal Coliform in biosolids must be less than ___

1

Class A Biosolids Alternative #?

Time and Temperature

2

Class A Biosolids Alternative #?

pH and time

pH above 12 - 72h and keeps it at 520C for 12h

3

Class A Biosolids Alternative #?

enteric viruses and helminths ova - one plaque-forming unit (PFU) per 4g of dry solids

4

Class A Biosolids Alternative #?

analysis w/ unidentified treatment process

analysis of the pathogens

5

Class A Biosolids Alternative #?

PFRP process

6

Class A Biosolids Alternative #?

PFRP equivalent process

55C for 3days

> or = 180C for 30mins

PFRP Class A

Composting - temp & time

Heat Treatment - temp & time

Heat Drying

PFRP Class A

dewatered biosolids are dried by direct or indirect contact w hot gases to reduce water content to 10%

thermophilic aerobic digestion

PFRP Class A

liq biosolids are agitated w air or no oxygen to maintain aerobic conditions and the MCRT is 10d at 55-60C

pasteurization

PFRP Class A

temperature of biosolids is maintained at > or = 70C for 30minutes

> or = 40C for 5days

PSRP Class B

Composting - temp and time

air drying

PSRP Class B

dried on sand beds or on paved or unpaved basins min 3 months

40d 55C and 60d at 60C

PSRP Class B

aerobic digestion - agitated w air or no oxygen to maintain aerobic conditions, for an SRT and temp bet __

35 to 55C

60C

PSRP Class B

anaerobic digestion

SRT 15 days temp _

SRT 60 days temp _

Lime stabilization

PSRP Class B

chemical is added to raise pH of the biosolids to pH 12 and maintained for 2hrs of contact

Sludge Thickening

procedure used to increase solids

removing PORTION of the liq

by gravity or flotation

not to thicken greater than 10%

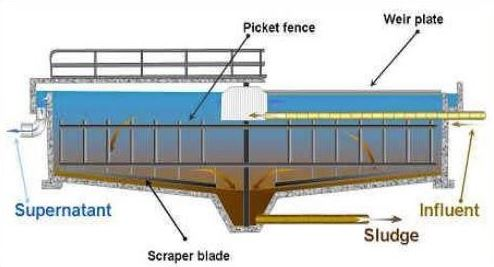

Gravity thickening

equipment is similar design to a conventional sedimentation basin

normal solids loading rate from 30-60 kg solids per sq.m of tank bottom per day

best for primary sludge/ raw sludge (heavier)

coagulant

improve settling; chemical conditioning

18h minimum

activated sludge residence time in the thickener

1-3% to 10%

in gravity thickening, purely primary sludge can be thickened from

SVR - Sludge Volume Ratio

volume of the sludge blanket held in the thickener divided by the volume of the thickened sludge removed daily

