PHYPHAR LEC - Micromeritics of Solids

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

Micromeritics

Science and technology of small particles

Involves properties such as size, shape, surface properties, density and porosity, among others

Sieving

USP Method

Uses a series of sieves calibrated by the National Bureau of Standards (NBS)

The particle size may be estimated by calculating the relative abundance of particles in each sieve

Variables causing sieving errors Sieve loading, duration and intensity of agitation

Very Coarse

All particles pass through a No. 8 sieve and not more than 20% through a No. 60 sieve.

Coarse

All particles pass through a No. 20 sieve and not more than 40% through a No. 60 sieve.

Moderately Coarse

All particles pass through a No. 40 sieve and not more than 40% through a No. 80 sieve.

Fine

All particles pass through a No. 60 sieve and not more than 40% through a No. 100 sieve.

Very Fine

All particles pass through a No. 80 sieve. There is no limit to greater fineness.

Microscopy

Ordinary Microscope

Particle Range: 0.2 um - 100 um

Electronic Scanners

Disadvantages:

Diameter is obtained only from the particle’s length & breadth

Slow & Tedious: Number to be counted is 300-500 in order to obtain a good distribution estimation

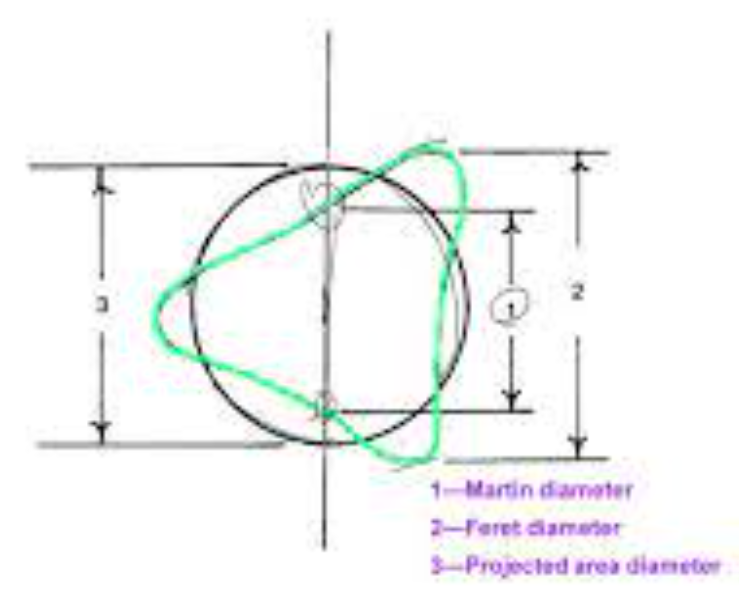

Martin’s Diameter

Length of a line that bisects the particle image

Feret’s Diameter

Distance between two tangents on opposite sides of the particle parallel to some fixed directions

Projected Area Diameter

Area of a circle with the same area as that of the particle observed perpendicular to the surface on which the particle rests

Particle Volume Measurement

Determining the particle volume distribution in suspended particles

Uses a Coulter Counter (Light Diffractor Analyzer)

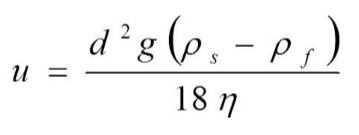

Sedimentation Method

This method employs the settling of particles in a liquid of a relatively low density under the influence of a gravitational or centrifugal field

Uses the Andreasen Apparatus

Utilizes Stoke’s law

Gas Adsorption Method

Particles with a small particle size have larger surface areas, and are good adsorbents

↓ Particle Size = ↑ Adsorption = ↑ Surface Area

Air Permeability Method

Based on the principle that the resistance offered to the flow of a fluid, such as air, through a plug of compacted powder is proportional to the surface area of the powder

↑ Air Permeability = ↓ Resistance = ↓ Surface Area

Porosity

Percentage expression of voids

Excellent

Carr’s Index

1-10

Hausner Ratio

1.00-1.11

Good

Carr’s Index

11-15

Hausner Ratio

1.12-1.18

Fair

Carr’s Index

16-20

Hausner Ratio

1.19-1.25

Passable

Carr’s Index

21-25

Hausner Ratio

1.26-1.34

Poor

Carr’s Index

26-31

Hausner Ratio

1.35-1.45

Very Poor

Carr’s Index

32-37

Hausner Ratio

1.46-1.59

Very, Very Poor

Carr’s Index

> 37

Hausner Ratio

> 1.59

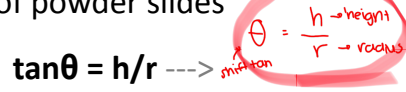

Angle of Repose

Maximum angle possible between the surface of a pile of powder and the horizontal plane

Good Flow

Low Angle of Repose = ____ Flow

Poor Flow

High Angle of Repose = _____ Flow