Operations Management - Exam 1

1/147

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

148 Terms

Benchmarking

a process in which one company studies the processes of another company to identify best practices

Benchmarking is important to

investors. it shows the relative cost of providing a good or service closely related to earnings growth

For benchmarking, you want to use a company that is

similar

What business parameters would you want to compare for benchmarking?

size, product, customer market, sector, location

Profit margin =

ratio income to sales revenue

Profit margin equation

annual income / annual sales revenue

Asset turnover is

the amount of sales generated for every dollar’s worth of assets

“Turnover = Revenue” or the rate at which

goods are sold and replaced in a store

Asset Turnover equation

= annual sales revenue / average total assets

Return on assets

income generated by assets

ROA equation

= profit margin x asset turnover = annual income / average total assets

Operations and supply chain management involves specialists in

product design, purchasing, manufacturing, service operations, distributions

Success in OSCM depends on

operations-related strategy, processes to deliver products and services

OSCM definition

the design, operation, and improvement of the systems that create and deliver the firm’s primary products and services

OSCM is concerned with

the management of the entire product production or service delivery system

Operations:

manufacturing and service processes used to transform resources into products

Operations include:

manufacturing produces physical products and services produce intangible products

Supply chain:

processes that move information and material to and from the firm

Supply chain includes:

logistic processes move products, warehousing processes store products, and information makes the process more efficient

Goods are

tangible, less interaction with customers, often homogeneous, and not perishable

Services are

intangible, interaction with customer required, inherently heterogeneous, perishable/time dependent

The Goods-Services continuum has 4 circles

pure goods, core goods, core services, pure services

Pure goods examples

food products, chemicals, mining

Core goods

appliances, automobiles, data storage systems

Core services

hotels, airlines, internet service providers

Pure services

university, medical, investment

Service bundling

refers to a company building service activities into its product offerings

Efficiency

doing something at the lowest possible cost

Effectiveness

doing the right things to create the most value for the customer

Value

the attractiveness of a product relative to its price

Sustaimability

the ability to meet current resource needs without compromising the ability of future generations to meet their needs

Shareholders

individuals or companies that legally own one or more shares of stock in the company

Stakeholders

individuals or organizations who are directly or indirectly influenced by the actions of the firm

Triple Bottom Line

the goal of sustainability means that the scope of the firm’s strategy must focus on these three ares: economic prosperity, environmental stewardship, social responsibility

Environmental means

no harm to the environment

Economic means

prosperity for shareholders

Social means

stakeholders = customers, competitors, suppliers, community you work in

Operations and supply chain strategy

setting broad policies and plans for using the resources of a firm - must be integrated with corporate strategy

corporate strategy

provides overall direction and coordinates operational goals with those of the larger organization

Operations Effectiveness

performing activities in a manner that best implements strategic priorities at a minimum cost

Competitive Dimensions has 3 points of the triangle

cost, quality, delivery or responsiveness

Trade-offs

management must decide which parameters of performance are critical and concentrate resources on those characteristics

Straddling

seeking to match a successful competitor by adding features, services, or technology to existing activities

How do we compete?

cost, quality, delivery or response

Risk is

uncertainty in the environment causes supply chain planners to evaluate the relative riskiness of their operations and strategies in the face of uncertainty in the environment

Supply Chain Risk is

the likelihood of a disruption that would impact the ability of a company to continuously supply products or services

