HGE Formulas 01

1/73

Earn XP

Description and Tags

Hydraulics

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

74 Terms

Density

ρ = mass / volume

Density of Water

ρw = 1000 kg/m3 = 1.94 slugs/ft3

Specific Volume

ν = 1 / ρ = volume / mass

Weight

w = mg

Unit Weight

γ = w/v = mg / v

Unit Weight of Water and Air

γw = 9810 N/m3 = 62.4 lbs/ft3

γair = 12 N/m3

Specific Gravity

sg = γ / γw = ρ / ρw

Specific Gravity of Common Fluids

Freshwater: 1.00

Seawater: 1.03

Oil: 0.80

Mercury: 13.6

Glycerin: 1.25

Surface Tension: Pressure inside a Droplet

p = 4σ / d

p = gage pressure

σ = surface tension

d = diameter of droplet

Surface Tension: Capillary Rise

h = 4σ cosθ / γd

h = capillary rise or depression

θ = contact angle from vertical

d = diameter of tube

Viscosity

µ = τ / (dV / dy)

µ = viscosity

τ = shear stress

dV / dy = change in velocity wrt distance

Kinematic Viscosity

ν = µ / ρ

Compressibility

ß = (- dV / V) / dp = 1 / EB

dV / V = change in volume

dp = change in pressure

EB = bulk modulus of elasticity

Pressure

p = γh

pB = pA + γh

Pressure Head

h = p / γ

hB = sgA / sgB × hA

Absolute Pressure

pabs = patm + pgage

patm = 101.325 kPa = 1 atm = 760 mmHg = 760 torr = 14.7 psi

Gas Pressure (Absolute)

p = ρRT ; R = 287.4 Nm / kg K

p = γRT ; R = 29.3 m / K

T = Temperature in Kelvin (°C + 273 K)

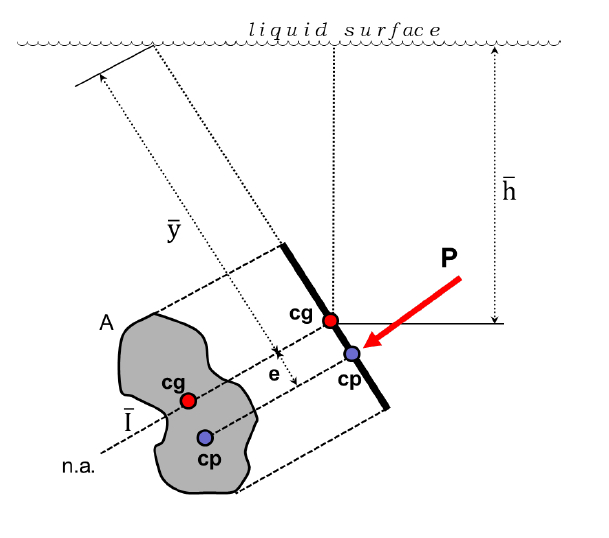

Hydrostatic Pressure: Plane Surface

P = γ × h-bar × A

e = I / Ay-bar

Location of Force: y-bar + e

h-bar = distance of the cg below the liquid surface “l.s.”, on the vertical

A = submerged area

e = distance of cp below the cg along the body

I = moment of inertia of A wrt centroidal axis

y-bar = distance of the cg below the liquid surface “l.s.”, on the vertical

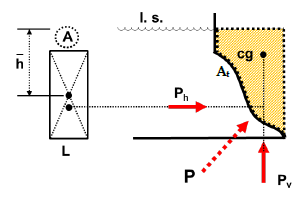

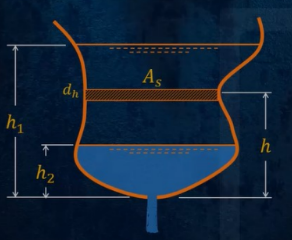

Hydrostatic Pressure: Curved Surface

Force = √(Ph2 + Pv2)

Ph = γ × h-bar × A → Location same as plane surface

Pv = γ × At × L = γ × Volume → Location at the c.g. of volume

Ph = Horizontal Component

Pv = Vertical Component

At = Area traced above the curved projection until the liquid surface

Archimedes’ Principle

BF = γf × Vd

BF = buoyant force

γf = unit weight of displaced fluid

Vd = volume of fluid displaced (body immersed)

