5.6 Production planning

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

26 Terms

Supply chain management

The management of the sequence of activities from the production of a good or service, to it being delivered.

What are the key functions of scm

-Stock control

-Quality control

-Supplier networks

-Transportation

What are advantages of SCM?

-it helps to achieve lean production

-Prevents mistakes from occuring

-Manages stock to prevent delays or high costs, increasing efficiency

What are drawbacks of SCM?

-Time/language/cultural differences can cause delays

-interdependance can cause major disruptions

What is Just-in-case?

It is maintaining large amounts of stock in case of supply or demand fluctuations (the opposite of Just-in-time). It is reserve stock for emergencies.

What are advantages of Just-in-case?

-Increased flexibility

-businesses can meet sudden changes in demand

-no need to wait for delivery of stock (it is time saving)

-Purchasing economies of scale - discounts when buying in bulk

What are disadvantages of Just-in-case?

-higher costs of storage (insurance, room costs)

-the business has more materials than they need, so many go to waste

-there are changing tastes and fashions

-food products may expire

What is stockpiling?

Holding excess stock, more than the business needs (Just-in-case)

What are stock-outs?

When a firm ran out of stock, so the product is unavailable for purchase

What are disadvantages of stockpiling?

-high storage costs

-if food is being stored, it may go bad

-there are changing fashions and tastes

What are disadvantages of stock-outs?

-lost sales and customers due to rivals (if someone goes to the store and what they’re looking for isn’t there, they go to another store)

-damaged corporate imagery

-decreased customer loyalty

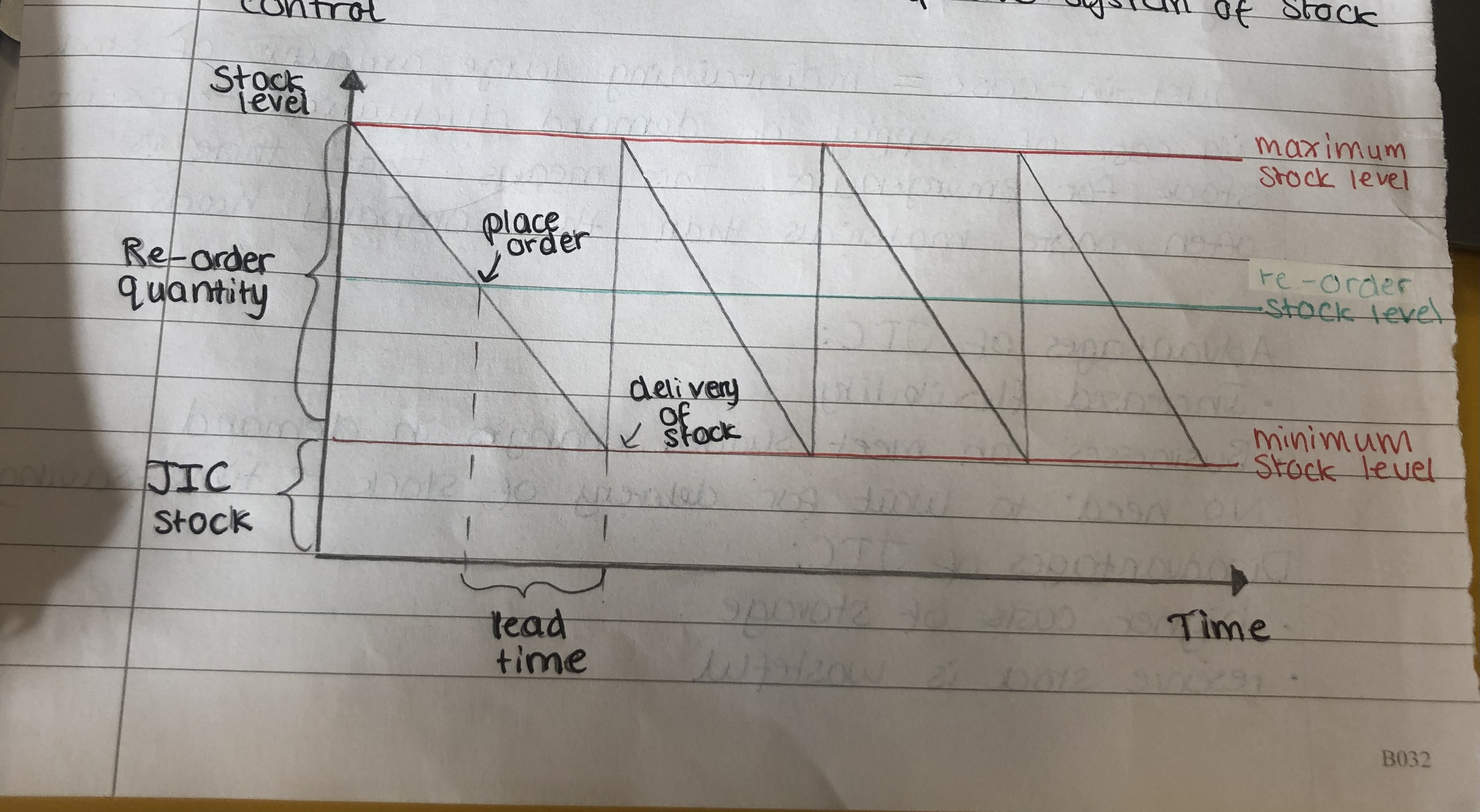

What is a stock control chart?

It is a chart which graphically illustrates a simplistic system of stock control

What factors influence the amount of stock held

-Short lead times → if the stock gets delivered quickly, the amount of stock held is lower

-Long lead times → if the stock takes long to be delivered, the amount of stock held is higher, to ensure that they will never run out

What is capacity utilization?

It measures the firm’s output level as a percentage of its potential output → how efficient they are being

How do you calculate capacity utilization rate?

(current output/productive capacity) x 100

What are defects?

Defects occur when the quality of a particular product is unacceptable

How do you calculate defect rate?

(defective output/total output) x 100

How do you calculate labour productivity?

(total output/number of workers) x 100

How do you calculate capital productivity?

(total output/number of capital hours) x 100

How do you calculate productivity rate?

(total output/ total input) x 100

The input can be number of capital hours, number of workers, amount of money invested etc.

What are some factors that determine productivity rate?

skills and experience of labour

technology → efficiency of machinery

the amount of competition

working conditions of labour

What is cost to buy?

How much a business would have to pay if they ordered products/materials for their own use

How do you calculate cost to buy?

price x quanitity

What is cost to make?

How much a business would have to pay if they were to make their own products/resources

How do you calculate cost to make?

fixed costs + (variable costs x quantity)

What are factors that play a role in make or buy decisions?

speed of delivery

time taken for production

costs

reliability of suppliers

skills and knowledge