Lecture 8 - Ceramics and Other Materials

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

19 Terms

What are Ceramics, Glasses and Glass Ceramics?

Definition: an ____ , ___ solid

prepared from ____ materials and

fabricated into products through the application

of ___Primarily ___ and ___ bonds

Categories of these materials

____ (bio-resorbable or inert) ceramics

glass, ___,

glass-ceramics, starts as a ____ and ends up as

a ____ ceramics possibly with a

residue ___ matrix.

General properties:

____ bond =>Difficult to ____, very low ____,

high ____ strength, low ____ strength;Low ___ and ___ conductivity

____ and high ___

High ___ → dental materials

Aesthetically pleasing appearance

Definition: an inorganic, nonmetallic solid

prepared from powdered materials and

fabricated into products through the application

of heatPrimarily ionic and covalent bonds

Categories of these materials

crystalline (bio-resorbable or inert) ceramics

glass, amorphous,

glass-ceramics, starts as a glass and ends up as

a polycrystalline ceramics possibly with a

residue glassy matrix.

General properties:

Ionic bond =>Difficult to shear, very low ductility,

high compressive strength, low tensile strength;Low thermal and electrical conductivity

Refractory and high Tm

High hardness dental materials

Aesthetically pleasing appearance

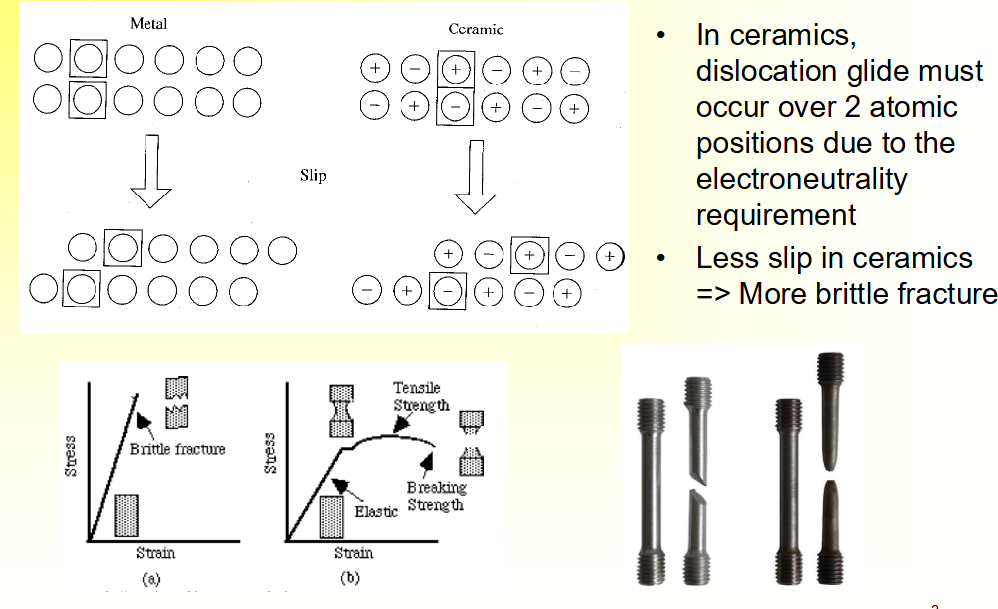

Variation in Slip Between Metal and Ceramics

• In ceramics, dislocation glide must occur over ___ atomic

positions due to the ____ requirement

• ___ slip in ceramics

=> More ___ fracture

• In ceramics, dislocation glide must occur over 2 atomic positions due to the

electroneutrality requirement

• Less slip in ceramics

=> More brittle fracture

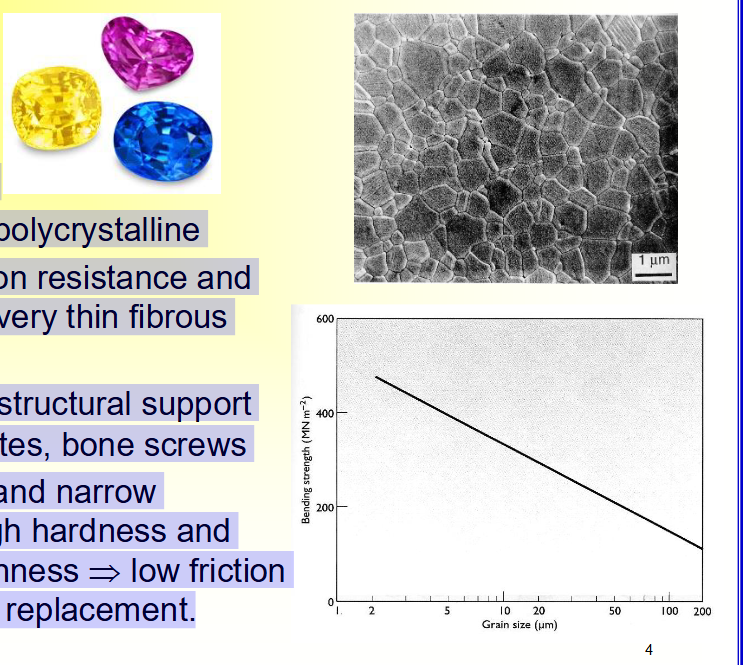

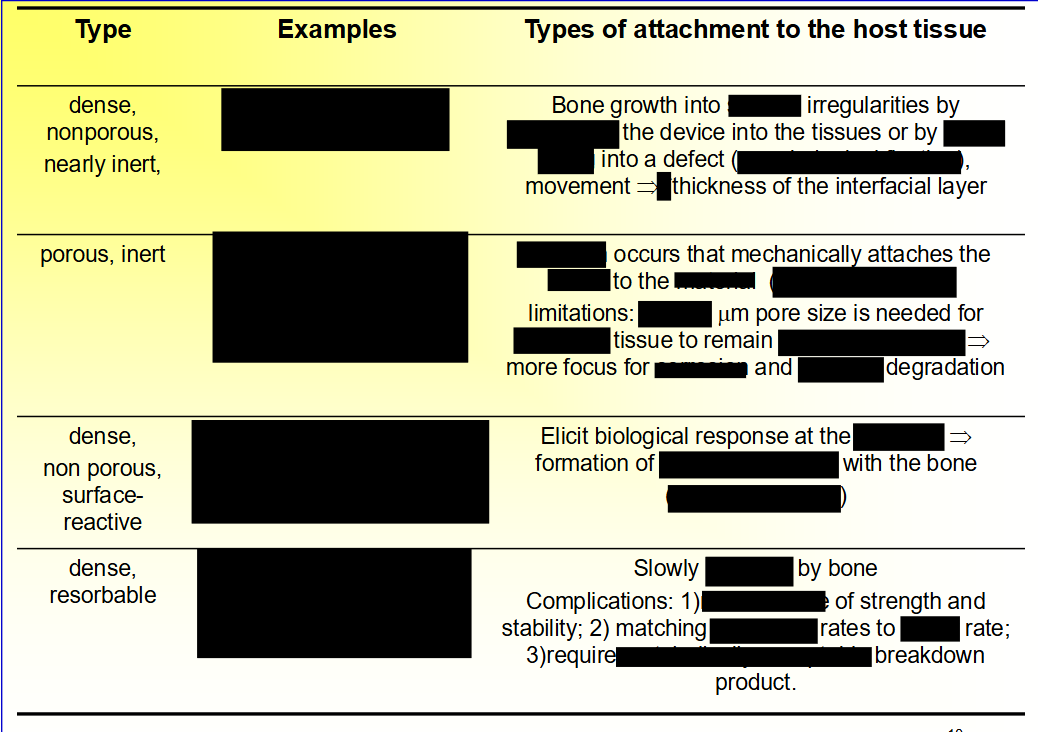

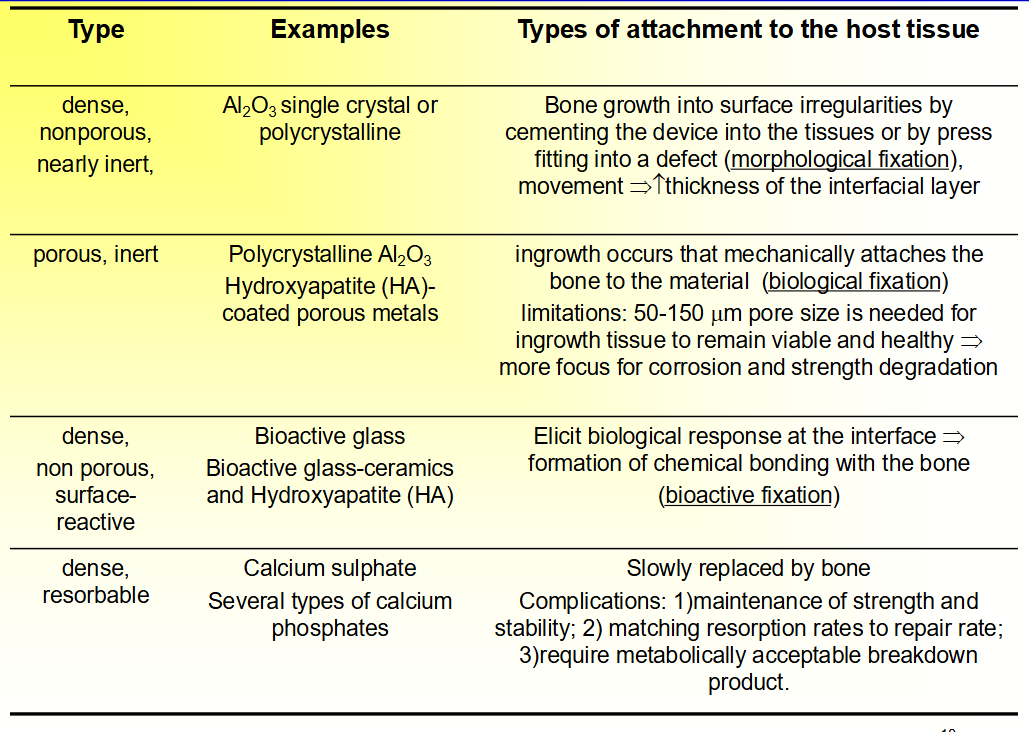

Nearly Inert Bioceramics

• ___ (Al2O3)

• ___ or ___

• ___ crystal or ____

• Excellent ____ resistance and ____ (very ___ fibrous layer)

• ___ strength → structural support such as ___ plates, ____ screws

• ___ grain size and ___ distribution → high ___ and

low surface ___ → low ___ and wear → joint replacement.

• Alumina (Al2O3)

• Sapphire or ruby

• Single crystal or polycrystalline

• Excellent corrosion resistance and biocompatibility (very thin fibrous layer)

• High strength → structural support such as bone plates, bone screws

• Small grain size and narrow distribution → high hardness and

