Levensmiddelentechnologie - Low Temperature Preservation

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

17 Terms

What is low T preservation?

increase in shelf life by inhibition but no destruction of MO and enzymes

→ T-increase permits growth of pathogens and increases spoilage

Careful control of cold chain (-1°C to 8°C)

Chilled storage at production plant

Refrigerated transport

Retail chill display cabinets

Domestic refrigerators

Low T preservation: outline

Mechanical vapor-compression system

Cryogenic chilling

Effect on MO

Case-study

Low T preservation: Mechanical vapor-compression system

Refrigerants

Components of a refrigeration system

Pressure-enthalpy charts

Mathematical expressions

Equipment

Low T preservation: Mechanical vapor-compression system - Refrigerants

Preruiquisites phase behaviour

High latent heat of vaporization → minimal amount of refrigerant

Low condensing pressure → avoid heavy construction

Freezing T < Evaporator T

High critical temperature → no liquification at T > critical T

Other conditions

Ammonia → flammable, toxic & corrosive

CO2 → causes suffocation

Hydrocarbons → highly flammable

Chlorofluorocarbons (CFCs) → ozone depletion

Hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) → no ozone depletion but greenhouse gas (global warming potential)

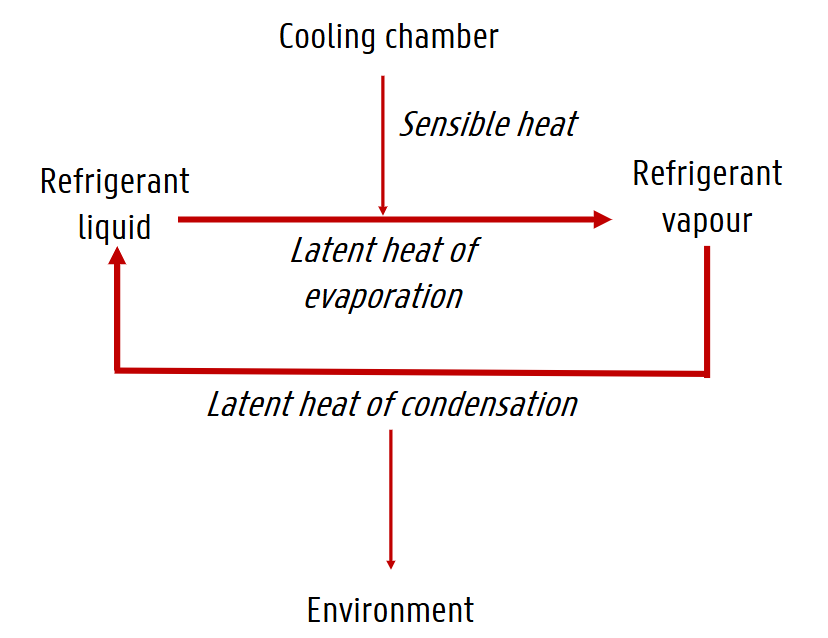