0.5 to 20days values

lower values are during warm weather - temp as catalyst

Sludge Blanket

depths may range from 0.5 to 2.5m

shallower depths are maintained in warmer months

2-3 ft for thickening

ferric chloride

reduce hydrogen sulfide in the anaerobic digester

co settling thickening

when primary clarifiers are used to thicken solid for downstream processing

SRT 12-24 hrs

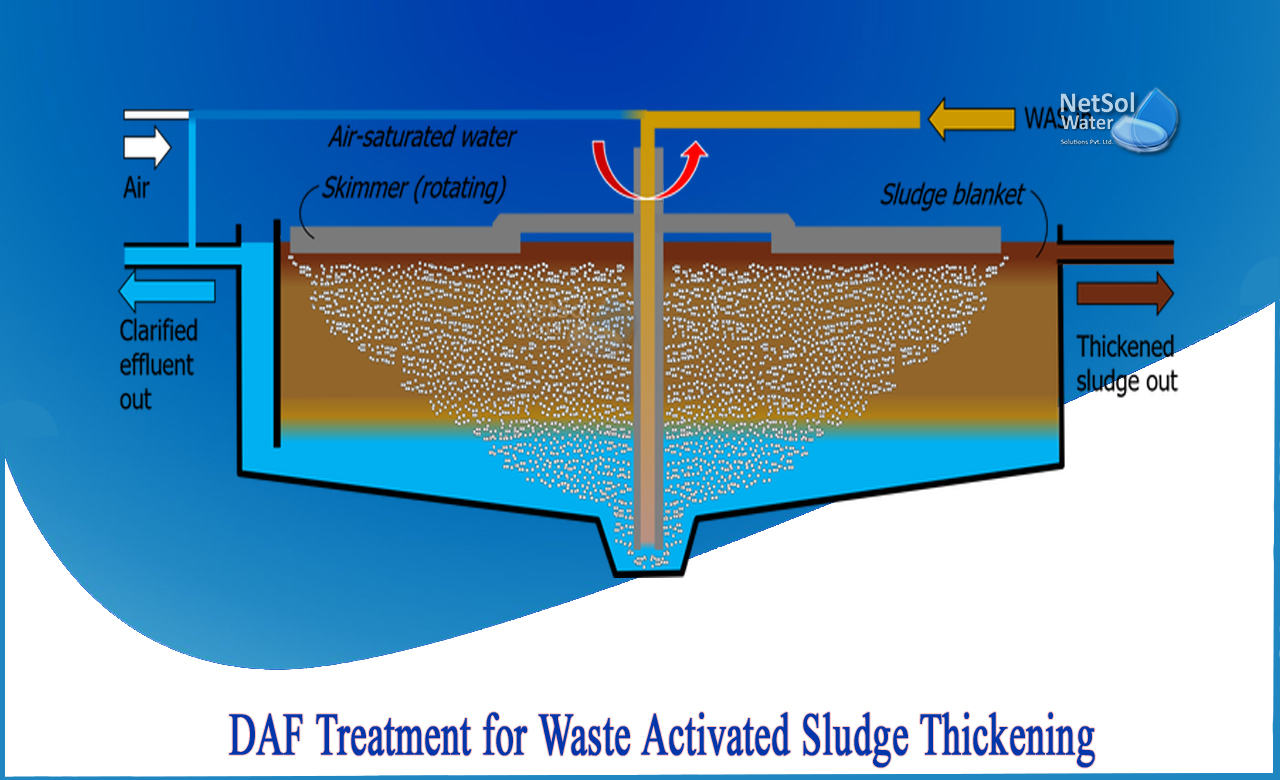

flotation thickener

releasing fine air bubbles that attach to sludge particles

dissolved air flotation (DAF)

