OMIS 340

1/76

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

77 Terms

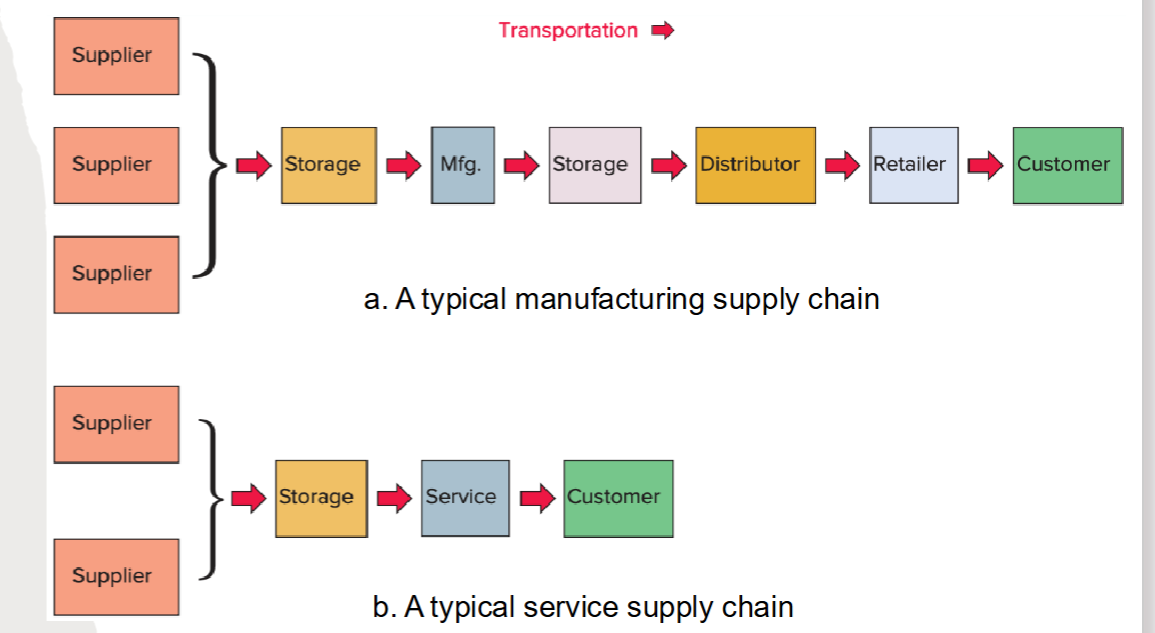

Supply chain

Network of orgs and activities

Produces and delivers products or services

Also called the value chain

Supply chain management (SCM)

Strategic coordination across the supply chain

Integrates supply and demand decisions

Focuses on end to end performance

Logistics

Manages forward and reverse flows

Goods, services, information, and cash

Typical Service Supply Chain

Goal of SCM

Match supply and demand efficiently and effectively

Key SCM Focus Areas

Outsourcing decisions

Procurement & supplier management

Customer relationship management

Rapid problem identification & response

Supply chain flows

Product & service flow -> goods, services, returns

Information flow -> forecasts, orders, tracking

Financial flow -> payments, credit terms, ownership

Benefits of Outsourcing

Lower labor operating costs

Docs on core competencies

Convert fixed costs to variable costs

Accessible supplier expertise

Free up capital

Support global expansion

Share selected risks with suppliers

Risks of outsourcing

Longer lead times and reduced flexibility

Higher transportation costs

Loss of control and business knowledge

Quality and productivity issues

Cultural and communication barriers

Intellectual property concerns

Increased coordination effort

Operations

That part of a business organization that is responsible for producing goods and/or services.

Operations management

The management of systems or processes that create goods and/or provide services.

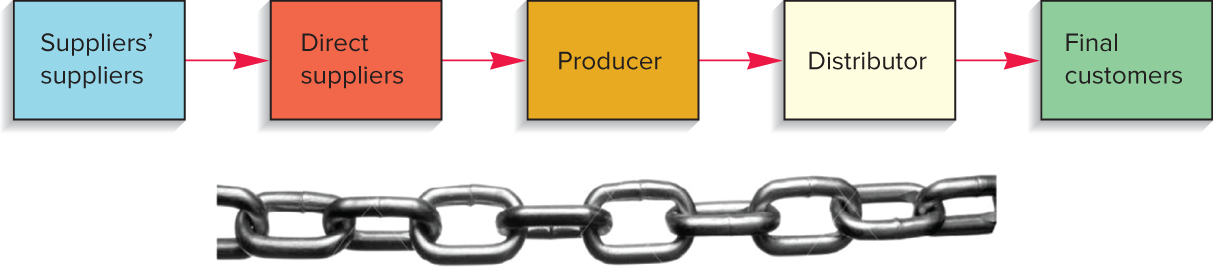

Supply chain

A sequence of organizations—their facilities, functions, and activities—that are involved in producing and delivering a product or service.

