module 2

1/118

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

119 Terms

cleaning agent

An agent, usually containing a surfactant, used for the removal of substances (e.g., dirt, debris, microbes, and residual drugs or chemicals) from surfaces.

aseptic

free from contamination with harmful micro-organisms

technique

the methods or procedures used to manipulate products

aseptic technique

a set of methods used to keep objects and areas free of microorganisms and thereby minimize infection

usp

describes the minimum standards

facillities

develops SOPs (standard operation procedure)

disinfectant

a chemical or physical agent used on inanimate surfaces an objects to destroy fungi, viruses and bacteria

sporicidal agents

a chemical or physical agent that destroys bacterial and fungal spores when used at a sufficient concentration for a specified contact time. It is expected to kill al vegetative microorganisms

why is entry-angle of the needle into the vial stopper important (what are we trying to prevent?)

trying to prevent “coring”

or creating a hole in the vial that will later lead into leakage from the vials

when is a visual inspection of a compounded CSP performed

after compounding

the day when it will be sent out before releasing and dispensing it to the patient

swfit

in lab what is our cleaning agent

sterile 70% IPA

in lab what is our disinfecting agent

daily

when to clean and disinfect pass through chamber, work surfaces, and floors in classified areas

monthly (CSP1/CSP2), weekly (CSP 3)

when to use sporicidal agents on pass through chamber, work surfaces and flors in classified areas

monthly

when to clean/disinfect/apply sporicidal to walls/doors/door frames, ceilings, storage shelving and equipment outside PEC

not in compounding area

should not be completed during the same time someone is garbing

where should doffing occur per USP 797 guidelines

dirty side of ante room

where should doffing occur per ACPHS guidelines

gloves, gown, haircover, mask, shoe covers, wash hands

order of doffing per ACPHS guidelines

inspect

hold up to light, look through unlabeled side, rotate bag slowly at least once

compounding record

documents the compounding process

all category 1/2/3 and immediate use CSPs for 1+ patient

per USP 797 when is a compounding record required

after compounding

when does the compounder sign the compounding record

particles, leaks, cracks, label doesnt match, discoloration, improper seal

examples of when a CSP would not pass a final check (5)

first air

air that flows into hood via HEPA filter

injection port, vial stopper, ampule necks

critical sites to be wiped down with 70% IPA when making a single additive CSP (3)

bevel up

what direction should needle bevel be facing when entering rubber stopper of vial

different filters in the hood

HEPA filter

Pre-filter (on top of the hood always the air in the room to go through the hood and get cleaned and come out the HEPA filter)

prevent leaks

why is entry angle of needle into vial stopper important

aseptic technique

set of methods used to keep objects and areas free of microorganisms and thereby minimize infection

tacky mats

remove debris from the bottom of your shoes, located outside the ante room door

must, should

cleaning agents used in the PEC ____ be sterile, outside the PEC agents ____ be sterile

before compounding, after compounding

when to use IPA on the horizontal work surface in PEC

wipe with 70% IPA

what should be done to items before they are introduced to the PEC

should

conventionally manufactured sterile products ____ be used when available

1+ nonsterile comp, non sterile supplies/devices

when is sterilization required (2)

terminal, steam filter with 0.22 micron

methods of sterilization (3)

order of use

how should items be placed in the DCA

DCA

critical area within the ISO class 5 PEC where critical sites are exposed to unidirectional HEPA= filtered air, also known as first air

2-3 in, 6 in, 6in

DCA is ___ from the back screen ___ from each side and ____ inside the front of hood

zone of turbulence

the area behind any item (e.g., vial, IV bag, syringe) on the hood where sterile airflow from the HEPA filter is interrupted

spray with IPA

correction if hands are taken out of the DCA

12 hours

28 days

After a single-dose vial is punctured in a PEC, how long can it be used if it is stored appropriately?

