MATERIAL (mechanical Engineering Yr1) Term1

1/70

Earn XP

Description and Tags

MATERIALS and their uses... (from manufacturing and materials module)

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

71 Terms

what do we test to see… Design/ Material selection criteria (Fitness for purpose)

The things we test to see :

Ability to withstand loads (strength, yield/ tensile)

dimensional stability (modulus, hardness, creep).. Expansion (Thermal/ moisture)

Durability (maintenance (corrosion, wear, firing)

What are the 3 product construction techniques?

manufacture

joining/ assembly

finishing

What are the 4 environmental factors/ sustainability factors?

availability of resource

energy content

utilization & storage wastes

recycling

what are the 3 aesthetic, primary and finishing process?

appearance

texture

feel

Tests for stiffness and strength

simple- uniaxial loading

complex- bi, triaxial loading

time dependence

environment

scale

testing as part of product/ structure

what are the different types of families of materials?

metals

polymers

ceramics

glasses

elastomers

material property definition: STRONG

definition: ability to carry load or force

material property definition: STIFF

definition: ability to resist deflection

material property definition: TOUGH

definition: ability to resist fracture

material property definition: LIGHT WEIGHT

definition: ability to perform without adding too much extra load

Mechanical properties: (Glossary)

elastic deformation

plastic deformation

elastic modulus

proof stress

tensile strength

plastic strain at fracture (ductility)

hardness

toughness

work hardening

how to calculate stress

force/area [N/m²]

how to calculate strain

change in length/ original length (dimensionless)

how to calculate shear stress

shear force/ shear area [N/m²]

how to calculate shear strain

deflection/ original length [dimensionless]

Elastic Modulus (Young’s Modulus) [N/m² or Pa] how to calculate?

yield strength(stress)/ strain

types of tensile failure (in metals)

ductile fracture

Brittle fracture

Tests for brittle material

tensile: -low variable fracture stress, - elastic deformation followed by fracture… NO plastic deformation.

compression

how to calculate Hardness, H

(F) Load/ Area (A)

how to calculate Vickers Hv Scale

H/ 10 [kg/mm²]

what is creep?

time dependent strain at constant stress

what is fatigue?

failure of material when it is subject to cyclic or fluctuating stress.

what is product tolerance?

allowable size range specified in the design and specified in Eng drawings

what is a + and - tolerance called?

Bilateral tolerance

what is process tolerance?

size range (limits) likely to occur due to the method of manufacture

what are the 3 reasons for process tolerance?

nature of manufacturing

variability in material

wear on tools and machines

types of basic process for metals (5)

casting

deformation

powder metallurgy

welding

material removal

what is metrology?

term for science of measurement of dimensions and shapes

why is meteorology important for manufacturing?

important for control of manufacturing processes and inspection of products.

9 factors that help identify materials

material color/ surface condition or appearance

density (mass per unit volume)

magnetic?

hardenability

tensile test

spark test

melting point

action of acids

action of alkalis

how can we identify material using density

weighing a material sample (archimedes principle for measuring density)

what is Archimedes principle for measuring density?

immersed sample in water measure mass (mass of sample in water - mass of water) giving M2 (force of buoyancy)= volume of water displaced

mass not immersed in water (kg) M1

M1/ M2= density in [Kg/10³g]

need to then convert to [kg/m³]

what is the spark test?

piece of metal held against a grindstone (different metals will produce difference forms and colors of …)

how will acids react with steel?

all acids attack steels, whenever moisture combined with oxygen, rusting place. (common salts will accelerate corrosion when combined with water.

