BEO Final - Chapter 10

1/42

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

43 Terms

what is Canada one of the largest producers of?

forest products in the world, with plants in nearly all provinces turning out a vast array of wood, furniture, and paper products.

The fourth industrial revolution

the phase of digitization in the manufacturing sector that involves data, analytics, and improved robotics

Research and Development (R&D)

work directed toward the innovation, introduction, and improvement of products and processes

newer and more advanced technologies/practices helps industries increase their production capability, improve productivity and expand their lines of new goods and services

production

the creation of goods and services using the factors of production: land, labour, capital, entrepreneurship, and knowledge.

historically was associated with manufacturing but has changed significantly

Production Management

has been the term used to describe all of the activities that managers do to help their firms create goods

Operations Management

a specialized area in management that converts or transforms resources (including human resources) into goods and services.

includes inventory management, quality control, production scheduling, follow-up services, and more

in the service industry this is all about creating high value experience for those who use the service.

service industries have increased their use of AI in their operations

Operations management planning

involves many of the same issues in both the service and manufacturing sectors

Facility location

the process of selecting a geographic location for a companies operations

the shift of manufacturing organizations from one city or province to another in Canada, or to other foreign sites is a major issue of the recent past

business move operations to:

reduce time to market

to build factories in foreign countries to get closer to international customers

or they move for the availability of inexpensive labour or the right kind of skilled labour

Outsourcing goods and services

this has become a cost saving practice

for example software development, call-center jobs, and back office jobs have been moving out of North America to developing countries

recently jobs like accounting, financial analysis, medicine, law, architecture and more have been outsourced

Facility layout

the physical arrangement of resources (including people) in the production process

