Plasticity L1,2,3- Mechanical behaviour

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

32 Terms

How to tell if directions lie in plane?

Direction will be perp to plane normal

Dot product of plane normal + direction = 0

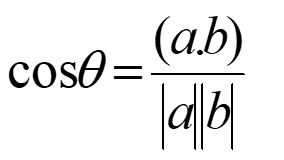

How to find angle between 2 planes?

What is the stacking direction in a cubic material?

[111]

What is work hardening?

increasing stress with increasing plastic strain

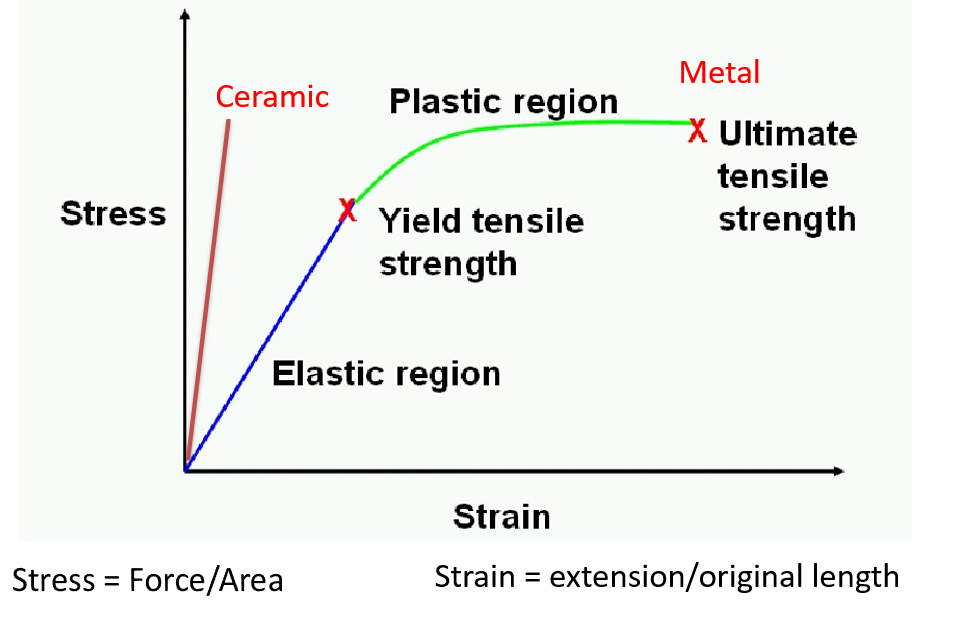

Toughness

Measure of energy of fracture

Where does necking start?

At strains beyond UTS (ultimate tensile strength)