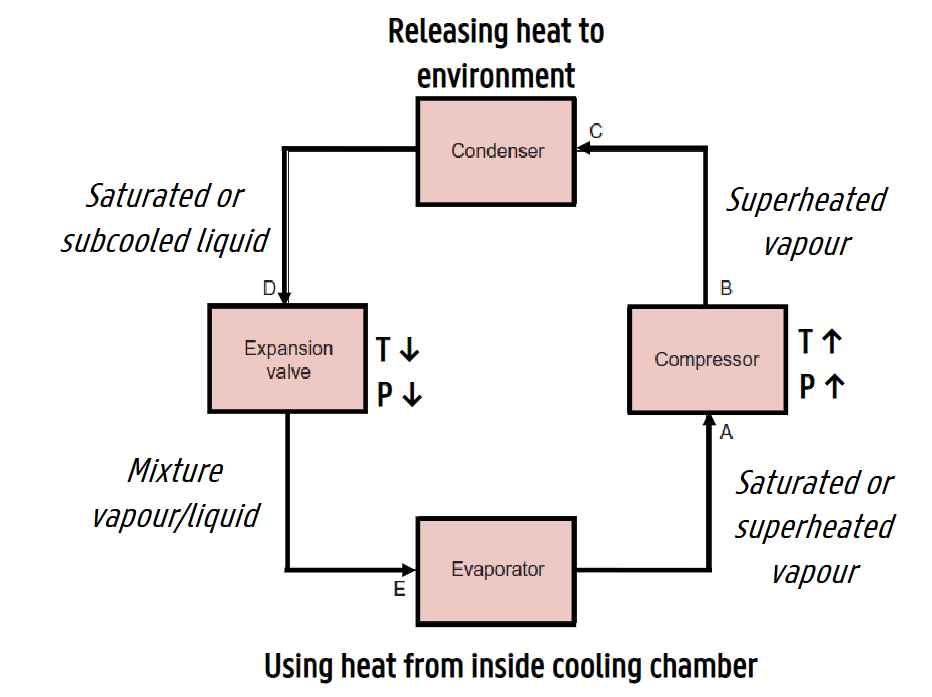

Low T preservation: Mechanical vapor-compression system - Components of refrigeration system

Evaporator (coils)

Compressor

P increase

Reciprocating compressor

Centrifugal compressor

Rotary compressor

T increases above ambient T

Heat can be released to environment in condenser

Condenser

Water-cooled

Air-cooled

Expansion valve

= metering device controlling the flow of liquid to the evaporator

High pressure saturated liquid → low pressure mixture liquid/vapour

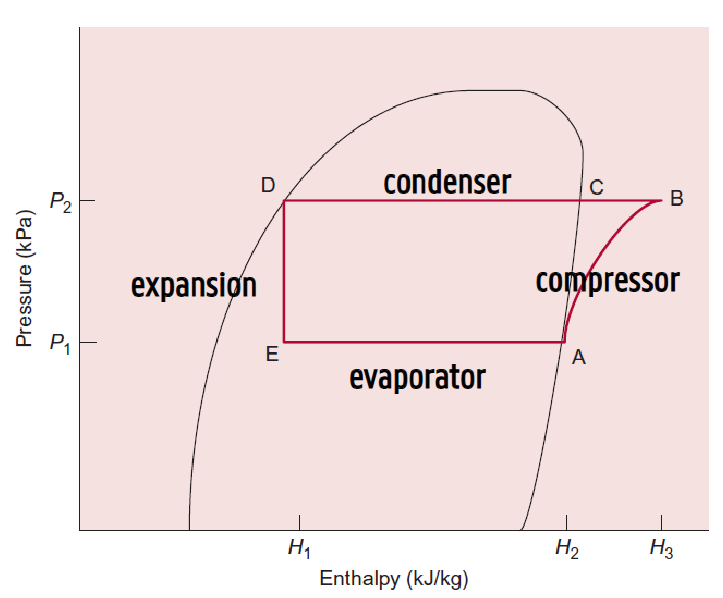

Low T preservation: Mechanical vapor-compression system - Pressure-enthalpy chart

Characteristic for each refrigerant

Indicates pressure and enthalpy changes of refrigerant throughout the refrigeration cycle

Evaporator: constant P and T

Condenser: constant P and T

Compresser = constant entropy

Expansion = constant enthalpy

D = saturated liquid

D’ = D more to left = subcooled liquid

A = saturated vapour

A’ = A more to right = superheated vapour

Mathematical expressions → see exercises

Low T preservation: Mechanical vapor-compression system - Equipment

Chilling equipment = reduce T of a product

Cold storage equipment = maintain a defined T

Temperature monitoring = integral part of quality and safety management

Low T preservation: Mechanical vapor-compression system - Equipment: Chilling equipment