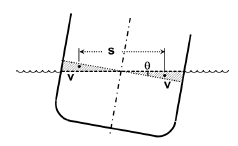

Distance of MBo

Rectangular Sections: MBo = B2 / 12D × [1 + 0.5 tan2 θ]

Other Sections (exact): MBo = v s / (V sinθ)

Approximate: MBo = I / V

θ = angle of tilting

v = volume of the wedge of immersion/emersion

s = horizontal distance between the centroids of v’s

I = moment of inertia of an area which is the top view of the body at the level of the liquid surface with respect to the axis of tilting

![<p>Rectangular Sections: MB<sub>o</sub> = B<sup>2</sup> / 12D × [1 + 0.5 tan<sup>2</sup> θ]</p><p>Other Sections (exact): MB<sub>o</sub> = v s / (V sinθ)</p><p>Approximate: MB<sub>o</sub> = I / V</p><p></p><p>θ = angle of tilting</p><p>v = volume of the wedge of immersion/emersion </p><p>s = horizontal distance between the centroids of v’s</p><p>I = moment of inertia of an area which is the top view of the body at the level of the liquid surface with respect to the axis of tilting</p>](https://knowt-user-attachments.s3.amazonaws.com/f668dd24-3bf0-41c7-8ef2-b78a4375f7b4.png)

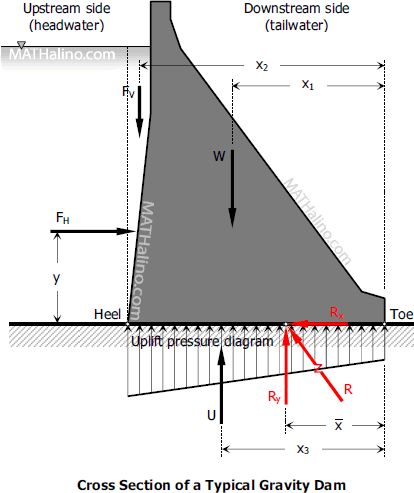

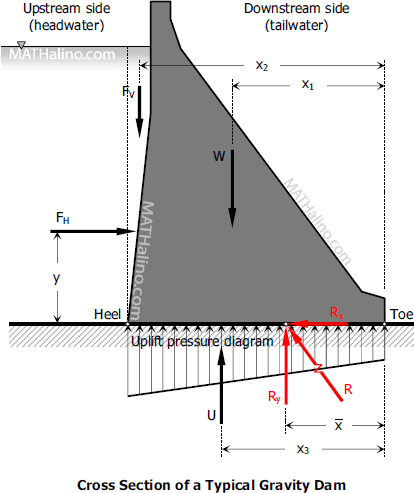

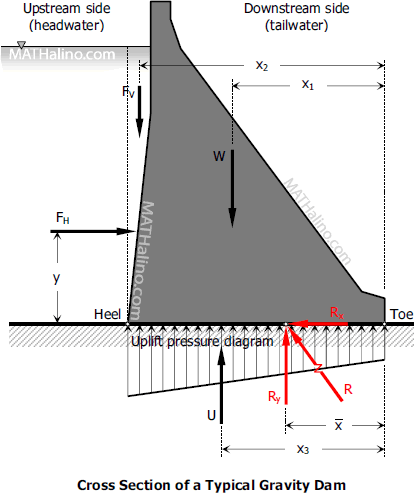

Dams: Factor of Safety against Overturning

FSO = RM / OM

RM = Righting Moment

OM = Overturning Moment

Note: Take moments at toe

Dams: Factor of Safety against Sliding

FSS = µRy / Rx

Dams: Location of Ry and e

x-bar = (RM - OM) / Ry

e = | B/2 - x-bar |

Dams: Foundation Pressure

If e ≤ B/6: q = Ry / B × (1 ± 6e / B)