Air to solid ratio

FACTORS NEED TO BE CONSIDERED IN THE DESIGN OF DAF SYSTEM

most important factor affecting the performance

most municipal ww - 0.02:1 to 0.06:1

hydraulic loading

FACTORS NEED TO BE CONSIDERED IN THE DESIGN OF DAF SYSTEM

typical design - 30 to 120cu.m/d - sq.m

sum of feed and recycle flow rate / net available flotation area

polymer addition

FACTORS NEED TO BE CONSIDERED IN THE DESIGN OF DAF SYSTEM

typica dosage - 2-5g dry polymer/ kg of dry feed solids

Bench Scale testing used for the dosage

solids loading rate

FACTORS NEED TO BE CONSIDERED IN THE DESIGN OF DAF SYSTEM

mass of solids /hour / effective flotation are

2-5 kg/h - sq.m

adding polymer

increase loading rate to 50-100%

solids float concentration increases 0.5-1%

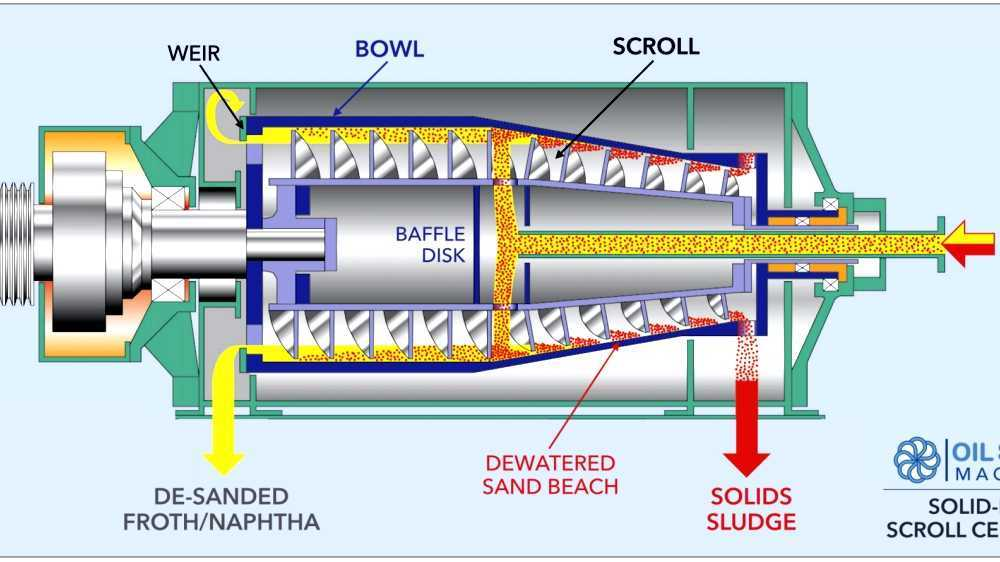

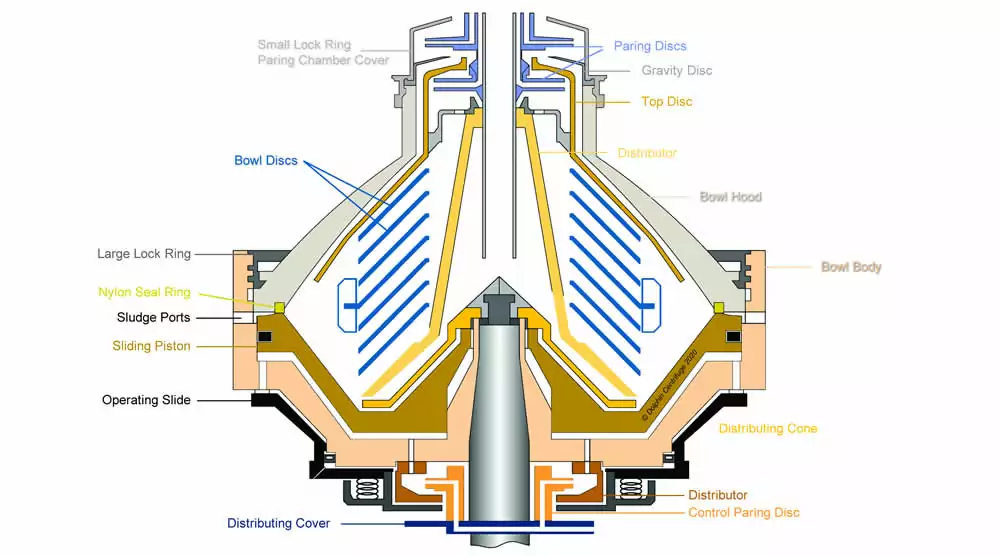

centrifuge

used as thickening device for activated sludge or as a dewatering process for digested or chemically conditioned sludge

