5 fossil

1/21

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

22 Terms

Where global coal reserves

asia and north america

where natural gas

asia north america equator

where oil

north america russia saudi arabia

Oil shale

an organic-rich fine-grained sedimentary rock containing kerogene from which liquid hydrocarbons can be produced

Peat: formation time and where

500 years north

Oil products

- Gasoline

- Diesel fuels

- Asphalt base

- Fuel oils

- Heating oils

- Kerosene

- Liquified petroleum gas

Liquified petroleum gas (LPG)

• Propane, butane

• Gaseous att atmospheric preassure but can be condensed into liquid state

• LPG vapour is denser thean air: leaking gasses can floe long distances from the source

Natural gas

• 95% methane

• Hagh caloric value

• Does nor require storage facilities on site

• No sulphur

Mixes readily with air without producing smoke or soot

Fossil fuel consumption: how many yeas left

Coal - 175 years att current consumption

Oil - 32 years at curent consumption

Natural gas - 43 years at current consumption

we are past peak oil

Advantages of fossil

• Large amounts of electricity can be generated in one place, at realtivley low direct cost

• Transporting oil and gas to the power stations is easy

• Gas-fired power stations are completley efficent and less poluting

• A fossil.fueled power station can be built alost anywhere

High energy density fuels that make them suitable for transportation and other aplications

Dissadvantages of fossil

• Air polution

• Contributes to global warming

• Acid rain due to SO2 and Nox emissions

• Healt effects

• Reduced harvest due to air polutants

• Enviromental risks due to mining

Depleation of limited resources

Removal of emissions at the source

Before combustion

Pre-treatment of fuels (reduce content of S, N, H2O and trace elements)

Oil refineries (fuels optimized for combustion)

During combustion

Optimize combustion conditions (reduce formation of CO, CxHyOz, soot, Nox)

After combustion

Capture emissions (various after-treatment of exhaust gases)

Catalytic cleaning (additional reaction steps, reduce CxHyOz, soot, Nox)

Filters (particles

Before comustion - refining for less emissions

• Removal of sulfur from coal: fysical, chemical and biological methods

Removal of sulfur from oil: heat treatment in a refinery

During combustion - refining for less emissions

• Optimize combustion conditions to reduce formation of CO, CxHyOz, soot and Nox

To optimizze:

- Mixing of fuel and oxygen, recidense time, temperature

- Compatibility between fuel propertioes and combustion unit design

Handling of the combustion equipment is important

After combustion - sulfur removal

Exampel: wet scrubbers

• Commonly used

• Removes ca 90% of the sulfur

Example: SNOX process (combined removal of sulfur and NOX)

• Catalytic reduction of NO to N2 using NH3

• Catalytic oxidation of SO2 to SO3

Production of H2SO4

Particle removal

• Inertial or interception (more efficent with increazing particle size)

• Diffusion to a solid or liquid collection surface

• Charging of particles

- Cyclones

- Fabric filters

- Electrostatic percipitators

Scrubbers

CO2 reduction

• Using less energgy

• Using low-carbon energy sources

• Usin carbon-containing fuels without emitting CO2 to the atmosphere (CCS)

CCS:

• Oxyfuel

• Membrane separation from other gases

• Carbon dioxide scrubbing

Co2 stored as compressed gas

Conciderations:

- Decrased power plant efficency by aproximatlety 10-40%

- Captures about 80-95% of the carbon in exhaust gas

Increases the price on electricity by aproximatly 30-60%

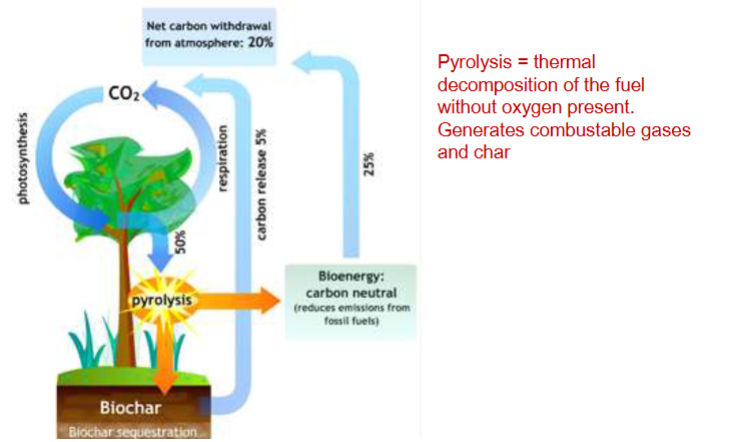

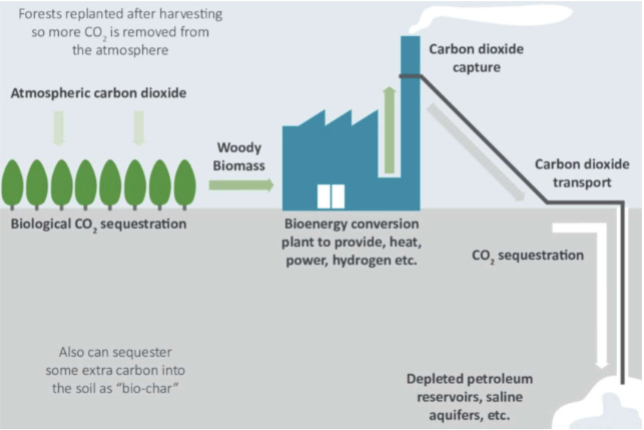

BECCS

Bioenergy with CO2 capture and storage (BECCS) to produce negative CO2 emissions

CCS advantages

• Can continue to use conventional sources and existing infrastructure

• Could be a potential accepted solution for countries having large scale coal reserves (China Usa)

• Ccs ON BIOENERGY CAN GIVE NEGATIVE co2 EMISSIONS

CCS dissadvantages

• CCS is not a long tem solution since both fossil fuels as well as the CCS storage potental are limited

• CO2 may leak from the storages

Investments in CCS thecnology may take research funding from thaé development of renewable resources

BIochar

Oyrolysis = thermal decomposition of the fuel without oxygen present. Generates combustables gasese and char