glass & glazing

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

18 Terms

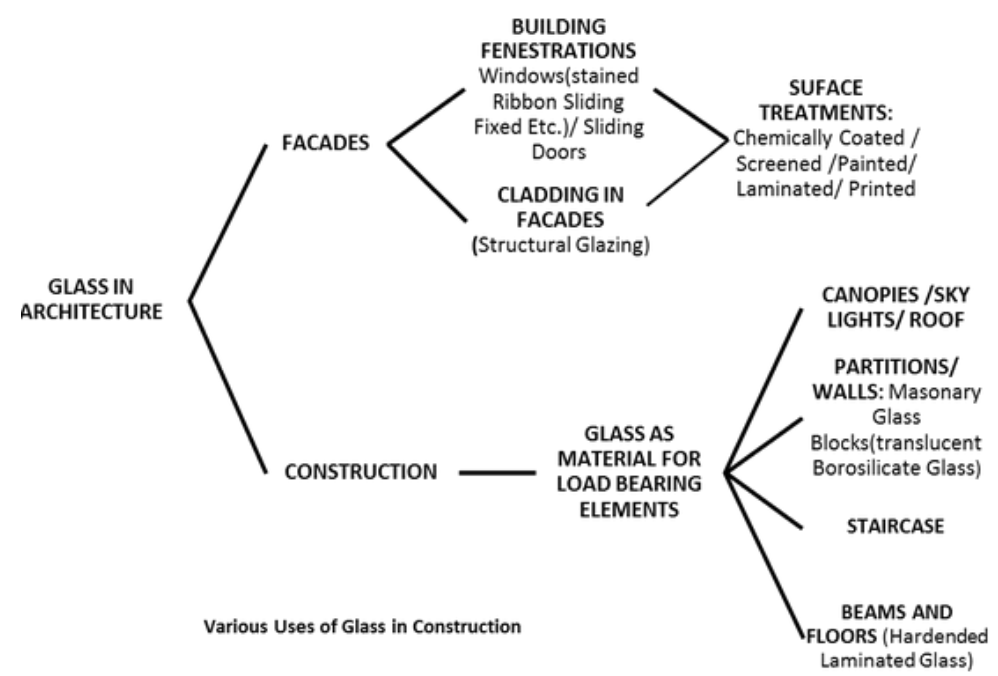

uses of glass in construction

Glass is the most-used cladding material for tall buildings due to its strength, light weight, durability, and wide range of available optical and thermal properties

glass ingredients & thicknesses

Glass is made from

Sand (silicone dioxide)

Soda ash (sodium hydroxide or sodium carbonate)

Lime (calcium)

Alumina

Potassium oxide

Thicknesses range from approximately 3/32 inch (single strength) to 1/8 inch (double strength) to 1 inch.

Heat treatments such as tempering impact glass strength and uses

glass properties

Strong: Glass is a brittle material but with the advent of science and technology, certain laminates and admixtures can increase its modulus of rupture.

Recyclable: 100% recyclable.

Workable: can be molded into a variety of shapes and sizes.

Transparent: lets natural light into a building (can offset internal lighting needs)

glass terms (1/3)

U-value: Measure of how much heat is transferred through the window.

Greenhouse effect: short wavelengths of visible light from the sun pass through glass and are absorbed, but the longer infrared re-radiation from the heated objects are unable to pass through the glass. This trapping leads to more heating and a higher resultant temperature.

Solar heat gain coefficient: It is the fraction of incident solar radiation that actually enters a building through the entire window assembly as heat gain.

glass terms (2/3)

Visible transmittance: Fraction of visible light that comes through the glass.

Energy efficiency and acoustic control: Energy-efficient glazing is the term used to describe the double glazing or triple glazing use in modern windows in homes. The air barrier also enhances acoustic control.

Air Leakage: measures the rate of air leakage around the window under conditions of an assigned pressure differential. The rating is expressed in cubic feet per square foot of window

glass terms (3/3)

U-value

Solar heat gain coefficient

Visible transmittance

Air Leakage (construction)

glass types by heat treatment & strength

Float glass: Sheet of glass made by floating molten glass on a bed of molten metal

Annealed glass: Regular float glass which is cooled slowly to reduce built-in stress

Tempered glass: Produced by cutting annealed glass to required size, reheating and then cooling rapidly. Higher strength and breaks into small shards

Heat-strengthened glass: Between annealed and tempered with breakage behavior like annealed

Laminated glass: Sandwich of multiple layers of glass with polyvinyl butyral (PVB) interlayer. Suitable for security applications as glass stays in place

Fire-rated glass: divided into two distinct categories: fire-protective and fireresistive glass. Can protect people and property in temperatures exceeding 1,600 degrees F

glass types by architectural treatments

Patterned glass: Hot glass can be rolled into sheets with many different surface textures and patterns to obscure vision for privacy

Fritted glass: Pigmented glass particles called frits are used to imprint glass. Glass is dried and fired in tempering furnace to make it permanent

Spandrel glass: Used to cover bands of floor/wall around the floor edges. Usually tempered or heat strengthened with insulation behind them

glass types based on solar radiation

Tinted Glass: Made by adding small amounts of selected chemical elements to the molten glass mixture

Reflective Glass or Solar Control Glass: Thin durable films of metal or metal oxide are deposited on the surface of either tinted glass or clear glass to make the glass reflective.