centrate

clear liquid from centrifuge

centrifugal application

limited application to WAS from secondary clarifier

solid bowl centrifuge

TYPE OF CENTRIFUGE

most widely used

rotates along horizontal axis

continuous feed

gravitational forces causes the solids to settle out on the inner surface

rotating bowl

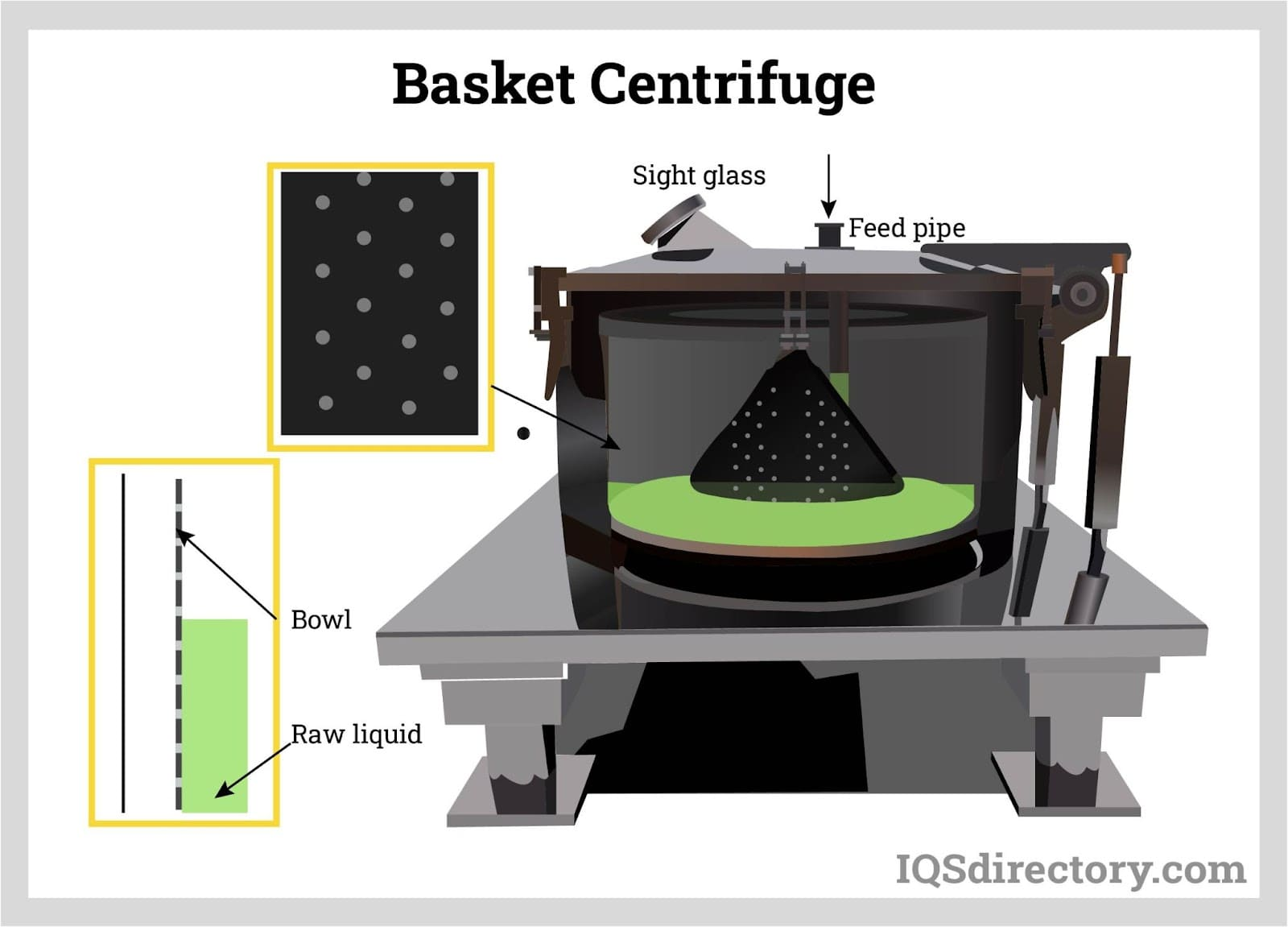

basket centrifuge

TYPE OF CENTRIFUGE

imperforate bowl

knife discharge type

operate in batch basis

vertically mounted spinning bowl

solid accumulate against the wall; centrate is decanted

60-85% max depth

suited for soft or fine solids that are difficult to filter

disc nozzle centrifuge

TYPE OF CENTRIFUGE

rotates along vertical axis

continuous feed

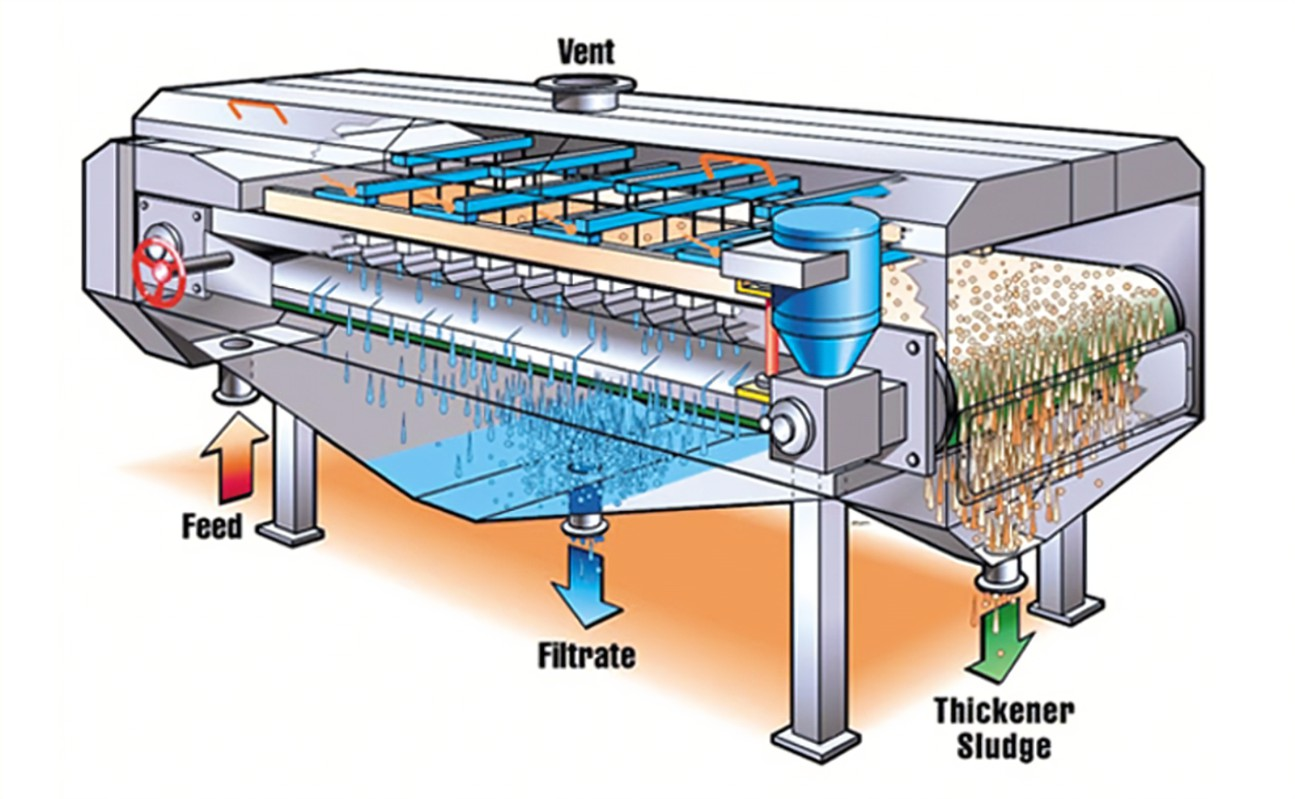

gravity belt thickener

application of belt presses for sludge dewatering

required polymer conditioning

continuously moving permeable fabric belt

dewatered sludge falls into a small hopper at the end of the belt for pumping

used for

WAS

anaerobically and aerobically digested sludge

industrial sludge

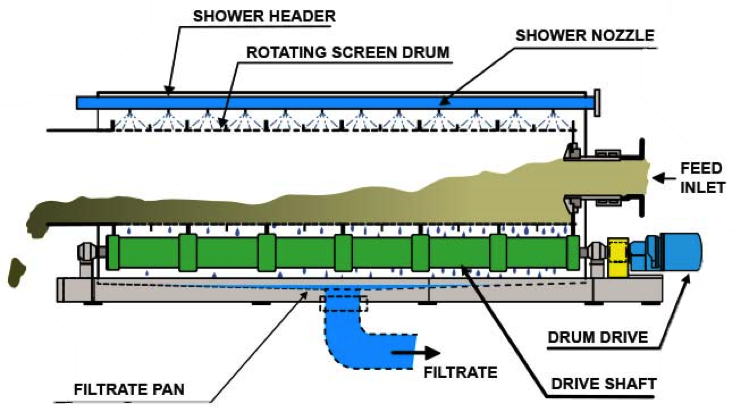

rotary drum thickener

similarly to gravity belt

as a pre thickening step before belt press dewatering

used in

small to med plants for WAS thickening

sludge stabilization (digestion)

REQUIRED treatment

purpose

reduce pathogens

eliminate offensive odors

inhibit reduce or eliminate the potential for putrefaction

safe to handled

used as soil conditioners

alkaline stabilization

METHODS FOR SLUDGE STABILIZATION

usually w lime (slaked lime- calcium hydroxide)

lime is added to untreated sludge to raise the pH to 12 or higher

high pH eliminate/ reduce

microbial reactions

odor production

vector attraction

can inactive microorganisms present

lime stabilization

METHODS OF ALKALINE STABILIZATION

adding chemicals and min 2h contact

hydrated lime Ca(OH)2

Quicklime CaO

disadvantage - temporary

musca domestica

example of vector that attract in offensive odor? other term for housefly

pH 11

if the pH drops in __, renewed bacteria and pathogen growth reoccur

lime post treatment

METHODS OF ALKALINE STABILIZATION

for dewatered wastewater treatment plant sludge using lime

advantages

dry lime can be used- no addt water is added to dewatered sludge

no special reqs

adequate mixing is critical to avoid pockets of putrescible material (can cause rot or bad smell) and to ensure contact of lime and sludge

