CPIM Module 1.6

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

35 Terms

functional strategy

a strategy that is built from the business functions such as finance, marketing, and production

operations strategy

the total pattern of decisions that shape long-term capabilities of an operation and their contribution to overall strategy. Operations strategy should be consistent with overall strategy.

Distinguish between operational management and operations strategy.

Operations Strategy Traits

A longer time frame - consists of trends in demand and supply, the effects on new technology, and the opportunities for internal investment and development. Focus on long-term plans for the use of the resources and the development/improvement of process and capabilities.

A broader perspective - consists of effect of forces inside and outside organization on operations

A higher level of focus - provides direction to create policies and processes needed to develop the strategy.

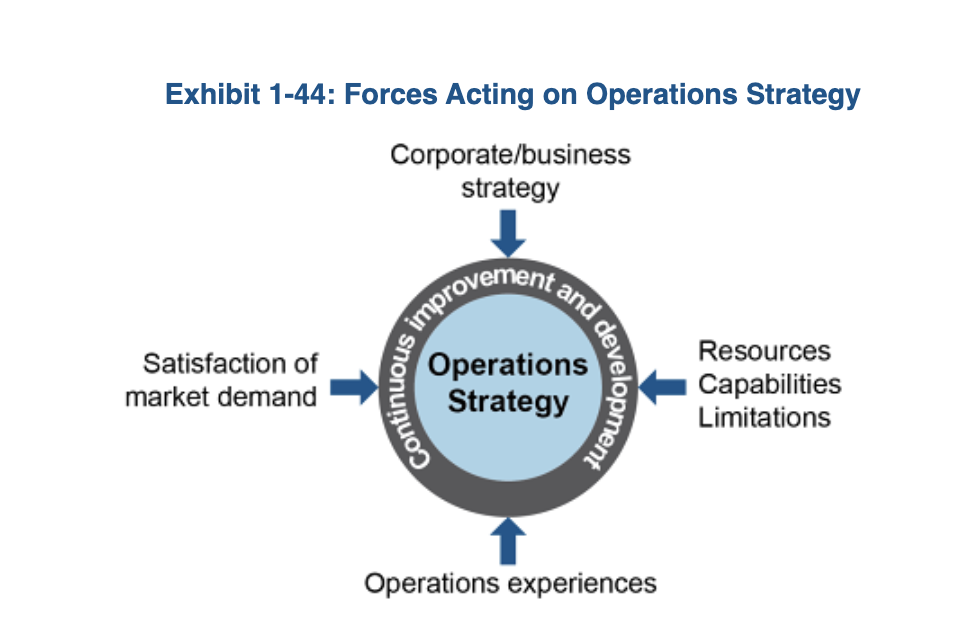

Forces acting on operations strategy

Requirements for a successful operations strategy

Consistent with the strategic choices made at the business strategy level

Mindful of the market requirements

Open to the lessons of experience from those involved in operations

Aware of the operation’s resources, capabilities, limitations.