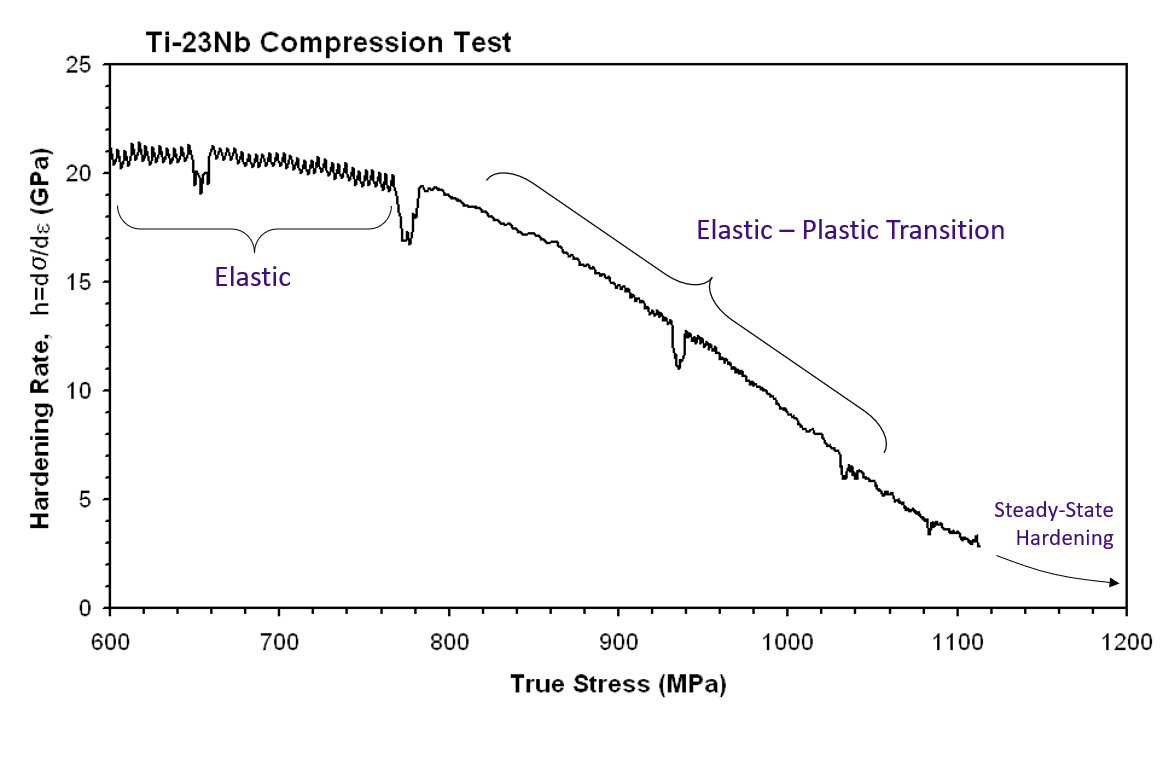

Stress-strain curve

When does necking and uniformity of deformation occur?

occurs when the rate of work hardening is less than

stress increase as the specimen diameter decrease hence area decreases

Why does non-homogenous deformation occur?

microstructural effects (Luders bands, polymer chain straightening)

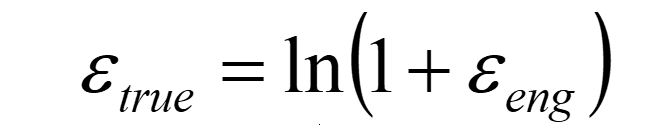

Equation for true strain

εeng = engineering strain

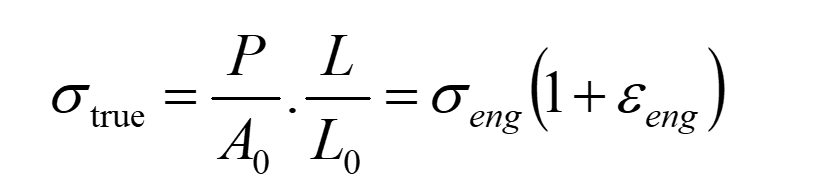

Equation for true stress

P = load (N)

A = Area

σeng = engineering stress

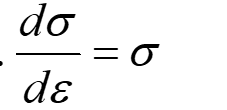

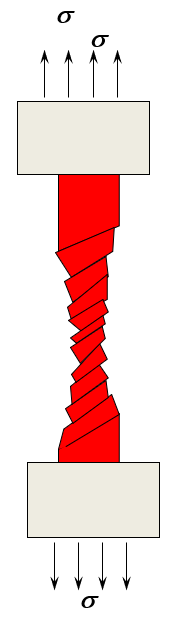

Considere’s Criterion

As vol = constant for plastic deformation

The faster the work hardens, the more stress

Work hardening curve

During plastic transition, work hardening rate decreases

Condition for neck to develop:

mσ/ε ≤ σ

Condition for necking :

ε≥m

m = work hardening rate

Slip plane

The plane on which deformation occurs- highest atomic density (except dislocations in ionic ceramics must be charge neutral)

slip system = slip plane + slip direction

Slip direction

the direction within slip plane + generally along line of highest atomic density

Slip system

crystal deforms by motion of dislocation on slip plane + in certain direction

Difference between Sessile + Glissile dislocations:

In Glissile dislocations slip plane contains both line + burgers vector ⇒ mobile

Sessile doesn’t

Plane family in FCC that has highest atomic density

{111}

Direction family in FCC that has highest atomic density

<110>

When does yield occur?

When resolved shear stress on 1 of favourable slip systems exceed a critical value i.e. critical resolved sheer stress,τcrss

Equation for CRSS on dislocation:

τcrss = σy cosλcosΦ

λ = angle of force normal to slip direction

Φ = angle to plane

σy= yield stress

cosλcosΦ = m = Schmid factor

During tensile testing, why will crystal lattice rotate ?

interplanar spacing remains constant

no. planes stays constant

hence shear strain from dislocation glide causes material to lengthen ⇒ angle of plane must change

Taylor criterion

In polycrystalline materials, each grain can’t deform freely so must take account of neighbouring grains

must be 5 + independent slip systems to ensure ductility in polycrystalline solid

results from 6 independent components of strain (3 normal + 3 shear)

During plastic def, vol = constant +

Δvol = sum of 3 normal strains

Hexagonal materials don’t have 5 independent slip systems so brittle

Type of schmid factor(m) we want:

Want the absolute largest/ maximum m value

Energy per unit length of dislocation equation

E ≈ αGb²

G = Sheer modulus

b = burgers vector

E = Energy per unit length of a dislocation

Frank’s rule

(b1² + b2²) > b3²

b= burgers vector

Why do we use Frank’s rule?

To decide if it’s energetically favourable for dislocation to combine or separate

Equation for true strain

εtrue = ln(1+εeng)

Equation for true stress

σtrue = σeng(1+εeng)

For plastic deformation

Volume is conserved