AS business topic 4 CAIE

1/32

Earn XP

Description and Tags

operations management

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

factors of production

land - all businesses need some form of land to operate their business for

labour - all businesses activity requires some labour input

capital - this refers to the tools, machinery, computers, and other equipment that businesses use to produce the goods and services they sell, capital also includes intellectual capital which is the intangible capital of a business which includes human capital, structural capital, and relational capital

enterprise - this is the decision-making skills and risk-taking qualities of entrepreneurs that are essential for new business formation

the stages of the transformational process

the transformational process os an activity or group of activities which transforms one or more inputs, adds value to them, and produces outputs for customers

the transformation process takes the inputs: enterprise, land, capital, and labour and through the transformational process turns them into outputs: finished goods, services, and components for other firms

contribution of operations to added value

operations managers can increase added value by effectively managing:

efficiency of production - keeping costs as low as possible which will help to give competitive advantage

quality - the goods or services must be suitable for the purpose intended

flexibility and innovation - the need to develop and adapt to new processes and new products is important

not all factors are operations management issues:

the design of the product

the efficiency of operations

branding to encourage consumers to pay more for the product than the cost of the inputs

the importance of productivity

productivity is to the same as level of production

productivity is the ratio of outputs to inputs during production

level of production is the number of units produced during a time period

production is the process that transforms inputs into outputs

measuring labour productivity

labour productivity = total output in a given time period / total workers employed

ways to raise productivity

there are four main ways in which to raise productivity:

improve the training of employees to raise skill levels

improve worker motivation

purchase technologically advanced equipment

more effective management

although, raising productivity does not always guarantee success

the importance of efficiency and effectiveness

efficiency - producing output at the highest ration of output to input

effectiveness - meeting the objectives of the business by using inputs productively to meet customers’ needs

the importance of sustainability of operations

sustainability of operations is the business operations that can be maintained in the long term

they can achieve sustainability of operations in a number of ways by:

reducing energy use and carbon emissions

reducing the use of plastic and other non-biodegradable materials

using recycled materials

manufacturing products that are recyclable

reducing waste from operation

buying from suppliers who use sustainable materials and processes

impact on a business of measured to improve sustainability of operations

benefits of increasing sustainability

reducing energy use can reduce energy costs

recusing use of plastic and non-biodegradable materials will attract more demand from green consumers

using recycled materials reduces demand for newly produced raw materials

making recyclable products reduces the cost of waste disposal

reducing waste from operations will reduce production costs

buying from sustainable suppliers helps to ensure that operations are sustainable and minimises the risk of bad publicity

limitations and costs of increasing sustainability

increasing sustainability might require capital investments

more environmentally friendly materials could cost more and may not protect or preserve goods as effectively as plastic

recycled materials might need to be cleaned or processed before use

development of recyclable products can be expensive and time-consuming

increasing sustainability might need investment in worker training and more accurate equipment

supplies from sustainable sources might be more expensive that from unsustainable sources so costs might rise

Labour intensive operations

labour intensive means it involves a high level of labour input compared with capital equipment

the advantages are:

interesting and varied work

low machine costs

one-off designs meet customer requirements

the limitations are

low output levels

skilled, high-paid workers

product quality depends greatly on the skills and experience of each worker

capital intensive operations

capital intensive means that it involves a high quantity of capital equipment compared with labour input

the advantages are:

economies of scale

consistent quality

low unit costs of production

the ability to supply the mass market

the disadvantages are:

high fixed costs

the costs of financing the equipment

high maintenance costs and the need for skilled workers to do repairs

the quick pace of technological change making the current equipment obsolete

operations methods - job production

job production is the production of a one-off item specially designed for the customer, it requires a highly skilled workforce

advantages

allows for specialist projects or jobs, often with high added value

high levels of worker motivation

disadvantages

high unit production costs

time-consuming

wide range of tools and equipment needed

operations methods - batch production

batch production is the production of a limited number of identical products and each item in the batch passes through on stage of production before passing to the next stage, it requires labour and machines which must be flexible to switch to making batches of other designs

