Topic 8: Strengthening Mechanisms in Metals

1/10

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

11 Terms

any plastic deformation increases the strength of a crystalline material → due to dislocation traffic jam

how does plastic deformation affect the strength of a crystalline material

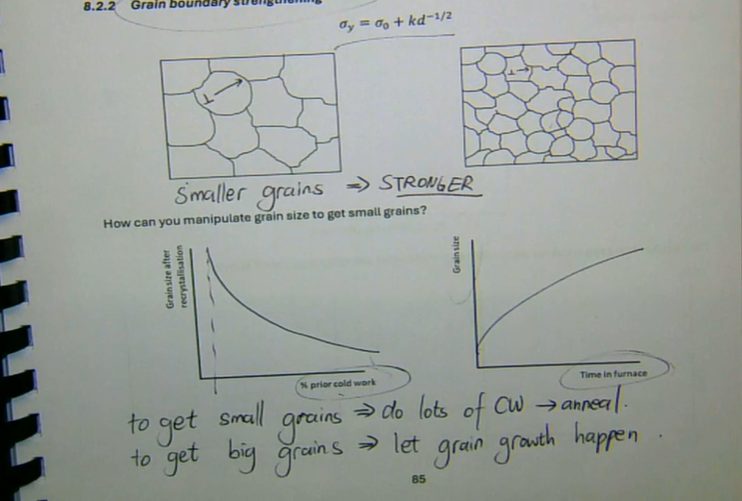

smaller grains → stronger

bigger grains → weaker

how does grain size affect strength

to get small grains → do lots of CW → anneal

to get big grains → let grain growth happen

how can you manipulate grain size to get small grains

if dislocation can move easily → weak and ductile material

to strengthen material → stop dislocation movements

what is the rule of thumb for strengthening mechanisms (for metals)

