Mdoule 2: CPI Overview

1/49

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

50 Terms

Chemical Process Industry

chemical reactions; extraction, separation, purification; preparation of specifically formulated mixtures

Heavy Chemicals

Those dealt in large quantity normally crude or less purified chemicals

Fine Chemicals

Those that are completely purified substances and produced in limited quantity

Organic Compound

includes nucleic acids, fats, sugars, proteins, enzymes, and hydrocarbon fuels (w/ C-H bo

Inorganic Compound

includes salts, metals, and other elemental compounds (w/o C-H bonding)

Natural Compound

Available in nature

Synthetic Products

Man-made compounds

Catalyst

increases or decreases the rate of a reaction without being consumed in the process. If consumed then it should regenerate at the end of the process.

Bulk Drug

the active substance used in a drug formulation. It becomes an active ingredient of the finished dosage form of the drug

Resin

natural or synthetic compound which begins in a highly viscous state and hardness with treatment

Pigments

defined as coloring agents that are practically insoluble in the application medium

Dyes

defined as coloring agents that are practically soluble in the application medium

Solvent

A liquid in which substances (or solutes) are dissolved to form a solution

Miscellaneous

All other compounds which do not cover in above class

Samahan sa Pilipinas ng mga Industriyang Kimika

SPIK

Chemical Industries Association of the Philippines

English of SPIK

Philippine Chemical Industry

the branch of the manufacturing sector that converts various materials into useful and profitable products via chemical reactions and process

Basic Chemicals, Chemical Products, Rubber Products, Plastic Products

Sectors of Chemical Industries in the Philippines (4)

Intermediates; Base Materials

Chemical process industries procures raw materials from natural environments to convert them into -, which subsequently serve as - - to every other kind of industry

Lithosphere

coal, natural gas, and petroleum

Earth’s Crust (Lithosphere)

mineral ores, carbon, hydrocarbons

Ocean Water (Hydrosphere)

1.5 x 10^21 L contains about 3.5 percent by mass dissolved material

Seawater (Hydrosphere)

Good source of sodium chloride, magnesium, and bromine

Air (Atmosphere)

N2, O2, Ne, Ar, Kr, and Xe

Earth’s Atmosphere

5 x 10^15 tons; unlimited

Vegetation and Animals (Biosphere)

agro-based industries

Natural Products (Biosphere)

oils, fats, waxes, resins, sugar, natural fibers, and leathers

Chemical Process

consists of a combination of chemical reactions such as calcination, ion exchange, electrolysis, oxidation, hydration, and operations based on physical phenomena such as evaporation, crystallization, distillation, and extraction

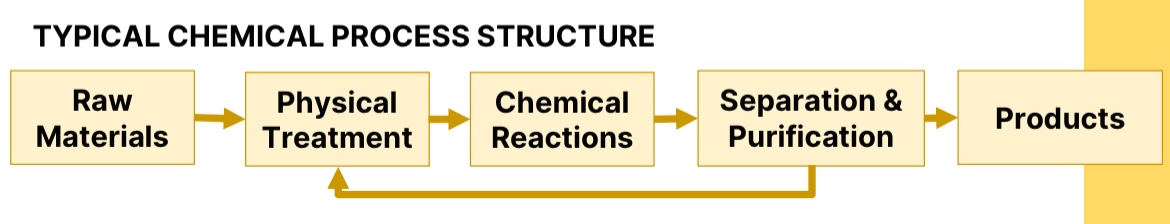

Typical Chemical Process Structure

Chemical Reaction

a process that always results in the inter conversion of chemical substances

Process Engineering

often the synonym for chemical engineering and focuses on the design, operation, and maintenance of chemical and material manufacturing processes

Product Engineering

process of designing and developing a device, assembly, or system such that it can be produced as an item for sale through some production manufacturing process

Batch Processing

This involves the processing of bulk material in batches through each step of the desired process. Used for small-scale production

Continuous Processing

This processing involves moving one work unit at a time between each step of the process with no breaks in time; volume remains constant

