Ch 12 inventory management

1/47

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

48 Terms

types of inventory

raw materials

components

work-in-process

finished products

distribution

maintenance, repair, operating inventory

types of inventory ; raw materials

purchased items or extracted materials that are transformed into components or products

types of inventory : components

parts or subassemblies used in the final product

types of inventory : work-in-process

unfinished products that are in process

types of inventory : finished products

products that are ready to be sold to customers

types of inventory : distribution

finished products in the distribution system

types of inventory : maintenance, repair and operating inventory

supplies that are used in the production process without being part of the final product

inventory purposes :

anticipation inventory / seasonal inventory

fluctuation inventory or safety stocj

lot-size inventory or cycle stock

transportation or pipeline invetory

speculkative or hedge inventory

inventory purposes : anticipation / seasonal inventory

built in anticipation of future demand, to maintain level production (eg promotional programs, seasonal fluctuations, vacations)

inventory purposes : fluctuation / safety stock

carried as a buffer against unexpected demand variation, to assure customer service levels

inventory purposes : lot-size inventory/ cycle stock

results from the actual quantity ordered or produced, to lower unit costs (eg quantity discounts, production minimum)

inventory purposes : transportation or pipeline inventory

results from the movement between locations (eg between manufacturer and distribution facilities)

inventory purposes : speculative or hedge inventory

protects against future events, to allow continuous supply (eg strikes, price increases, product scarcity)

inventory management objectives :

provide desired customer service level

ensure cost-efficient operations

minimize inventory related investments

inventory management objectives : provide desired customer service level

percentage of orders shipped on schedule

percentage of line items shipped on schedule

percentage of dollar volume shipped on schedule

idle time due to material and component shortages

inventory management objectives : ensure cost-efficient operations

carry work-in-process inventory between workstations, to avoid idle time

maintain a level workforce despite seasonal demand, to avoid costs of overtime, hiring, firing, training, subcontracting

schedule long production runs, to decrease setup cost

order large volumes, to receive quantity discounts

inventory management objectives : minimize inventory related investments

calculate the inventory turnover = annual cost of goods sold / average invenrtory value

and the weeks of supply = average inventory on hand / average weekly usage

inventory related costs :

item costs

holding costs

ordering costs

shortage costs

inventory related costs : item costs

direct costs associated with the purchase (eg purchase price, transportation, insurance, taxes, handling,

inventory related costs : holding costs

variable expenses related to the value of inventory (eg capital (interest rate/ rate of return), storage, risk)

inventory related costs : ordering costs

fixed costs incurred for each order placed

(eg administration, handling, setup)

inventory related costs : shortage costs

incurred when demand exceeds supply

eg back order handling, loss of customer goodwill, lost saled

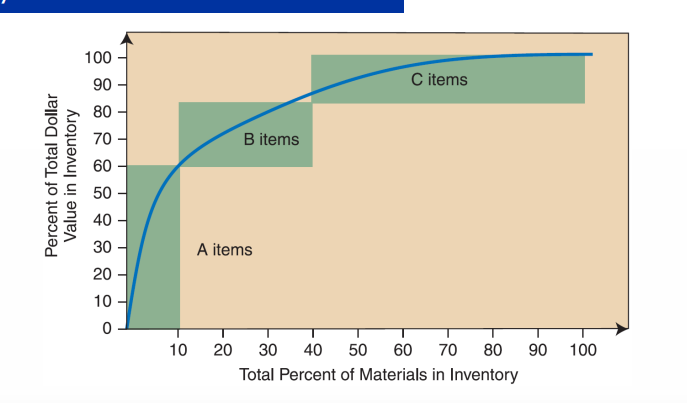

how to determine the appropriate review frequency for inventory items ? → pareto’s law (20/80)

items are segmented based on annual dollar volume

A items : high dollar volume → continuous review (EOQ model) → typically 20% of the items, representing 60-80% of inventory value)

B-items ; medium dollar volume → periodic review (TI model) → typically 30% of the items, representing 25-35% of inventory value

C-items : low dollar volume → less frequent review or two-bin system → typically 50% of the items, representing 5-15% of inventory value

inventory record accuracy errors reasons for occuring

errors occur because of unauthorized withdrawals of material (customer, employees), unsecured stockrooms, inaccurate paperwork, human errors

inventory record accuracy errors meaning

any displacement between what your computer system says you have and what is physically on the shelf

two methods to counter inventory record accuracy errors

periodic counting an opportunity to correct errors

cycle counting for prespecified items

→ automated inventory tracking system

common ordering approaches

lot-for-lot

fixed order quantity

min-max system

order n periods

common ordering approaches : lot for lot

order exactly what is needed

common ordering approaches : fixed order quantity

= order a predetermined alount each time an order is placed

common ordering approaches : min-max system

when on hand inventory falls below a predetermined minimum level, order a quantity that will take the inventory back up to its predetermined maximum level

common ordering approaches : order n periods

order enough to satisfy demand for the next n periods

determining order quantities : multiple-period models

fixed order quantity models → continous review

economic order quantity (EOQ)

economic production quantuty (EPQ)

extensions to the EOQ model : quantity discounts, safety stock

fixed time interval models → periodic review

target inventory TI

(single-period model)