low surface roughness → low friction and wear → joint replacement.

Joint Replacement Applications of Alumina

____ socket and ball, coefficient of friction ___ with time and approaches the value of a ___ joint → wear 10 times ___ than metal-PE surfaces

Alumina socket and ball, coefficient of friction decreases with time and approaches the value of a normal joint wear 10 times slower than metal-PE surfaces

Biodegradable or Resorbable Ceramics:

What causes the biodegradability or resorption?

– Physiochemical ____, depending on the ____ of the material and local __

– Physical ___ into small ___ as a result of preferential chemical attack of ___ ____

– Biological factors, such as ___, which also causes a decrease in local ___

– Physiochemical dissolution, depending on the solubility of the material and local pH

– Physical disintegration into small particles as a result of preferential chemical attack of grain boundaries

– Biological factors, such as phagocytosis, which also causes a decrease in local pH

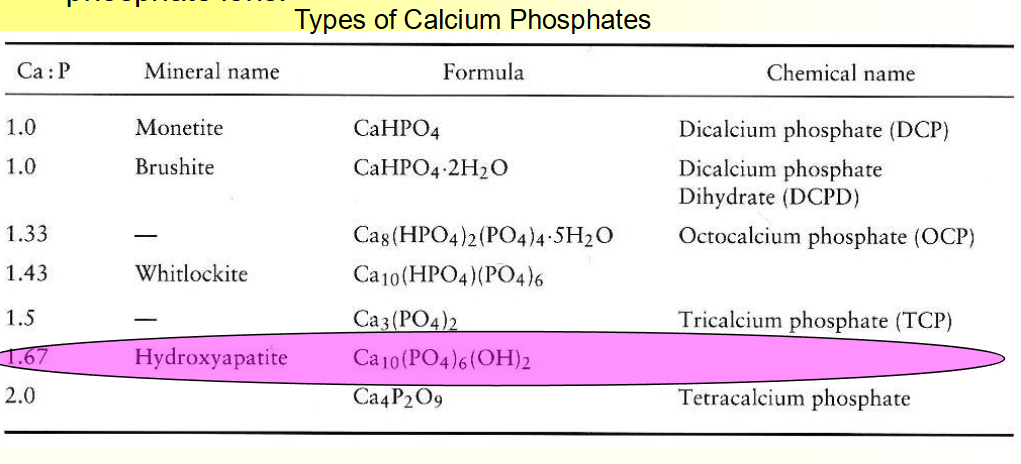

Calcium Phosphate

• The mineral phase of bone and teeth is mainly ___ and

___ ions.

____ CERAMIC

• Solubility and hydrolysis ___ with increasing __/_ ratio.