After a multiple-dose vial is punctured in a PEC, how long can it be used if it is stored appropriately?

mL/hour

Which of the following units will you most commonly use in the Rate of Administration field of the Patient SpecificLabel

8

You are adding 8 mL of diluent to a drug vial for reconstitution. How many milliliters of air should you remove fromthe drug vial?

false

True or False: After preparing a CSP, you will label the CSP in the PEC.

environment, aseptic processing, starting components, sterility testing, storage

5 factors that affect sterility

Category 1 CSP

must be prepared in an ISO class 5 or better PEC

PEC may be located in an unclassified SCA or within cleanroom suite

Category 2 CSP

must be prepared in an ISO class 5 or better PEC, PEC must be located within clean room suite

category 3 CSP

must be prepared in an ISO class 5 or better PEC

PEC must be located within cleanroom suite

enhanced personnel competency

additional garbing

increased environmental monitoring

increased frequency of sporadical

sterility testing

bacterial endotoxin (one or more nonsterile components)

immediate use CSP

direct and immediate administration to a patient

Aseptic processes

physical and chemical compatibility

no more than 3 different sterile products

single dose containers discarded after use

admin begins 4 hours following start of prep

<12 hours

BUD for a category 1 CSP at room temperature

<24 hours

BUD for a category 1 CSP that is refrigerated

1 day

BUD for a category 2 CSP that was aseptically processed had no sterility testing performed, not prepared from only sterile starting components at CRT

4 days

BUD for a category 2 CSP that was aseptically processed had no sterility testing performed, not prepared from only sterile starting components that is refrigerated

45 days

BUD for a category 2 CSP that was aseptically processed, had no sterility testing performed, not prepared from only sterile starting components that is stored in the freezer

4 days

BUD for a category 2 CSP that was aseptically processed, had no sterility testing performed, was prepared from only sterile starting components that is stored at CRT

10 days

BUD for a category 2 CSP that was aseptically processed, had no sterility testing performed, was prepared from only sterile starting components that is stored in the refrigerator

45 days

BUD for a category 2 CSP that was aseptically processed, had no sterility testing performed, was prepared from only sterile starting components that is store in the freezer

30 days

BUD for a category 2 CSP that was aseptically processed and had sterility testing performed and passed, that is stored at CRT

45 days

BUD for a category 2 CSP that was aseptically processed and had sterility testing performed and passed, that is stored in the refrigerator

60 days

BUD for a category 2 CSP that was aseptically processed and had sterility testing performed and passed, that is stored in the freezer

14 days

BUD for a category 2 CSP that was terminally sterilized and had no sterility testing performed, that is stored at CRT

28 days

BUD for a category 2 CSP that was terminally sterilized and had no sterility testing performed, that is stored in the refrigerator

45 days

BUD for a category 2 CSP that was terminally sterilized and had no sterility testing performed, that is stored in the freezer

45 days

BUD for a category 2 CSP that was terminally sterilized and had sterility testing performed and passed, that is stored at CRT

60 days

BUD for a category 2 CSP that was terminally sterilized and had sterility testing performed and passed, that is stored in the refrigerator

90 days

BUD for a category 2 CSP that was terminally sterilized and had sterility testing performed and passed, that is stored in the freezer

60 days

BUD for a category 3 CSP that was aseptically processed, sterility tested, and passing all applicable test stored at CRT

90 days

BUD for a category 3 CSP that was aseptically processed, sterility tested, and passing all applicable test stored in the refrigerator

120 days

BUD for a category 3 CSP that was aseptically processed, sterility tested, and passing all applicable test stored in the freezer

90 days

BUD for a category 3 CSP that was terminally sterilized, sterility tested, and passing all applicable test stored at CRT

120 days

BUD for a category 3 CSP that was terminally sterilized, sterility tested, and passing all applicable test stored in the refrigerator

180 days

BUD for a category 3 CSP that was terminally sterilized, sterility tested, and passing all applicable test stored in the freezer

chemical/physical properties of drug, material of container, compatibility of container with CSP

factors that affect stability (3)

USP 797, expiration dates, manufacturer

3 factors to consider when determining BUD (more stringent applies)

regular needle

when filtering is required and a filter needle is used which needle is used first?

will change from regular needle to filter needle after fluid is drawn up and before priming

when filtering is required and a filter needle is used when is needle change made?

upright position

in what position is the filter needle/syringe held during priming

filter straw

when filtering is required and a filter straw is used which is used first?

use straw first to put liquid in syringe, then change to regular needle

when filtering is required and a filter straw is used when is the change of straw to needle made?

prime with the filter needle

with the filter needle procedure, will you prime to regular or filter needle?

no

do you need to prime a filter straw?

2

how many needles are required when using a filter disc

upright

what position is the filter disc held in during priming?