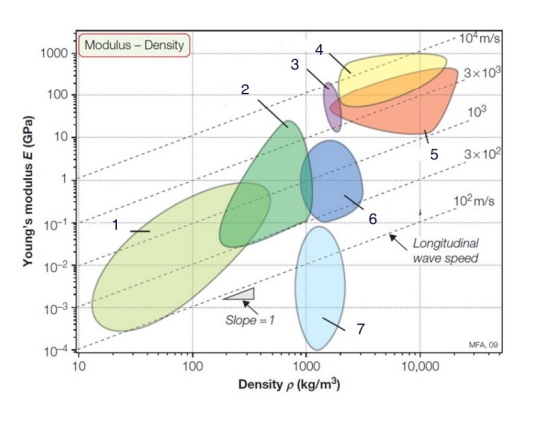

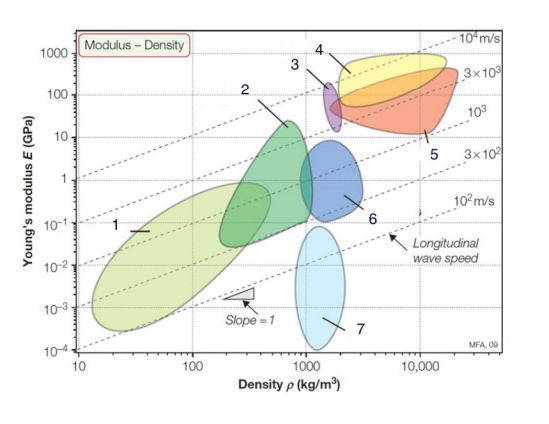

Name the materials on the Ashby diagram (numbered from 1 to 7)

foams

natural materials

composites (materials made from multiple materials or mixed with another material to make it stronger)

ceramics

metals

polymers

elastomers

what is a Ferrous metal?

a metal that contains Iron [Fe]

what are cast iron’s properties (Ferrous metal)

properties:

poor ductility

poor tensile strength

poor plasticity

poor toughness

poor malleability (due to flakes of graphite)

typically the alloy contains 2.5% to 4% carbon)

typically the alloy contains 1% to 3% silicon

typically the alloy contains 0.1% to 1.2% Manganese

good compressive strength

how can properties of Cast Iron be improved

treating it to alter structure of carbon in it.

what properties does iron (ferrite) impart in carbon steel:

ductility

malleability

plasticity

magnetism

softness

some elasticity

Low carbon steel [MILD STEEL] properties (ferrous metal)

contains 0.5% to 0.25% carbon by weight (mass of carbon emission)

contains 0.6% to 0.9% of Manganese

doesn’t increase in hardness as physical force is applied (doesn’t work harden)

BUT cold bending and hammering causes work hardening

*NOTE: hardening can be removed by heat treatment

good welding properties

what properties does medium/ high carbon steel have

contains about 1% carbon

contains up to 1.65% Manganese

some specific quantities for deoxidization

higher % of carbon= higher tensile strength and hardness

higher % of carbon= reduced ductility and malleability

higher % of carbon= greater risk of welds and bends cracking

readily forming rust (rusting when exposed to oxygen and water)

heavy scaling when at red heat (forging)

what are alloy steels used for mainly? (ferrous metal)

used to obtain enhanced properties specifically higher strength, hardness, wear and corrosion resistance.

what do alloy steels tend to be mixed with? (ferrous metals)

Nickle [Ni], Chromium [Cr] and Molybdenum [Mo]

Chromium [Cr] and Vanadium [V]

could have high carbon [1%] (used for production of ball bearings)

Manganese [Mn]

Copper [Cu]

Tungsten [W]

Titanium [Ti]

what are non-ferrous metals?

metals that do not contain iron

copper (non ferrous metal) metal, what is it’s properties?

soft in annealed conditions (annealing= heat treatment process which changes physical and sometimes chemical properties)

red color (recognizable)

harder by cold working (e.g hammering, rolling or pressing)

what are three advantages of copper?

excellent for deep drawing extrusion and drawing into wire

can be annealed by heating to dull red (500 degrees Celsius) and allowing to cool or quenched (quenching is rapid cooling to adjust mechanical properties)

resistant to corrosion BUT attacked by Nitric and Hydrochloric acid quite vigorously

2 examples of non- ferrous metal copper alloys and their percentages

Brass, (copper-zinc Alloy) 67% Cu and 33% Zn

Phosphor Bronze (Copper-Tin Alloy) 0.5-11% Sn and 0.01-0.35% P

properties of copper alloy (non ferrous metal) BRASS (Zn and Cu):

higher malleability than zinc and copper

low melting point (900 degrees C)

flows when melted

when combined with iron, Al, Si, Mn make corrosion resistance

capable of stress cracking when exposed to Ammonia (NH3)

not as hard as steel

what other elements can be added to phosphor bronze to create what specific properties?