• Ca/P ratio __ 1 is not suitable for biological implantation.

• The mineral phase of bone and teeth is mainly calcium and

phosphate ions.

bIODEGRADABLE CERAMIC

• Solubility and hydrolysis decrease with increasing Ca/P ratio.

• Ca/P ratio less than or equal to 1 is not suitable for biological implantation.

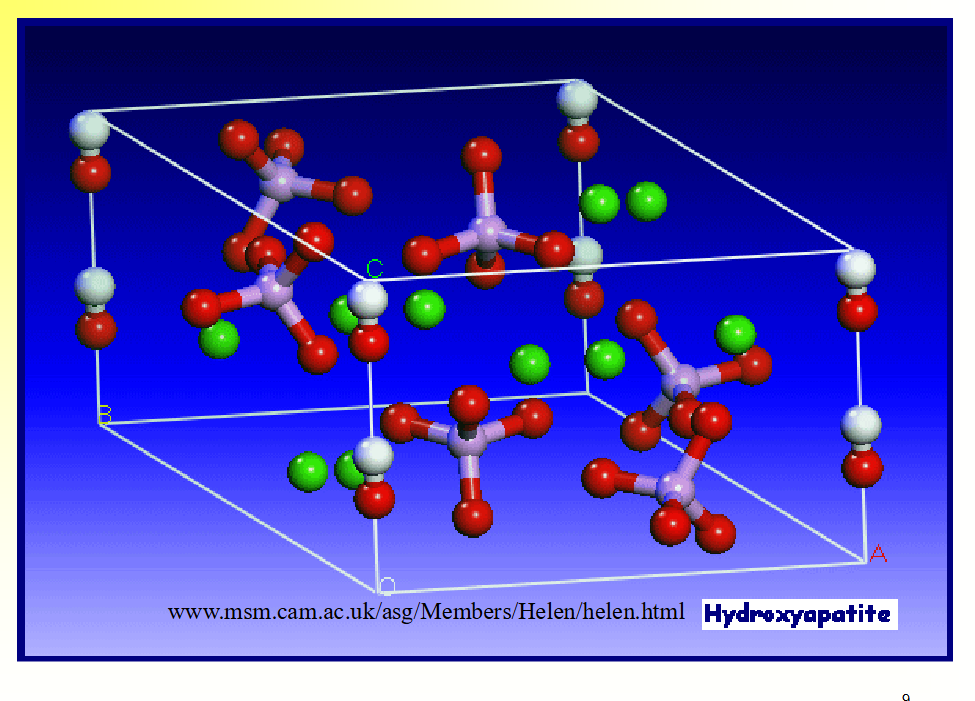

Hydroxyapatite (HA)

Ca10(PO4)6(OH)2,

Hard tissue contain _% HA (mostly carbonate HA), 25% water and 15% organic materials. HA can be converted from ___ or animal __

Manufacturing:

– Ca(NO3)2 + NaH2PO4 → precipitate of HA → drying and filtering → furnace 1150 degrees C → grounding →sieving → pressing in a die → sinteringElastic modulus (__-___ GPa),

– Enamel: 74GPa

– Dentin: 21GPa

– Compact bone: 12-18 GPaHexagonal rhombic crystal

– Substitute of OH- by F-, __ chemical stability

– Defects and impurities can be characterized by __ ___ (crystalline phase), ___ (chemical groups)

Ca10(PO4)6(OH)2,

Hard tissue contain 60% HA (mostly carbonate HA), 25% water and 15% organic materials. HA can be converted from coral or animal bone

Manufacturing:

– Ca(NO3)2 + NaH2PO4 → precipitate of HA → drying and filtering → furnace 1150 degrees C → grounding →sieving → pressing in a die → sinteringElastic modulus (40-117 GPa),