Supply chain coordination risks are

associated with the day-to-day management of the supply chain

Disruption risks are

caused by natural or manmade disasters

3 Steps of Risk management framework

identify the sources of potential disruptions

2. assess the potential impact of the risk

3. develop plans to mitigate the risk

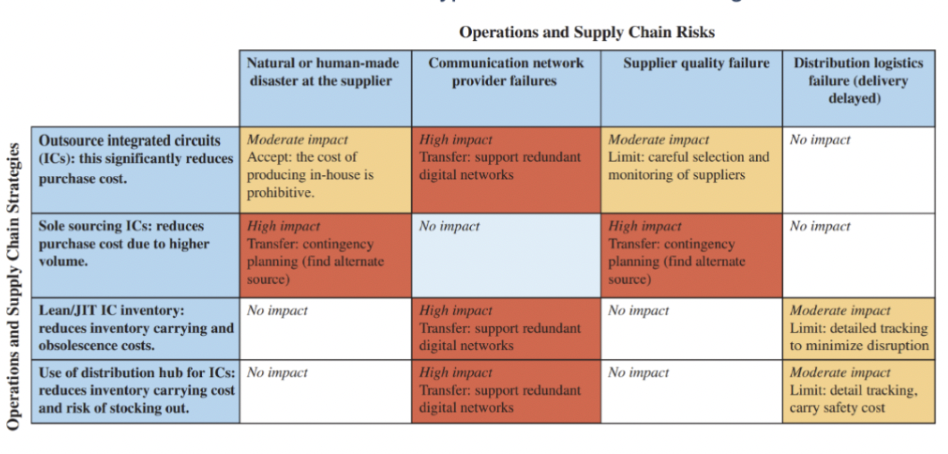

What does the supply chain risk matrix show us?

the level and type of risk for various strategies

Productivity is

a common measure of how well resources are used

Productivity equation

outputs / inputs

Productivity measure is a

relative measure - to compare to something else (similar operations within its industry) (measuring over time within the same operations)

3 Types of Measures

partial productivity, multi factory productivity, total productivity

Partial Productivity

measures the ratio of some output to a SINGLE input

Multifactor Productivity

measures the ratio of some output to a GROUP of inputs

Total Productivity

measures the ratio of ALL outputs to ALL inputs

Forecasting is the basis of

corporate planning and control

2 Different ways of forecasting

Strategic and tactical

Strategic forecast

used to estimate aggregate demand (total demand), informs strategic decisions, medium to long term

Tactical forecasts

use to estimate near-term demand, guide (inputs) to day-to-day demand, short term

Product family forecasts or aggregate forecasts are

more accurate than individual product forecasts

Decoupling points occur when

inventory is positioned in the supply chain to allow processes or entities to operate independently

Forecasts of demand is used to set inventory at

decoupling points to the proper level

2 Types of Forecasting

Quantitative and Qualitative

Quantitative is basically

data and calculations

Quantitative forecasting inclues

time series analysis, casual relationships, simulation

Qualitative forecasting is basically

data and calculations and business judgements

Seasonality can have other cycles like

monthly, yearly, weekly

Cyclicality is

change in demand over many years

Time series analysis is

using the past to predict the future

Short term forecasting time window

less than three months

Short term forecasting is mainly used for

tactical decisions (replenish inventory and scheduling)

Medium term forecasting time window

3 months to 2 years

Medium term forecasting is used to

develop a strategy which will be implemented over the next 6 to `8 months (meeting demand, changing production rates)

Long term forecasting time window

more than 2 years

Long term forecasting is used for

detecting general trends and identifying major turning points

Stationary is where there is

no trend or cyclicality

Other forecasting considerations

accuracy required

2. size of forecasting budget

3. availability of qualified personnel

4. degree of flexibility (can the firm react quickly if the forecast is inaccurate?)

5. consequence of a bad forecast ( important or costly decisions require a good forecast)

Simple moving average forecast is based on

demand over the most recent periods

Simple moving average is useful when

demand is not growing nor declining rapidly and no seasonality is present

Selecting the period length is important because

longer periods provide more smoothing, shorter periods react to trends more quickly

The simple moving average formula implies that

all periods are equally important

The weighted moving average allows

unequal weighting of prior time periods

with the weighted moving average, all the weights must be equal to

one

in weighted moving average, the more recent data is given

more significance than older data

Forecast errors occur when

the forecast value and what actually occurs are different

All forecasts generally contain some

level of error

2 sources of error

bias and random

Bias

when a consistent mistake is made

Random

errors that are not explained by the model being used

Market Research

ask customers needs and purchasing plans with surveys or interviews

useful for demand and product design and planning

may be overly optimistic as customers may act differently than what they say

SURVEYS AND INTERVIEWS

Historical analogy

use demand characteristics from similar related products to create a forecast

Panel of consensus

leverage multiple individuals and more experience to make forecast

“executive judgement” panel when upper management involved in making key forecasts and decisions

could suffer from “group think”

Delphi Method

select experts and develop questionnaire

distribute questions and collect reponses

summarize and distribute results along with new questionnaire

refine forecast by re-cycling through these steps as needed until final result is reached

Capacity

the ability to hod, receive, store, or acommodate

In business, capacity is viewed as

the amount of output that a system is capable of acheiving over a specific period of time

Capacity management considers both

resource inputs and product outputs

3 Capacity Planning Time Durations

long range, intermediate, short range

long range window

greater than a year