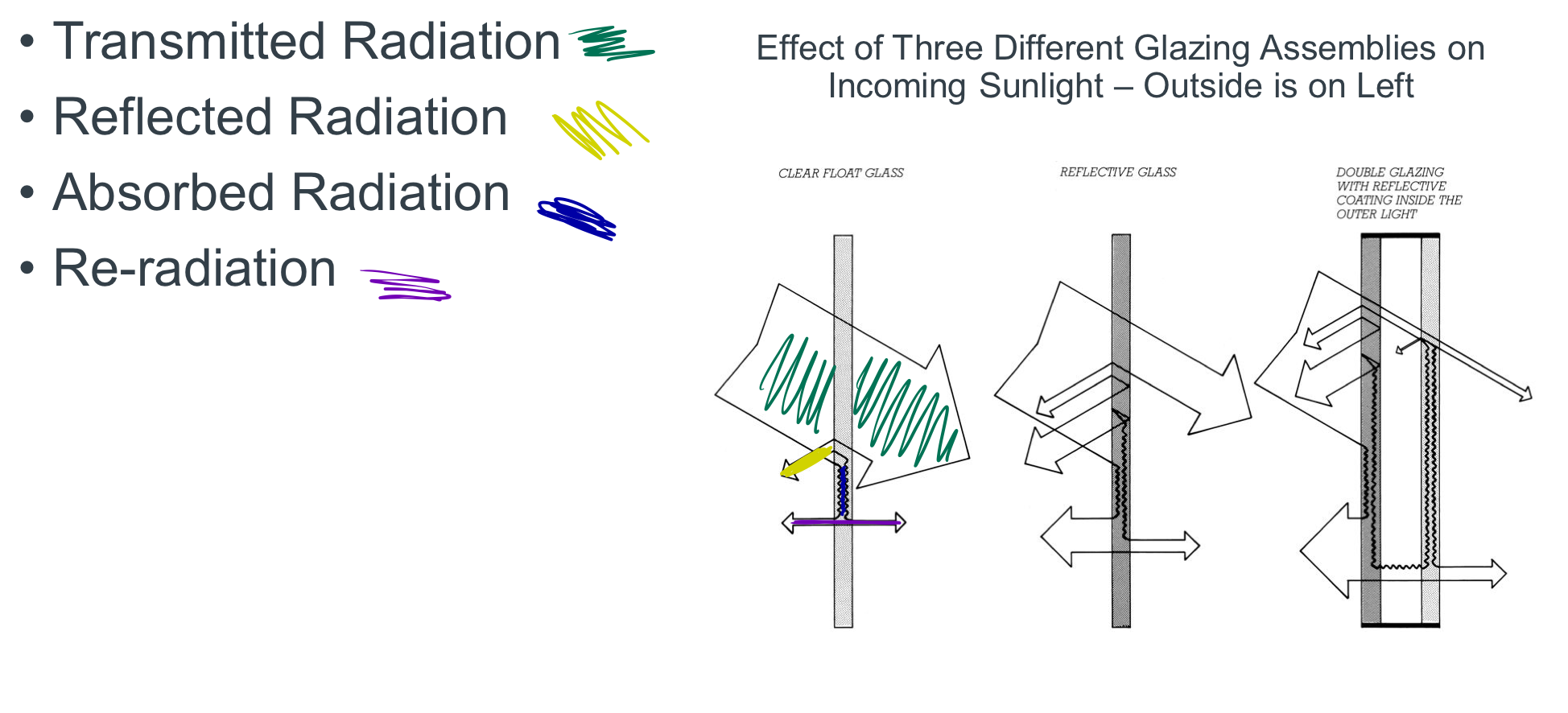

control of visible light & solar radiation

Transmitted Radiation

Reflected Radiation

Absorbed Radiation Re-radiation

glass & thermal considerations

IGU – Insulating Glass Unit

Made of multiple glass layers with sealed air space reducing conductance

Space filled by air or inert gas in a hermetically sealed cavity

Performance given in terms of U values

Low Emissivity coated glass (low-e) •

Formed with transparent metallic coating to improve thermal performance

Located on surface 2 and sometimes on surface 3.

Improves thermal performance

glazing small lights

Not subject to excessive wind force or stresses due to thermal expansion

glazing large lights (1/3)

Large lights, those over 6 ft2 require more care in glazing due to stresses

Design objectives are

Support weight of glass without abnormal stress patterns

Support glass against wind pressure and suction

Allow for expansion and contraction of glass and frame without damage

Avoid contact of glass with any hard material such as frame

glazing large lights (2/3)

Setting blocks are of synthetic rubber and support weight of glass

Bite or depth of grip on the edge of glass of certain amount is required to resist wind load

Glazing components used between frame and glass are either wet or dry such as

Preformed solid tape sealant made of polybutene

Wedge or roll in gasket

Lock strip gasket

In good design, waterproofing relies on wet and dry seals in conjunction with pressure equalization and drainage

glazing large lights (3/3)

Lockstrip gasket is a dry glazing method. It is faster, easier and less dependent on workmanship then wet glazing method.

Wet glazing: (silicone) with good workmanship is more effective.

advanced glazing systems (1/3)

Butt-joint glazing system

Head and sill of the glass sheets are supported conventionally in metal frames, but vertical mullions are eliminated

The vertical joints between sheets of glass are made by injection of colorless silicone sealant

Horizontal strip windows that need to appear mullion-less only from the outside can use a mullion on the inside

Sill and head are conventionally glazed

advanced glazing systems (2/3)

Suspended Glazing Systems and Glass Mullion System

Used primarily for high walls of glass around building lobbies

Tempered glass sheets are suspended from above and stabilized by tempered glass perpendicular stiffeners

Metal fittings are used to join multiple sheets of glass

Stainless steel cables and fittings are used in roof applications

advanced glazing systems (3/3)

Four-point spider fitting

Adjustable vertical stainless steel rod carries the load to the structure

The spider fittings and cable system must resist wind, seismic, and dead loads without inducing bending forces in the glass or creating stress concentrations around the points of attachment.

A suspended glazing system with "saddle" curvature keeps the entire wall system in tension.