(2) 5 different powerpoints lol

1/13

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

14 Terms

Key components & features of quality assurance (QA) program

QA = total process ensure certain level of QUALITY is maintained

QC = systematic actions → ensure products/process performs accordingly

1) establish standards/procedures (action/tolerance levels)

2) simple & reliable tests

3) appropriate equipment to perform QC checks

4) systemic monitoring of equipment (hardware & software)

5) double check tx & tx plans, verification of dose delivery

What are needed by staff for a good QA program

1) communication

2) involvement of all staff (assign responsibilties)

3) knowledgebale staff (continuing education)

4) adequate # of staff (hard to ensure QA if you don’t have enough staff members)

5) document & reporting system

investigate unusual cases

collect/analyze statsitical info w/ reccs

regulatory body (ensure standards are met)

What are rules for recording patient information?

Enter:

- accurately

- concisely

- immediately

- chronological order of events

- proper terminology

Should be:

- signed/signed by person who made entry

- do NOT enter editorial comments (should be objective, no need for subjective comments)

What is a therapists role in a QA program?

1) perform warm up procedures

2) perform quality CONTROL tests on simulation + Tx units

3) *key: verify presence of completed & signed prescription & consent forms (everyday when you treat, review the tx plan w/ patient)

4) deliver accurate Tx adhering to prescription

5) record Tx delivered

6) evalulate health status of patient

7) patient/family education

8 provide care/comfort/needs of patient

9) immobilization devices

10) treatment planning

LO1: define the performance objectives & criteria for RT equipment

making sure the system works the way its meant to.

just as it did when first bought, to throughout the rest of its life

objectives =

- tolerance level

- action level

- functional

LO2: define & discuss:

1) tolerance level

2) action level

3) functionality

1) difference b/w measured value & expected value is AT or BELOW tolerance level → no action needed

2) difference b/w measured value & expected value is EXCEEDS action level → action is needed

→ bring back to tolerance level

→ ask for physicist to fix

3) it either WORKS or DOES NOT WORK

All equipment in RT is subject to __

What are the 3 types?