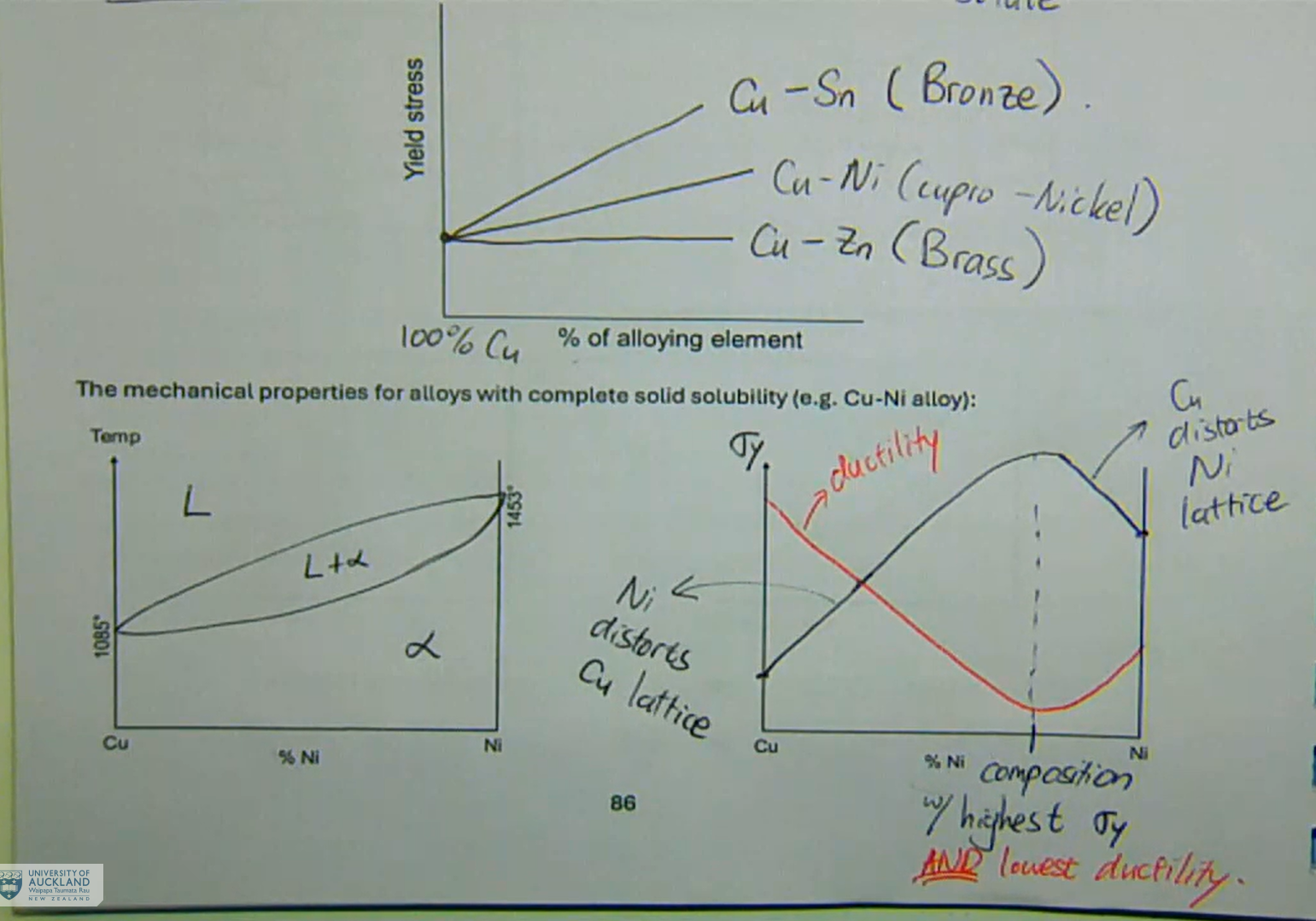

solid solutions can be substitutional or interstitial

atoms of different elements will have different sizes

when atoms of another element are inserted into a crystal lattice, there will be some distortion

smaller solute → greater distortion

the electrical resistivity of the alloy would also change with differing amounts of alloying component

