Intro to Wood Framing Construction

1/46

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

47 Terms

● Flexibility in design – Easy to modify and expand.

● Readily available materials – Wood is widely available and

renewable.

● Fast and efficient construction – Prefabrication methods

speed up building time.

● Renewable Resource: sustainable material when

harvested responsibly. Trees can be replanted.

● Lightweight yet Strong

● Ease of Workability: Can be cut, shaped, and joined

easily using basic tools

Benefits of Wood Framing Construction

● Susceptibility to Moisture & Decay

● Fire Hazard: Wood is combustible, so fire-resistant

treatments and safety measures must be implemented.

● Pest Infestation: Termites, carpenter ants, and other

pests can damage untreated wood.

● Dimensional Instability: Wood expands and contracts

with changes in moisture content.

● Code Restrictions: building codes limit the height and

use of wood in certain types of structures due to fire

safety concern

Limitations of Wood Framing Construction

Softwood

○ Derived from coniferous trees (e.g., pine, spruce, fir).

○ Grows faster, making it more readily available and cost-

effective.

○ Common grades: #1 and #2 structural lumber used for

framing.

Most common wood type in Construction

Hardwood

○ Comes from deciduous trees (e.g., oak, maple, birch).

○ Expensive and harder to work with compared to

softwoods.

Used more for finishes, flooring, and cabinetry than for structural framing.

Nominal size

refers to the rough-sawn dimensions before the lumber is finished

Actual dimension is ½” less than the nominal dimension

UP TO 6”. Above 6”, the actual dimension is ¾” less

than the nominal dimension

Dimensions of Wood after drying and planing

New Growth

Trees that have regrown after previous harvesting, typically within 40-100 years

Old Growth

Forests that have remained largely undisturbed for centuries, producing denser, more durable wood

Clear Cutting Harvesting

Removes all trees in an area; efficient but can cause habitat destruction if not managed properly

Selective Cutting Harvesting

Removes only certain trees, preserving the ecosystem and promoting natural regrowth

Shelterwood Cutting Harvesting

Gradually removes mature trees while allowing younger trees to grow

FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative)

Certifications that ensure ethical harvesting

Deforestation

The large-scale removal of forests, often for agriculture,

urban development, or logging

Loss of Biodiversity, Climate Change Contribution, Soil Erosion & Desertification, Disruption of Water Cycles

Environmental Effects of Deforestation

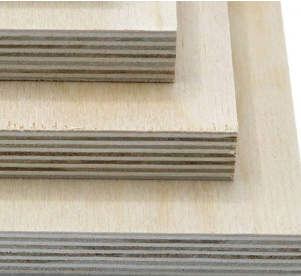

Plywood

Multiple thin layers (plies) glued together at alternating grain angles for strength. Used in subfloors, sheathing, and cabinetry

Oriented Strand Board (OSB)

Made from compressed wood strands and adhesives, widely used for sheathing and subfloors

Laminated Veneer Lumber (LVL)

Engineered wood beams with high strength; used in headers and load-bearing applications

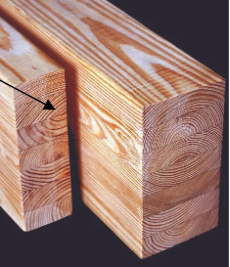

Glue-Laminated Timber (Glulam)

Large beams made from multiple layers of lumber bonded

together; used in exposed structural elements

Pressure Treated Wood

Infused with chemicals to resist decay, insects, and moisture damage. Used for outdoor applications, sill plates, and foundation contacts.

Fire-Retardant Wood

Chemically treated to reduce flammability, required in certain building code applications

Kiln Dried Wood

Dried in an oven to reduce moisture content and prevent shrinkage and warping. Essential for framing stability

Nails

common, framing, ring-shank Fastener

Screws

Fastener used in select structural applications

Joists

Horizontal structural members that support the floor. Spaced 16" on center

Beams & Girders

Large horizontal supports that transfer loads to foundation piers or walls.

Subflooring

Typical plywood provides a base for finished flooring

Bridging & Blocking

Increases stability and prevents joist movement

Studs

Vertical members spaced at 16" on center

Plates

Horizontal top and bottom members (top plate, bottom plate, and sometimes a double top plate)

Headers

Reinforced beams over doors and windows

Bracing

Diagonal supports for added structural stability (e.g., let-in bracing or metal straps)

Sheathing

Plywood or OSB attached to the exterior for rigidity

Balloon Framing

has continuous studs that run the height of the two-story wall. Creates a continuous wall cavity that runs from the first floor to the second floor. This cavity is a fire hazard because flames spread easily up the inside of the wall from one floor to the next

Platform Framing

has studs that run for one floor only, then the second floor is built as a platform. The platform acts as a fire-break to stop the spread of fire from floor to floor

Rafters

Traditional sloped members meeting at a ridge beam in a roof structure

Trusses

Prefabricated triangular frames that distribute loads efficiently in roof structures

OSB or plywood, provides support for roofing materials

Roof sheathing

Gable, Hip, Gambrel, and Shed

Common roof shapes in wood-frame construction

Joists or rafters

Ceiling below the roof

Wood frame construction

the most common building method for residential and light commercial structures in North America

Douglas Fir

Highly valued for its strength and stiffness. Top choice for structural framing, particularly in regions with heavy snow loads

Southern Yellow Pine

this wood is renowned for its strength, density, and resistance to decay. Is ideal for framing applications in humid or coastal areas

Spruce-Pine-Fir (SPF)

Lightweight and easy to work with, making it suitable for various framing applications

Slab-on-grade

concrete slab is poured directly on the ground, typically reinforced with steel rebar or wire mesh

-Cost effective and commonly for foundations in warmer climates or areas where ground doesn’t freeze

-Require moisture barrier under concrete and perimeter insulation in cold climates

Basement Foundation

involves excavating the space below ground level to create a basement, with foundation walls built on concrete footings

Crawl Space foundation

involves excavating a space beneath the house, creating a crawl space between the foundation floor and the house

How wood framing connects to foundation type

-Anchor sill plates using 1/2” anchor bolts embedded in concrete, space max 6’ apart

-An anchor bolt is a fastener used to secure the wooden framing to the concrete foundation. It plays a critical role in ensuring the stability and safety of a structure, especially lateral forces like wind and earthquakes