advantages

some economies of scale

faster production with lower unit costs than job production

some flexibility in design of product in each batch

disadvantages

high levels of inventory at each production stage

unit costs likely to be higher than with flow production

operations methods - flow production

flow production is the production of items in a continually moving process, it requires specialised and expensive capital equipment and a high steady demand for standardised products

advantages

low unit costs due to constant working of machines

high labour productivity and economies of scale

disadvantages

it is inflexible and is often very difficult and time consuming to switch from one type of a product to another

expensive to set up flow-line machinery

operations methods - mass customisations

mass customisation is the use of flexible computer aided technology on production lines to make products that meet individual customers’ requirements for customised products, it requires many common components as well as flexible and multi skilled workers, it also needs flexible equipment that allows for variation in the product

advantages

combines low unit costs with flexibility to meet customers’ individual demands

disadvantages

expensive product re-design may be needed to allow key components to be switched to allow variety

expensive flexible capital equipment needed

problems of changing operations methods

the problems that result from changing from job to batch production include:

the cost of equipment needed to handle large numbers in each batch may be too high

additional working capital is needed to finance work-in-progress inventory

there is a risk of worker demotivation as there is less needs for an individuals’ craft skills

the problems that result form changing from job or batch to flow production include:

the cost of capital equipment needed for flow production may be too high

employee training needs to be flexible and multi skilled and so if this does not happen then workers may end up on one boring repetitive task and become demotivated

accurate estimates of future demand are needed to ensure that output matches demand

reasons for holding inventory

raw materials and components

work in progress

finished goods

inventory management needs to be handled effectively or else:

there might be insufficient inventories to meet unforeseen changes in demand

out-of-date or obsolete inventory smith be held if an effective rotation system is not used

inventory wastage might occur due to mishandling or incorrect storage conditions

high inventory levels have high storage costs and a high opportunity cost

inventory management is the process of ordering, storing, and using a company's inventory

costs and benefits of holding inventory

costs

opportunity cost

storage costs

risk of wastage and obsolescence

benefits

reduces risk of lost sales

allows for continuous productions

avoids the need for special offers from suppliers

large orders of new supplies reduces cost

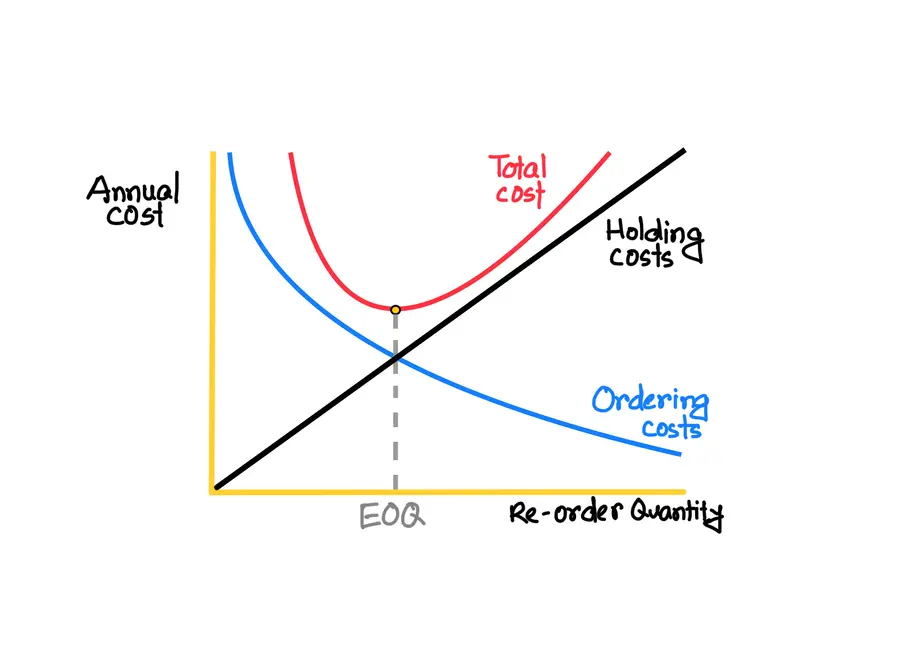

Optimum order size

It can be hard to purchase the right amount of inventories and so the purchasing manager must ensure that supplies of the right quality are delivered at the right time and in sufficient quantities to allow continuous production

the economic order quantity (EOQ) can be calculated for each product

economic order quantity is the optimum or least-cost quantity of stock to re-order taking into account delivery costs and stockholding costs