max lattice distortion → max resistivity

solid-solution strengthening

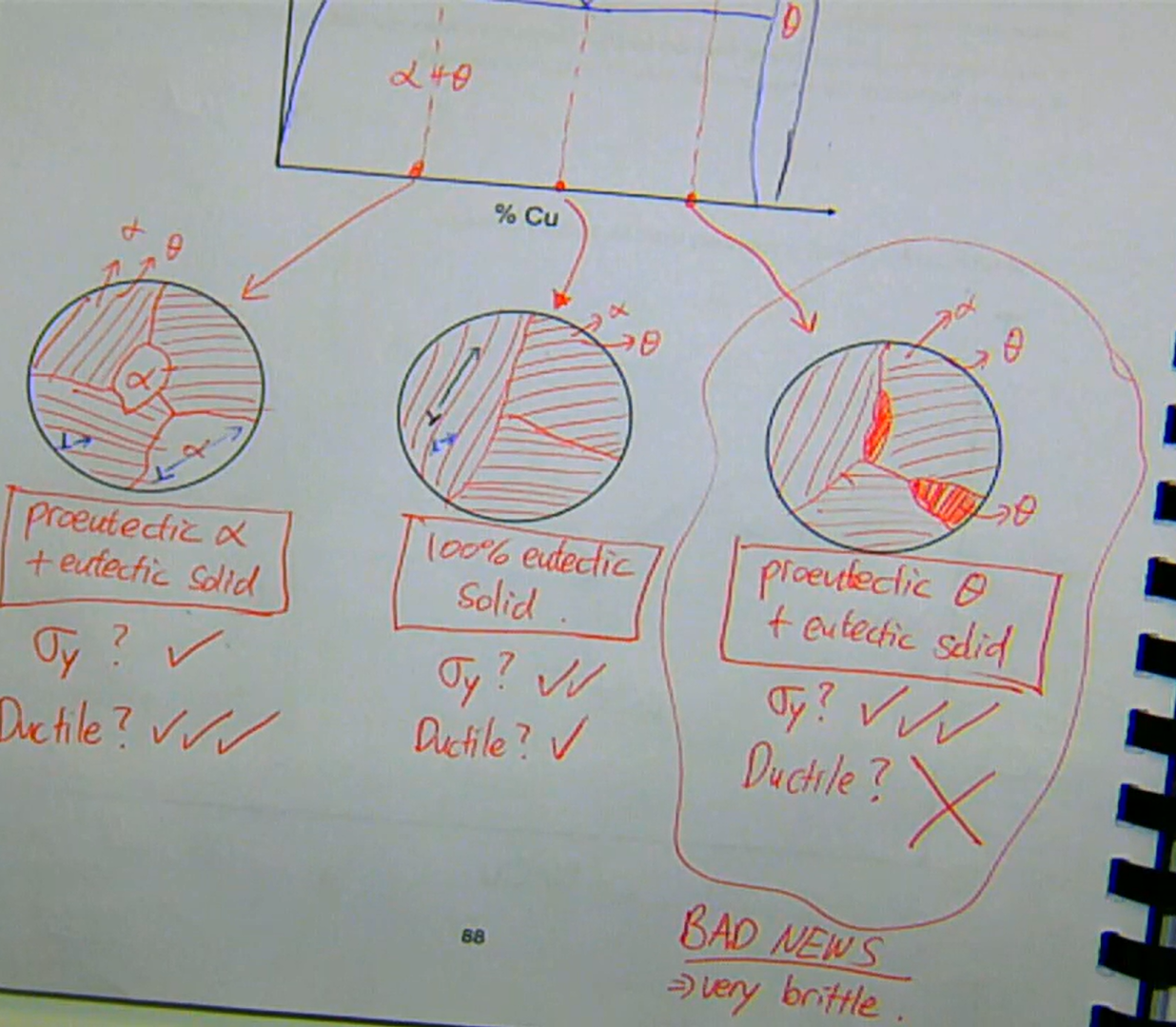

any boundary can inhibit dislocation movement in the crystal lattice

a boundary between two phases (phase boundary) will also inhibit dislocation movement

if you understand how the phase diagram for that alloy works, then you can choose an alloy to maximise the number of boundaries to maximise its strength

to maximise σy → increase % eutectic solid

in the eutectic system, there are only two solid phases of interest:

α → FCC

→ weak and ductileθ → BCT

→ strong and brittle

multiphase strengthening

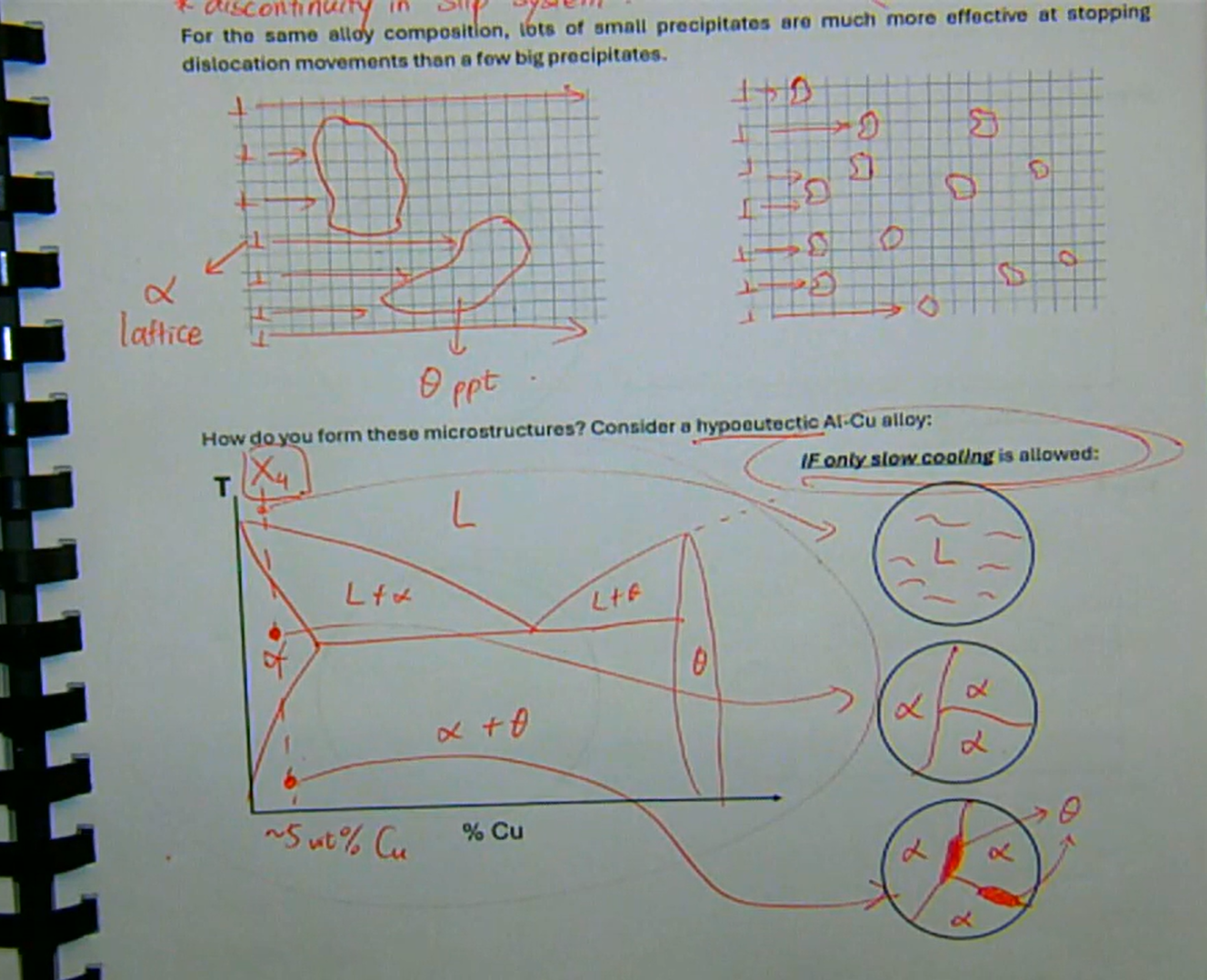

you can further increase the number of boundaries to stop dislocation movements

this is done by having lots of small hard phases (ppts) in a ductile matrix

there are two mechanisms by which precipitates can inhibit dislocation movement and strengthen the alloy:

1. discontinuity in slip system

2. distorting parent lattice

for the same alloy composition, lots of small precipitates are much more effective at stopping dislocation movements than a few big precipitates