– Enamel: 74GPa

– Dentin: 21GPa

– Compact bone: 12-18 GPaHexagonal rhombic crystal

– Substitute of OH- by F-, more chemical stability

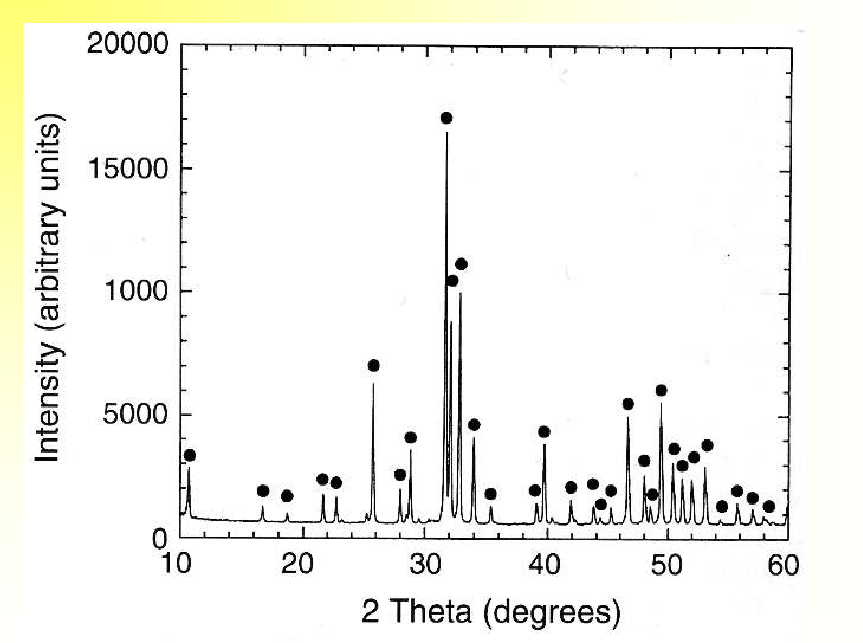

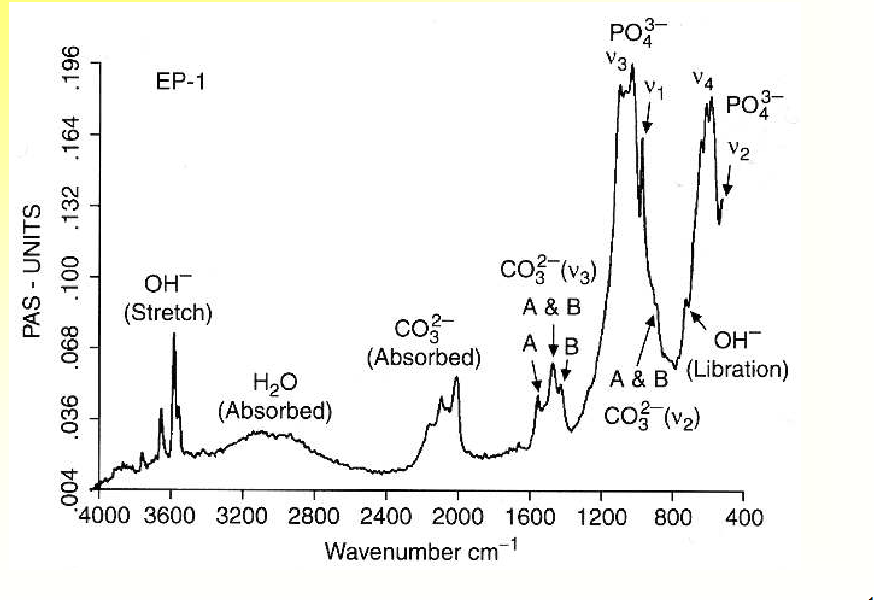

– Defects and impurities can be characterized by X-ray diffraction (crystalline phase), FTIR (chemical groups)

X-Ray Diffraction of HA

Typical FT-IR Spectrum of HA

Factors Influence Degradation Rate of Calcium Phosphate

– Rate of degradation increases as

• Chemical susceptibility to dissolution ____

• Surface area ____

• Crystallinity ____

• Crystal perfection ____

• Grain size ____

• F- substitution ____

– Rate of degradation increases as

• Chemical susceptibility to dissolution increases

• Surface area increases

• Crystallinity decreases

• Crystal perfection decreases

• Grain size decreases

• F- substitution decreases

Clinical Application of Calcium Phosphate

• Advantages: ___ and ___

• ___ bonding mechanism

– differentiated osteoblasts produce a cellular bone matrix of 3-5 micrometer layer at the surface → 0.05 to 0.2 micrometer → normal bone ____

through a thin epitaxial bonding layer to the ___ ___

• As dense form:

– small ___ implants such as in the ___

___ implant,

• As porous form

– ____ for filling bony defects in orthopedic

and dental surgery

• As coatings

– with reinforcing ___ posts as in dental

materials,

• As fillers in ____

• Advantages: bioactive and osteoconductive

• Bioactive bonding mechanism

– differentiated osteoblasts produce a cellular

bone matrix of 3-5 micrometer layer at the surface →

0.05 to 0.2 micrometer → normal bone attached

through a thin epitaxial bonding layer to the bulk

implant

• As dense form:

– small unloaded implants such as in the middle

ear implant,

• As porous form

– granules for filling bony defects in orthopedic

and dental surgery

• As coatings

– with reinforcing metal posts as in dental

materials,

• As fillers in composites

Bioactive Glasses and Glass-ceramics

• Specific composition → highly ____ surface in aqueous medium

– ___ less than or equal to 60%,

– ___ Na2O and CaO,

– ___ CaO/P2O5

• The surface forms a ___ ____ carbonated ___ layer that

provides the bonding ___ with tissue. The ____ strength

greater than or equal to the bulk strength of both the ___ and tissue

• Clinical applications

– 45S5, SiO2 45%, Ca/P=5:1

– Ceravital®, middle ear surgery to replace ___ damaged by chronic infection

– ____ defect repair, maintenance of the alveolar ridge for denture wearers

– Toothpaste ingredient against ____

• Specific composition → highly reactive surface in aqueous medium

– SiO2 greater than or equal to 60%,

– high Na2O and CaO,

– high CaO/P2O5

• The surface forms a biologically active carbonated HA layer that

provides the bonding interface with tissue. The interfacial strength

the bulk strength of both the implant and tissue

• Clinical applications

– 45S5, SiO2 45%, Ca/P=5:1

– Ceravital®, middle ear surgery to replace ossicles damaged by chronic infection

– Periodontal defect repair, maintenance of the alveolar ridge for denture wearers

– Toothpaste ingredient against sensitivity

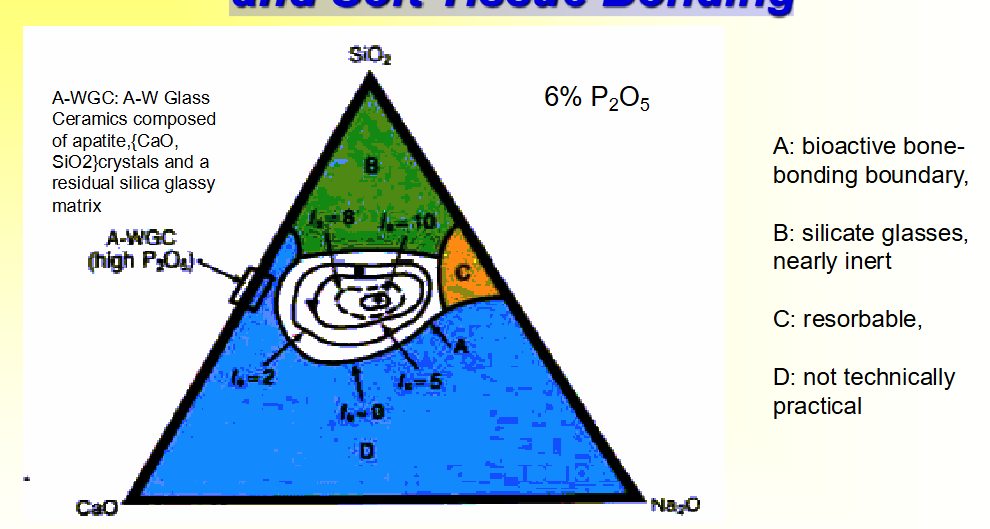

Compositional Dependence (w%) of Bone and Soft Tissue Bonding

The level of bioactivity of a specific material can be related to the time for more than

50% of the interface to be bonded, (t0.5bb) e.g.: (Index of Bioactivity) IB = (100/t0.5bb).

