21-25 Stresses

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

Ultimate stress (Su).

It is defined as the largest stress obtained by dividing the largest value of the load reached in a test to the original cross-sectional area of the test piece.

Breaking stress.

The stress corresponding to point F, at which the specimen breaks away after necking and reduction of cross-sectional area.

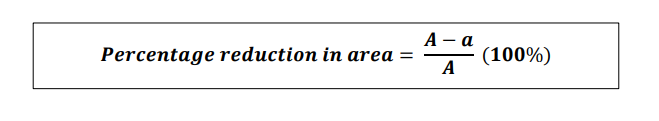

Percentage reduction in area

It is the difference between the original cross-sectional area and cross-sectional area at the neck (i.e. where the fracture takes place). This difference is expressed as percentage of the original cross-sectional area.

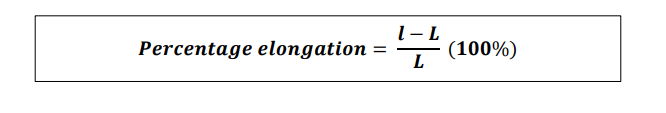

Percentage elongation

It is the percentage increase in the standard gauge length (i.e. original length) obtained by measuring the fractured specimen after bringing the broken parts together. It gives a measure.

WORKING STRESS

When designing machine parts, it is desirable to keep the stress lower than the maximum or ultimate stress at which failure of the material takes place. This stress is known as the working stress or design stress. It is also known as safe or allowable stress.

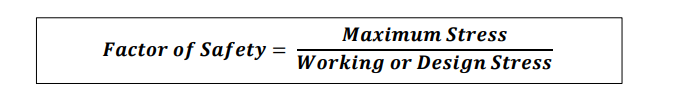

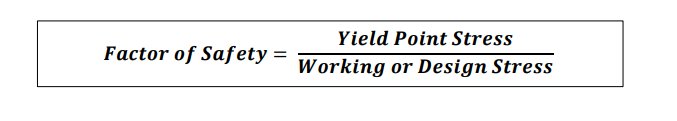

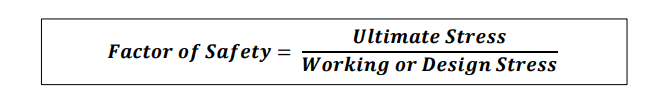

FACTOR OF SAFETY

It is defined, in general, as the ratio of the maximum stress to the working stress.

FACTOR OF SAFETY OF DUCTILE MATERIALS

where the yield point is clearly defined, the factor of safety is based upon the yield point stress.

FACTOR SAFETY OF BRITTLE MATERIALS

the yield point is not well defined as for ductile materials. Therefore, the factor of safety for brittle materials is based on ultimate stress. This relation may also be used for ductile materials

SELECTION OF FACTOR OF SAFETY

The selection of a proper factor of safety to be used in designing any machine component depends upon a number of considerations, such as the material, mode of manufacture, type of stress, general service conditions and shape of the parts.

Before selecting a proper factor of safety, a design engineer should consider the following points:

• The reliability of the properties of the material and change of these properties during service;

• The reliability of test results and accuracy of application of these results to actual machine parts;

• The reliability of applied load;

• The certainty as to exact mode of failure;

• The extent of simplifying assumptions;

• The extent of localized stresses;

• The extent of initial stresses set up during manufacture;

• The extent of loss of life if failure occurs; and

• The extent of loss of property if failure occurs.

STRESSES IN COMPOSITE BARS

A composite bar may be defined as a bar made up of two or more different materials, joined together in such a manner that the system extends or contracts as one unit, equally, when subjected to tension or compression.

In case of composite bars, the following points should be kept in view:

1. The extension or contraction of the bar being equal, the strain i.e. deformation per unit length is also equal.

2. The total external load on the bar is equal to the sum of the loads carried by different materials.

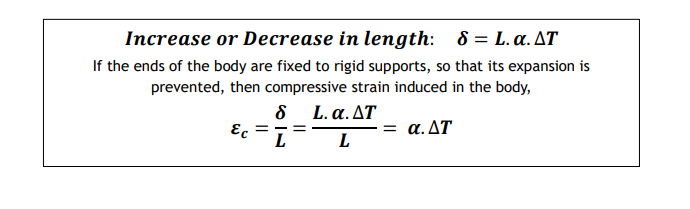

THERMAL STRESSES – STRESSES DUE TO CHANGE IN TEMPERATURE

Whenever there is some increase or decrease in the temperature of a body, it causes the body to expand or contract. A little consideration will show that if the body is allowed to expand or contract freely, with the rise or fall of the temperature, no stresses are induced in the body. But, if the deformation of the body is prevented, some stresses are induced in the body. Such stresses are known as thermal stresses.

When a body is composed of two or different materials having different coefficient of thermal expansions, then due to the rise in temperature

the material with higher coefficient of thermal expansion will be subjected to compressive stress whereas the material with low coefficient of expansion will be subjected to tensile stress

LINEAR AND LATERAL STRAIN

Every direct stress is accompanied by a strain in its own direction which is known as linear strain (longitudinal strain) and an opposite kind of strain in every direction, at right angles to it, is known as lateral strain.

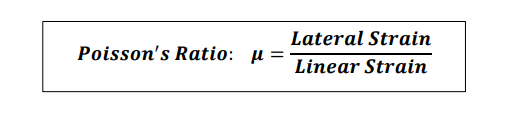

POISSON’S RATIO

It has been found experimentally that when a body is stressed within elastic limit, the lateral strain bears a constant ratio to the linear strain (longitudinal strain).

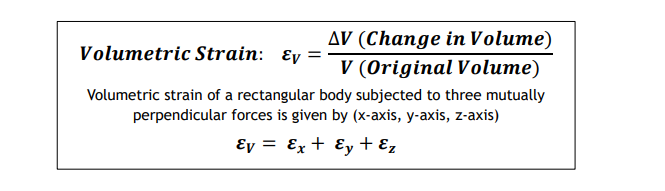

VOLUMETRIC STRAIN

When a body is subjected to a system of forces, it undergoes some changes in its dimensions. In other words, the volume of the body is changed. The ratio of the change in volume to the original volume is known as volumetric strain.

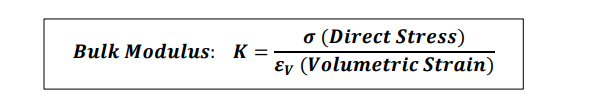

BULK MODULUS

When a body is subjected to three mutually perpendicular stresses, of equal intensity, then the ratio of the direct stress to the corresponding volumetric strain is known as bulk modulus. It is usually denoted by K.