If e > B/6: qmax = 2Ry / (3 × x-bar); qmin = 0

Hoop and Circumferential Stresses: Walls Carrying Stress in Pipes and Tanks

t = pD / 2St (eff)

t = thickness of the wall

D = inside diameter

p = unit pressure of fluid

St = actual or allowable tensile stress in the wall

eff = efficiency of the connections

Hoop and Circumferential Stresses: Hoops Carrying Stress in Pipes and Cylindrical Tanks

S = 2T / pD

S = center to center spacing of the hoops

T = tensile force in one hoop

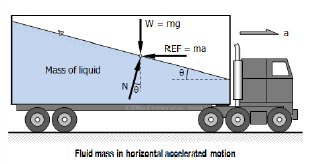

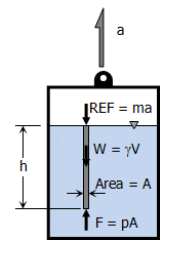

Moving Vessel: Horizontal Motion

tan𝜃 = a / g

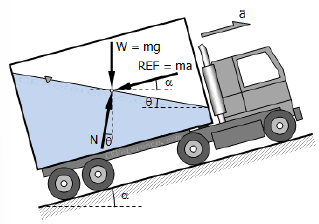

Moving Vessel: Inclined Motion

tan𝜃 = ah / (g ± av)

Note: (+) = upward motion, (-) = downward motion

Moving Vessel: Vertical Motion

p = γh (1 ± a / g)

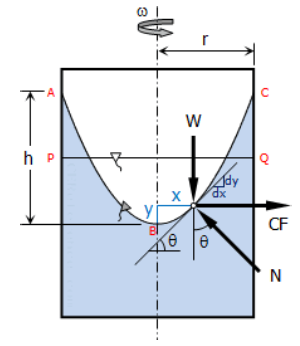

Rotating Vessel

tan𝜃 = ω2 x / g

y = ω2 x2 / 2g

r2 / h = x2 / y

Note: 1 rpm = π/30 rad/sec

Fluid Flow: Discharge

Q = AV

A = cross-sectional area of flow

V = velocity of flow

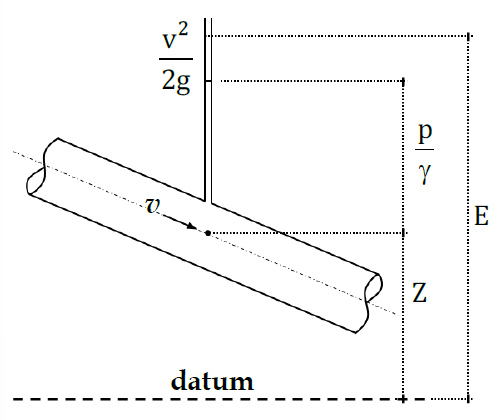

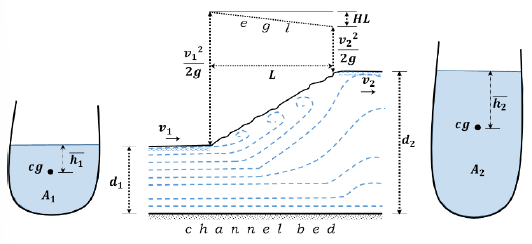

Total Head/Energy

E = v2 / 2g + p / 𝛾 + z

Velocity Head: v2 / 2g

Pressure Head: P / 𝛾

Elevation Head: z

Bernoulli’s Principle of Fluid Flow

Theoretical: v12 / 2g + p1 / 𝛾 + z1 = v22 / 2g + p2 / 𝛾 + z2

Actual: v12 / 2g + p1 / 𝛾 + z1 = v22 / 2g + p2 / 𝛾 + z2 + HL

w/ Pump or Turbine: v12 / 2g + p1 / 𝛾 + z1 + HA = v22 / 2g + p2 / 𝛾 + z2 + HL + HE

HL = head loss

HA = head added by pump

HE = head extracted by turbine

Slope of EGL

S = HL / L

Power of Pump or Turbine

P = Q 𝛾 E

E = HA (pumps) or HE (turbines)