5 micron

what is the filter size for a filter needle

5 micron

what is the filter size for a filter straw

0.2 micron

what is the filter size for a filter disc

filter needle/straw

what filtering devices are appropriate to filter glass or paint from an ampule?

disc

what filtering devices are appropriate sterilize a product

docking

connecting the proprietary bag to the vial

activation

breaking the seal between the proprietary bag and vial so that fluid mixes with drug powder for reconstitution for drug to be given

ADD-vantage

proprietary bag system requiring a specific drug vial to twist in

Minibag plus

proprietary bag system that can use any vial and snaps on (better then ADD-vantage)

multiple dose container

a drug container that is penetrated multiple times and usually contains a preservative to inhibit growth of microorganisms and minimize risk of contamination

28 days

BUD for multi dose vials per USP 797

master formulation

required for all CSPs prepared from:

non-sterile ingredients

or

CSPs prepared for more than one patient

always, dont always

you ____ need a CR (compounding record) , you __ ____ need a MR (master formulation)

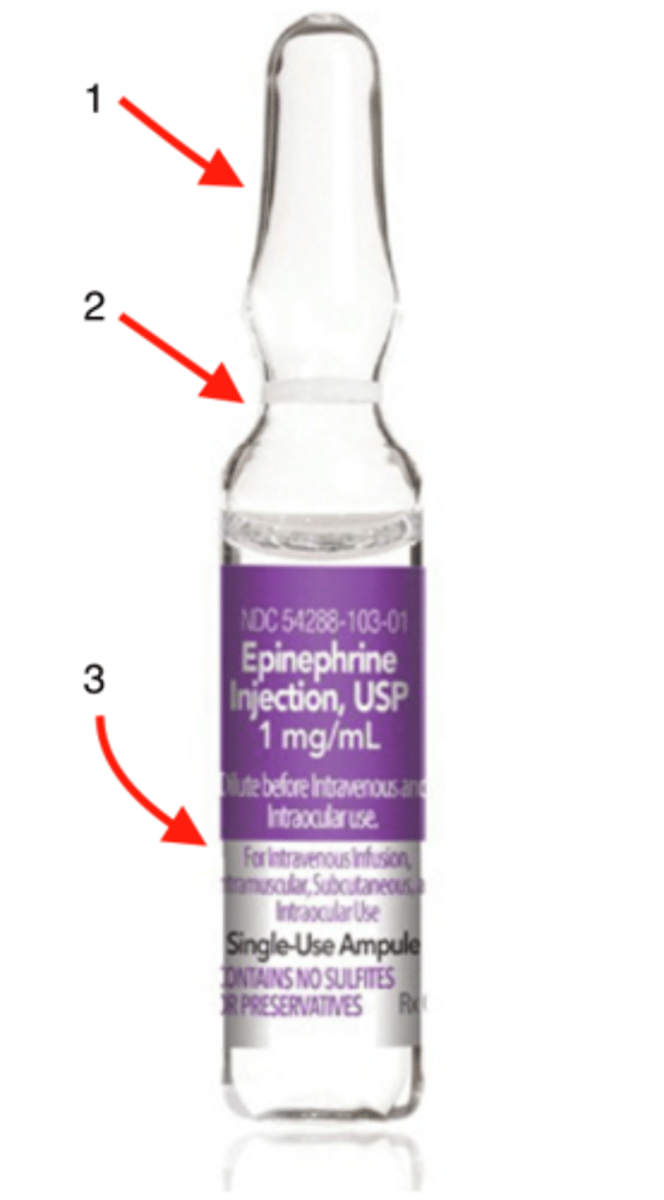

head

1

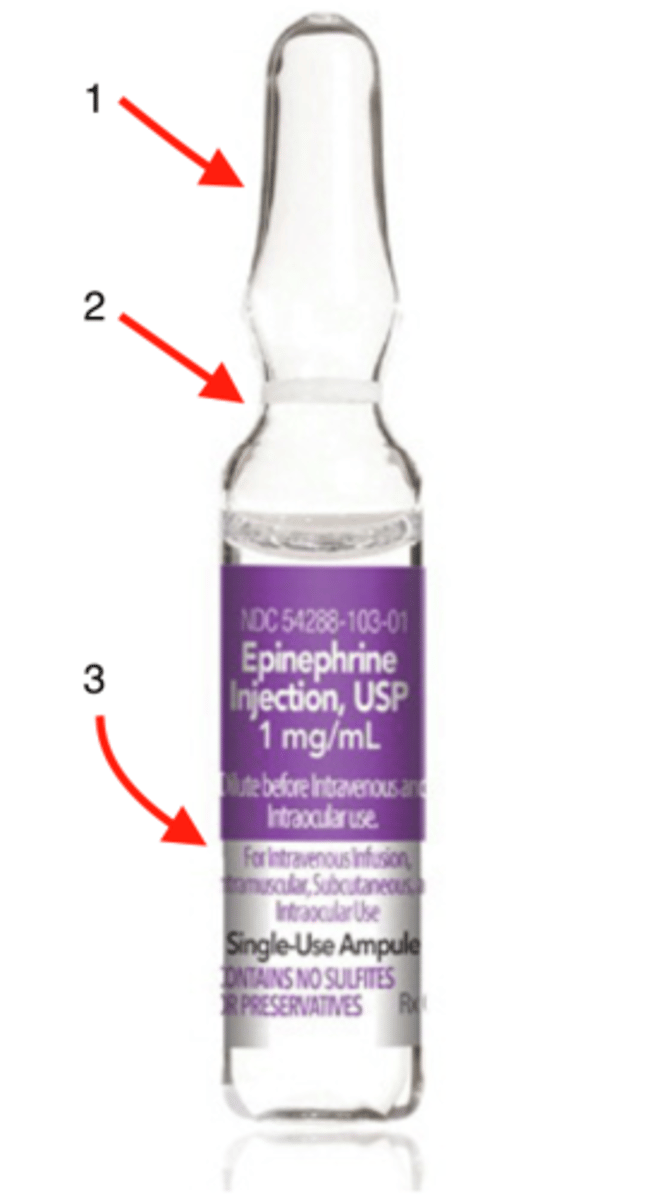

neck

2

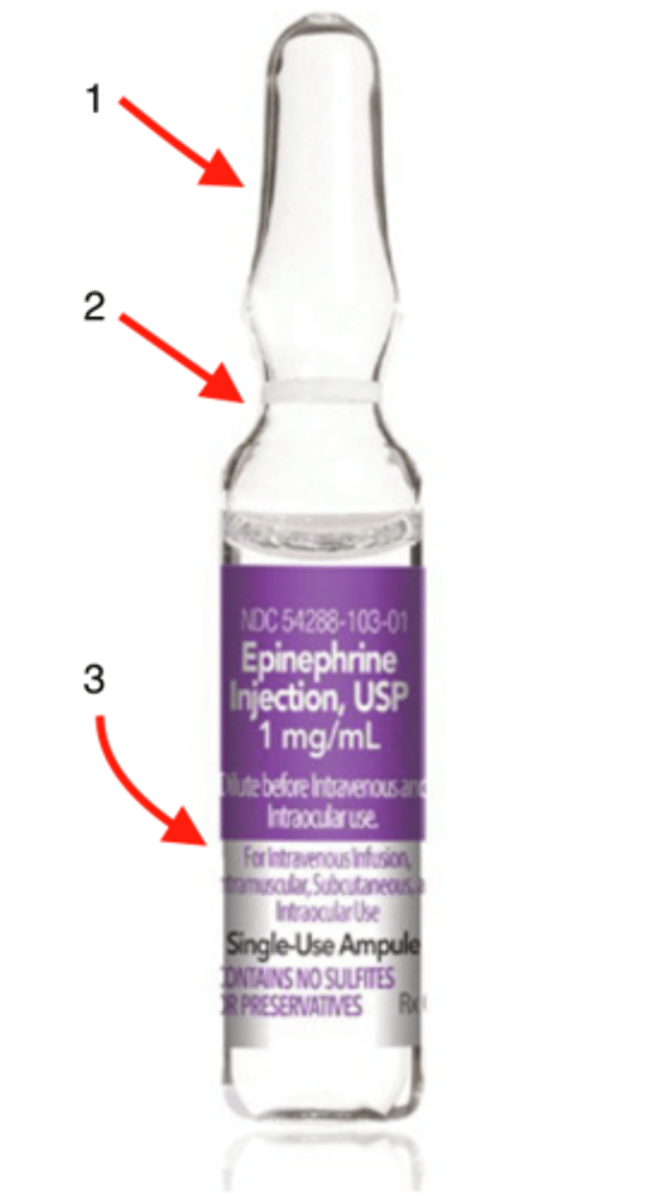

body

3