Exam 2 (Chapters 4-6)

1/244

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

245 Terms

high-bulk yarn

acrylic spun yarns that are lofty, bulky, and soft

yarn

a continuous strand of textile fibers, filaments, or materials in the form suitable for knitting, weaving, or otherwise intertwining to form a textile fabric

factors that affect yarn properties

fiber content - thick/thin, shape, surface structure, regularity, luster, if it is spun or filament, basic properties, etc

fiber length

amount of twist

yarn size

regularity of the yarn

uniformity of the yarn

we generally classify and identify yarns by:

fiber content and length

yarn twist

yarn size

regularity/irregularity

smooth filament yarn

no twist or low twist yarns

monofilament yarn

a single-coarse filament fiber

tape and network yarns

made from splitting an extruded film and heat-stretching the fibers

multifilament yarns

several, uniform, individual fibers

flat

tape or network yarns

bulk yarns

modified filament yarns that produce greater volume or apparent covering than a conventional yarn of similar linear density and of the same basic material with normal twist

tape yarns

coarse; usually used in carpet backing, rope, cord, fishnet, bagging, and interior support fabrics

network yarns

bulkier and less dense than multifilament, monofilament, and tape yarns; made of fibers than are connected in a network arrangement; have ribbon-like characteristics

pros and cons of textured yarns

Pros:

higher stretch and/or bulk with greater cover than smooth filament yarns

greater breathability, insulation, and/or absorption

softer and drier hand

spunlike yarn characteristics

more wrinkle resistant than spun yarns or smooth (regular) filament yarns

Cons:

tendency to snag and damage to fabric is likely greater since it is a filament fiber

not suitable for apparent intended for “rough use” (children’s garments)

growth problems

poor abrasion resistance

easy soil penetration

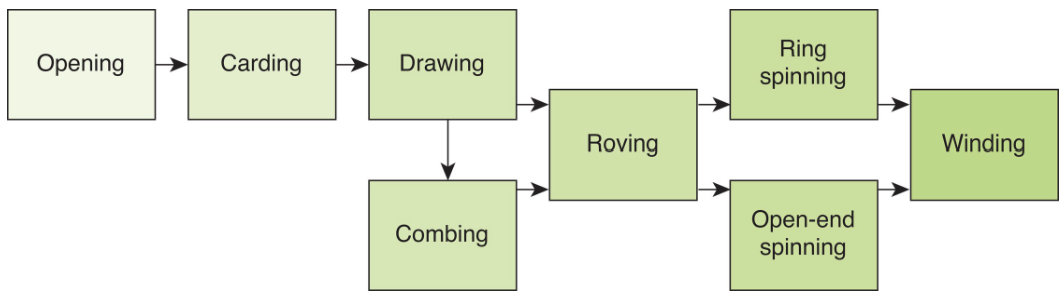

How are staple fibers processed into spun yarn?

opening

loosens, cleans, blends the fibers

carding

partially align the fibers and form them into a thin web that is brought together as a soft, very weak rope of fiber called a carded sliver

drawing:

process than increases parallelism of the fibers and combines several carded or combed slivers into drawn sliver

if long staple fibers are to be spun, another step is added:

the combing step

combing

aligns the fibers in a parallel arrangement and removes short fibers so that fibers in the combed sliver will be more uniform in length

roving

reduced the drawn sliver, increases the parallel alignment of the fibers, and inserts a small amount of twist in the strand

Methods of spinning

ring spinning, open-end (OE) spinning

which fibers must be carded?

staple fibers

carded yarns

carded yarns from cotton or cotton-blend fibers

combed yarns

combed yarns from cotton or cotton-blend fibers

woolen yarns

carded yarns made of wool or wool-blends. they are fizzier, uneven

worsted yarns

combed yarns made of wool or wool-blends. they are smooth, have little fizziness, and are more even

tow linen yarns

yarns made of short flax fibers; they are irregular and coarse

line linen yarns

combed flax yarns; they are long and produce a smooth and fine linen used for fine table linen and lightweight blouses

why do fibers for fine, lightweight yarns need to be combed?

you need the longer fibers to ensure proper strength

combed yarns have ___ fibers

longer

why are combed yarns so expensive?

more steps in the process, fewer fibers are used

what are some cases where combed yarns are less desirable than carded yarns?

napped fabrics - needs short fibers to give it the fuzzy surface

denim - carded yarns give it the rugged, natural look

terry cloth - fuzzy, soft bulkiness of carded yarns allow the terry cloth to remove moisture

