Micro + Mesoporous Solids

1/49

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

50 Terms

What are porous materials?

materials with a network of atoms containing voids or pores that can selectively trap, adsorb, or react with guest molecules

useful since their pores provide high SA + selectivity for adsorption, storage + reactions

used in both industrial + domestic applications:

gas separation

energy storage

ion exchange

heterogeneous catalysis

green chemistry

detergents

What’s a porous solid?

A solid that contains pores (cavities, channels, or interstices) that are deeper than they are wide.

What’s the difference between microporous, mesoporous + macroporous materials?

microporous: materials with pore diameters less than 2 nm

mesoporous: nanoporous materials with pore diameters between 2-50 nm

macroporous: materials with pore diameters greater than 50 nm

How is porosity (ε) defined + what does it exclude?

ratio of total pore volume (Vp) to the apparent volume (V) of a particle or powder

excludes interparticle voids (spaces between particles)

What is a zeolite?

family of hydrous aluminum silicate minerals (or their synthetic equivalents) that contain cations (Na⁺, K⁺, Ca²⁺, Sr²⁺, Ba²⁺) + are used as molecular filters and ion-exchange agents

pores 4-10 Å + cavities 10-13 Å

structure: crystalline (periodic + regular)

What is a Secondary Building Unit (SBU)?

repeating structural motif formed from linked SiO₄ tetrahedra (ex. 6-membered ring made of 6 SiO₄ units)

topology determines arrangement of pores + channels, influencing molecular transport + adsorption

pore structure can be tailored by altering the SBUs

larger SBUs create larger pores

What happens when Al substitutes for Si in the structure?

creates an aluminosilicate with a net (-) charge that can attract cations or metal dopants

Sn, Hf or Ti added as dopants for catalysis

What happens when Al substitutes for Si in a silica framework?

It introduces a –1 charge that must be balanced by a counterion cation (ex. Na⁺, K⁺, Ca²⁺, Mg²⁺).

How does low Al + high Al concentration affect the structure?

low: minimal effect on the structure + maintains silica-like stability

high: structural distortion increases + more cations are needed to balance charge

How do cation size and charge influence zeolite properties?

They affect pore size, stability, and adsorption capacity — larger cations can block pores.

What is the lowest possible Si/Al ratio?

Si/Al = 1 (equal amounts), but typically Si > Al for stability.

What is the significance of Si/Al > 10?

Minimal structural effect + reduced Al–O–Al linkages due to Al avoidance.

What does the Al avoidance rule mean?

Aluminum atoms prefer not to bond directly to each other (no Al–O–Al linkages).

How does low silica (Si/Al ~1-3) affect properties (ex. Zeolite A & X)?

has lots of Al, so the framework carries many (-) charges → needs many cations to balance

high ion exchange capacity: can easily swap cations like Na⁺, K⁺, Ca²⁺, etc.

very hydrophilic

high acidity due to many Al sites (each Al site acts as a weak acid)

structurally weaker: Al–O bonds are less stable + can be attacked by water or acids

poor thermal stability

How does moderate silica (Si/Al 3-5) affect properties (ex. Modenite & Zeo Y)?

fewer Al sites → less charge → fewer cations needed

improved thermal stability: more Si–O–Si bonds make the structure stronger

lower acidity due to fewer Al sites

more balanced performance: stable + moderately acidic, good for catalysis

How does high silica (Si/Al ~10-100) affect properties (ex. USY, ZSM-5)?

very little Al → almost neutral framework (few negative charges)

hydrophobic

very thermally stable: strong Si–O–Si bonds resist heat

no ion-exchange capacity: very few cations present

low acidity: few active sites left for catalysis.

good for hydrocarbon adsorption + catalytic cracking (ex. in fuels)