Air chillers

Forced convection to reduce boundary film → increased rate of heat transfer

Batch chillers

Trolleys or pallets are placed in a tunnel

Continuous chillers

Product moves through tunnel

Speed ~ adequate cooling

Blast chillers

Loading → chilling → defrosting

T control: loggers and alarms

Eutetic plate system

Local distribution

Salt solution (KCl, NaCl or NH3Cl) → frozen to eutectic T

Air circulated across the plates

The plates are regenerated by re-freezing in an external freezer

Vacuum cooling

Cooling takes place as moisture evaporates from the surface

Fresh foods with larger surface area: lettuce, mushroom, broccoli

Vacuum chamber (pressure reduced to 0,5 kPa)

Hydrocooling

= direct immersion in chilled water or brine

e.g. fruits and vegetables, poultry, fish, cheese

Plate heat exchanger or scraped-surface heat exchanger

cool (semi-)liquid foods after pasteurization)

Low T preservation: Mechanical vapor-compression system - Equipment: Cold storage

Circulation of cold air → mechanical refrigeration system

T < 5°C

Control of relative humidity

Composition of storage atmosphere

Adequate circulation of air using fans

Low T preservation: Mechanical vapor-compression system - Equipment: Temperature monitoring

Temperature data loggers + temperature sensors

Air temperature or product temperature

load test = establish a relation between air and product T

difficult in open retail cabinets → measure product T

Critical temperature indicators

Cumulative t,T exposure above reference T

Specific reactions or growth above reference T

Full history time-temperature indicators

Continuous integrated t,T history

overall quality loss

Intelligent packaging

barcode system

smart label

Type of indicators

Liquid crystal coatings: change colour with storage T

melting of wax releasing a coloured dye

Diacetylene changes as function of time and T

Enzymic reaction → pH indicator

Low T preservation: Cryogenic chilling

Solid or liquified CO2

preferred for chilling

higher boiling/sublimation point

Most of the heat capacity in phase change

Better control over temperature

Liquified nitrogen

Preferrred for freezing

Lower boiling/ sublimation point → larger T gradient

Heat capacity: gas absorbs sensible heat → special gas-handling equipment

Equipment

Solid CO2 → dry ice-pellets

Liquid CO2 → injected in air (= snow)

Liquid nitrogen → injected in air (= immediate vaporization) → fans distribute this gas

Continuous cryogenic chilling

inclined, cylindrical barrel

Rotates slowly → food tumbles through the cold gas

Disadvantages

Suffocation

Cold burns

Frostbite

Hypothermia

Low T preservation: Effect on MO

Temperature decrease

→ prolonged lag phase

→ decreased growth rate

→ changes at cellular level: cell membrane structure, uptake of substrate, enzymic reactions

G- bacteria

most common spoilage MO in chilled foods

max growth T: 0-3°C

Contamination by water, bad cleaned equipment or surfaces

produce slime, off-flavour or off-odors

Yeasts and moulds

Able to tolerate chill temperatures

grow more slowly than bacteria

out-competed unless other environmental factors limit the growth of bacteria

if bacteria growth is limited → yeasts may cause spoilage

Yeasts can grow in the absence of oxygen

Pathogenic bacteria

Some can grow at chilling T

Some are sufficiently virulent → poisoning after digestion of only few cells

Some are unable to grow at < 5 °C but may grow if T abuse occurs and then persist in the food

!! Be aware of the psychrophilic and psychrotrophic MO still being alive

Low T preservation: Case study → Fresh foods

cooling → enzymatic changes ↓ → respiration and biological aging is retarded

Factors to control fresh-crops in cold storage

Type of food and variety of cultivar

Part of the crop selected

Condition of the food at harvest

Temperature during harvest

Relative humidity of storage atmosphere → influence dehydration losses

Gas composition of storage atmosphere

Storage life ~ Respiration rate

Climacteric vs non-climacteric

Climacteric: ripen after harvest + respiration peak (e.g. bananas)

Non-climacteric: do not ripen after harvest + no respiration peak (e.g. orange, lemon)

Low T preservation: Case study → Fresh foods (Quality losses)

Chilling injury

storage temperature is reduced below a specific optimum for the individual crop

Effects

Imbalance in metabolic activity → over-production of metabolites → toxic to the tissues

Changes in membrane lipid structure, enzyme activity and structural proteins → loss of membrane integrity and leakage of solutes

