MATE EXAM 3

1/66

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

67 Terms

Hydrogen bonding

adds/shares on electron with another to fill its shell; sigma bond

hydrogen molecule

rotational motion about bond and axis - s orbitals

Carbon-Carbon bonding

pi - p orbitals; no coincident with axis and no rotational motion

sigma - 2s² and 2p²; shares valence electrons to form an octet

polymer bonding

molecular solids with major bond rotational motion as long as there are no pi bonds

polyethylene (PE)

homopolymer with only C backbone and H

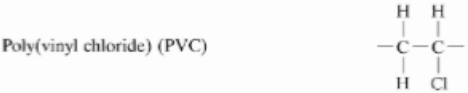

Poly(vinyl chloride) (PVC)

homopolymer with Cl

Polypropylene (PP)

homopolymer - with CH3

Polytetrafluorothylene (PTFE)

copolymer - includes F

Polystyrene (PS)

copolymer including a nylon

molecular chemistry

no single rule; logic required

Molecular shape

based on molecular weight, degree of polymerization, and physical length

molecular size

physical outline - influences rotation and chain flexibility

less flexible = higher modulus = stiffer polymer

molecular structure

mer unit arrangment:

linear = single chain (PE, PVC, PS, nylon)

branched: side chains off main

cross-linked: linear joined by covalent bonds

networked: 3D networks (PE, PTFE, epoxies)

thermoplastic polymer

soft when heated, hard when cooled

linear or branched

bonding diminished, movement between chains increases

thermosetting polymers

permanently hard when cross-linked/networked

no melting, held by primary bonds, disintegrate/burn

chain folded model

platelets/lamellar/interwoven chains folding in on themselves

spherulites

bulk polymers crystallized from melt; semi-crystalline

ductile and brittle polymers

weaker and softer - time/temp sensitive

ductile/brittles effected by

strength of inter-molecular secondary bonding

ease of rotational motion

ductile/brittles behaviors

elastic primary bond stretching <1%

elastic chain reorientation »1%

plastic primary bond breakage ~1%

plastic chain slippage »1%

brittle

little to no chain slippage:

bond stretch

bond break

ducrtile

some chain mobility:

elastic primary bond stretch & chain reorientation

plastic primary breakage & chain slippagesome chain mobility: allows deformation before fracture, characterized by both elastic and plastic responses.

viscoelasticity

applied stress in instantaneous elastic strain followed by viscous

viscoelasticity behaviors

brittle at low temps

viscous at high temps

Creep

time-dependent strain

stress relax

time-dependent stress

FIllers

sand, glass, clay:

improve tensile/compressive strengths, abrasion resistance & toughness

plasticizers

small molecules occupying positions between polymer chains to increase distance between chains/decrease interactiosn

increase flexibility and ductilitysta

stabilizers

prevent degradation/burning

UV absorbers enhance UV resistance

Thermoplastics

formed above Tg; recyclable, flash reusedt

thermosetting polymers

prepare linear polymer, curing/hardening of crosslinking

not recyclable

molding

injection: 1+ molds

extrusions: constant cross-sections through die

blow

casting

spinning

fabrication of fibers: molten/solution state pumped through spinnert with small holes, rapidly solidifes

films

makes sheets, bags, films, molten extrusion molding through die and calendaring

natural composites

bone: tough protein/collagen particles of brittle mineral

artificial composites

concrete: aggregate particles mixed into cement

particle matrix phase

continuous, surrounding dispersion phase

disperesed phase

discontinuous, imbedded din matrix

large composies

particles increase the modulus over matrix

A composite found in high-performance applications

lower modulus material is the glue

fiber composite structure

high strength polymers used in composites/textile threads

natural fiber

wood:flexible cellulose fibers held by stiff lignin

artifical fiber composite

fiber-glass: glass fibers mixed into polyester

fiber composite structures

Ef>Em

Lf>Lc

fiber composite behaviors

large particle L<Lc

discontinuous L<15 Lc

continuous L> 15 Lc

general tensile fiber composite

1) fiber and matrix deform elastically

2) matrix yields plastically but fiber continuous elastically3) ultimate tensile strength is determined by the fiber's strength and the fiber-matrix bond quality.

fiber composite longitudinal failure

fiber failure → matrix failure → composite failure

electrochemical corrosion

anode loses ions + oxidizes

cathode gains electrons + reduces

rate-controlling variables

temp: higher = faster rxn

conc: higher=faster

viscosity: faster=further corrosion

galvanic corrosion

basic

two dissimilar metals

crevice corrosion

concentration difference of oxygen

erosion corrosion

combined chemical + mechanical abrasion

stress corrosion

stressed material corrodes by forming cracks

thermal expansion

solid materials expand with heat, contract with cooling

caused by assymetry of potential energy curve

metal heats = decreased density

thermal stress

material unable to undergo expansion/contraction from temp; internal stress develops

conductivity

heat transported from high to loe temps

must have free elctrons

resistivity

property limiting current in a material; length and cross-sectional area relation

electronic band rules

No two electrons in closed system with same energy state OR only two have the same energy

Image shelves on shelves or highway analogy

Last band = valence; first empty band = conduction

Band gap energy E(g) in insulators & conductors is associated with bond strength

electronic bands of metals

In metals electrons conduct in valence band

electronic bands in semiconductors/insulators

In semiconductors/insulators, electrons conduct in conduction band

In semiconductors/insulators, electrons must be promoted from valence band to conduction band to conduct

In semiconductors/insulators, valence band is full

recombination

excited electrons losing energy and dropping back to empty state

thermal vibration

move off perfect equilibrium sites, constantly scattering, always thermal vibrations

conduction in metals

large electron concentrations in partially full band - easy excitation

affected by purity of alloys and temperature

conduction in semiconductors

Orbitals become bands,

Completely full valence band

Conduction band is completely empty

Elemental/compound materials have better covalent bonds – Silicon

intrinsic

electrons concentration equal to hole concentration

extrinsic

derived from impurities/dopants

donor: 1+

acceptors: 1-

n-type extrinsic

small dopant

p-type extrinsic

large dopant