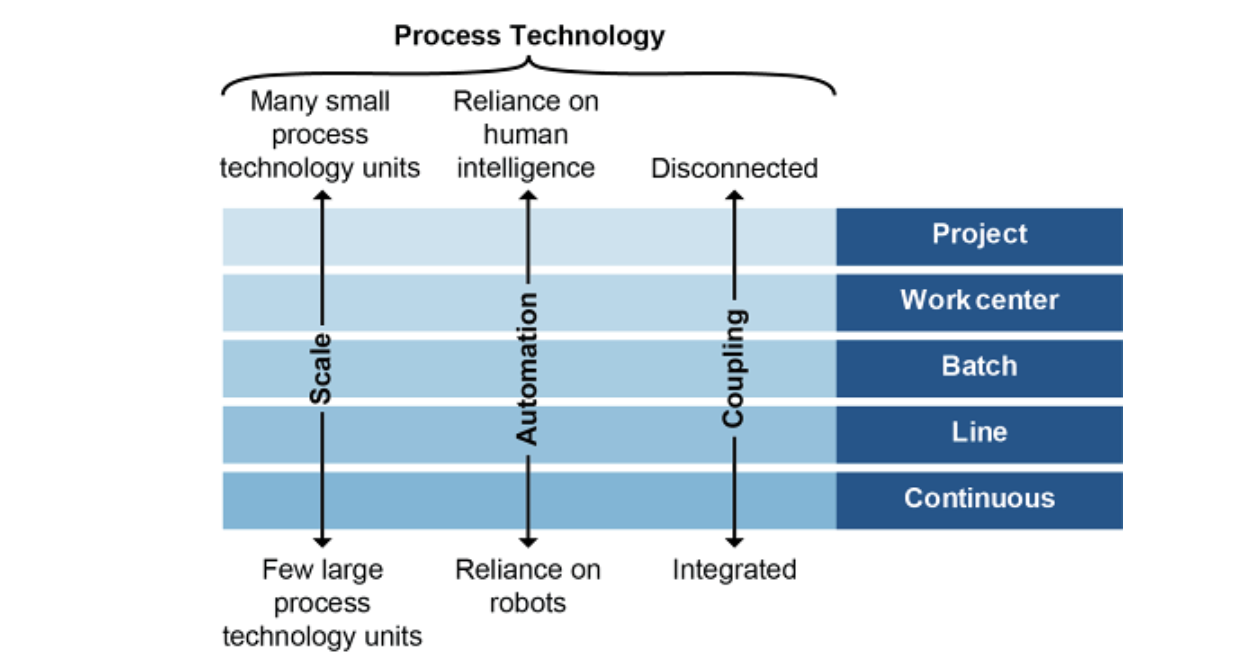

Process Technology and Manufacturing

Project Manufacturing

a type of manufacturing process used for large, often unique, items or structures that require a custom design capability (ETO). This type of process is highly flexible and can cope with a broad range of product designs and design changes. This process usually uses a fixed-position type layout.

Work center or job shop

1) An organization in which similar equipment is organized by function. Each job follows a distinct routing through the shop. 2) A type of manufacturing process used to produce items to each customer’s specifications. Production operations are designed to handle a wide range of product designs and are performed at fixed plant locations using general purpose equipment.

Batch manufacturing

A type of manufacturing process in which sets of items are moved through the different manufacturing steps in group or batch.

Line Manufacturing/Repetitive Manufacturing

Performed by specialized equipment in a fixed sequence.

Continuous Manufacturing

A type of manufacturing process that is dedicated to production of a very narrow range of standard products. The rate of product change and new product information is very low. Significant investment in highly specialized equipment allows for a high volume of production at the lowest manufacturing cost. Thus, unit sales volumes are very large, and price is almost always a key order-winning criterion. Examples of items produced by continuous manufacturing include gasoline, steel, fertilizer, glass, and paper.

Cost-Volume-Profit (CVP) Analysis

The basic concept of cost-volume-profit (CVP) analysis is that the selling price of a product or service impacts demand to a lesser or greater degree, depending on the item in question. (This is called price elasticity.) The level of demand then affects volume. If lowering a price increases volume sufficiently, it will make up for the lower profit per unit. Conversely, if raising a price does not decrease volume by too much, the higher profit per unit will cover the lost volume.

Contribution Margin (CM) Analysis

CM Ratio

Sales - Variable Costs

CM/Sales

Break-Even Analysis

a study of the number of units or amount of time required to recoup an investment.

Fixed Costs/Unit CM

Target Income Volume Analysis

(Fixed Costs + Target Income)/Unit CM

Sales-Mix Analysis

the proportion of individual product-type sales volumes that make up the total sales volume.

Factoring according to different proportions (product-based) of total sales of a company