these microstructures are formed only if slow cooling is allowed

dispersion strengthening/age hardening/precipitation hardening

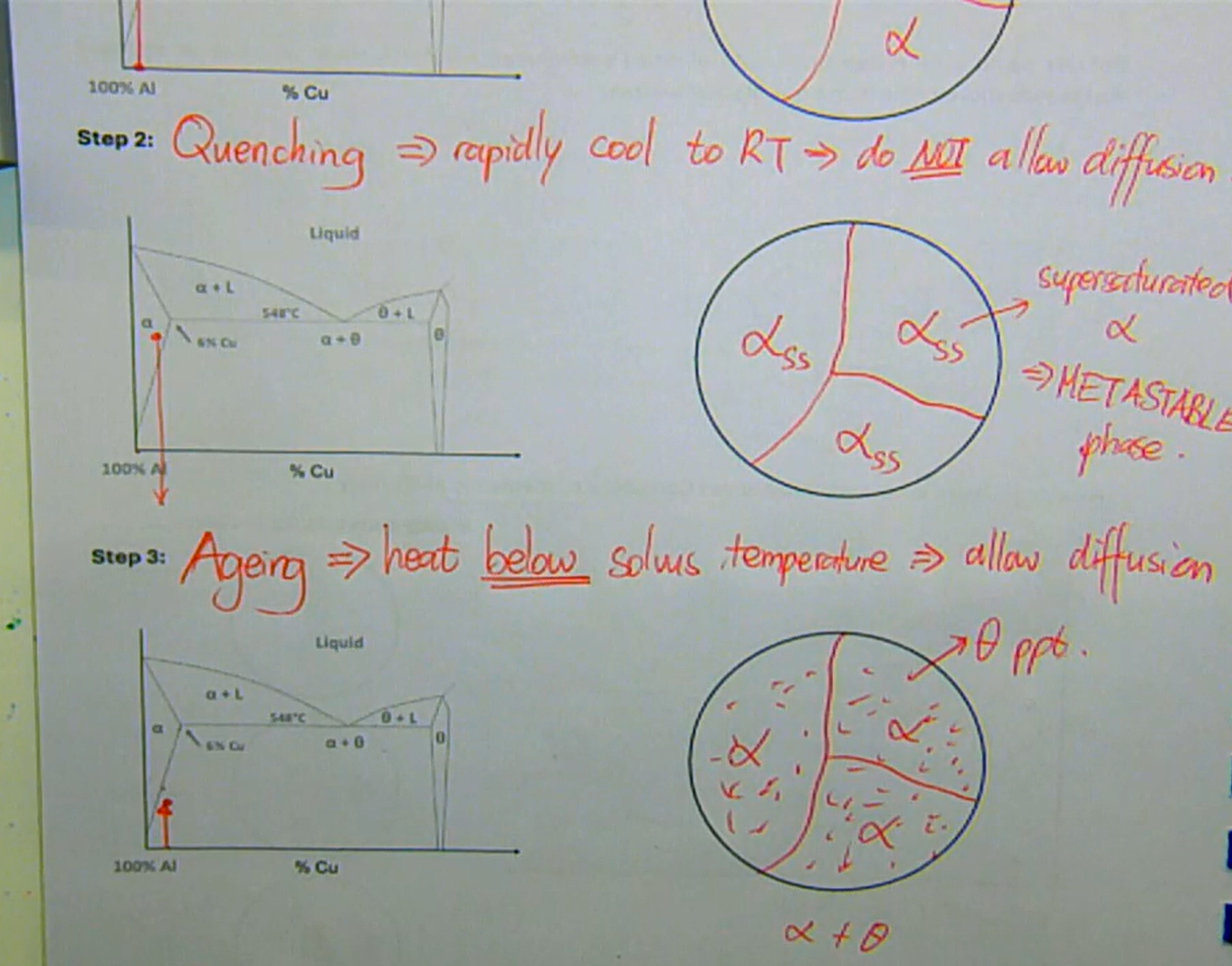

solution heat treatment → heat alloy above solvus to dissolve all Cu atoms

quenching → rapidly cool to RT → do not allow diffusion

forms super saturated α

this is known as the metastable phase

aging → heat below solvus temperature → allows diffusion

what are the three stages of heat treatment used for preparing small precipitates dispersed in another phase