How does pure silica (Si/Al = ∞) affect properties (ex. silicalite)

no Al

completely neutral + hydrophobic

extremely thermally + chemically stable

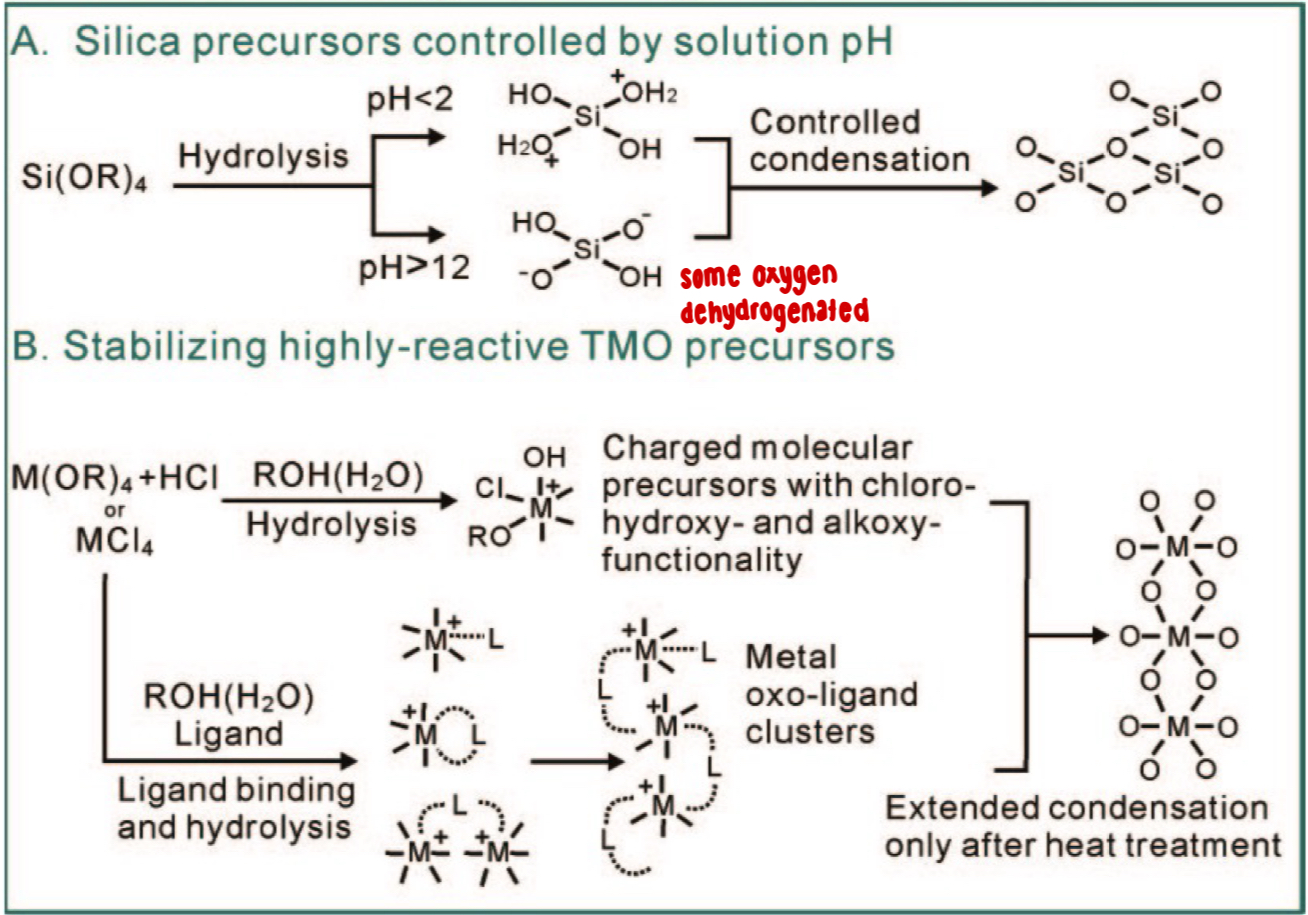

Can you explain how stable charged inorganic precursors are formed during the sol-gel process?