(0.5-3% of Lead) forming free-machining phosphor bronze:

used for springs, bolts, bushings and bearing.

density of Aluminum

2700 kg/m³

what does UTS stand for and what does it mean

Ultimate Tensile Strength- material’s maximum stress tolerance before breaking under tension, determining how a material behaves under load

properties of Aluminum/ Aluminum Alloys

silvery-white

lightweight metal

soft and malleable

PURE Al relatively weak

Al ALLOYS have higher UTS than pure Al of about (500 N/mm²)

doesn’t rust BUT does corrode

low melting point of about 660 C

economically cost efficient

how does Aluminum protect itself from corrosion and what is the possible step backs

the aluminum oxide coating highly resistant and renwes itself if damaged keeping it relatively safe from corrosion

BUT

some factors can cause coat to become unstable

what is Anodising

a protective surface treatment to enhance oxide coating (the Aluminum oxide coating which helps avoid corrosion of Al)

what are some applications of Aluminum

extrusion

anodising

pressure die casting

what is a composite material?

material made from 2 or more different types of material

two examples of composite materials that are “fiber”

Carbon fiber re-enforced polymer CFRP

Glass fiber GFRP

(RP= reinforced polymer)

what is Carbon fibre (CFRP) made up of?

90% of carbon fiber: Polyacrylonitrile (PAN)

10% of carbon fiber: rayon or petroleum pitch

what is carbon fiber?

organic polymers (PAN, Rayon and petroleum pitch) characterized by long strings of molecules bound together by carbon atoms

what is Glass fiber made up of (GFRP)

non-crystalline material with short range network structure

name 4 advantages of composites

freedom to tailor the thickness, shape (to increase strength of functionality) etc.

reduce weight

reduction of no. of parts in design

doesn’t corrode like steel or Al

what material is used in industrial ceramics (engineering ceramics)

Alumina [aluminum oxide Al2O3]- inert, odorless, white amorphous material used in industrial ceramics

what are the uses of Alumina (eng ceramic)?

life extending application

society enhancing application

used in medical field

why is Alumina used in the medical field (what properties does it have that makes it helpful)

hardness

bio-inertness

chemical properties

what are some examples of when Alumina (eng ceramic) used in the medical field?

bionic implants

prosthetic eyes

tissue reinforcements

dental crowns

abutments

bridges

(dental implants)

lab equipment

what is Tungsten Carbide (WC) and some examples of tools that use WC

compound of tungsten [W] and carbon [C]. known for superior durability and high melting point (2,870 C)

widely used in applications that require superior wear or impact resistance (abrasives, cutters, dies and bunches)

meaning of Biomedical materials (Biomaterials)

biomaterial is metal, ceramic, polymer OR natural materials that can be used to provide structure or function to an implantable medical device in the body

materials for biomaterials and their characteristic they’re known for

wear resistant metal alloys

bioactive ceramics

biodegradable polymers

application and examples of biomaterials (METAL)

stainless steel: [Nickle, chrome alloy with iron and low carbon content] LOW infection results when nickel free alloys are used.

Titanium alloys: provides good results with low rates of infection

APPLICATION: orthopedic surgery, dental surgery, bone screws, hip/knee replacements

applications and examples of biomaterials (CERAMICS)

Aluminum oxide (alumina) AND zirconium oxide (ZrO2)

APPLICATION: deposited on metal surfaces cuz extremely hard and offer good wear resistance. artificial bones. Dentistry (implants)

good corrosion resistance… ALMOST chemically inert

BUT BRITTLE

applications and examples of biomaterials (POLYMERS) [what types of polymers ae used]

Polyurethanes/ polyester

polycarbonate/ polyethylene

APPLICATION: prostheses, tissue engineering, drug delivery tubes, special mesh for wound management [NOT all biodegradable], plastic liners hip replacements