Supply chain steps image

Types of analytics

Descriptive analytics - Analytics that involves summarizing data.

Diagnostic analytics - Analytics that relates to answering the question of why something happened.

Predictive analytics- Analytics that focuses on what will happen.

Prescriptive analytics - Analytics that involves analyzing data to determine how to influence a desired change.

Key issues in business operations today:

Economic conditions

Innovating

Quality problems

Risk management

Cybersecurity

Competing in a global economy

Common Supply Chain Risks (DIRQ?!)

Disruptions

Information risks

Risk management

Quality failures

Resiliency

ability of a business to recover form an event that negatively impacts the supply chain

Disruptions

Natural disasters

supplier failures

Quality failures

Recalls, liability, reputational damage

Information risks

Loss of sensitive or proprietary data

Risk management

Identify and assess risks

Evaluate likelihood and impact

Develop response strategies

Risk avoidance

Risk reduction

Risk sharing

Keys to effective risk management

Know your suppliers

Improve supply chain visibility

Develop rapid response capability

What makes a supply chain global?

Design, sourcing, and production span multiple countries.

Manufacturing and services often outsourced for cost advantages

Products sold in global markets

Key complexities

Cultural and language differences

Currency fluctuations

Political and economic instability

Longer lead times and higher transportation costs

Greater need for trust and coordination among partners

How do natural disasters (such as hurricane helene) impact supply chains? (QUIZ QUESTION)

transportation difficulties

can’t access facilities/ they are damaged

relied heavily on a single critical source with few readily available alternatives

What could be done during a goods shortage? (ex: IV bags) (QUIZ QUESTION)

outsource from other facilities (diversify sourcing)

don’t rely heavily on a single critical source with few readily available alternatives

restore the main facility via:

gov support

increased production from other manufacturers

reducing demand through conservation

reduced hoarding

sharing across facilities

What could be done for quartz shortage (good that was inaccessible due to the mines being clogged from the hurricane and could not have been prevented) (QUIZ QUESTION)

no immediate replacement supply

Short term: focus on restarting operations quickly

Long term: substitute materials, alternative sources.

Key lessons manufacturers and retailers learned about the supply chain disruption from pandemic (QUIZ QUESTION)

companies become more flexible diversifying suppliers

diversify their routes to manage delays

moving away from cheapest only sourcing (quality)

relaxing overly lean inventory policy

increasing lead times and order quantity

ordering earlier

using alternative ports when needed

What are the benefits of regionalization, nearshoring, and reshoring? (QUIZ QUESTION)

prevent delays

save costs

reduce external disruptions

reduce transportation/ shipping costs for longer travel

keeps issues localized (not global)

reduces the impact of pandemic related disruptions

reduces pandemic related disruptions

What are the negatives of regionalization, nearshoring, and reshoring? (QUIZ QUESTION)

it can be more expensive

is typically cheaper to outsource

unrealistic for smaller businesses to participate in bc its too expensive

can take months to yrs to reorganize supply chain operations

must weigh benefits between higher costs and different risks against original benefits

significant investment to restructure supply chains

underlying causes of the drug shortages? (QUIZ QUESTION)

not meeting FDA requirements

not enough manufacturers producing each generic drug

need for lowest price = limited transparency

poor quality can halt production

difficulty obtaining ingredients

seasonal demand

disease spread

drug life cycles

healthcare trends

How can reshoring help with drug shortages (QUIZ QUESTION)

helps reinstall reliability into the supply chain

no more issues w/ international distributors, financial strains, manufacturer shutdowns

increased quality

better transparency for parties involved

3 SCM decisions

Strategic - (Long term, direction setting)

Tactical - (Midterm, planning focused)

Operational - (short term, execution focused)

Strategic planning

(Long term, direction setting)

Supply chain strategy alignment

Network configuration

IT

Product And service design

Capacity planning

Strategic partnerships

Distribution strategy

Risk and uncertainty management

Tactical planning

(Midterm, planning focused)

Forecasting

Sourcing

Operations planning

Inventory planning

Transportation planning

Collaboration

Operational planning

(short term, execution focused)

Scheduling

Receiving and transforming

Order fulfillment

Inventory control

Shipping

Information sharing

Day to day control

Procurement -

Responsible for obtaining materials, parts, and services

Supports production and service delivery

Goals of procurement

ensure right quality

Ensure right timing

Align purchasing with operation technology

The purchasing cycle

receive requisition

Select supplier

Place order

Monitor order

Receive goods/ services

Centralized purchasing

uses one main team for all buying, focusing on cost savings, standardization, and control

