TOPIC 6 - Production & Process Control

1/12

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

13 Terms

General Production Requirement

Written procedures for production and process control are needed to ensure product identity, strength, quality, and purity

Follow procedures during execution and document real-time performance

Deviations must be recorded, explained, and critical deviations investigated and documented (both the investigation and conclusion)

In-process controls and testing are required to ensure batch uniformity and integrity

Equipment must be cleaned, maintained and sanitised regularly to prevent contamination or malfunction

A formal change control system must assess changes affecting production or control of drug products

Controls

Purpose: To ensure drug products are produced with the required quality attributes (ie. identity, purity, potency, safety, etc)

GDP and SOPs must be followed at every production step

OVERVIEW

Before starting production – Area & Line Clearance

During Production – GDP/SOPs

After Production – Batch Record Review

Cleaning, Maintenance & Calibration

Deviation Management & CAPA

Change Control

Before Starting Production (Area & Line Clearance)

Check that:

SOPs and documents are correct and of the latest revision (ie. remove old batch documents)

Raw materials, intermediates and packaging correctly identified and within expiry

Correct, clean, calibrated and functional equipment and appropriate lines are selected and changeover done if needed

All previous deviations resolved

After Production (Production Record Review)

Quality Assurance must review and approve all records (ie. production, control) before a batch is released

Ensures batch was made according to intended process and consistent in quality

Must comply with GMP and GDP

All deviations/non-conformance, including related batches, to be investigated in accordance to company procedures

Equipment Cleaning & Maintenance

Equipment and utensils must be regularly cleaned, maintained and sanitized to prevent contamination and malfunction

Cleaning:

Removes product residue to prevent cross-contamination

Removes food source for microorganisms

Uses cleaning detergents and soaps with high purity water; hot water alone used when possible

Sanitising (NOT Sterilisation):

Reduces microbial counts on equipment surfaces

Uses thermal or chemical sanitising agents

Water utility systems primarily follow sanitization practices

Degree of cleaning and maintenance depends on if the next batch is of the same or different product

Product changeover is more stringent

SOPs (for equipment cleaning and maintenance) must have:

Personnel responsibility

Schedule, frequency and status expiry

Methods for cleaning/maintenance (including equipment and materials used), disassembly and reassembly

Protection of clean equipment before use

Inspection of equipment for cleanliness before use

Maintenance of cleaning/maintenance records

Clean In Place (CIP)

Cleaning is done without disassembling equipment (eg. vessels, tanks, associated pipings)

Cleaning chemicals and rinse water (PW and/or WFI) are sent through pipes in a circulating or once-through manner

Removes media, culture, and product residues to a consistent, acceptable level and cleaning agents by final WFI rinse

CIP Cycle:

Pre-rinse with PW/WFI

Caustic wash with KOH (dissolve and remove organic residues and kill microorganisms)

Rinse with PW/WFI

Acid wash with H3PO3 (removes inorganic deposits and neutralises metal surfaces → prevents corrosion)

Rinse with PW/WFI

Final Rinse with HOT PW/WFI (removes all remaining cleaning agents)

Air blow (blows out residual water and dry equipment → prevents stagnation and reduces moisture)

Clean Out of Place (COP)

Used to clean parts or systems that must be removed, disassembled or brought out of place

eg. flexible hoses, sanitary clamps, end caps etc.

Can be manual and automated

Care must be taken to prevent contamination from environmental exposure or personnel interference

COP washer is an automated COP system

Cleans disassembled and brought out of place parts/fittings

Same stages as CIP cycle

Uses jet sprays inside wash chamber to create turbulent flow and mixing (for effective cleaning)

CIP vs COP

Advantages of CIP:

Eliminates environment and personnel exposure to the containment

Improves cleaning process consistency and reproducibility

No need to shut down or disassemble equipment so does not impact manufacturing efficiency

Equipment Maintenance

To ensure equipment reliability and prevent reactive failures through scheduled programs

SOPs must outline:

Responsibility

List of critical instrument

Maintenance schedules

Description of methods, equipment and materials used in maintenance operations

Management of Out-of-Tolerance (OOT) observations

Records

2 types of maintenance – ① Preventive ② Predictive

Preventive | Predictive |

Time-interval maintenance | Condition-based maintenance |

Based on calendar time or equipment running hours | Based on equipment conditions |

