Pharma Exam Revision

1/46

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

47 Terms

Main Types of Biological Products + Examples

Proteins

Antibodies

Enzymes

Collagen

Metabolites

Antibiotics

Ethanol

Vitamins

Cells

Stem Cells

Yeast Extract

Baking/Brewing Yeast

Protein Structures

Primary Structure: Sequence of amino acids in the chain (covalent bonding)

Secondary Structure: Local structure of the peptide backbone (hydrogen bonding) e.g. α-helices & β-pleated sheets

Tertiary Structure: Overall 3D Shape of a protein (side chain intramolecular interactions)

Quaternary Structure: Arrangement of folded polypeptide chains

Protein Production Steps

Transcription - DNA is transcribed to an RNA copy of the gene by RNA polymerase

Translation - RNA is transcribed into a polypeptide by ribosomes

Metabolites

Chemical compounds that are intermediates or end-products of cellular metabolism

Primary Metabolites

Essential metabolites involved in normal cell growth and reproduction

e.g. Ethanol, Citric acid, Amino acids

Secondary Metabolites

Non-essential metabolites that have specialised roles in ecological interactions

e.g. Antibiotics, Antifungals, Chemotherapy drugs

Biological Sources of Metabolites Examples

Bacteria

Ethanol

Citric Acid

Amino Acids

Plants

Terpenoids

Alkaloids

Flavonoids

Key Industrial Microbes + Biological Products they produce

Bacteria

Escherichia coli – widely used for protein production in research and industry

Lactic acid bacteria – can grow at relatively low pH so widely used in food & beverage production

Fungi

Saccharomyces cerevisiae (Baker’s yeast) – used industrially for ethanol production and insulin

Aspergillus niger (Black mould) – widely used filamentous fungi producing citric acid and enzymes

Key differences between bacteria, yeast, fungi

Metabolic & Oxygen Classification

Autotrophs: use inorganic carbon (CO2) to produce organic molecuules

Photoautotrophs: use energy from sunlight

Chemoautotrophs: use chemical energy from the oxidation of inorganic compounds

Heterotrophs: use organic carbon sources

Photoheterotrophs: use sunlight for energy and organic carbon for carbon

Chemoheterotrophs: use organic carbon molecules for both energy and carbon

Aerobes: use aerobic respiration for ATP production

Anaerobes: use anaerobic fermentation for ATP production

Obligate anaerobes die in the presence of oxygen

Facultative anaerobes use aerobic respiration if oxygen is present, or fementation if not

Nutritional Requirements of Microbes

Macronutrients: microbes need these elements in relatively high amounts

N, C, H, O, P, S (components of carbohydrates, lipids, proteins and nucleic acids)

Micronutrients: microbes also need various metals in trace amounts

Mn, Zn, Co, Mo, Ni, Cu

Growth Factors:

Amino acids

Purines & pyrimidines

Vitamins

Types of Microbial Growth Media: Difference + Pros/Cons

Defined (synthetic media): concentrations of all chemical compounds are known

Pro: allows for consistent control of nutrients in industrial application

Con: need to know nutritional requirements of the microbe

Complex media: rich nutrient sources with no precisely known compositions

Pro: supports rapid growth and cultures wide range of microbes

Con: no precise control

Bioreactor Key Features

SMMALT

Sampling: aseptic sampling port

Measurement: sensors for temperature, pH, dissolved oxygen, foaming

Mixing: motorised impeller

Aeration: sparger, gas inlets and outlets

Liquid addition: feed pumps and inlets for nutrient, acid/base and anti-foam additions

Temperature control: heating/cooling coils or jackets

Microbial Growth Phases

Lag phase: cells adjust to environmental conditions

Exponential growth phase: cells replicating at constant growth rate

Deceleration phase: growth rate slows due to nutrient depletion or build-up of toxic waste products

Stationary phase: cells enter a non-growing state, no net cell growth occurs but secondary metabolites are produced