Batch Process

Medicine

Continuous Process

Ammonia

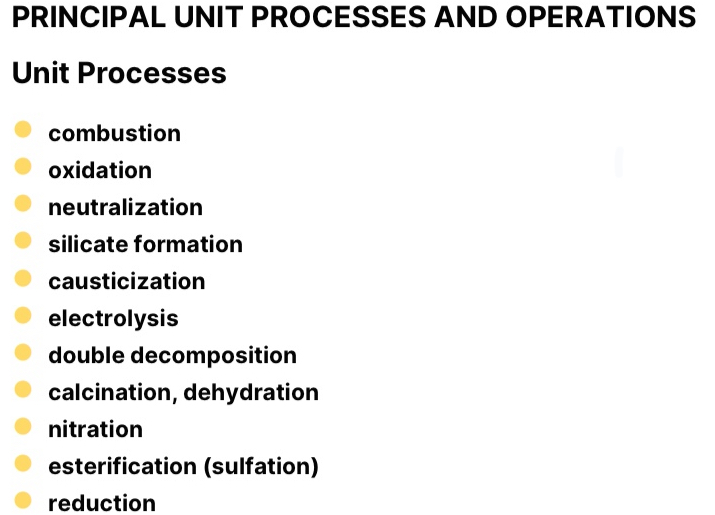

Unit Process

commercialization of a chemical reaction under such conditions as to be economically profitable; chemical transformations or conversions

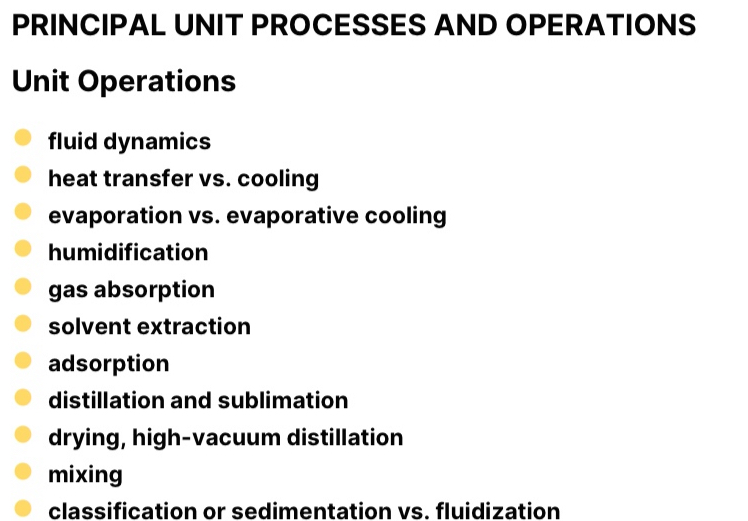

Unit Operations

Based on fundamental laws and physiochemical principles. Design, material of construction and operation; and calculation of various physical parameters (mass flow, heat flow, mass balance, power and force, etc.); Physical Change

