Lecture 5: Rapid Prototyping

1/15

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

16 Terms

material addition RP technologies

all of which work by adding layers of materials of one at a time to build the solid part from bottom to top

geometric modelling

this consists of modelling the component on a CAD system to define its enclosed volume

tessellation of the geometric model

in this step, the CAD model is converted into a format that approximates its surfaces by triangles or polygons, with their vertices arranged to distinguish the object’s interior from its exterior

slicing of the model into layers

in this step, the model in STL file format is sliced into closely spaced parallel horizontal layers

what are the 3 types of classification method of rapid prototyping techniques

liquid-based, solid-based and powder-based

what are the 3 types of liquid-based rapid prototyping systems

stereolithography, solid ground curing an droplet deposition manufacturing

stereolithography

a process for fabricating a solid plastic part out of a photosensitive liquid polymer using a directed laser beam to solidfy the polymeri

What is the equation to complete a single layer?

Ti=Ai/vD + Tr

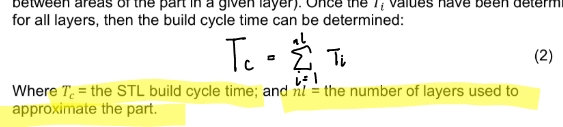

What is the equation for the value of build cycle time to be determined?

Tc= Ti

Solid ground curing

like stereolithography, solid ground curing (SGC) works by curing a photosensitive polymer layer by layer to create a solid model based on CAD geometric data

What are the processes for solid ground curing process for each layer?

mask preparation, applying liquid photopolymer layer, mask positioning and exposure of layer, uncured polymer removed from surface, wax filling, milling for flatness and thickness

droplet deposition manufacturing

these systems operate by melting the starting material and shooting small droplets onto a previously formed layer

laminated-object manufacturing

laminated-object manufacturing produces a solid physical model by stacking layers of sheet stock that are each cut to an outline corresponding to the cross-sectional shape of a CAD model that has been sliced into layers

fused deposition modelling

an RP processing which a filament of wax or polymer is extruded onto the exisiting part surface from a workhead to complete each new layer

Selective Laser Sintering

Selective laser sintering uses a moving laser beam to sinter heat-fusible powders in areas corresponding to the CAD geometric model one layer at a time to building the solid part

powder-based rapid prototyping systems

is when the starting material is powder for the RP technologies