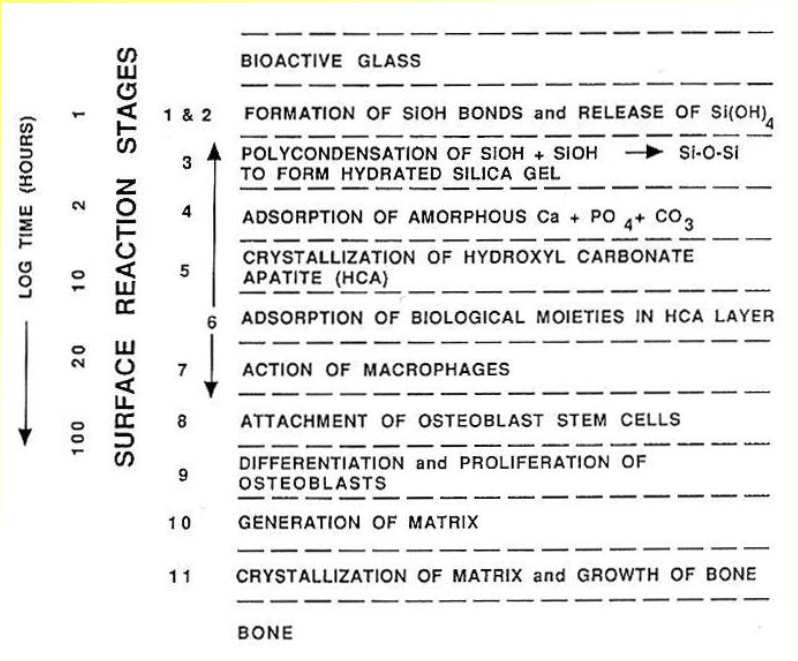

Sequence of Interfacial Reactions Involved in Forming a Bond Between Tissue and Bioactive Glass