Death phase: cells die due to nutrient exhaustion or toxicity

How to monitor cell growth rate in reactor

Turbidity: via spectrophotometer

Capacitance: via cell membrane polarisation

Substrate depletion: via enzymatic probe

Respiration rate: via rate of oxygen uptake

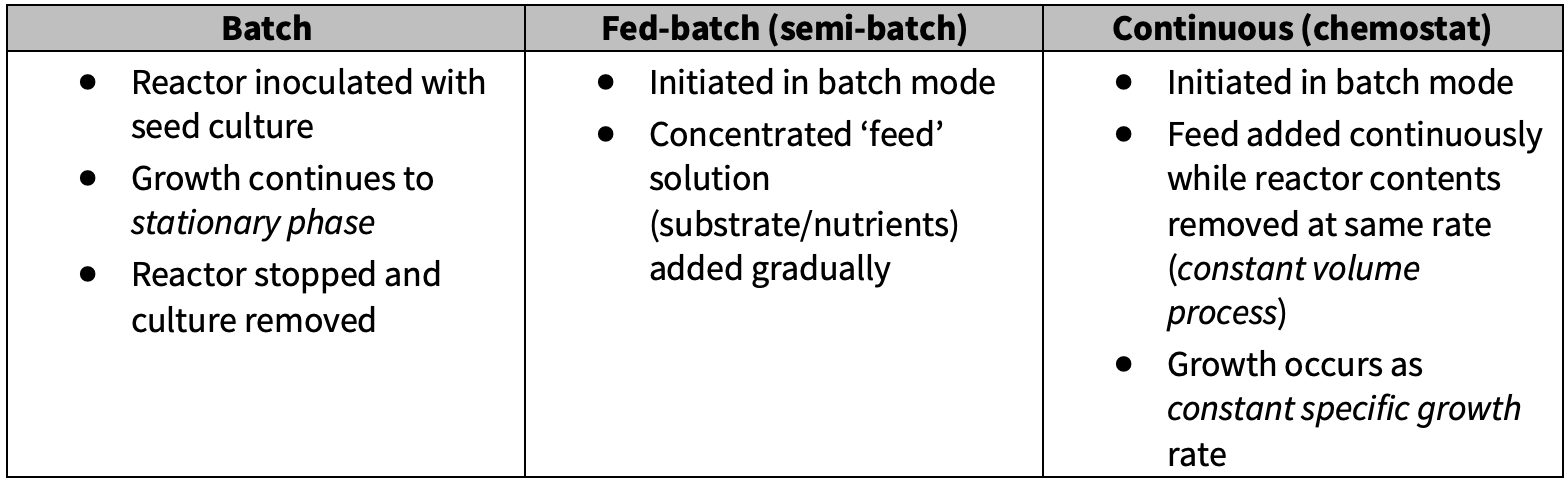

Differences Between Cell Culture Modes

Feeding Control Strategies for Industrial Fed-Batch Culture

Feedforward Control: assuming constant specific growth rate using equation

Feedback Control: based on measurement data which has a stronger correlation to the condition of the bioreactor

Key Features of a Plasmid

Promoter: recruits transcription machinery

Restriction enzyme sites: for gene insertion

Selectable markers: to distinguish native and transcofrmed cells

Affinity tag sequences: for protein purification

Origin of replication: controls replication of plasmid inside cells

Steps to Produce Protein from a Foreign Source

Extract target gene & replicate via PCR

Insert gene into plasmid

Cut plasmid & PCR product with restriction enzyme (matching sticky ends)

Join fragments using DNA ligase to create recombinant DNA

Alternatively, do Gibson assembly via overlapping regions between DNA

Transformation

Introduce plasmid into microbe via chemical transformation (CaCl2 + Heat Shock) or electroporation

Selection

Plate cells on a medium containing antibiotic, only those with plasmid with antibiotic resistance gene survive

Alternatively, do blue-white screening for visual identification

Expression

Pick a colony and grow in a cell culture

Control gene expression via constitutive (always on) or inducible (on/off) promoters

Harvest & Purify

Lyse cells to release protein

Use affinity tags and chromatography to isolate the target protein

PCR Reaction Components & Steps

Components

Template DNA: contains target gene to be amplified

Nucleotides: four DNA bases (ACGT)

Primers: match start & end of DNA region to be amplified

DNA polymerase: enzyme that copies DNA

Steps

Denaturation: double-stranded DNA heated, strands separates

Annealing: primers bind target sequences

Extension: DNA polymerase binds to annealed primer, nucleotides incorporated into new DNA strand

How ‘tags’ can assist in purification of proteins

Tags are peptides joined to the end of a recombinant protein. In affinity chromatography, tags attached to the protein are attracted to the affinity resin