Intervals are based on average deterioration rate | Uses trend data from condition monitoring to predict failure |

Increases reliability of assets and reduces reactivity to failure | |

Preventive Maintenance

All production-related equipment must be certified by accredited bodies to ensure accuracy at all times

Preventive maintenance program:

Ensures all equipment are in optimal condition

Documents all maintenance activities, dates and personnels involved

Calibration (Standards)

All relevant data-recording equipment must be calibrated to ensure accuracy

New or repaired instruments require calibration before use

All equipment to be reviewed on calibration requirements upon receipt

Maintain clear inclusion/exclusion lists with reasons, location and final approval by Quality

Calibration standards must be traceable to national or international standards (eg. SPRING Singapore, NIST)

Calibration Guidelines

Classification of equipment depends on severity of accuracy of equipment on the product

Critical (affects product quality) – Calibrated minimally every 6 months

Non-critical (no direct impact) – Calibrated minimally every 12 months

Accuracy requirements should be set in consent with Quality and Calibration departments

Non-conforming equipment must NOT be used

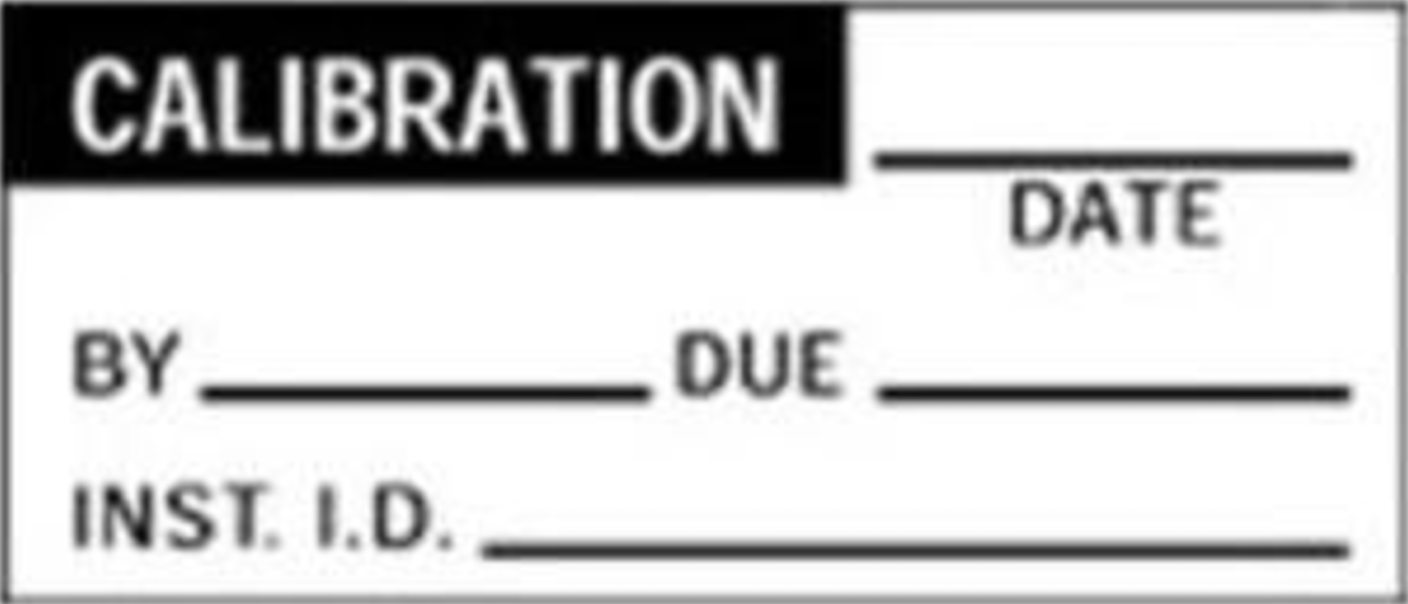

Calibration Records

Must include:

Equipment identification

Calibration dates

Individual performing each calibration

Next calibration date

Records must be displayed on/near the equipment or be readily available