Efficiency of Pump/Turbine

Eff = Output / Input

HA - Output

HE - Input

Head Loss: Darcy-Weisbach

General Formula: hf = fL / D × v2 / 2g

Circular Pipes: hf = 0.0826fL Q2 / D5

Head Loss: Manning Formula

General Formula: hf = 6.35 n2L v2 / D4/3

Circular Pipes: hf = 10.29 n2L Q2 / D16/3

Head Loss: Hazen-Williams Formula

General Formula: v = 0.8492 C R0.63 S0.54

Circular Pipes: hf = 10.67LQ1.85 / (C1.85D4.87)

Hydraulic Radius for non-circular pipe

R = A / P

D = 4R

Note: P = wetted perimeter

Minor Head Loss

hm = km v2 / 2g

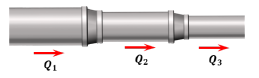

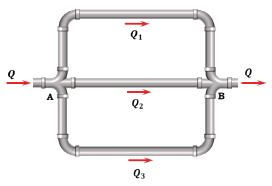

Pipes in Series

Q1 = Q2 = Q3

HL = hf1 + hf2 + hf3

hf = Δp / γ

Pipes in Parallel

Q = Q1 + Q2 + Q3

hf1 = hf2 = hf3

Celerity for rigid pipes

c = √(EB / ρ)

Celerity for Non-Rigid Pipes

c = √(EC / ρ)

1/EC = 1/EB + d/Et

d = internal diameter of pipe

E = modulus of elasticity of pipe material

t = pipe thickness

Water Hammer: Time required for the pressure wave to travel from the

valve to the reservoir and back to the valve is:

T = 2L / c

Water Hammer Pressure

Rapid Closure (tc < 2L/c): Ph = ρcv

Slow Closure (tc > 2L/c): Ph’ = 2Lρv/tc

Reynold’s Number

NR = VD / ν

V = velocity of flow

D = diameter of pipe

ν = kinematic viscosity

Friction Factor given Reynold’s Number

NR < 2000: f = 64 / NR

NR > 2000: 1 / √f = -2log(ε / 3.7D + 2.51 / NR√f)

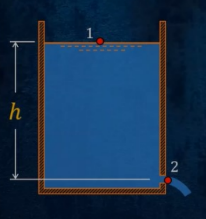

Torricelli’s Formula for Orifice

Theoretical: v2 = √2gh

Actual: v = Cv√2gh

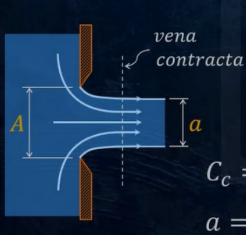

Orifice: Vena Contracta

Cc = a/A

C = Cc Cv

Q = av = CcCvA√2gh = CA√2gh

HL = v2 / 2g × (1 / Cv2 - 1)

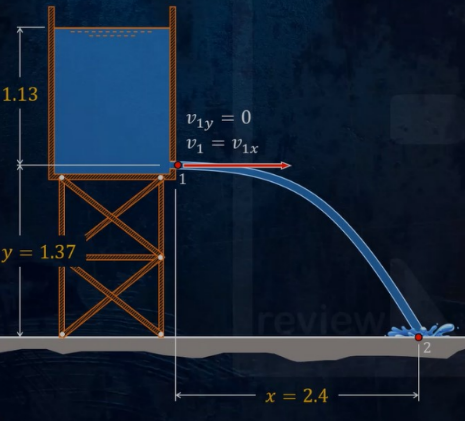

Projectile of Orifice

x = v1x t

y = v1y t - ½ gt2

v2y2 = v1y2 - 2gy

y = xtanθ - gx2 / (2v12 cos2θ)

Falling Head: Orifice

General Formula: t = ∫ Asdh / CA√(2gh) from h2 to h1

Constant As: t = 2As / (CA√2g) × (√h1 - √h2)

Open Channel: Discharge and Velocity

Q = Av

v = C√RS (Chezy Formula)

Chezy Coefficient

Theoretical: C = √(8g / f)

Manning: C = 1/n × R1/6

Bazin: C = 87 / (1 + m/√R)