Key Issues with Protein Production in Microbes & Solutions

Inclusion bodies: aggregates of insoluble protein formed by many recombinantly expressed proteins in microbes

Avoid by optimising culture conditions, using weaker promoter, or lower copy number plasmid

Low expression levels

Optimise culture conditions and media components

DNA sequence optimisiation

Algae Cell Growth at Various Levels of Light

Weak-Moderate light

Carbon fixation proportional to light recieved

Intense Light

Photoinhibition can limit growth

Photodamage occurs when excessive light is maintained

No Light

Aerobic respiration of cellular organic carbon used to power and maintain cellular activities

Algae products

Products

Pigments (β-carotene, etc)

Lipids (biofuels, etc)

Proteins

Carbohydrates

Algae Commercial Advantages

Genetic diversity with wide range of physiological and biochemical characteristics

Potential to be bioengineered for strain improvements

High growth rates (compared to terrestrial plants)

Classifications of algae

Macroalgae: large, multicellular; source of polysaccharides

Microalgae: microscopic, unicellular; source of pigments, lipids, proteins, etc)

Algae Growth Systems Pros/Cons

Open ponds: low cost, contamination risk, low control

Photobioreactors: high control, small footprint, high cost

Photobioreactor Scale-Up Considerations

Changes in illumination

Gas transfer

Temperature

Turbulence

Algae Production Flow Charts

Discovery

Identification of metabolite

Species selection

Production

Cultivation

Harvest

Screening

Thickening

Dewatering

Drying

Challenges in Engineering & Processing of Algae

Low productivities

High recovery cost

Light penetration, O2 accumulation, mixing, scaling up

Plant-derived Pharmaceuticals Examples

Morphine (from opium poppy)

Paclitaxel (anti-cancer drug - from Pacific yew tree but now in plant cell culture)

Artemisinin (anti-malaria drug - from sweet wormwood but now from yeast)

Why use plant cell culture vs obtain from plants

Independent of crop supply

Controlled environment (no crop disease, weather)

Improved yields (metabolites normally at low concentration)

Easier genetic manipulation of cells vs plants

Simplify metabolite extraction (less contaminants)

Disadvantages of plant cell culture vs microbial cells

Slower growth rates

Lower yields

Higher medium costs

Intracellular product accumulation

Higher shear sensitivity

Formation of cell aggregates

Plant vs microbial cell culture bioreactor & downstream differences

Bioreactor Design

Plant cells larger, so more shear sensitive - needs gentle mixing such as airlift or bubble column

Cell aggregation causes diffusion limitations and metabolic hetereogeneity , so gentle circulation is required to minimise gradients

Intracellular product accumulation means that continuous immobilised systems are not suitable

Downstream Processing

Secondary metabolites retained within vacuoles, requiring cell disruption to release products

High viscosity and suspended aggregates complicate filtering, separation and extraction

Lower yields and slower growth make process intensification and recovery efficiency more critical

Need for Growth Regulators in Plants vs Microbes

Plant cells need growth regulators (e.g. auxins and cytokinins) to mimic the hormonal signals that regulate growth and differentiation in whole plants

Enhancing Metabolite Production

Removal of growth regulators or starving cells or nutrients

Addition of product precursor molecule

Elicitors to initiate defence or stress response

Plant Cell Culture Production Steps

Take plant tissue, wound it, grow on solid media with growth regulators

Extract callus (mass of undifferentiated plant cells)

Start suspension cell culture

Optionally genetically modify

Scale-up into bioreactor

Genetic Modification of Plant Cells

Agrobacterium tumefaciens transformation

Bacterium creates tumors in plants, containing a plasmid transferring a segment of its DNA into plant cell genomes

Particle bombardment (gene gun)

DNA-coated particles are propelled into plant cells which enter the nucleus and integrate into the plant genome

Pros/Cons of Mammalian Cells vs Microbial

Types of Post-Translation Modifications

Applications of Mammalian Cell Culture

Viral vaccines

Monoclonal antibodies

Therapeutic glycoproteins (interferons, hormones, blood clotting factors)

Tissue/organ replacement

Medical research applications

Steps for the preparation and culture of animal cells

Differences between normal/transformed cells

Difference between stem/differentiated cells

Fermenter/growth set ups for adhesive and suspension cell cultures

Components within media and importance to cell growth and process development & optimisation