Fill out this chart

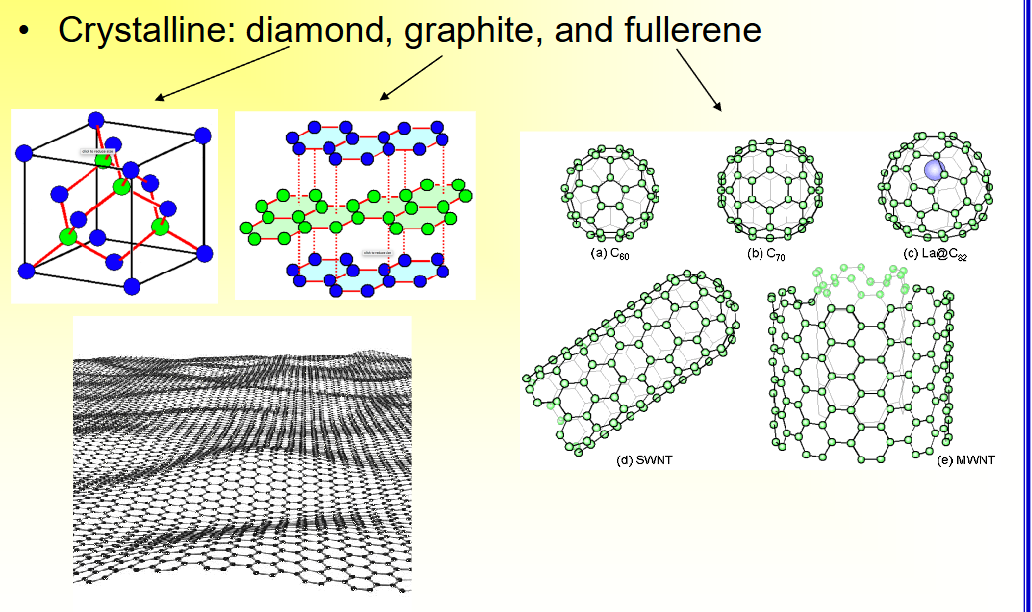

Crystalline Carbon Materials

• Crystalline: diamond, graphite, and fullerene

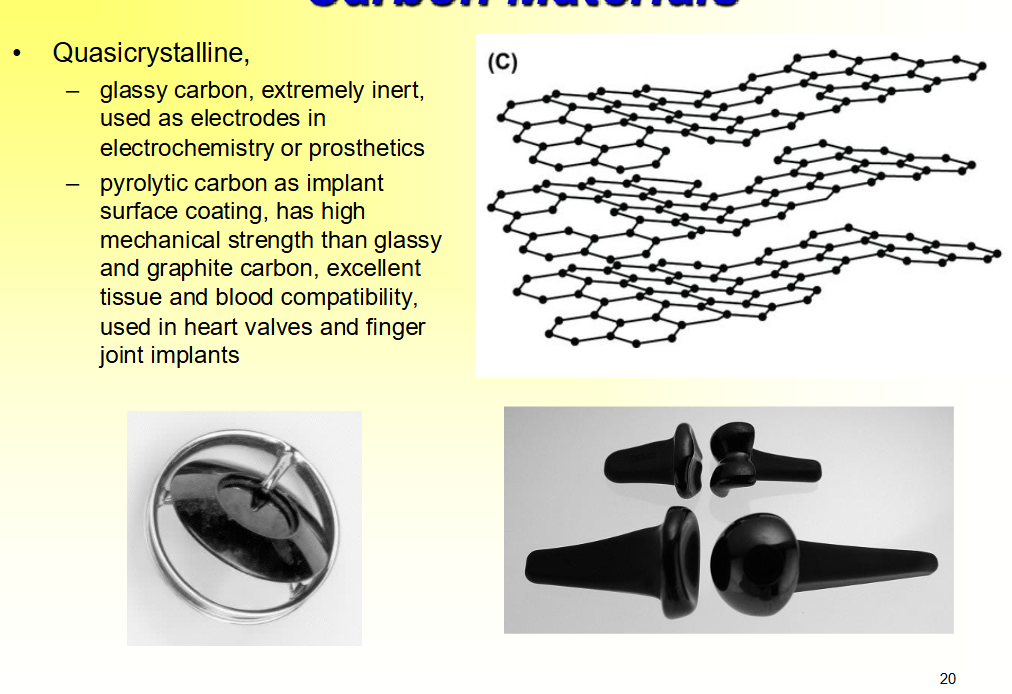

Quasicrystalline Carbon Materials

• Quasicrystalline,

– ____ carbon, extremely ___, used as ____ in electrochemistry or ____

– ____ carbon as implant surface coating, has ____ mechanical strength than glassy and graphite carbon, ____ tissue and blood compatibility,

used in ___ valves and finger joint ____

• Quasicrystalline,

– glassy carbon, extremely inert, used as electrodes in electrochemistry or prosthetics

– pyrolytic carbon as implant surface coating, has high mechanical strength than glassy and graphite carbon, excellent tissue and blood compatibility,

used in heart valves and finger joint implants

Composite Materials

• Consisting of ___ or more chemically distinct parts in the ___-scale, having a distinct ____ separating them

• Fiber or particulate composites usually consists of one or more

_____ phases (usually ____, called reinforcing materials)

embedded in a _____phase (called matrix)

• The property of the composite material depends on

– Properties of each ____

– ___ of the heterogeneities

– ____ fraction

– ___

• Natural tissue such as bone and tendon or vessel are ____.

• Consisting of 2 or more chemically distinct parts in the macro-scale, having a distinct interfaces separating them

• Fiber or particulate composites usually consists of one or more

discontinuous phases (usually stronger, called reinforcing materials)

embedded in a continuous phase (called matrix)

• The property of the composite material depends on

– Properties of each constituent

– Shape of the heterogeneities

– Volume fraction

– Interface

• Natural tissue such as bone and tendon or vessel are composites.

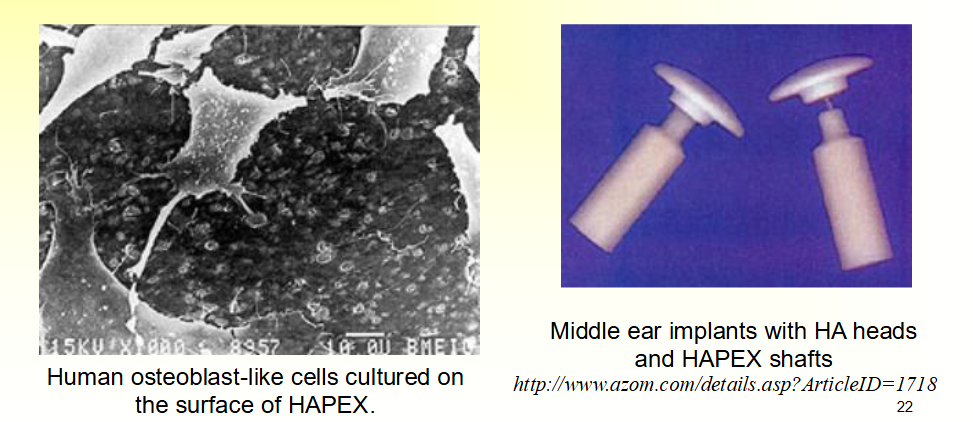

HAPEXTM

• Composite of hydroxyapatite in a polyethylene matrix

• Stiffness similar to cortical bone

• High toughness

• Bone bonding in vivo

• Orbital implant and middle ear implants