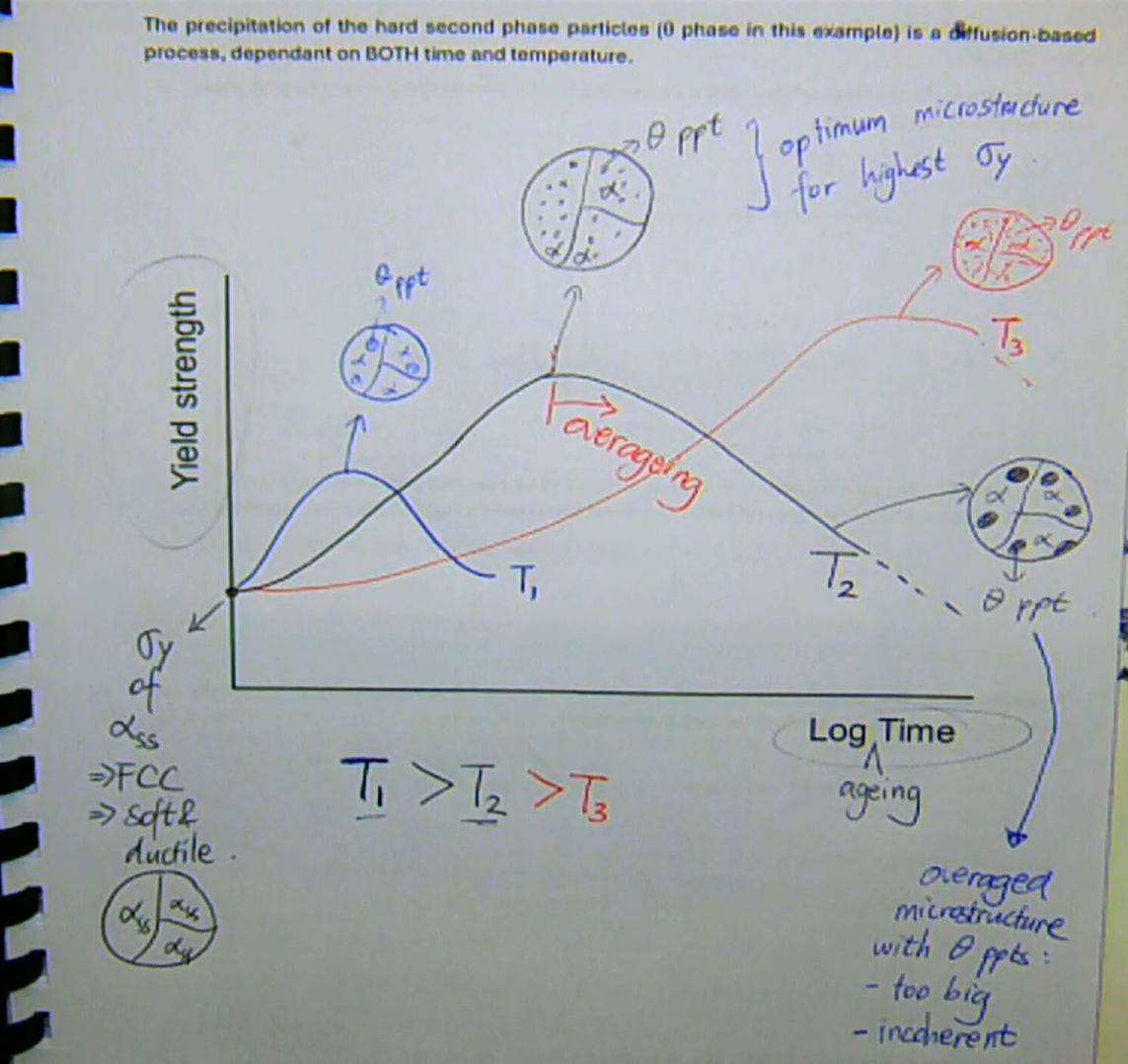

the precipitation of the second phase particles is a diffusion-based process, dependent on BOTH time and temperature

higher aging T (below solvus)

→ less time to reach max σy

→ lower max possible σy (and vice versa)