formed through hydrolysis + condensation reactions

silica precursors (Si(OR)₄):

under acidic conditions (pH < 2): hydrolysis forms (+) charged silanol species

under basic conditions (pH > 12): hydrolysis forms (-) charged silanol species

these intermediates undergo condensation reactions (–OH + –OH → –O– + H₂O), gradually forming Si–O–Si linkages

some O atoms are dehydrogenated ➡ growing silica network

transition metal oxide (TMO) precursors (M(OR)₄ or MCl₄):

hydrolysis with HCl or ROH(H₂O) forms charged molecular precursors containing chloro-, hydroxy- + alkoxy-functionalities

ligands (alcohols, water) coordinate with the metal, stabilizing reactive centers + preventing premature condensation

controlled ligand binding + hydrolysis form small metal oxo-ligand clusters (M–O–M)

extended condensation occurs only after heat treatment, removing ligands + producing a continuous metal–oxygen–metal (M–O–M) solid network

In the sol-gel process, what is the role of the surfactant/amphiphile in the 2nd step: molecular interactions?

interacts with metal ion precursors, helping organize the ions + solvent to guide structured network or pore formation in the material

important to choose correct surfactant since it ensures effective interaction with the metal precursor, which controls the nanostructure + porosity of the final material

What characterizes the hydrophobic + hydrophilic part of a surfactant in the sol-gel process?

