Adaptive Metallurgy Midterm Exam

1/83

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

84 Terms

Casting

Mechanical Working

Fabrication by Joining

Machining

Powder Metallurgy

5 Principal Methods in Shaping Metals

Casting

the production of shaped articles by pourung molten metal into moulds

Mechanical Working

the shaping of metals in the solid state by plastic deformation above or below the recrystallization temperature.

Fabrication by Joining

the production of structural units by the joining of smaller components manufactured in other ways

Machining

the production of shaped articles by cutting from plain or roughly shaped forms using machine tools

Powder Metallurgy

The production of shaped parts by the die pressing and sintering of metal powders

No restriction on the type of metal or alloy

No restriction on the size of the component

Intricate external and internal shapes

A wide range of properties

Economically suitable

Cheapest available technique

6 Advantages of casting

High energy consuming process

Highly labour intensive

The quantum of raw materials required is quite high

The time required is quite long

Quite bad working condition in foundries at different stages

5 Disadvantages of Casting

According to the type of metal or alloy cast in the unit

Nature of their production

Basis of the casting process

3 Classification of Foundries

Jobbing

Production

Semi-production

Captive

Independent

5 Types of Foundries according to the Nature of their Production

Jobbing

one having a physical plant such that it usually contracts to produce a casting or a small number of castings of a given kind

Production

a highly mechanized shop which requires that large numbers of a given kind of casting be made in order to produce them at low cost

Semi production

are those in which a portion of the work is a jobbing nature while the balance is production casting.

Captive

one which is an integral part of some manufacturing company and whose castings are consumed mainly in the products of the parent organization

Independent

usually a separate company that produces castings for any number of customers

2 Types of Foundries on the Basis of the casting Process

Expendable mold processes

Permanent mold processes

Expendable mold processes

uses an expendable mold which must be destroyed to remove casting

Permanent mold processes

uses a permanent mold which can be used over and over to produce many castings

ARCO METAL PRODUCTS COMPANY, INC.

CEBU IRON FOUNDRY CORP. (CIFCO)

FONDERIE OUELLET ASIA, INC.

MAKATI FOUNDRY, INC.

QAMTIS PHILIPPINES, INC.

SUPERCAST FOUNDRY AND MACHINERY CORP.

SAN GABRIEL METAL CONCEPTS, INC.

TIGER MACHINERY AND INDUSTRIAL CORP.

8 Factories that produce metal castings

Lack of quality of raw material

Shortage of electric power in many regions

Shortage of capital/finance (use of obsolete equipment causing low productivity)

Lack of trained manpower

Metal casting is generally a low profit-making, low productive industry with larger risks from capital, employees, power and materials.

Environmental Pollution

6 Challenges for Filipino Foundry Industry

Mining and mineral processing

Core sector

Chemicals, machine tools, transport, textiles etc.

3 Important Industrial Sectors using castings

liquid or is in a highly plastic condition

Solidification Processes

We consider starting work material is either and a part is created through solidification of the material

Metals Ceramics, specifically glasses

Polymers

polymer matrix composites (PMCs)

Solidification processes can be classified according to engineering material processed:

Casting

Process in which molten metal flows by gravity or other force into a mold where it solidifies in the shape of the mold cavity The term casting also applies to the part made in the process

Melt the metal

Pour it into a mold

Let it freeze

Steps in casting seem simple:

Big parts

Small parts

2 Parts Made by Casting

Big parts

Engine blocks and heads for automotive vehicles, wood burning stoves, machine frames, railway wheels, pipes, bells, pump housings

Small parts

Dental crowns, jewelry, small statues, frying pans

ferrous and nonferrous

All varieties of metals can be cast

foundry

Casting is usually performed in a

making molds

melting and handling molten metal

performing the casting process

cleaning the finished casting

Foundry = factory equipped for

Mold

is a container with cavity whose geometry determines part shape

shrinkage

Actual size and shape of cavity must be slightly oversized to allow for of metal during solidification and cooling

sand

plaster

ceramic

metalTwo forms of mold:

Molds are made of a variety of materials, including

open mold

closed mold

Two forms of mold:

open mold

simply a container in the shape of the desired part

closed mold

in which the mold geometry is more complex and requires a gating system (passageway) leading into the cavity.

