Polymer Manufacturing Processes

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

32 Terms

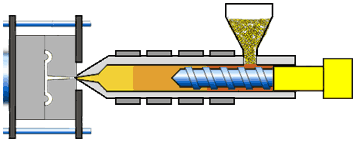

Injection moulding

Pros of injection moulding

Complex 3D shapes producible, high volume producible, consistent quality

Cons of injection moulding

Initial setup costs high, die moulds are expensive to produce

Signs of injection moulding

Complex 3D shape, integrated fixings, webbing, ejector pin marks

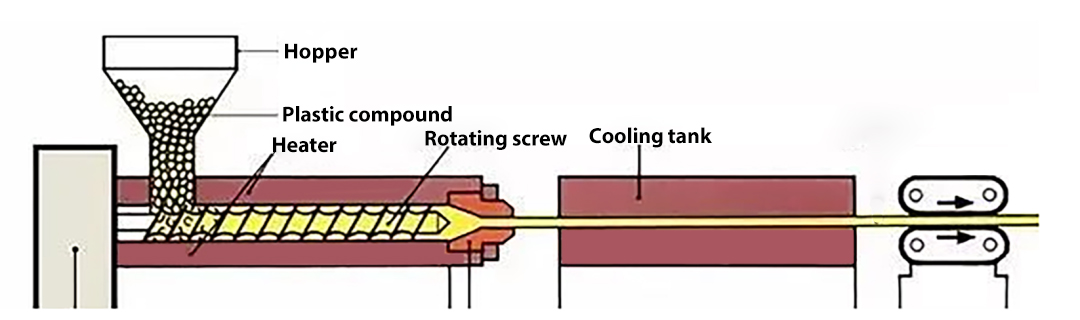

Extrusion

Pros of extrusion

Very long products producible, constant sectional profile with no taper angle, relatively complex shapes producible