Anaerobic Digestion

METHODS FOR SLUDGE STABILIZATION

oldest process, 1850s

commonly used for high organic load

decomposition of organic and inorganic matter

chemical and biochemical reactions

3 types of ____ that occur in anaerobic digestion

hydrolysis

fermentation

methanogenesis

procaryotic

microbial communities in anaerobic operations are primarily __

hydrolysis

type of chemical and biochemical reactions that occur in anaerobic digestion

solubilization and size reduction

addition of water and breakage of chemical bonds

cellulases

enzymes that breakdown celluloses

amylases

enzymes breakdown starch into sugar

proteases

enzymes breakdown of protein bonds into amino acids

Hydrolytic and Fermentive Bacteria

examples are

Bacteroides (Human Gut; Colon in human, dog, cat & soil)

clostridia

bifidobacteria (probiotic food, milk, breastmilk)

Acidogenesis (Acid production Process) - acidogenic bacteria

another type of chemical and biochemical reactions that occur in anaerobic digestion is fermentation that has two important groups

conversion of simple sugars, amino acids & fatty acids to

organic acid such as

acetate, butyrate, formate, lactate, succinate

alcohols

ethanol and methanol

acetone

carbon dioxide, hydrogen, water

volatile and malodorous (bad odor) & can be used directly methane forming bacteria

characteristic of end product from Acidogenesis (Acid production Process)

Acetogenesis - acetogenic bacteria

another type of chemical and biochemical reactions that occur in anaerobic digestion is fermentation that has two important groups

conversion of organic acids and alcohol to acetic acid

acetate & hydrogen and can be used directly methane forming bacteria

end product or produced by Acetogenesis - acetogenic bacteria

fermentation

What type of chemical and biochemical reactions that occur in anaerobic digestion that is involved in several significant operational conditions like the following

production of

malodorous organic compounds

PHB granule

substrate for methane forming bacteria

rapid and undesired growth of septic loving filamentous organisms

rising sludge in secondary clarifiers and thickeners

methanogenesis

type of chemical and biochemical reactions that occur in anaerobic digestion

carried out by the organisms methanogens (methane formers)

Aceticlastic (Acetoclastic) methanogens

another type of chemical and biochemical reactions that occur in anaerobic digestion is methanogenesis

what group is this?

most common

produce most of the methane

produce methane by splitting acetate

split acetate into CH4 and CO2

methanosarcina and methanothrix (methanosaeta) are the ONLY ORGANISM TO USE acetate and produce CH4 and CO2

Hydrogen-utilizing methanogens (hydrogenotropic methanogens)

another type of chemical and biochemical reactions that occur in anaerobic digestion is methanogenesis

what group is this?

H2 as electron donor

CO2 as electron acceptor

produce 30% of all CH4

Methylotrophic methanogens

another type of chemical and biochemical reactions that occur in anaerobic digestion is methanogenesis

what group is this?

rare

produce relatively small quantity of methane

produce CH4 by removing methyl (-CH3) groups for simple substrate

ACETATE

CH3COOH

CARBON DIOXIDE

CO2

CARBON MONOXIDE

CO

FORMATE

HCOOH

HYDROGEN

H2

METHANOL

CH3OH

METHYLAMINE

CH3NH2

methane forming bacteria/ methanogens

group of archaea

bacillus, coccus and spirillum

oxygen sensitive anaerobes

found in rich in degradable organic compounds

live in animal digestive tract

live bet. mesophilic 30-35C and thermophilic 50-60C

40-50C almost all of them

active in pH 6.8-7.2

reproduce very slow 3-30 days

produce very few sludge

0.2 lbs of sludge/ lb of substrate degraded

Decreasing pH

In what condition this reaction will happen?

methane forming bacteria/ methanogens - less active

fermentive bacteria - active and continue to produce fatty acid