Yeast & fermentation management

1/62

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

63 Terms

What are the most ESSENTIAL things a winemaker wants from a yeast strain?

They must be able to SURVIVE, ADAPT & GROW under conditions such as:

Anaerobic

High sugar (10-15 Bé)

pH below 4.0

Temp range 8-35*C

What are some other things a winemaker wants from a yeast?

Nutritional requirements that allow predictable behaviour and convenient fermentation management

Alcohol tolerance for complete fermentation

Consistent end-product formation under fermentation conditions

In the yeast’s perspective; what must it be able to do?

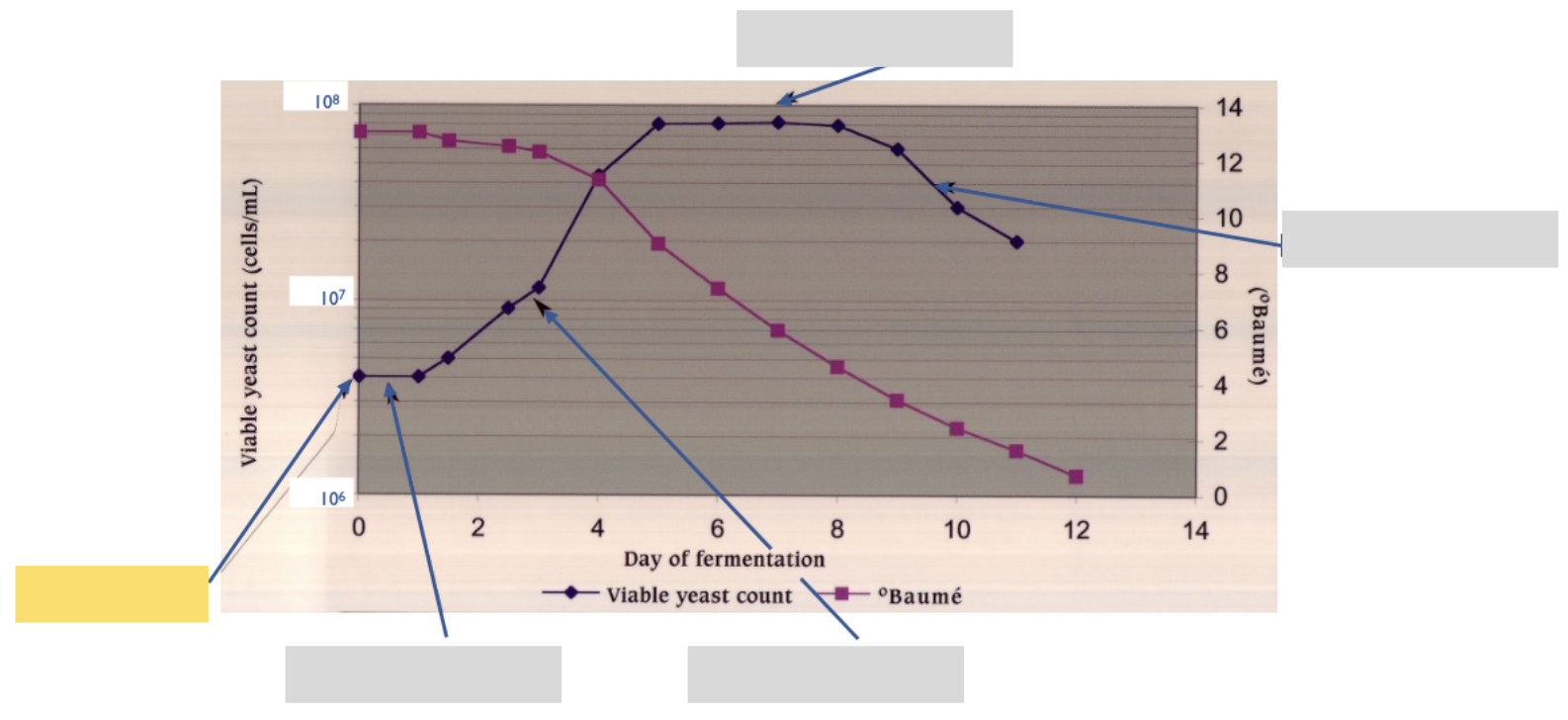

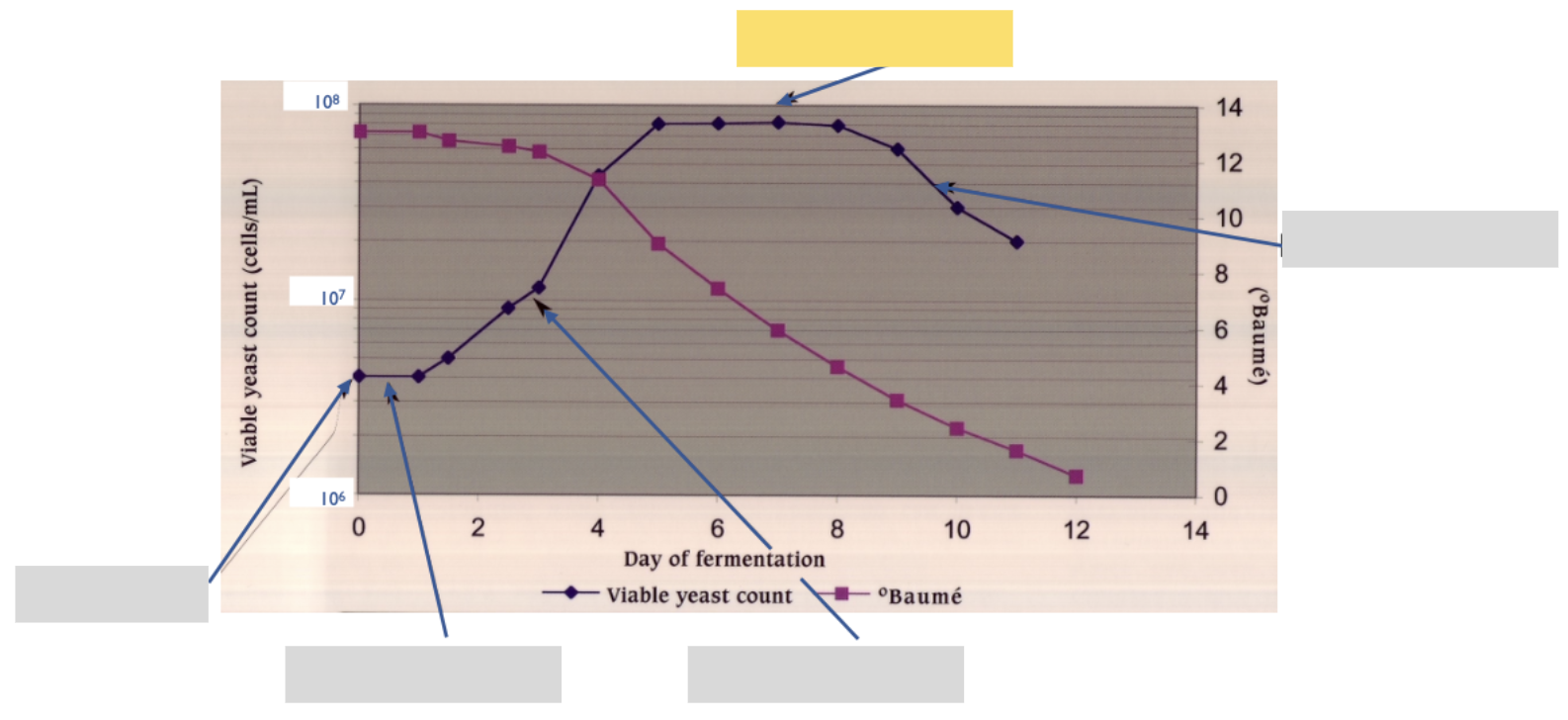

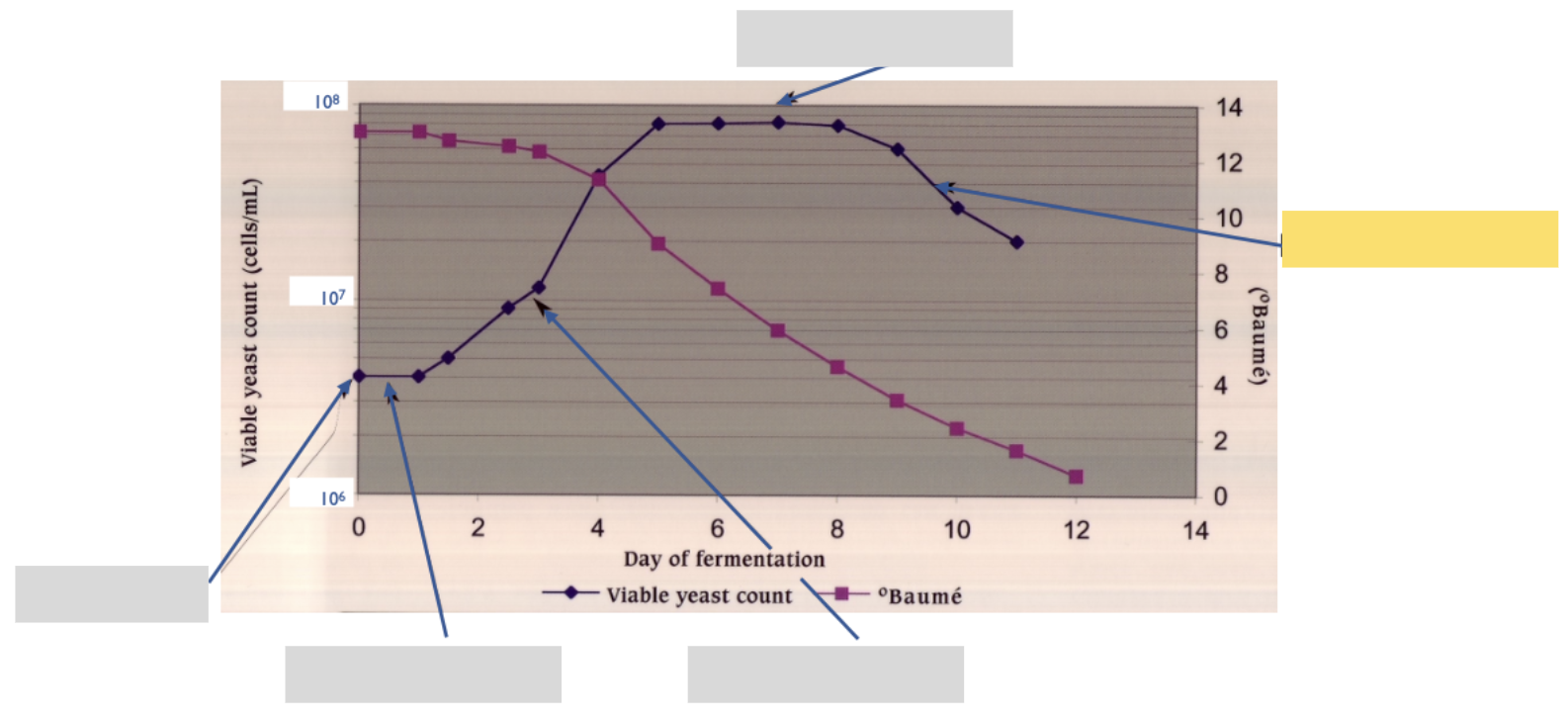

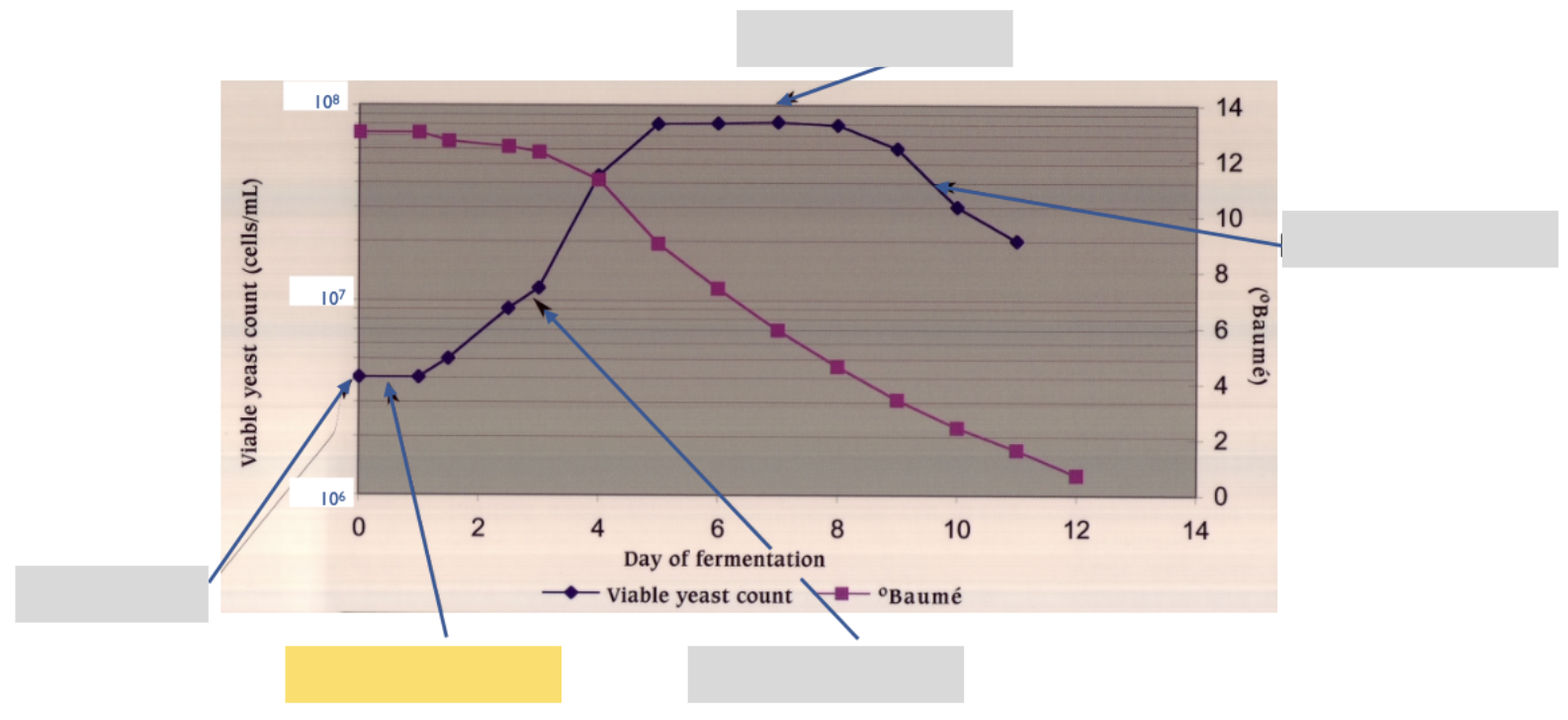

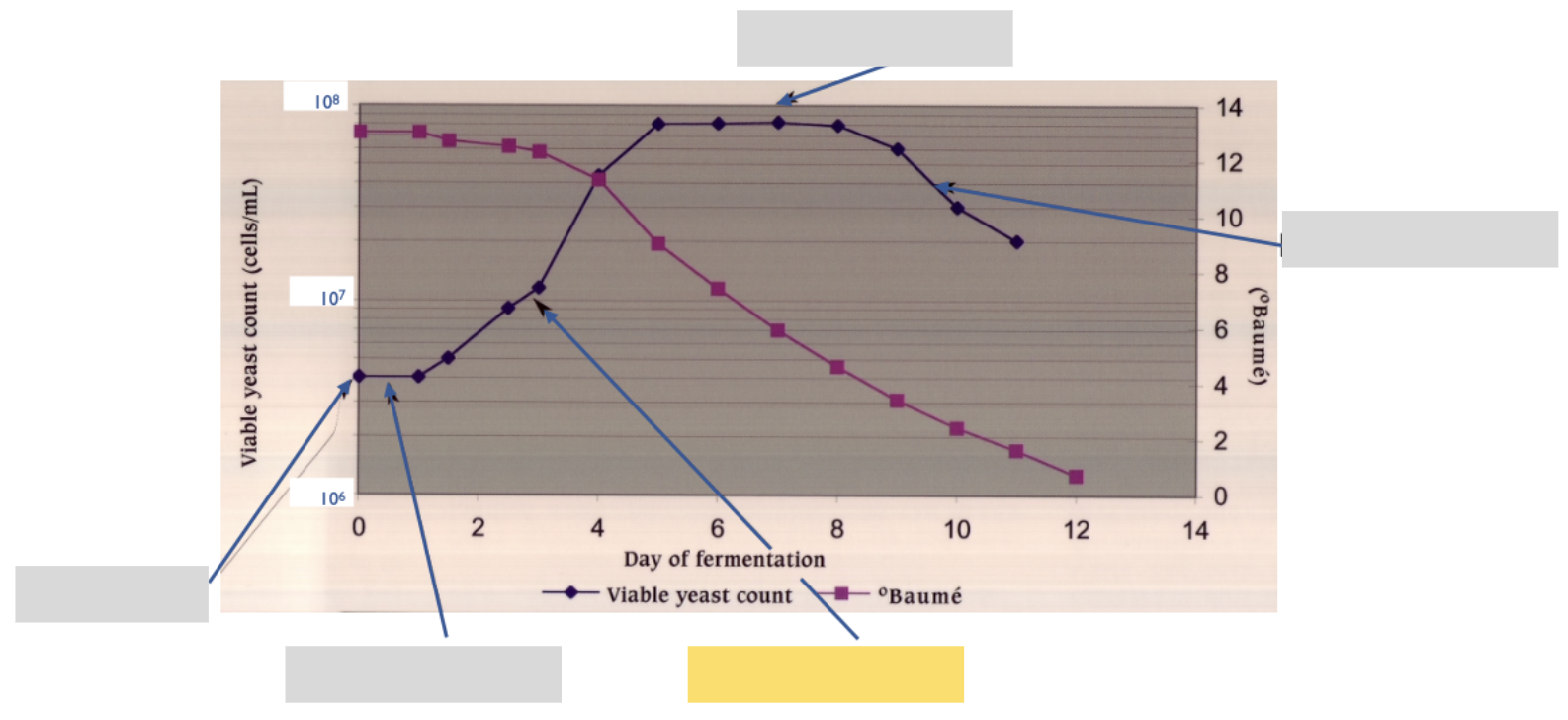

Increase population from 1-5 × 10^6 cells/mL to 1-2 × 10^8 cells/mL

Accommodate ‘batch’ system design

decline in nutrients

accumulation of toxic end-products

What is the highlighted phase called?

Inoculation

What is the highlighted phase called?

Stationary phase

What is the highlighted phase called?

Decline/death phase

What is the highlighted phase called?

Lag phase

What is the highlighted phase called?

Exponential phase

What is the oenological consideration at the lag phase and decline phase?

To AVOID temperature shocks

What does the lag phase in yeast growth/death involve?

Healthy yeast and gradual environmental transition

Temperature control is difficult in which phase of yeast growth/death?

The exponential phase

What does the exponential phase in yeast growth/death involve?

Heat evolution and sugar transport rate limiting

During the stationary phase it is important to what?

Avoid nutrient limitation

What does the stationary phase in yeast growth/death involve?

Nutrient decrease and end-product build up

What does the decline phase in yeast growth/death involve?

Nutrient exhaustion, ageing/dying population

What can you expect occurs during alcoholic fermentation in terms of yeast populations?