Expendable mold processes

Permanent mold processes

Two Categories of Casting Processes

Expendable mold processes

uses an expendable mold which must be destroyed to remove casting Mold materials: sand, plaster, and similar materials, plus binders

Permanent mold processes

uses a permanent mold which can be used over and over to produce many castings Made of metal (or, less commonly, a ceramic refractory material)

Sand casting

cast part produced by forming a mold from a sand mixture and then pouring molten liquid metal into the cavity in the mold. The mold is then cooled until the metal has solidified

Pour the molten metal into sand mold CAVITY

Allow time for metal to solidify

Break up the mold to remove casting

Clean and inspect casting

Separate gating and riser system

Heat treatment of casting is sometimes required to improve metallurgical properties

5 Steps in Sand Casting

5 General Steps in Casting terms

Pattern-making

Core-making

Molding

Melting and pouring

Cleaning

Pattern-making

design to be replicated

Core-making

internal cavity surface

Molding

preparation for the receiving of molten metal

Cleaning

removal of mold, core, scales, or excess metal

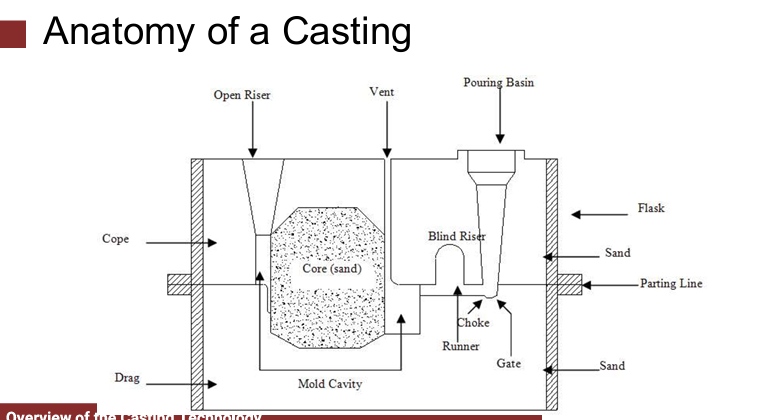

Cope

Drag

Mold consists of two halves

Cope

upper half of mold

Drag

bottom half

flask

Mold halves are contained in a box, called a

parting line

The two halves separate at the

The cavity in the sand mold is formed by packing sand around a pattern, then separating the mold into two halves and removing the pattern

The mold must also contain gating and riser system If casting is to have internal surfaces, a core must be included in mold

A new sand mold must be made for each part produced

Making the Sand Mold

Cavity

inverse of final shape with shrinkage allowance

Pattern

model of final shape with shrinkage allowance

Wet sand

made by adding binder in the sand

Cavity is inverse of final shape with shrinkage allowance

Pattern is model of final shape with shrinkage allowance

Wet sand is made by adding binder in the sand

Mold cavity is formed by packing sand around a pattern When the pattern is removed, the remaining cavity of the packed sand has desired shape of cast part The pattern is usually oversized to allow for shrinkage of metal during solidification and cooling

Forming the Mold Cavity

Cavity

provides the external features of the cast part

Core

provides internal features of the part. It is placed inside the mold cavity with some support.

Gating System

It is channel through which molten metal flows into cavity from outside of mold

It is channel through which molten metal flows into cavity from outside of mold Consists of a down-sprue, through which metal enters a runner leading to the main cavity

At the top of down-sprue, a pouring cup is often used to minimize splash and turbulence as the metal flows into down-sprue

Gating System

Riser

It is a reservoir in the mold which is a source of liquid metal to compensate for shrinkage of the part during solidification

Most metals are less dense as a liquid than as a solid so castings shrink upon cooling, which can leave a void at the last point to solidify. Risers prevent this by providing molten metal to the casting as it solidifies, so that the cavity forms in the riser and not in the casting

Riser

The Pattern

A full-sized model of the part, slightly enlarged to account for shrinkage and machining allowances in the casting.

Pattern materials:

Wood

Metal

Plastic

Wood

common material because it is easy to work, but it warps

Metal

more expensive to make, but lasts much longer

Plastic

compromise between wood and metal

solid pattern

split pattern

match-plate pattern

cope and drag pattern

Types of Patterns

Solid Pattern (Loose or Single Piece)

Problem in locating the parting line. Locating is skill dependent. Suitable for low production

Split pattern

Relatively easy to locate parting line. Used for low-medium size production

Match-plate pattern

The cope and drag portions of the pattern are mounted on opposite sides of a wood or metal plate conforming to the parting line. Match plates are also integrally cast in which cast pattern and plate are cast as one piece in sand or plaster molds. It is used with some type of molding machine, in order to obtain maximum speed of molding. Advantages of the match-plate patterns are: (a) Costly but good production rate (b) Increase the dimensional accuracy

Cope and Drag pattern

(a)Similar to match-plate pattern but split pattern halves are attached to separate plates.

(b)The pattern contains built-in gating system thus save time for making separate gating system in each mold.