Carded Yarn Properties

Fiber length: short staple

Yarn:

size and appearance: less regular

twist: medium-to-low

protruding ends: more

final result: bulkier, softer, fuzzier

abrasion resistance: more sensitive to abrasion

fibers present: more

Fabric:

may become baggy in areas of stress

fabrics vary from soft to firm

always used in blankets

wide range of uses

less expensive

Yarn term based on fiber type:

cotton: carded

flax: tow or hackled

wool: woolen

Combed Yarn Properties

Fiber length: long staple

Yarn:

size and appearance: more regular

twist: medium-to-higher

protruding ends: fewer

final result: fewer protruding ends

abrasion resistance: longer wearing, stronger

fibers present: fewer

Fabric:

smoother surface, lighter weight

do not sag

take and hold press

fabrics range from sheers to suitings

more expensive

Yarn term based on fiber type:

cotton: combed

flax: line or well-hackled

wool: worsted

most common method of yarn spinning

ring spinning method

ring/conventional spinning

consists of a series of operations designed to clean and make parallel fibers, draw them out into a finer strand and twist them to keep them together and give them strength

open-end rotor spinning

eliminated formation of roving, less operator supervision needed, production speed is about 10 times higher than that of ring spinning

characteristics of ring spun yarns

finer

smoother

comfortable hand

better quality

more uniform

create fewer problems in fabrication

characteristics of OE spun yarns

harsher hand

weaker

limited to coarse- and medium-sized yarns

improved abrasion resistance

more uniform and regular in appearance

more opaque in appearance

improved absorption

characteristics of a spun yarn

Structure: more air between fibers than for filament; fuzzy, with protruding ends (high twist yarns are less “hairy”)

Appearance: protruding ends contribute to dull luster, fuzzy appearance (especially with low twist)

Comfort: more comfortable, breathable, and absorbent; spun yarns with low twist has more air spaces than spun yarns with high twist and thus better insulating characteristics

Durability: sheds lint, pills

Strength: depend on the individual fiber strength, the fibers’ cohesiveness or slinging power and on the points of contact resulting from twist or other binding mechanisms used to produce spun yarn; long staple, high twist yarns are stronger

characteristics of filament yarns

Structure: long, continuous strand; can be one strand (monofilament) or multiple strands (multifilament)

Appearance: smooth, lustrous; twist, texturing, and delustering reduce luster

Comfort: less comfortable than spun yarns; high bulk yarns resemble spun yarns more

Durability: do not shed lint or pill

Strength: stronger than spun yarns; the strength depends on the strength of each filament fiber and number of filament fibers used, but they are in general stronger than spun yarns

either no or very little twist; twist is only needed to keep multiple filaments together; or very high (crepe twist)

spun yarns vs filament yarns

uniformity: filament yarns are more uniform

smoothness and luster: filament yarns are smoother and generally higher luster

strength: filament yarns tend to be stronger

twist

the spiral arrangement of the fibers around the yarn’s axis

amount of twist affects:

strength

cost

yarn hairiness

comfort

linting

s or z twist

refers to the direction of the twist

s-twist

the spirals conform to the direction of the slope of the center portion of the letter S

Z-twist

the spirals conform to the direction of the slope of the center portion of the letter Z

TPI

twists-per-inch

Low/soft twist yarn

used to maintain integrity within smooth multifilament yarns

twists in low twist yarn

2-3 tpi

low twist yarn characteristics

smooth or bulky; twist may be hard to see

napping twist

produces lofty, spun yarns; used in filling yarns of fabrics that are to be napped; napping teases out the ends of the staple fibers and creates the soft, fuzzy surface

twists in napping twist yarn

8-15 tpi

characteristics of napping twist yarn

bulky, soft, fuzzy, may be weak

average twist

used most commonly for yarns made of staple fibers but seldom for filament yarns; most durable

twists in average twist yarn

15-30 tpi

characteristic of average twist yarn

most common, smooth, regular, durable, comfortable; produces smooth, regular fabrics

voile/hard twist

produces a harsh hand; fibers are close together and compacts the yarn; twist-on-twist

twist-on-twist

the direction of twist in the single yarn is the same as that of the plying twist, so it increases the total amount of yarn twist

twist in voile twist yarn

30-40 tpi

twists in hard twist yarn

20-30 tpi

characteristics of voile/hard twist yarn

strong, fine yarns; fabrics have harsher hand due to yarn twist

crepe twist

highest number of tpi, also know as unbalanced yarns and twist and kink on themselves; require twist-set before they can be used in knitted or woven fabrics