Unit Processes

Unit Operations

Block Diagram

Units as Blocks

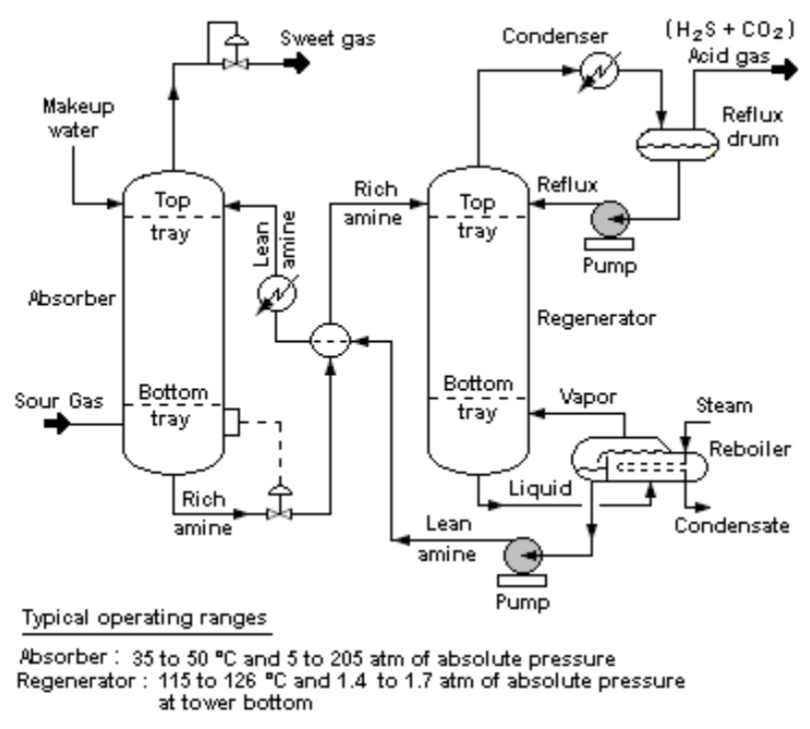

Process Flow Diagram

Detailed Schematic Units

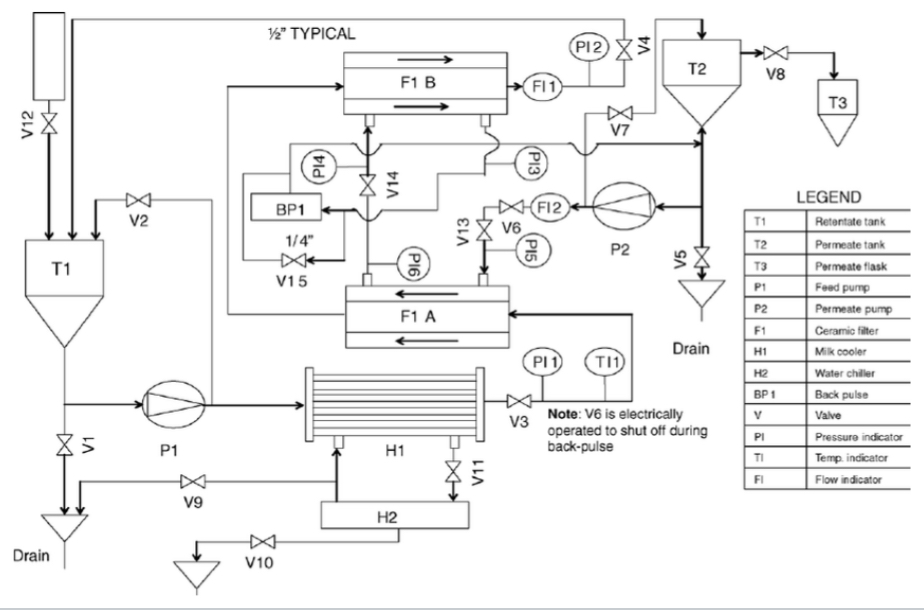

Process & Instrumentation Diagram

Block Diagram

Schematic Flow Diagram; shows what is to be done rather than how it is to be done

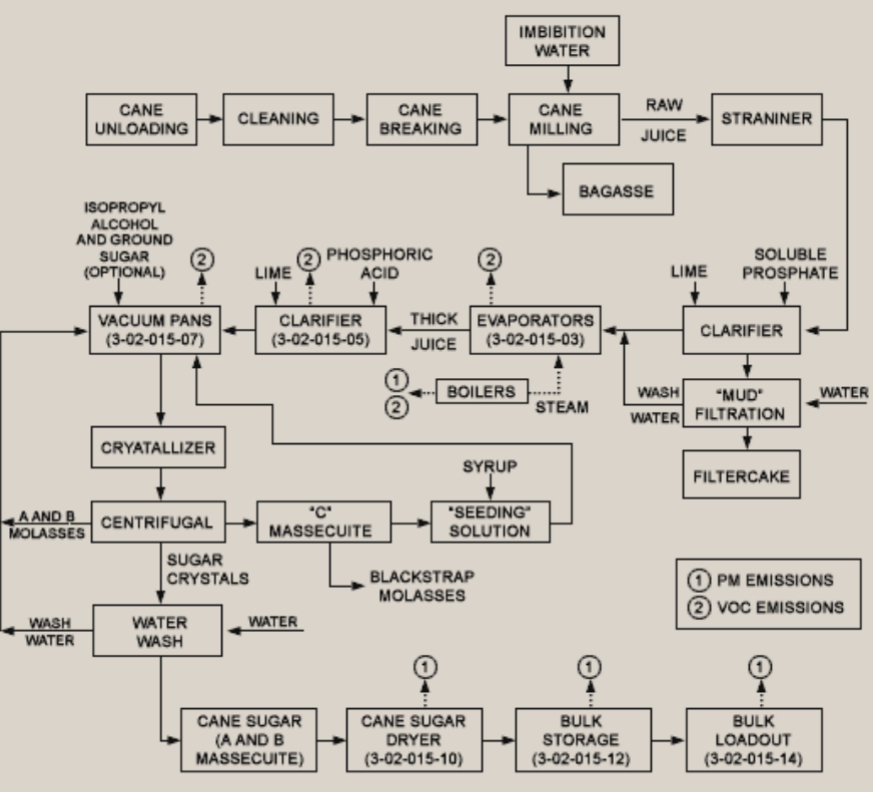

Process Flow Diagram

System Flow Diagram (SFD) or Flowsheet; describes the general flow of plant processes and equipment;

Process & Instrumentation Diagram

Process and Instrumentation Diagram; Graphical representation of equipment, piping, and instrumentation; w/ minor details such as piping details and designations; used by technicians

LEARN FD SY

LEARN FD SY

parameter being controlled/measured

P&ID: first letter

type of control device being used

P&ID: second letter

loop it represents

the number (logical numerator)