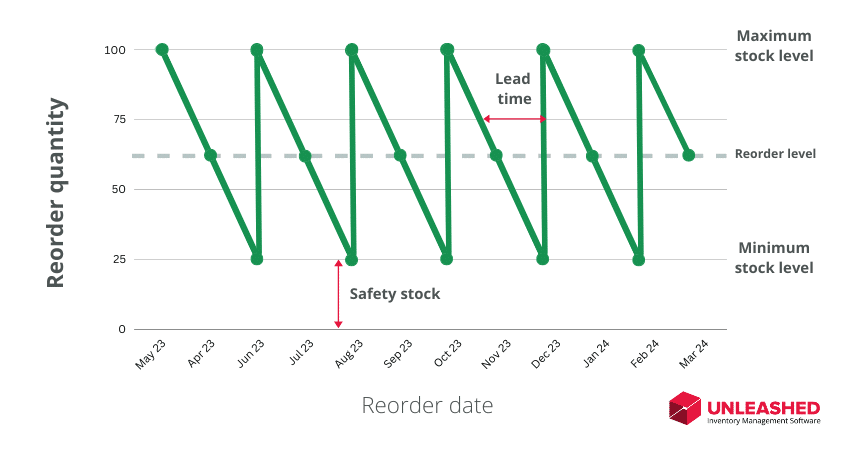

inventory control chart

A typical inventory control chart has certain key features:

buffer inventories - the greater the degree of uncertainty about delivery times or production levels, then the higher this buffer level will have to be

maximum inventory level - this may be limited by space or the financial costs of holding even higher inventories

re-order quantity - this is influenced by the EOQ

load time - the longer this period of time then the higher the re-order inventory level

re-order level - this depends on how long it takes suppliers to deliver new supplies and the rate of usage of inventories

buffer inventory - is the minimum inventory level that should be held to ensure that continuous production is possible should delivery delays occur or output increase

re-order quantity - is the number of units ordered each time

lead time - the time between ordering new supplies and their delivery

re-order level - is the level of inventory that triggers a new order to be sent to suppliers

the importance of supply chain management

operational efficiency can be improved by managing the supply chain with the aim of minimising costs and improving customer service and supply chain management is a management function of growing importance in nearly all businesses

supply chain is the network of all the businesses and activities involved in creating a product for sale, starting with the delivery of raw materials and finishing with the delver of the finished product

supply chain management is the handling of the entire production flow of a product to minimise costs and improve customer service

aims and benefits of supply chain management

aims to reduce the time period of the production process by:

establishing excellent communications with supplier companies, which helps to ensure the right number of goods of the right quantity are received exactly when needed

cutting the time taken to deliver all materials required for production by improving transport systems

speeding up the new product development process to improve the competitiveness of the business

speeding up the production process with technology and flexible workforces

minimising waste at all production stages to cut costs

benefits of effective supply chain management:

improve customer service

reduces operating costs

improves profitability

just-in-time (JIT) and just-in-case (JIC) inventory management

just-in-time inventory management aims to avoid holding inventories by requiring supplies to arrive just as they are needed in production and completed products are produced to order

just-in-case inventory management aims to reduce the risk of running out of inventory to the minimum by holding high buffer inventory levels