Maintenance

1) scheduled maint = procedures on a day, weekly, monthly basis

2) preventative maint = planned, replacement of parts

3) non-scheduled = break downs, requires technician

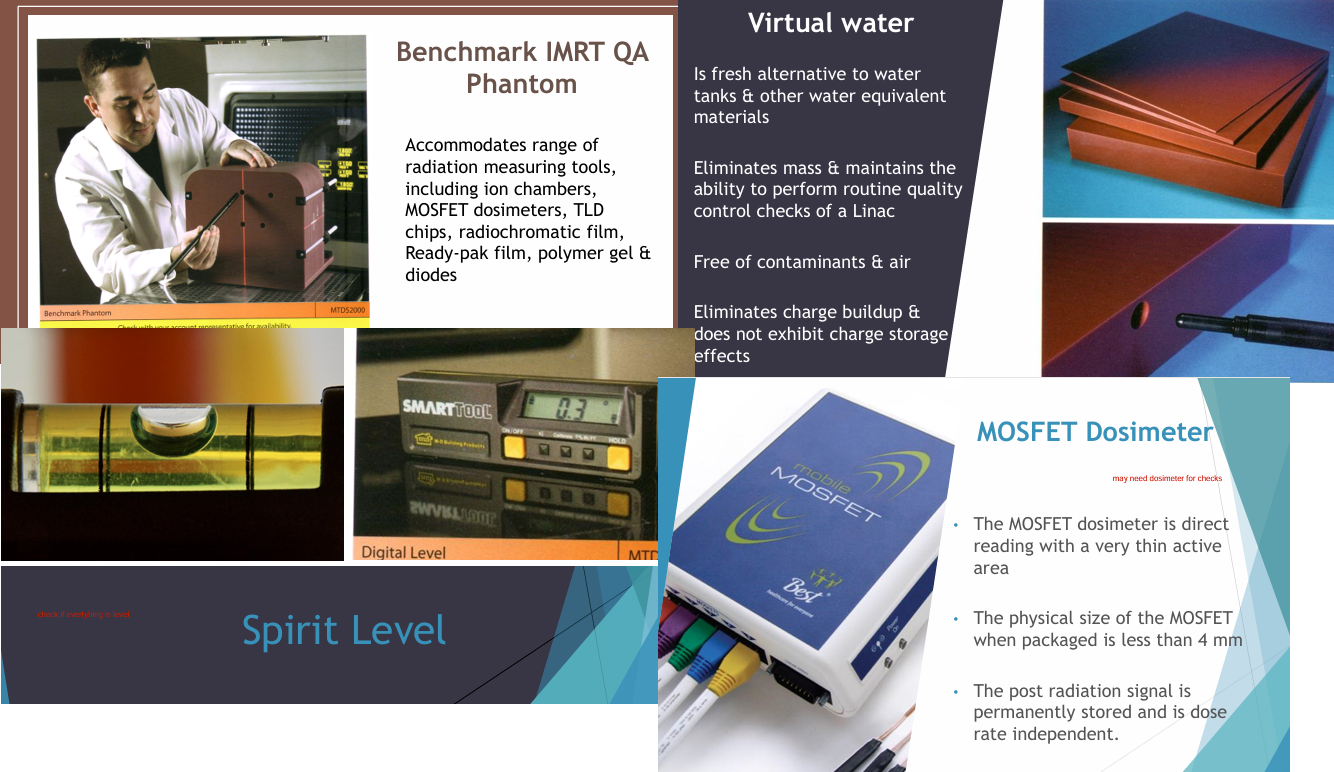

Eqipment used in RT for QC check:

- MOSFET Dosimeter

- Spirit Level

- QA phantom

- Virtual water

LO1: How do we ensure all equipment adhere to the highest quality?

We do:

A) acceptance testing (physicist)

- check what exactly were getting

- equipment meets performance specs & safety standards

- examine manufacturer specs & detect systematic errors

- accept the unit → then pay

- takes long time

B) commissioning (physicist)

- check everything (field size)

- distances etc

- takes long time

C) Regularly scheduled quality control

- medical physicist/radiation therapist

just remember yellow; more on this below

LO2: Identify the CRITERIA for evaluation of RT equipment

1) Functionality = equipment work or NOT

2) Reproducibility = are routine tests same as those produced when machine first set-up

3) Accuracy = do results deviate from expected or defined value

(eli: are results close to what they’re supposed to be?)

4) Characterization = performance of unit be characterized by measurements

(can we measure and describe how well the equipment is performing - we want 10Mv, is it actually giving 10mV)

5) Completeness = are procedures performed, reviewed, analyzed, documented?

Describe ACCEPTANCE TESTING

What’s the PURPOSE?

Purpose:

- units meet specs

- establish baseline for QC program (what we RT’s refer to)

- familiarize customer w/ new unit

- establish compliance w/ radiation safety codes

Others:

- Radiation survey = make sure radiation levels outside room are safe, room barrier strong enough to contain beam

- test of interlocks, warning lights, emergency switches

Describe COMMISIONING

What’s the PURPOSE?

Preparing for clinical service (use on ppl)

- collect additional beam data

→ used for benchmark for all future beam testing + calculation of radiation dose

Discuss the role of RT in QC standards

RT does:

regular & repetive contact w/ pt, tx units, tx records

assess units day to day

assess units day to day

- measure performance

- compare performance to given standard

- perform actions necessary to KEEP/REGAIN standard

- create QA standards based on national/internation bodies

- implement guideliens/standards

What is QC?

quality control = system of routine technical activities to measure & control the quality of the product or service

QC standards based on recommendations by national/international bodies

-there are slight variations in values to be expected, therefore tolerance & action levels are determined