Note: m and n are roughness coefficients

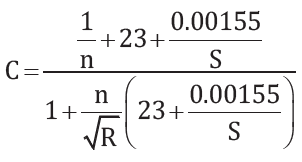

Kutter’s Formula

Chezy-Manning Formula

v = 1/n × R2/3 × S1/2

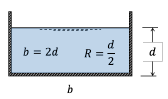

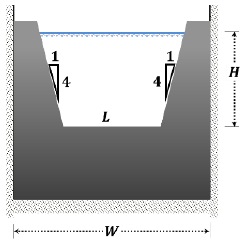

Open Channel: Most Efficient Rectangular Section

b = 2d

R = d/2

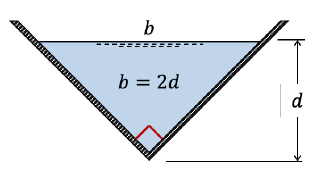

Open Channel: Most Efficient Triangular Section

b = 2d

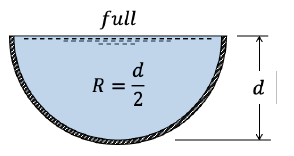

Open Channel: Most Efficient Semicircular Section

channel is full; R = d/2

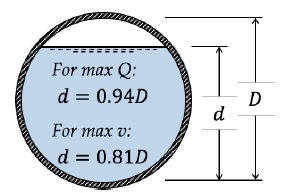

Open Channel: Most Efficient Circular Section

Max Q: d = 0.94D

Max v: d = 0.81D

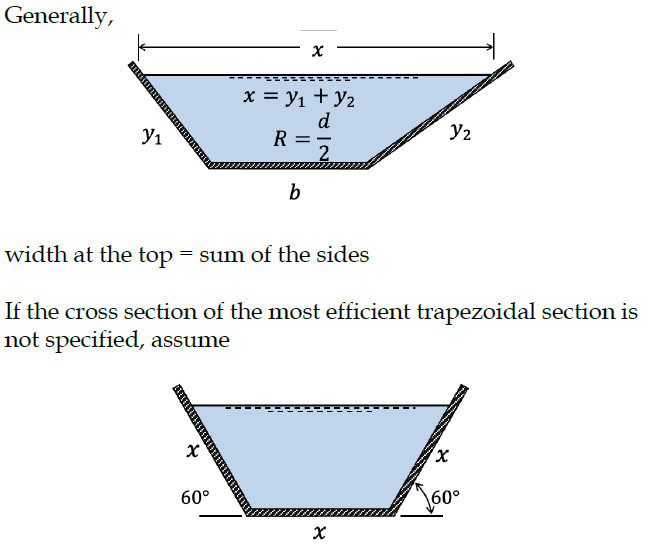

Open Channel: Most Efficient Trapezoidal Section

For given cross-section: x = y1 + y2 and R = d/2

For cross-section not specified: x = y1 = y2 (half regular hexagon)

Froude Number

NF = v / √gdm

dm = average depth = A/B

B = width of liquid surface

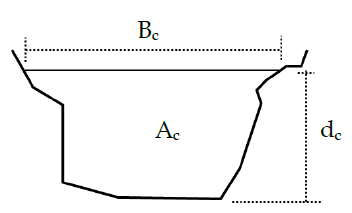

Critical Depth

Q2 / g = Ac3 / Bc ; q = discharge per meter width

Rectangular Sections:

dc = 3√q2 / g

dc = 2/3 × Ec; Ec = vc2 / 2g + dc

Critical vs. Subcritical vs. Supercritical Flow

Critical: NF = 1

Subcritical: NF < 1

Supercritical: NF > 1

Hydraulic Jump

Power lost = Qγ(HL)

P2 - P1 = Qγ/g (v1 - v2)