JIT is becoming a lot more common than JIC in industries in all economic sectors

advantages and disadvantages of JIT inventory management

advantages

capital invested in inventory is reduced and the opportunity cost of inventory holding is reduced

costs of storage and inventory holding are reduced

there is much less chance of inventories becoming outdated or obsolete

the greater flexibility needed for JIT leads to quicker response tomes to changes in consumer demand or tastes

the multi-skilled and adaptable stand required for JIT to work may gain improved motivation

disadvantages

any failure to receive supplies of materials or components in time will lead to expensive production delays

delivery costs will increase as frequent small deliveries are an essential feature of JIT

order administration costs may rise as so many small orders need to be processed

there could be a reduction in the bulk discounts offered by suppliers as they are small orders

the reputation of the business depends significantly on outside factors such as the reliability of suppliers

advantages and disadvantages of JIC inventory management

advantages

there is very little chance of running out of inventory

there is much less need for accurate sales forecasting than with JIT

economies of scale from very large orders of supplies/components are possible

disadvantages

high capital cost of finance invested in inventories

high storage, insurance and other costs are associated with inventory holdings

inventories could lose value if fashion or technology changes while they are being held

conditions for JIT to operate successfully

excellent supplier relationships

production employees must be multi-skilled and flexible

equipment and machinery must be flexible

accurate demand forecasts

IT equipment is needed for JIT

excellent employee-employer relationships

quality must be everyone’s priority

measurement of capacity utilisation

the maximum capacity is the highest Lebel of sustained output that can be achieved

capacity utilisation measures the proportion of that capacity that is currently being used and is calculated by the formula:

rate of capacity utilisation = current output level/maximum output level x100

the impact of operating under maximum capacity on a business

when capacity utilisation is low, fixed costs will have to be borne by fewer units and average fixed costs will rise

when a business is operating at less than fill capacity it means there is excess capacity

there are multiple methods of fixing this

the impact of operating over maximum capacity on a business

when capacity utilisation is at a high rate, the fixed costs of rent and machinery depreciation are spread over a large number of units

employees may feel under pressure due to the workload and this could raise stress levels, operations managers also cannot afford to make any production scheduling mistakes

regular customers who wish to increase their orders will have to be turned away or kept waiting for long periods

machinery will be working constantly which doesn’t leave any time for maintenance and repairs

methods of improving capacity utilisation - short term excess capacity

maintaining high output levels which adds to inventories and could be expensive and risky if sales do not recover

adopting a more flexible production system, allowing other products to be made that could be sold at other times of the year

insisting on flexible employment contracts so that, during periods of low demand and excess capacity, workers work fewer hours to reduce capacity and costs

methods of improving capacity utilisation - long-term excess capacity

rationalisation - which is the closing of factories or other production units

advantages

reduces overheads

results in higher capacity utilisation from the remaining production units

disadvantages

redundancy payments might have to be payed

workers may worry about job security

industrial action may be a risk

capacity may be needed later if the economy picks up to if the business develops new products

the business may be criticised for not fulfilling its social responsibilities

research and develop new products

advantages

new peoiucts will replace existing products and make the business more competitive

if introduced quickly enough, new products might prevent rationalisation and associated problems

disadvantages

this may be expensive

it may take too long to prevent cutbacks in capacity and rationalisation

without long-term planning, new products are introduced too quickly, without a clear market strategy, and may be unsuccessful

methods of improving capacity utilisation - capacity shortage

capacity shortage is when demand for a product exceeds production capacity

use subcontractors or outsourcing of supplies, components, or even finished goods

advantages

no major capital investment is required

it should be quite quick to arrange

it offers much greater flexibility than expansion of facilities

disadvantages

it gives less control over the quality of output

it may add to administration and transport costs

there may be uncertainty over delivery times and reliability of delivery

unit cost may be higher than in-house production due to the suppliers profit margin

invest capital in the expansion of production facilities

advantages

it increases capacity for the long term

the business is in control of quality and delivery times

the new facilities should be able to use the latest equipment and methods

other economies of scale should be possible too

disadvantages

the capital cost may be high

there may be problems with raising capital

it increases total capacity but problems could occult if demand falls

it takes time to build and equip a new facility and customers may not wait

outsourcing

outsourcing is where a business uses another business to undertake a part of the production process rather than doing it within the business using the firm’s own employees

the reasons for outsourcing are:

reduction and control of operating costs

increased flexibility

improved company focus

access to quality service or resources

freeing up internal resources

drawbacks of outsourcing are:

loss of jobs within the business

quality issues

customer resistance

security

corporate social responsibility