hydrophobic: hydrocarbon tail or a carbon-rich polymer block

it avoids water + prefers non-polar environments

hydrophilic: charged head group or an oxygen-rich polymer block

interacts with water + polar species, including metal ions

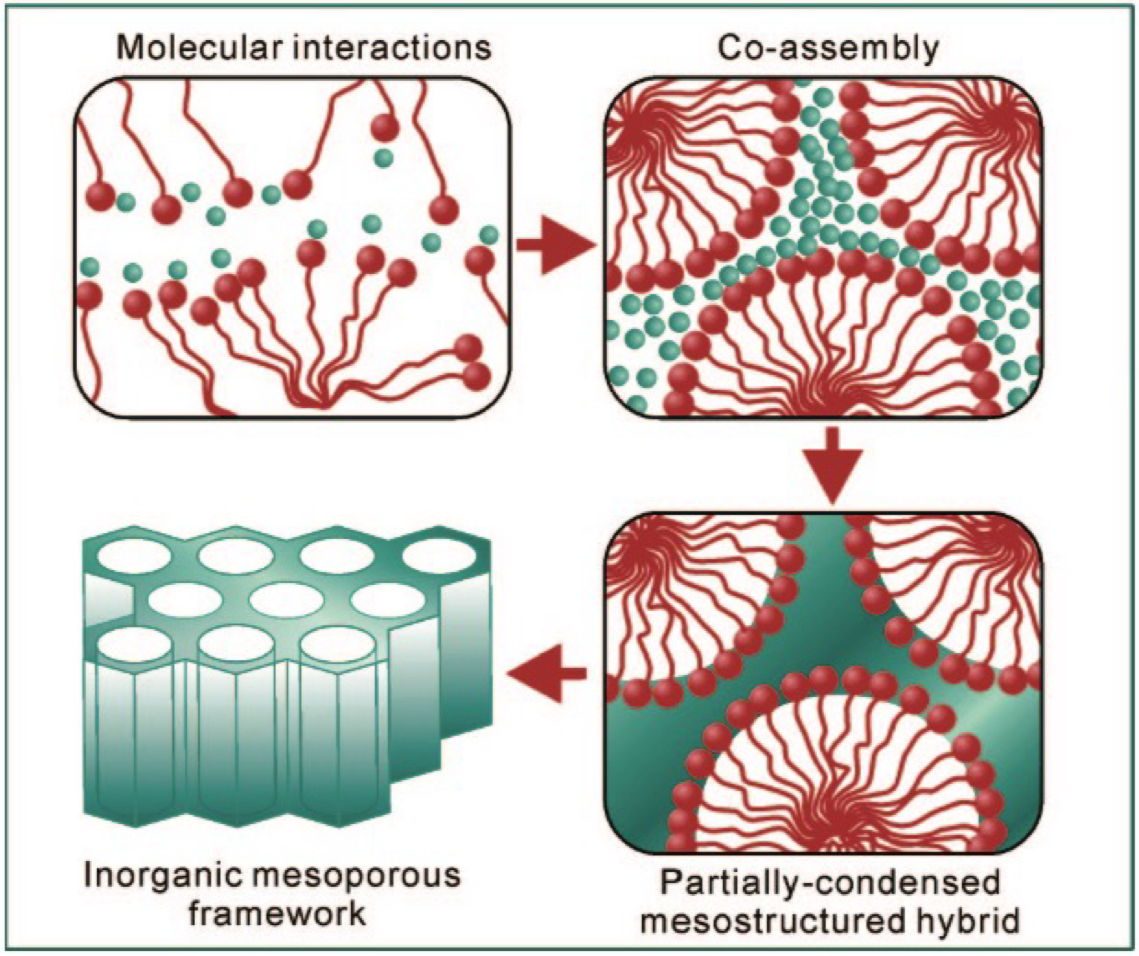

What is the main goal of the mesostructure synthesis in the sol-gel process?

To create conditions under which the surfactant can self-assemble, guiding the formation of an ordered inorganic mesoporous framework.

What are the stages of the 3rd step: mesostructure synthesis in the sol-gel process?

molecular interactions

co-assembly of surfactant + metal species

partially condensed mesostructured hybrid

inorganic network starts forming but is not fully rigid; the surfactant template is still present, maintaining the structure

inorganic mesoporous framework

surfactant is removed

Why is controlling the self-assembly conditions important in the sol-gel process?

Because the pore size, shape + order of the final mesoporous material depend on how the surfactant + metal precursors co-assemble.

What types of non-covalent interactions drive self-assembly?

H-bonding, van der Waals forces + electrostatic interactions.

What happens during the “bake” step of the sol-gel process?

heating removes the organic surfactants (burns them to CO₂) + dehydrates the metal sol-gel, forming a hard, rigid inorganic oxide

sol-gel material is “hard as a rock” since metal oxide network condenses + loses water

What are inorganic-organic (I/O) hybrid materials?

materials that combine inorganic + organic components at the molecular level, often prepared via the sol-gel process

steps:

formation of sol

inorganic + organic precursors are dissolved or dispersed to form a stable colloidal solution

crosslinking of the sol

precursor molecules are chemically bonded to form gel

aging

gel network strengthens + evolves as condensation reactions continue

drying

solvent + byproducts are removed, yielding the final solid hybrid material

What factors influence the properties of I/O hybrids?

chemical composition of precursors

ratio of inorganic to organic components

structure of building blocks

distribution of building blocks

How are organic molecules incorporated into sol-gel materials?

they’re dissolved in the sol-gel precursor solution + the gel forms around them

physically trapped but not covalently bonded ➡ retains their functionality

Why is sol-gel processing suitable for embedding biomolecules?

mild, allowing sensitive biomolecules to be incorporated without denaturation

stabilizes the molecules, preserving their function for applications

What does covalent modification in sol-gel hybrids involve?

attaching organic R groups to the inorganic sol-gel network, typically via organosilane precursors

modifies networks polarity + chemical environment, influencing hydrophobicity + flexibility

reduces crosslinking because the R groups occupy sites that would otherwise form Si–O–Si bonds

Why use covalent modification in sol-gel materials?

To tailor the physical + chemical properties of the hybrid material by choosing specific organic groups.

How do R substituents affect connectivity in sol-gel networks?

They reduce the number of reactive sites per silicon, changing connectivity + often preventing fully cross-linked 3D networks

What type of structure is formed using di-substituted or mono-substituted precursors?

di-substituted: linear systems

mono-substituted: cage systems (POSS)

Why is it difficult to prepare 3D gel networks from organically substituted precursors?

because the organic R groups reduce the number of bonding sites

fully crosslinked networks are more easily formed with tetraalkoxysilanes (Si(OR)₄)

How do bulkier R groups influence the reaction?

They can sterically slow the reaction, but electronic effects are usually more significant in controlling hydrolysis.