twists in crepe twist yarns

40-80 tpi

characteristics of crepe twist yarn

lively yarns that kink and twist in fabrics with good drape and texture

yarn count system

most commonly used for spun yarns; indirect system

indirect system

the finer the yarn, the larger the number

yarn numbering system

most commonly used for filament yarns; direct system; yarn denier/yarn tex

direct system

the finer the yarn, the smaller the number

single yarn

has one strand and is the simplest type

ply yarn

made by a second twisting operation that combines two or more single yarns; each part of the yarn is called a ply

simple yarns

alike in all its parts

what direction are ply yarns twisted

in the opposite direction of that of the twist of the single yarns

cord

made by a third twisting operation which twists ply yarns together

rope

heavy, thick cord; braided, twisted; core covered sheaths

blended

made of two or more fiber types

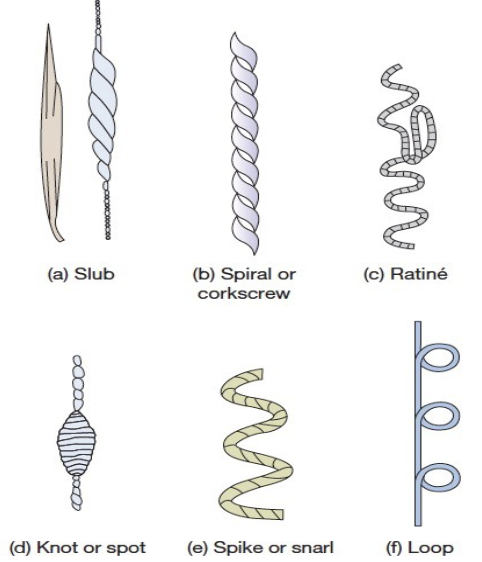

novelty yarns (fancy yarns)

deliberately have unlike parts that are irregular at intervals

stretch yarns

bare elastic

covered yarns

core-spun yarns

textured yarns

types of fancy yarns

Single: tweed, slub, metallic

Ply: ratine, spiral, knot, snarl, boucle, slub, metallic, chenille, braided, knit, stitched

nips

thin spots in the yarn

air-jet method

a jet of high-velocity air is directed at a multifilament yarn, which separates the fibers, forcing some filaments to form loops and turns

bare elastic yarn

Stretch fiber component: spandex

Stretch type: power

Recovery power: moderate

Uses and features: lightweight foundations, swimwear, athletic wear—gym clothing, bike shorts

covered elastic yarn

Stretch fiber component: spandex or rubber

Stretch type: power

Recovery power: high

Uses and features: heavy foundations, elastic bandages, surgical stockings, athletic supporters; rubber has higher power and recovery than spandex but poor shelf life—it begins to decay in one year

core-spun yarns

Stretch fiber component: spandex

Stretch type: comfort

Recovery power: very low to low

Uses and features: active sportswear, stretch denim

textured yarn

Stretch fiber component: nylon or polyester

Stretch type: comfort

Recovery power: low

Uses and features: blouses, sportswear, stretch pants, hosiery, polyester men’s socks; polyester has a tendency to pill

chenille yarn

have soft pile protruding from their surface

appearance resembles pipe cleansers without the wire

woven fabric cut lengthwise into narrow strips; each strip is a chenille yarn

can be made up of any fiber

low abrasion resistance

cotton count system

count system for cotton and cotton blends, are designated as “c.c” or “Ne”; expressed by 2 numbers: first is yarn size and second indicates the yarn ply

decitex system

used to measure the weight of yarn in grams of 10,000 meters of length

tex system

grams per 1000 meters of yarn; direct system

denier system

grams per 9000 meters; direct system; used for filament fibers and filament yarns

false-twist method

most widely used technique for producing textured yarns in finer deniers; yarns are twisted, heat-set, and untwisted in one operation

gear crimping

passing the filament yarn through a series of heated rollers or sets of heated gears that deform the filaments; a type of textured yarn

growth

unrecovered stretch in textile fabrics

knife-edge method

passing the filaments over a heated roll and then pulling them over a sharp edge at an acute angle to create a textured yarn

knit-deknit method

produces bulk textured yarn that has more stretch than yarn produced by other methods; knit into a narrow-diameter tubular form; fabric is rolled up, heat set, then unraveled

lea

spun yarn count expression for linen; used for flax jute, hemp, or ramie fibers; NeL is also used

metallic yarns

flat and ribbonlike; used mostly for decorative purposes; can be supported by loosely twisting one or more fine-filament yarns around them to increase both strength and abrasion resistance

metric yarn count

expresses the number of kilometers of yarn per kilogram of weight - “Nm”

run

woolen or woolen blends of yarn

set-textured

accomplished in some instances by winding previously textured stretch yarns onto spools under moderate tension and then heat-setting the yarn a second time