yield-strength - log(aging time) graph

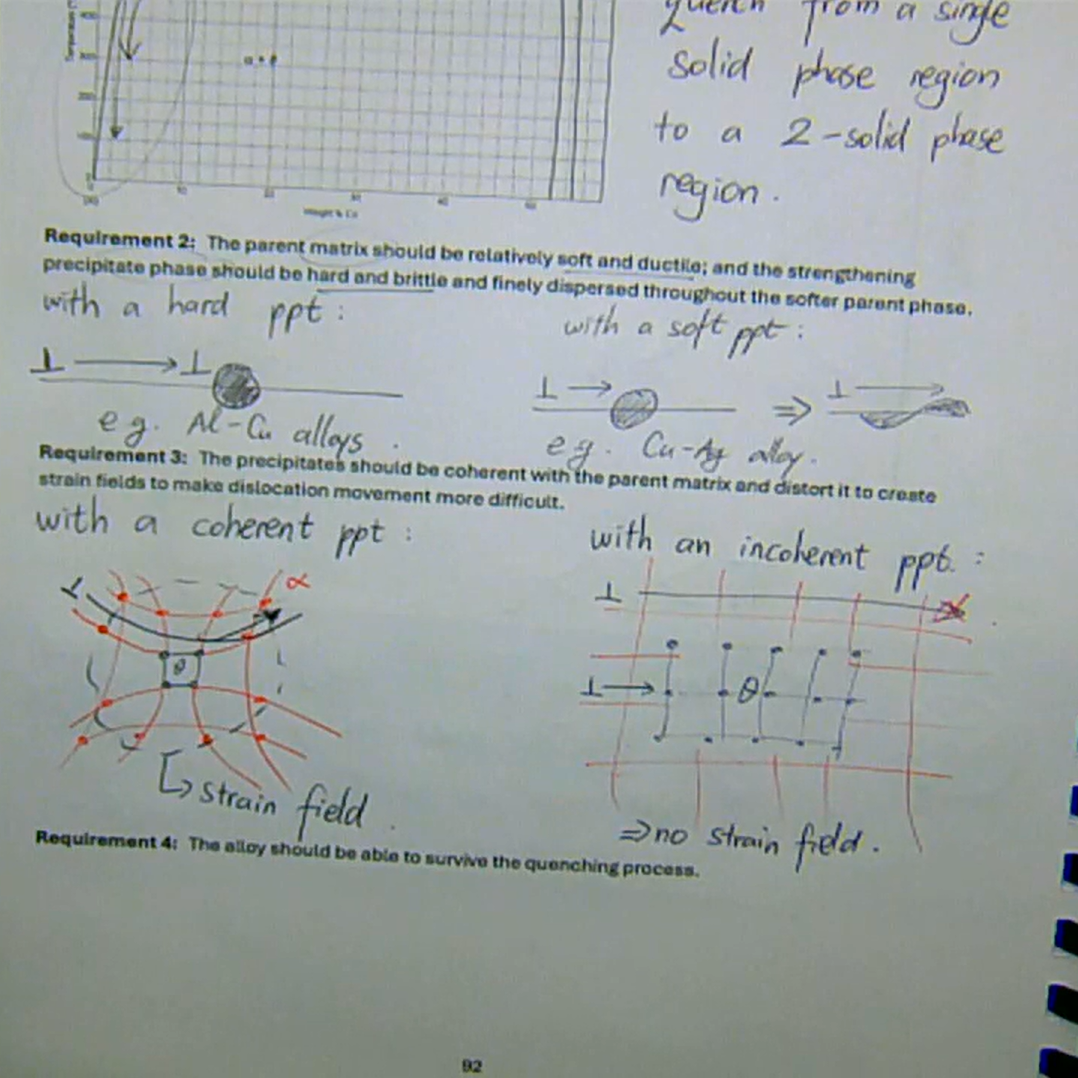

phase diagram must show decreasing solid solubility of the strengthening phase with decreasing temperature

must be able to quench from a single solid phase region to a 2-solid phase region

the parent matrix should be relatively soft and ductile; and the strengthening precipitate phase should hard and brittle and finely dispersed throughout the softer parent phase

the ppts should be coherent with the parent matrix and distort it to create strain fields to make dislocation more difficult

the alloy should be able to survive the quenching process

sudden T change → thermal shock → can cause shape distortions and cracks

what are the four basic requirements before an alloy can be age-hardened

they can not be welded because they will form hard and brittle θ at joints

overage

options for joining:

rivets

screws

glue

why can’t aluminium-based age-hardening alloys be welded together