Lower price through volume consolidation

Better supplier service

Better handling of specialized items

Decentralized purchasing

empowers individual departments, branches, or teams to manage their own procurement needs directly, rather than relying on a central, corporate purchasing office

Departments understand needs better

fast er response time

Flexibility with local suppliers

Supplier management includes:

Selecting suppliers

Vendor analysis

Supplier audits

Supplier certification

Supplier relationship management

Key supplier evaluation tools

Vendor analysis

Price, quality, reputation, service

Supplier audits

production/ service capability

Quality and delivery performance

Supplier certification

Verifies supplier meets buyer requirements

Reduces need for incoming inspection

Types of supplier relationships

Short term

Competitive bidding

Minimal interaction

Medium term

Ongoing relationship

Long term

Highly cooperative

Often evolves into partnerships

Strategic partnering

long term collaboration for mutual benefit

ex:

Supplier holds inventory

Customer commits long term

Lower inventory costs and stable demand

Collaboration approaches CPFR

Collaborative planning, forecasting, and replenishment

Inventory velocity

speed at which inventory moves through the supply chain

Bullwhip effect

small changes in customer demand

Lead to larger demand swings upstream

Causes increasing inventory fluctuations across the supply chain

Main causes of the bullwhip effect

Forecast inaccuracies

Overreaction to stockouts

Order batching

Sales incentives and promotions

Quantity discounts

Product and service mix changes

Ways to reduce bullwhip effect

Strategic inventory buffering

Information sharing across the supply chain

Replenishment based on actual demand

Vendor managed inventory (VMI)

Supplier monitors inventory levels

Supplier replenishes inventory when levels are low

Reduces demand distortion and improves coordination

Bullwhip effect is fundamentally

an information problem not a demand problem

Order fulfillment

processes used to respond to customers

Order fulfillment strategies

Engineer to order (ETO) - product designed after order is received

Make to order (MTO)- production starts after order

Assemble to order (ATO) - final assembly after order

Make to stock (MTS) - products produced in advance and stocked

Remember

ETO -> MTO -> ATO -> MTS moves from high customization to high efficiency

Logistics manages the movement of:

Materials

Services

Cash

Information

Logistics activities

Movement within facilities

Incoming and outgoing shipments

Objectives of logistics activities

Getting goods to the right place at the right time

Movement within a facility

Flow of materials between:

Receiving

Storage

Work centers

Shipping

Incoming & outgoing shipments (traffic management)

Oversees shipment scheduling and routing

Considers:

Transportation costs

Government regulations

Organizational needs

Shipping delays or disruptions

Tracking goods with

RFID

Uses radio waves to identify and track items

Compared to barcodes

More information

No line of sight required

Multiple items read at once

Benefits of RFID

Greater supply chain visibility

Improved inventory management

Better quality control

Strong supplier and customer relationships

3rd Party Logistics (3PL)

Outsourcing logistics activities

Common services

Warehousing

Distribution

Benefits of 3PL

Logistics expertise

Advanced information systems

Lower shipping costs

Logistics is about

flow, visibility, and coordination. Technology and outsourcing exist to improve all three

Key considerations

Cost

Speed (delivery time)

Availability of shipping modes

Type of material shipped

Flexibility

Environmental impact

Common shipping modes:

Truck

Rail

Air

Water

Time-cost trade off

Faster shipping -> higher cost

Slower shipping -> lower cost

Choice depends on:

Business strategy (low cost vs. responsive)

Urgency of the shipment

Managerial insight

When urgency is low, firms compare:

Shipping cost savings vs. additional inventory holding cost

Incremental holding cost equation

(H * d)/ 365

H = annual holding (earning) cost of the item

d= difference in delivery time(days)

Decision rule -

Choose slower shipping if

Shipping cost savings> incremental holding cost

Choose faster shipping otherwise

Creative an effective supply chain

Foundations of an effective supply chain - begins with strategic sourcing

Focuses on:

Reducing waste and non-value added activities

Lowering costs and risks

Improving supplier performance

Key enablers for creating an effective supply chain

trust

Effective communication

Fast information flow

Supply chain visibility

Event management capability

Performance metrics

SCOR framework

A standard model for designing and managing supply chains.

Parts of framework:

Plan

Source

Make

Deliver

Return

Managing returns (reverse logistics)

managing the flow of returned products

Elements of return management:

Gatekeeping - screen returns to prevent incorrect acceptance

Avoidance - reduce the number of returns

Closed loop supply chain

firm manages both forward and reverse logistics

Key challenges in creating effective supply chains

Organizational integration barriers

Gaining top management support

Managing trade offs (cost, speed, flexibility, service)

Resource constraints for small businesses

Variability and uncertainty in demand and supply

Meeting required response times.