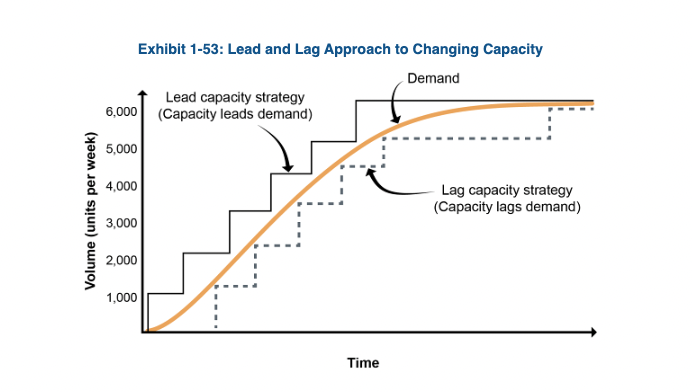

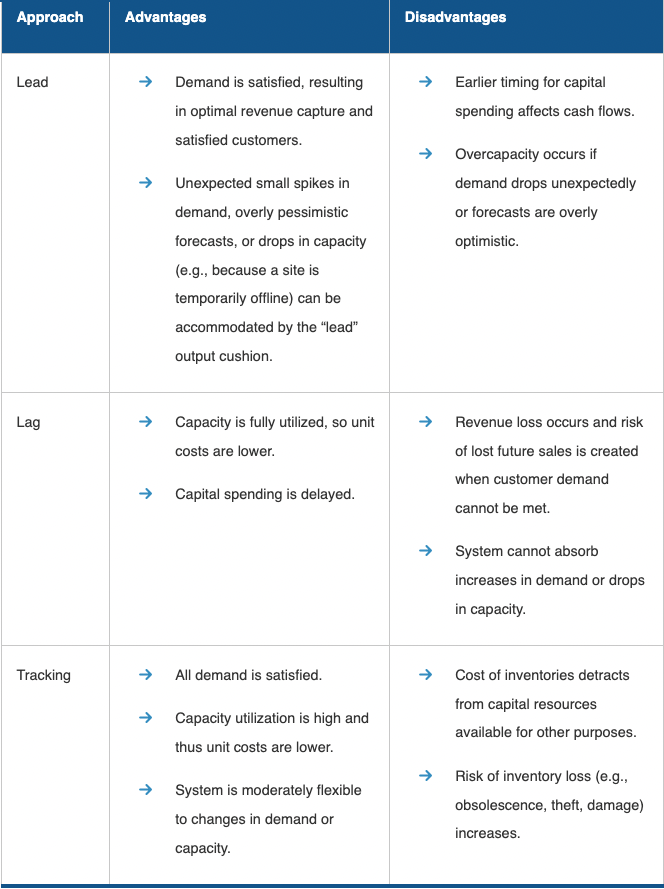

capacity strategy

one of strategic choices a firm must make as part of its manufacturing strategy. There are 3 commonly recognized capacity strategy: lead, lag, tracking

capacity planning

the process of determining the amount of capacity required to produce in the future. This process may be performed at an aggregate product-line level (resource requirement planning), at the master-scheduling level (rough-cut capacity planning), and at the material requirement planning level (capacity requirement planning).

In general, 1-3 years time horizon.

surge capacity

the ability to meet sudden, unexpected increases in demand by expanding production with existing personnel and equipment.

lead capacity strategy

adding capacity to a resource in anticipation of increased future demand. This is done to ensure the ability to satisfy market demand when increase occurs.

lag capacity strategy

not adding capacity until the firm is operating at or beyond full capacity. This keeps unit costs minimized by working at full capacity but does not satisfy total demand.

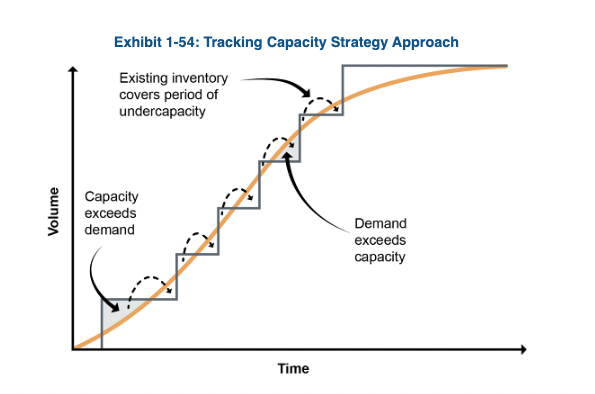

tracking capacity strategy

adding capacity in small amounts to attempt to respond to changing demand in real time in the marketplace. This approach may satisfy total demand and help minimize unit costs, but it can be difficult in some situations to add incremental amounts of capacity, especially if the facility has no more space available.