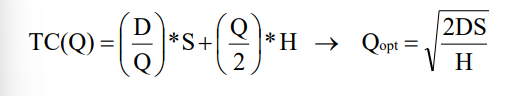

objective Economic order quantity (EOQ)

= satisfy demand with minimized sum of order costs and holding costs

→ to be determined : when to order and how many items per order

assumptions :

the total demand is known and constant (no safety stock)

all demand needs to be satisfied on time (no backorders)

the lead time L is known and constant

the fixed ordering cost S is known and constant (independent of quantity)

the holding cost is known and proportional to the average inventory level

no quantity discounts are applicable

the ordered items are delivered at once

economic order quantity (EOQ) order size that minimzes TC

screen

economic order quantity ; EOQ - when to place a new ordder

R = d*L (d = demand / week / day)

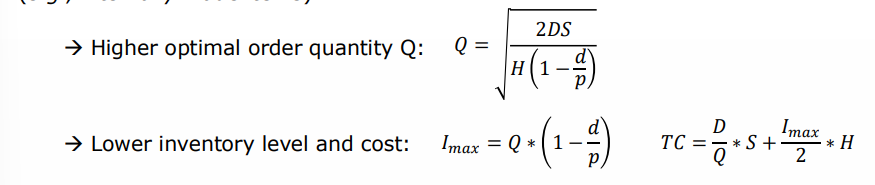

economi production quantity EPQ - difference compared to EOQ model

inventory is gradually replenished and can be used as soon as it arrived (eg internally made items)

Higher optimal order quantity

lower inventory level and costs

→ production rate p must be larger than depletion rate d

maximul inventory level Imax must be smaller than EPQ

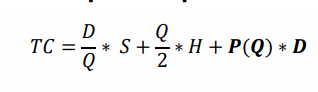

quantity discount model : difference compared to EOQ model

vendors allow quantity discounts when large quantities are ordered → multplie unit proces levels (P) depending on the quantity ordered

quantity discount model - procedure

1) starting from the lowest item price P, check which value of P is the first for which a feasable EOQ is obtained and compute TC

2) compute te TC for all order quantities Q at price breaks to curves associated with a lower item price P

3) select the option involving the lowest TC

when might companies invest in safetystock

if demand during the lead time is uncertain, to decrease the probability of shortages

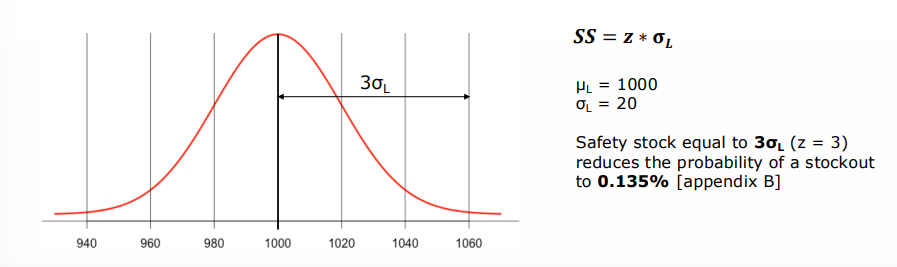

determine an adequate level of safety stock (SS) based on the order-cycle service level

the probability that demand during the lead time will not be exceed on-hand inventory

the use of safety stock changes the reorder point

the company places a new order when the remaining stock is 250 (instead of 200), which creates a buffer to avoid stockouts during the lead tume

the amount of safety stock to hold depends on

the variabillity of demand and lead time

and the desired order-cycle service level

order-cycle service level approach

assumption : demand during the lead tiem is normally distributed with meal mu L and standard deviation sigma L

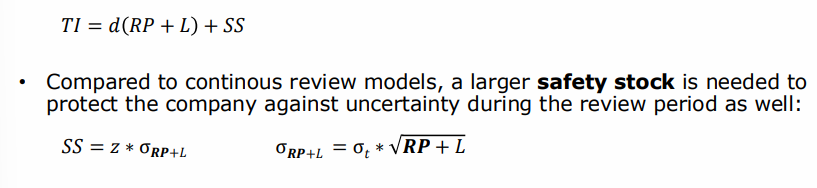

target inventory model : periodic review system

the inventory on hand is measured at fixed time intervals (eg once a week) → review period RP

the order quantity is variable and determined based on the difference between a target inventory level (TI) and the current inventory level on hand (OH)

periodic review system : advantages

no need to continuously monitor the inventory level

items from the same supplier can be reviewed on the same day to save order costs

periodic review system : disadvantages

replenishment quantities vary and may not qualify for quantity discounts

higher average inventory levels needed to protect against stockouts

target inventory level (periodic review system)

based on the expected demand during a review period and the lead time

compared to continous review models, a larger safety stock is needed to protect the company against uncertainty during the review period as well

single-period inventory level

designed for products with these characteristics

sold at their regular price at a specific occasion or during a short period (eg newspapaers, perishable products)

a discrete demand distribution is known

the salvage value is less than the purchasing cost → a loss is made on products that cannot be sold at their regular price