Cons of extrusion

Limited cross sectional size, high setup cost

Signs of extrusion

Long piece, constant sectional profile, no seam marks

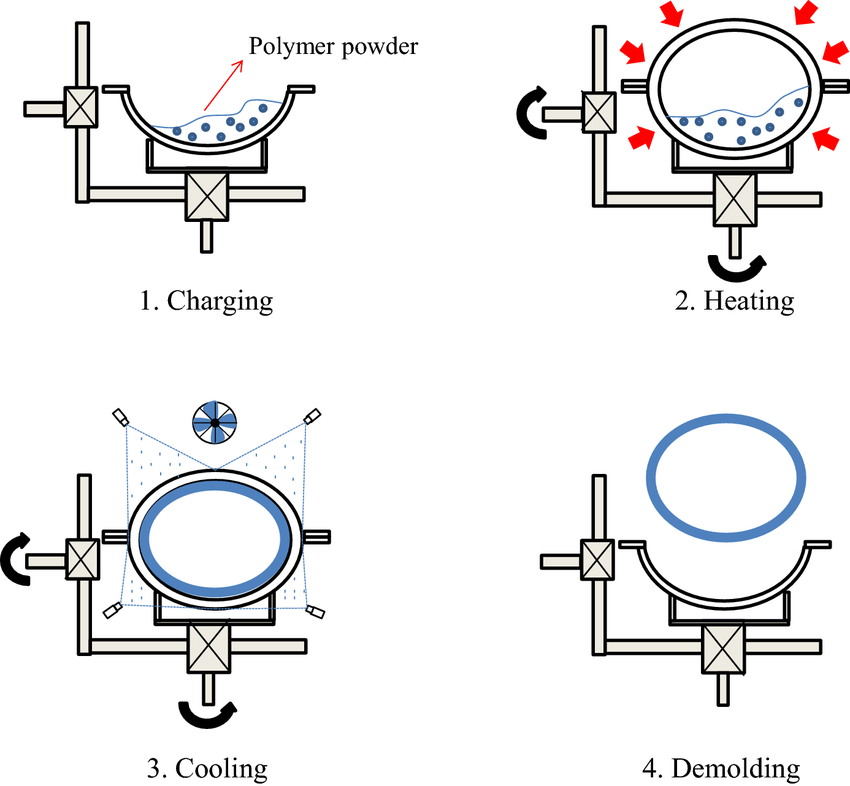

Rotational moulding

Pros of rotational moulding

Very large products producible, one piece hollow products producible

Cons of rotational moulding

Slow process, relatively simple shapes only

Signs of rotational moulding

One piece hollow product, large, relatively simple shape, thick walls

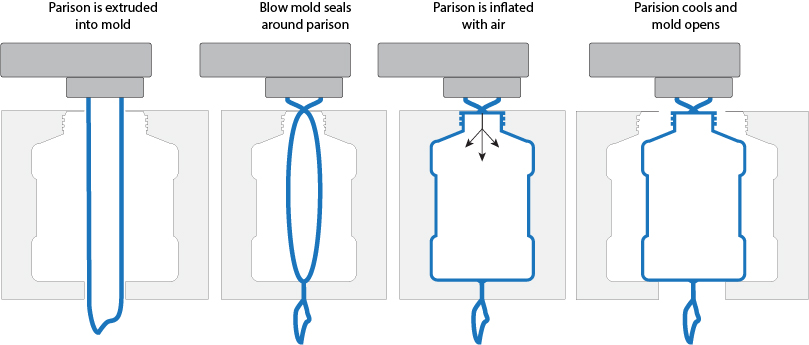

Extrusion blow moulding

Pros of extrusion blow moulding

Low energy, low cost process, one piece hollow shapes producible

Cons of extrusion blow moulding

Limited shapes producible

Signs of extrusion blow moulding

One piece hollow object, one opening, rounded edges, clear base seam

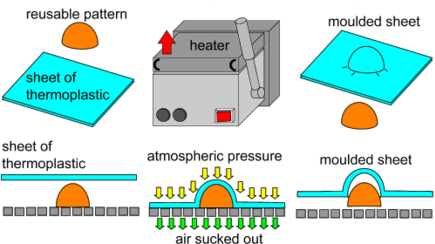

Vacuum forming

Pros of vacuum forming

Low energy, low setup cost, moulds quick and cheap to make

Cons of vacuum forming

Simple shapes only, slow process, large draft angles needed

Signs of vacuum forming

Simple shape, large draft angle, irregular wall thickness

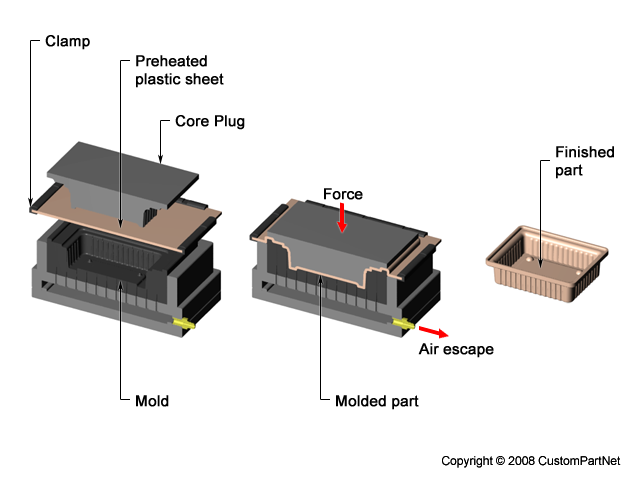

Thermoforming

Pros of thermoforming

Low energy, low setup cost, moulds quick and cheap to make, greater detail than vacuum forming

Cons of thermoforming

Same as vacuum forming - simple shapes with large draft angles and slow process

Signs of thermoforming

Simple shapes with fine details, large draft angle, irregular wall thickness

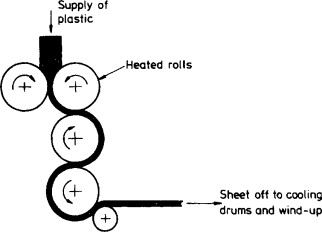

Calendering

Pros of calendering

Very thin film produced, fast process, very large pieces possible

Cons of calendering

Only suitable for film, high setup cost

Signs of calendering

Thin film

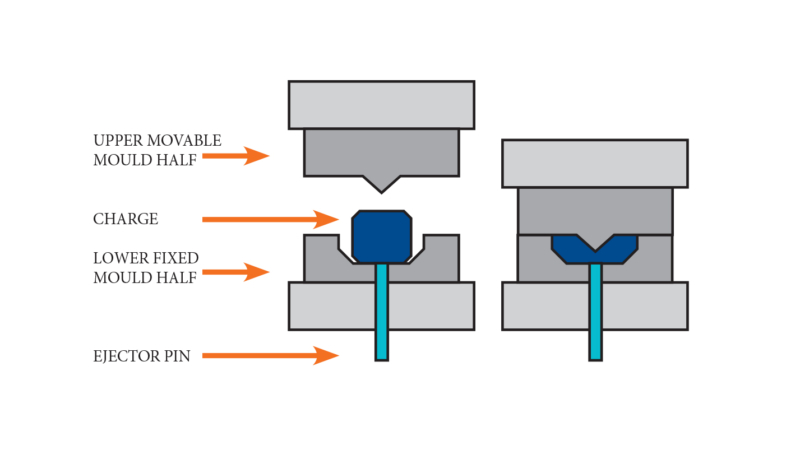

Compression moulding

Pros of compression moulding

Large, complex shapes producible, thick wall sections producible

Cons of compression moulding

Slow process, high energy, no undercuts

Signs of compression moulding

Thick walls, small draft angle, relatively complex, seam lines