Rectangular Section: q2 / g = d1 d2 (d1 + d2) / 2

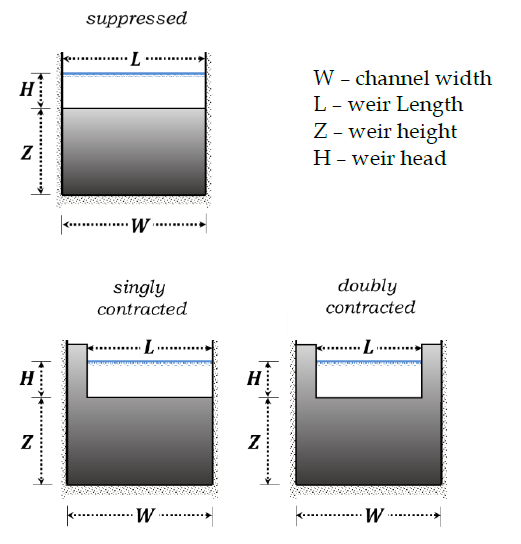

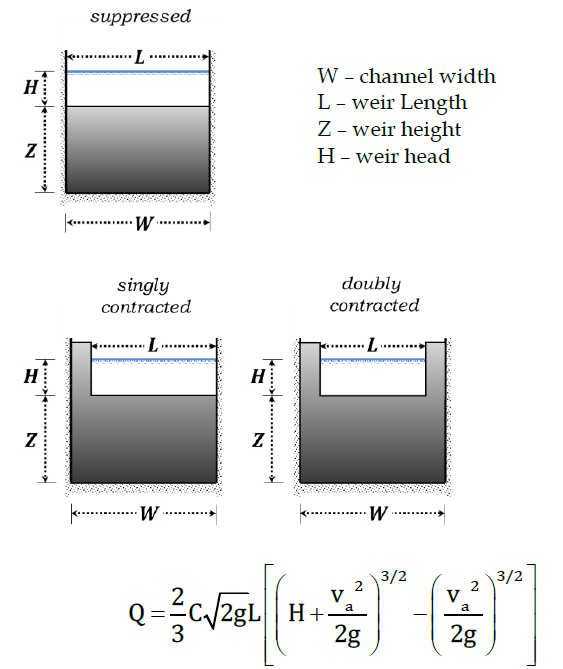

Rectangular Weir

Q = mLH3/2 or Q = 1.84LH3/2 (Francis formula)

For contracted sections:

L’ = L - 0.1H (singly contracted)

L’ = L - 0.2H (doubly contracted)

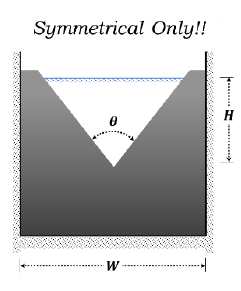

Triangular Weir

Q = 8/15 × C√2g × tan(θ/2) × H5/2

Q = 1.4H5/2 for θ = 90°

Cipolletti Weir

Q = 1.86LH3/2

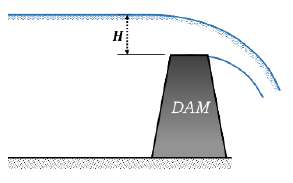

Broad-Crested Weirs (Dams)

Q = 1.71LH3/2

L = length of dam

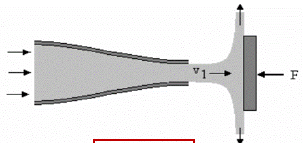

Impact of a Jet on a Plane/ Force on the Jet

F = ρQv

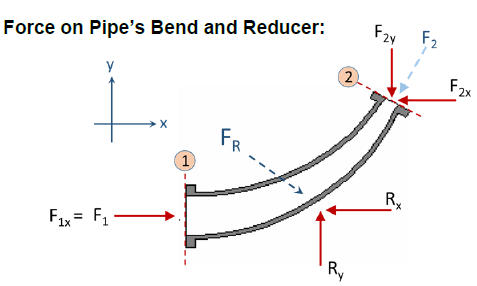

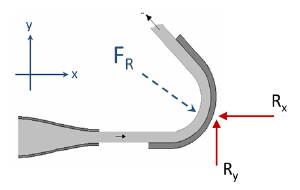

Force on Pipe’s Bend and Reducer

ΣFx = ρQ (v2x - v1x)

ΣFy = ρQ (v2y - v1y)

Force on a Curved Vane/Blade

ΣFx = ρQ (v2x - v1x)

ΣFy = ρQ (v2y - v1y)