Assembly-line layout

used for repetitive tasks

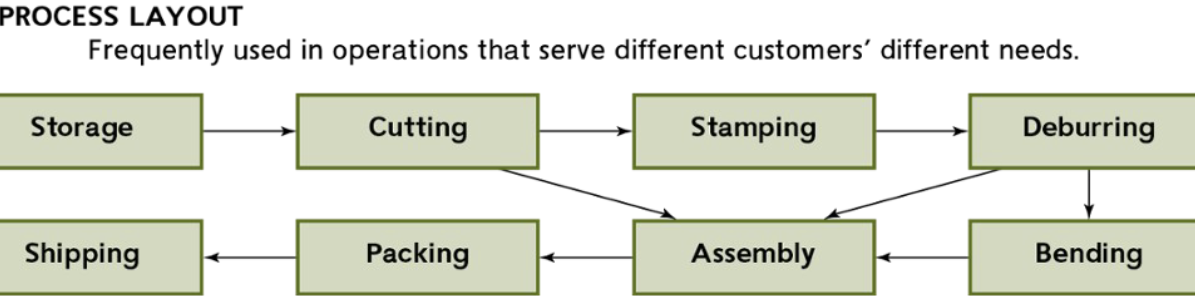

Process layout

frequently used in operations that serve different customers different needs

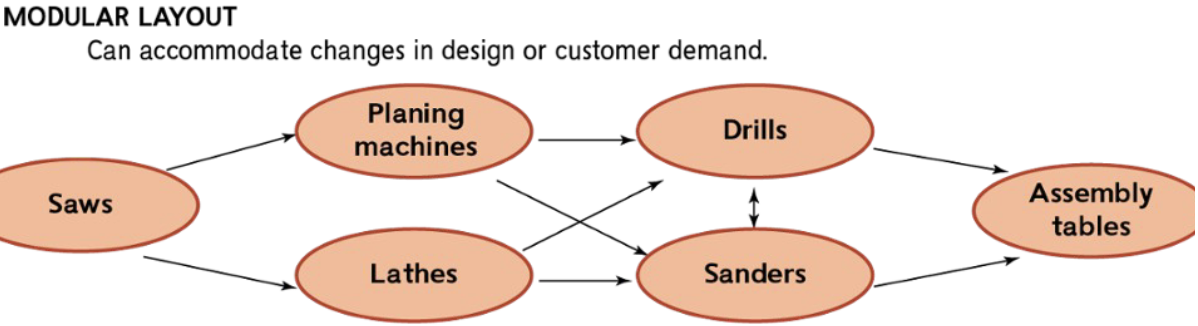

Modular layout

Can acomodate changes in design or customer demand

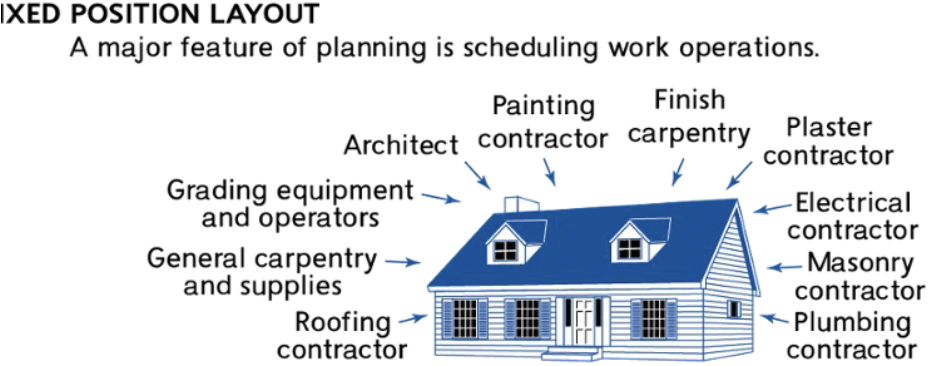

fixed position layout

a major feature of planning is scheduling work operations

Materials Requirement planning (MRP)

a computer-based operations management system that uses sales forecasts to ensure that needed parts and materials are available at the right time and place in a specific company

Enterprise resource planning (ERP)

a computer based application that enables multiple firms to manage all of their operations (finance, requirements planning, human resources, and order fulfilment) on the basis of a single, integrated set of corporate data

the newest version of MRP

Purchasing

the functional area in a firm that searches for quality material resources, finds the best suppliers, and negotiates the best price for quality goods and services

Just-in-time inventory (JIT)

keeps a minimum of inventory on the premises and parts, supplies, and other needs are delivered just in time to go one the assembly line.

to be effective this system requires excellent coordination

will run into problems when suppliers are farther apart

shipments could be delayed for a variety of reasons

Quality Control

maintaining quality means constantly producing what the customer wants while reducing errors before and after delivery to the customer

quality control approaches: Six Sigma Quality

sets a benchmark of just 3.4 defects per million opportunities, detecte potential problems to prevent their occurance

quality control approaches: statistical quality control (SQC)

the process some managers use to continually monitor all phases of he production process and assure quality is built into the product from the beginning

Quality control approaches : statistical process control (SPC)

the process of testing statistical samples of product components at each stage of production and plotting the test results on a graph

quality control approaches: Deming cycle

the process of testing statistical samples of product components at each stage of production and plotting the test results on a graph

Excellence Canada

this is the leading authority in Canada on organizational excellence based on quality systems, innovation, and healthy workplace criteria

The Canada awards for excellence (CAE) are presented annually to private, public, and not-for-profit organizations

ISO series and standards

the international organization for standardization (ISO) is a worldwide federation of national standards bodies from more than 160 countries that set global measures for the quality of individual products

it is a non-governmental organization established to promote the development of world standards to facilitate the international exchange of goods and services

ISO 9001

the common name given to quality management and assurance standards

the standards require that a company must determine what customer needs are, including regulatory and legal requirements

why is ISO 9001 so important

the European Union is demanding that companies that want to do business with the EU be certified by ISO standards

some major Canadian companies are also demanding that suppliers meet these standards

ISO 14001

a collection of the best practices for managing an organizations impact on the environment

certifications in both ISO 9001 and ISO 14001 would show that a fime has world class management system in both quality and environmental standards

Logistics

activities that focus on getting the right amount of the right product or services to the right place at the right time at the lowest possible cost

Supply chain

the sequences of firms that perform activities required to create and deliver a good or service to consumers or industrial users

supply chain management

the integration and organization of information and logistics activities across firms in a supply chain for the purpose of creating and delivering goods and services that provide value to customers

When implementing supply chain management, firms are trying to improve quality, reduce costs, increase flexibility and speed, and improve customer service while reducing the number of suppliers used.

Production Process

consists of taking the factors of production and using the inputs to produce goods, services, and ideas. planning, routing, scheduling, and the other activities are the other activities are the means to accomplish the objective—output

can either be continuous or intermittent

form utility

the value producers add to materials in the creation of finished goods and services (example making silicone unto computer chips as this changes the form)

also exists in services (example: baker turning flour into bread)

process manufacturing

physically or chemically changes materials

assembly process

puts together components

example: eggs, toast, and coffee → breakfast

Ways in which you can improve production techniques

flexible manufacturing

lean manufacturing

mass customization

robotics

computer aided design and manufacturing

3D and additive manufacturing

Flexible Manufacturing

involves designing machines to do multiple tasks so that they can produce a variety of products.

Flexible manufacturing (also known as flex) not only leads to improved productivity, but it may also result in cost savings.

lean manufacturing

the production of goods using less of everything compared to mass production: less human effort, less manufacturing space, less investment in tools, and less

engineering time to develop a new product.A company becomes lean by continuously increasing its capacity to produce high-quality goods while decreasing its need for resources.

Mass customization

tailoring products to meet the needs of a large number of individual customers

Robotics

Mass customization is easy for industrial robotics where machines can work 24 hours a day, seven days a week, with great precision.