Lead and Lag Strategy

Tracking Capacity Strategy

Advantages and Disadvantages

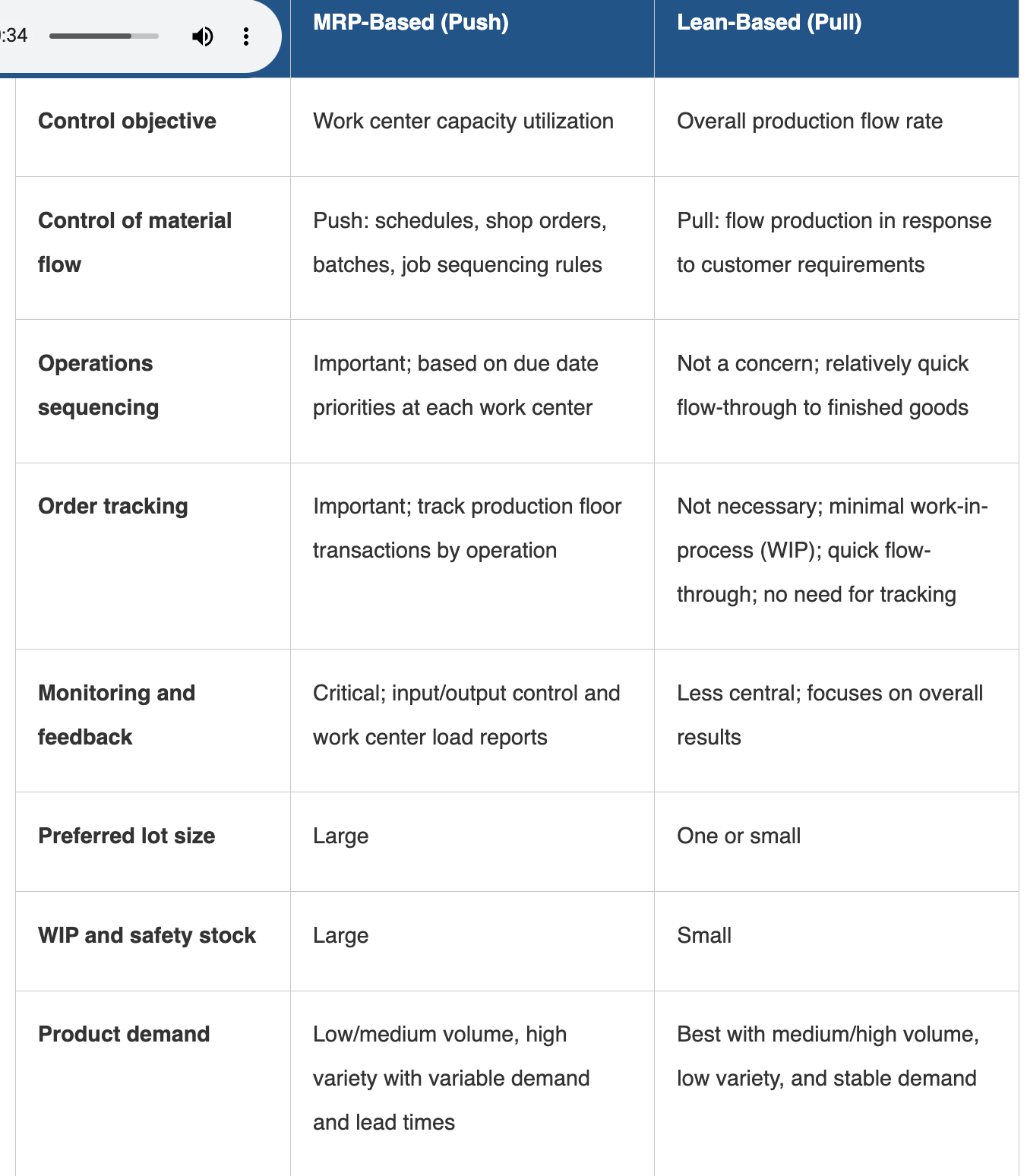

Control System (Push vs Pull)

Insourcing vs Outsouring

you insource activities according to you core competencies

Facility Location Selection Criteria

Market Factors

Operational Factors

Value Chain Activities Locations

Dispersed - advantageous in case of multiple foreign countries

Focused - production advantages, economies of scale, learning curve effects, better coordination with suppliers or customers