What is a major challenge when using mixtures of organically modified sol-gel precursors?

phase segregation: different precursors separate instead of forming a homogeneous gel

occurs since TS of hydrolysis + condensation reactions differ between precursors ➡ uneven reaction rates

Why is pH important in sol-gel precursor mixtures?

It affects hydrolysis + condensation rates, which influence the structure, uniformity + potential phase segregation of the gel.

What is Rw in sol-gel chemistry?

The alkoxy-to-water ratio: moles of water per mole of alkoxy groups in the precursor.

How does Rw ≤ 2 affect the sol-gel reaction VS Rw >> 2 VS Rw = 1?

Rw ≤ 2: favours hydrolysis, forming Si–OH groups over Si–O–Si condensation

Rw >> 2: favours condensation, forming Si–O–Si linkages + promoting network formation

Rw = 1: full hydrolysis with minimal condensation

Why does excess water make condensation less likely?

Because more water molecules reduce the likelihood that Si–OR groups encounter each other, making reaction with water more probable.

What happens at the gel point + are chemical reactions stopped?

viscosity increases, freezing the network (glass-forming process)

hydrolysis + condensation continue, allowing further chemical evolution of the gel

What is an alcogel + how does it affect aging?

alcogel: gel with a continuous liquid phase containing solvent, particles + unreacted monomers

allows ongoing condensation of M–OH + M–OR groups, leading to network densification, shrinkage (syneresis) + structural rearrangements

What processes occur during ripening/coarsening in aging + what are their effects?

material redistributes from thermodynamically unfavourable regions via reversible hydrolysis/condensation

effects:

reduces net curvature

removes small particles

fills pores (analogous to sintering)

optimizes porosity, network strength + mechanical properties

What are the 3 main stages of drying a sol-gel?

shrinkage stage:

gel volume decreases as liquid flows from core to surface

flexible networks deform + OH groups can react

pore size shrinkage increases surface tension

rigid network stage:

surface tension can no longer deform the network

shrinkage stops + cracking may occur

liquid/gas interface retreats, leaving continuous liquid film on pore walls

diffusion stage:

liquid film ruptures

remaining liquid exists in isolated regions + leaves the network via gas-phase diffusion

What is Ostwald ripening + what factors influence particle growth in sol-gel systems?

process where small particles dissolve + redeposit onto larger ones, favouring the formation of larger particles over time

growth stops when solubility differences between small + large particles are minimal

factors:

pH: silica grows to 5–10 nm when pH > 7; 2–4 nm at lower pH

T: higher T → larger particles + system dynamics (ex. ouzo effect)

How does the Stöber method control silica particle size and morphology?

TEOS reacts in a basic solution (ammonia catalyst) with excess water

particle size is mainly controlled by T + reactant concentrations

silica spheres form through nucleation + growth, followed by cycles of dissolution + re-precipitation

this rate-limited monomer–cluster growth keeps monomer levels steady, producing uniform + well-defined particles

What is Rate-Limited Monomer Cluster Growth in Stöber silica?

growth of silica spheres is controlled by how quickly monomeric TEOS-derived species attach to existing clusters

this slow monomer addition allows repeated nucleation, dissolution + re-precipitation

produces uniform, monodisperse silica particles

What causes network collapse + cracking in sol-gel materials?

slower shrinkage of the interior results in pressure gradient that causes cracking

larger pores will empty faster than small pores, causing uneven stress on walls + cracking

Whats the difference between xerogel powder + aerogels?

xerogel powder:

formed when gels are conventionally dried

cracking can be minimized but shrinkage is inevitable

aerogels:

formed by replacing solvent with a gas

causes little or no change to network structure or volume

How do square planar copper nodes + tritopic linkers determine MOF structures, and what role does the node-to-linker ratio play?

square planar copper nodes act as corners

tritopic linkers connect 3 nodes

controlling the node-to-linker ratio tunes connectivity + mesoporous crystal topology

resulting MOFs have tailored pore sizes, shapes + functionalities for catalysis, gas storage + separations