Current studies predict that almost a quarter of automated tasks will be performed by robots in the next decade.

CAD, CAM and 3D printing

CAD/CAM, the use of both computer-aided design and computer-aided manufacturing made it possible to custom-design products to meet the

needs of small markets with very little increase in cost.The latest CAM technology includes 3D printers that make a product layer by layer until it appears as a finished good.

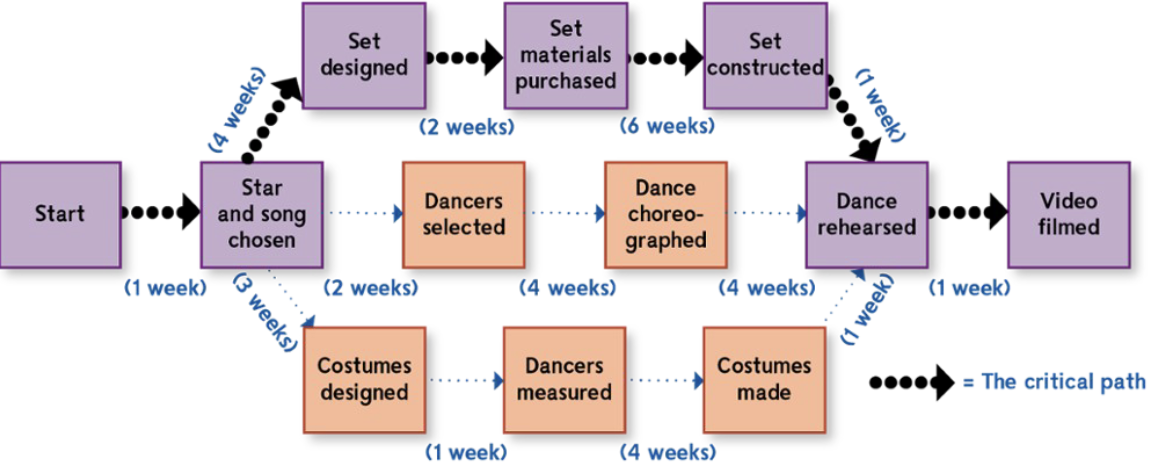

Control Procedurs: PERT

program evaluation and review techniques (PERT) is the technique for monitoring the progress of production

users analyze the tasks to complete a given project, estimate the time needed to complete each task, and compute the minimum time needed to complete the whole project.

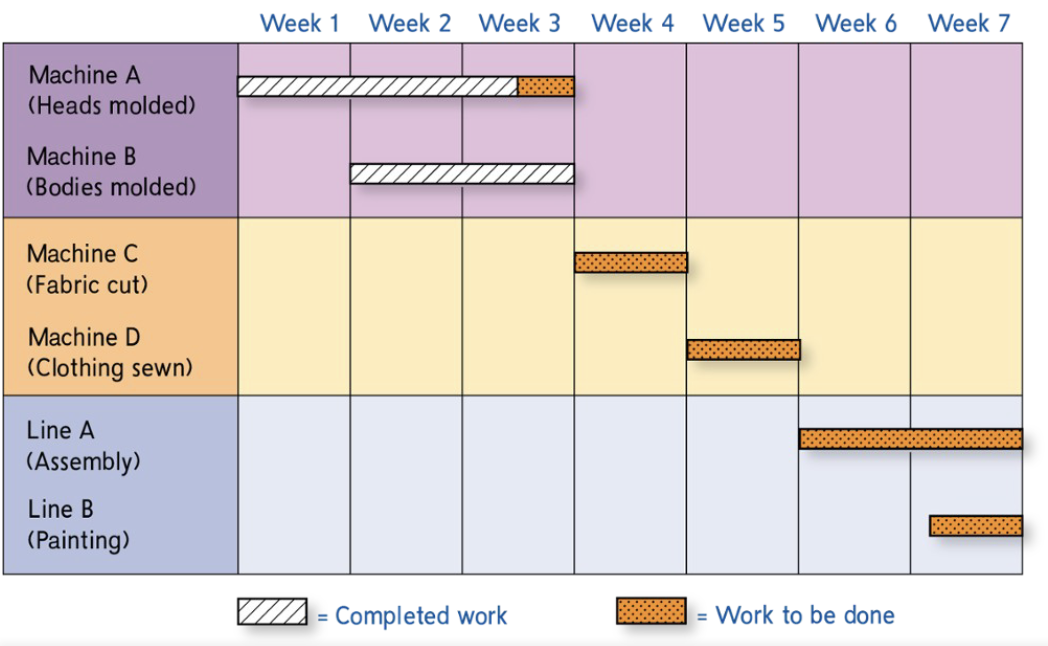

Control procedures: GNATT

A Gnatt chart is a bar graph, now also preperd by computer, that clearly shows what projects are underway and how much of the project has been completed at any given time