Options for entering global markets:

export

licensing

franchising

creation of subsidiaries

creation of local strategic alliances or joint ventures

Advantages and Disadvantages of Export

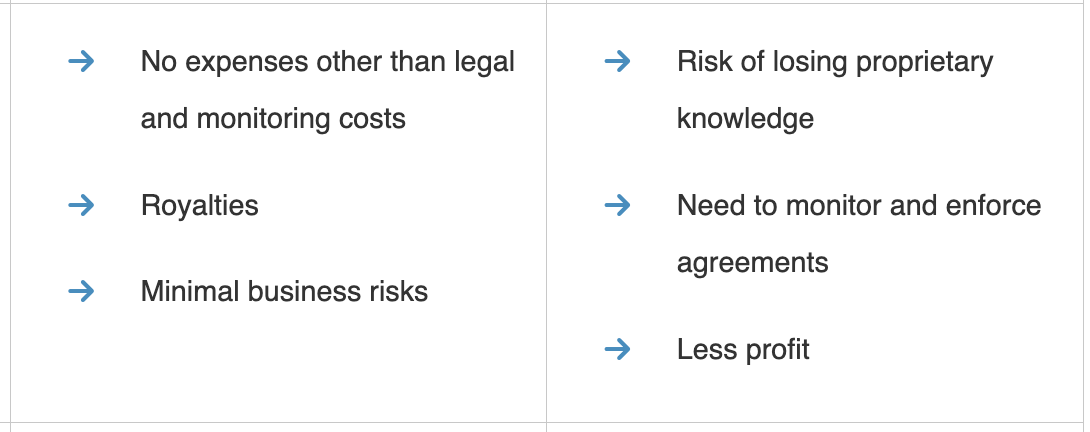

Advantages and Disadvantages of Licensing

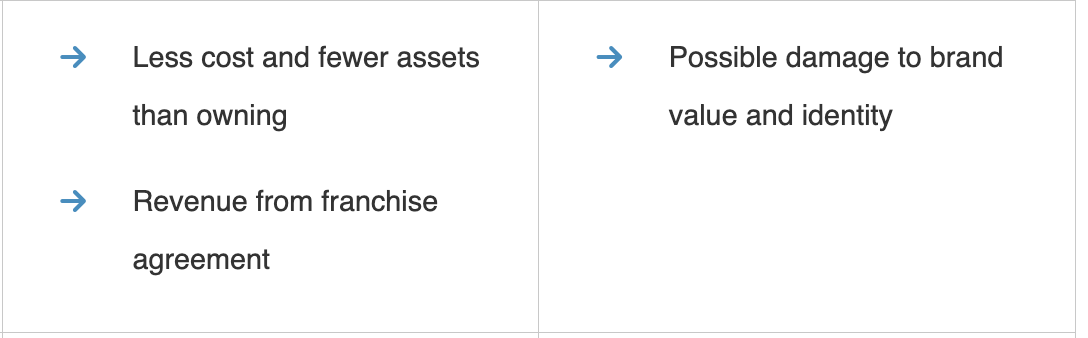

Advantages and Disadvantages of Franchising

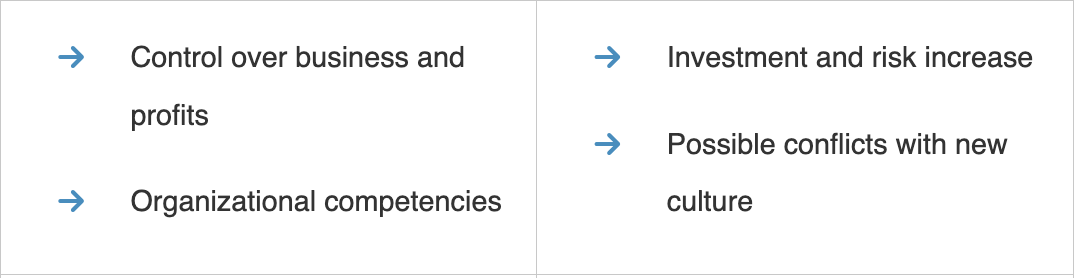

Advantages and Disadvantages of Subsidiary

Advantages and Disadvantages of Strategic Alliance/Joint Veinture