Transpiration

Excessive storage time

Incorrect temperature

Mechanical damage to drops

Effects

enzymatic browning

wilting

weight loss

Losses of vitamin C

Accelerated at higher storage T and longer storage t

sometimes higher losses at lower storage T

moisture loss → vitamin C loss

Especially for leafy vegetables

Cause: bruising, mechanical injuries and excessive trimming

Influence on carotenoids

dependent on type of fruit: increase or decrease

→ !! Fresh-cut fruits visually spoil before any significant nutrient loss occurs

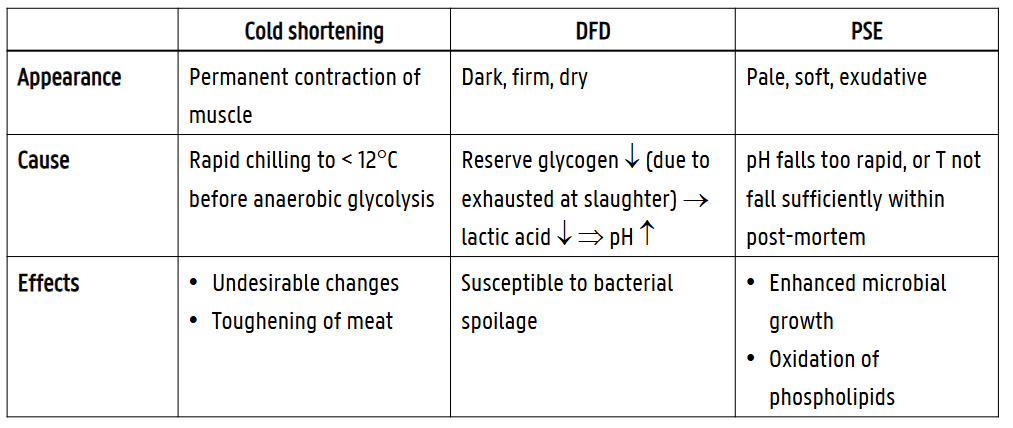

Low T preservation: Case study → Fresh foods: meat and meat products

Muscles

glycogen, creatine-phosphate and sugar phosphate

used for ATP production by glycolysis

ATP supply stops → rigor mortis tissue

Anaerobic respiration

Glycogen → lactic acid → pH falls from ~= 7 to between 5.4 and 5.6

contribute to the flavour

against contaminating bacteria

protein denaturation → drip losses

T-dependent → lower T is required → slow down biochemical reaction

Low T preservation: Case study → Fresh foods: meat and meat products (Quality losses)

Lipid oxidation

Adverse changes to flavour, colour, texture and nutritive value → production of toxic compounds; oxidized flavour or “warmed-over flavour”

Enzyme activity

Both positive and negative effects

Loss of nutrients

Vitamin C, folate → due to chilling time, storage T and oxidation

Low T preservation: Case study → Fresh foods: Processed foods

categorize by degree of microbial risk

Class 1: containing raw or uncooked ingredients (salad, cheese…)

Class 2: mixture of cooked and low-risk raw ingredients

Class 3: cooked food and then packaged

Class 4: packaged and then cooked

Shelf-life is determined by

Type of food

Preservative factors (pH, aw, chemicals)

Microbial destruction/ enzyme inactivation by unit processes

Hygienic control during processing/packaging

Temperature history

Different processes

“Cook-chill” or “Cook-pasteurize-chill” processes

“Sous vide” products: vacuum pack → pasteurisation → cooling → cold storage → shelf life of 2-3 weeks

To replace warm-holding in institutional catering

High-care area

area with almost no contamination possible

Modified atmospheres

= extra measure to control growth of MO in chilled foods and to control product quality

Types

MAS = modified atmosphere storage

CAS = controlled atmosphere storage

Mechanism

78% N + 21% O + 1% of CO2, water vapour and other gasses

Proportion of oxygen ↓ and/or ↑ proportion of CO2 with specified limits in the atmosphere → maintain the original product quality and extend the shelf life