You can expect the yeast population to increase to 1-2 × 10^8 cells/mL

For sugar accumulation in alcoholic fermentation, distinction occurs between two phases. What are the phases and what is the distinction?

Exponential phase: approximately 50% of sugar is directed to biomass and energy production

Stationary phase: near 50% of sugar is directed to energy production and by-product formation without a significant change in cell biomass

What is the exponential phase characterised by and what should you do to support yeast cells/the fermentation?

Characterised by high viability and high budding

do haemocyctometer counts, flow cycometry

do viable/vital staining

What is the stationary phase characterised by and what should you do to support yeast cells/the fermentation?

Characterised by declining viability and budding

do carefully monitor progress of fermentation

do accurately determine residual sugar towards end of fermentation

During the stationary phase, in addition to ethanol and CO2 what are some other metabolic end-products that are formed?

organic acids

higher alcohols

esters

carbonyl compounds

polyols (glycerol)

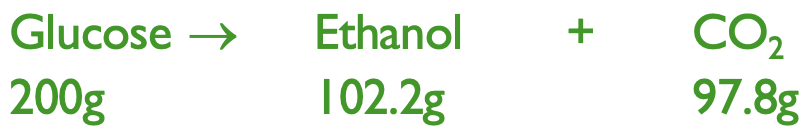

The theoretical ethanol yield is never realised

200g of glucose makes 102.2g of ethanol and 97.8g of CO2

What are the range and concentration of yeast by-products determined by?

Characteristics of the strain

Wine production steps

Nutritional and physiochemical conditions of fermentation

What features and risks do a indigenous ferment bring?

Add complexity as there will be more than 1 strain working

Risks: extended lag phase - low population to start with

What are some other things you can do to ensure you have selected the correct yeast for your ferment?

Continuing to research:

extending knowledge of yeast behaviour

Yeast performance can be value adding (alternative genera & species)

However:

still experience sluggish/stuck fermentations

How can yeast influence on quality of wine?

Can influence wine in different ways:

be consistent & reliable with minimal impact plus:

can influence grape varietal expression (extracellular enzyme activity) & mouthfeel perception (polysaccharide production)

can contribute via addition of yeast derived flavours (esters etc.)

What are the basic features of a saccharomyces selection?

tolerance to sugar, alcohol, SO2

predictable & controllable (some can be FAST fermenters - research & decide what’s best)

desirable fermentation by-product profile

nitrogen demand (generally need more nutrition than suggested by tech reports)

Desirable characteristics of saccharomyces selection

basic growth factor requirements

high osmotolerance

ability to tolerate SO2

tolerate alcohol produced

minimal production of undesirable by-products

low foaming, ability to flocculate & settle

Yeast performance is dependent on environmental conditions:

physio-chemical

influence of winemaker

Special features of saccharomyces selection

low temp fermentation

beta-glucosidase fermentation aromatics

mouthfeel & phenolic extraction

colour enhancement

compatibility with LAB

Other features of saccharomyces selection

regional & style contribution (e.g., France regions where you are bound to a particular style)

low ethanol yield

killer activity (not sensitive to other yeasts killer factors/toxins)

Why is yeast strain a critical step?

take into account strain characteristics related to wine style

predictable and controllable fermentation at desired temp (fit with refrigeration/control capacity)

predictable nutritional demands

other physio chem limitations

What are some characteristics of non-saccharomyces strains?

typically not able to complete AF

need to over-inoculation with sacch

range of different impacts

bioprotection (grape transport, cold soak, stabulation)

mimicking uninoculated fermentation (early to mid stages of AF

Why might one use non sacch yeasts?

To get a range of different compounds and added complexity - higher costs as you need to buy more than one yeast strain though

What are some important things to note when rehydrating dried yeast?

follow instructions of yeast packet

if you inoculate below 15 degrees - more problems

don’t inoculate with a temp difference greater than 5 degrees

What is ergosterol?

ergosterol is a sterol, a type of lipid, that yeast cells synthesize under aerobic (oxygen present) conditions, essential for maintaining cell membrane integrity and functionality

Why is ergosterol important?

It enhances yeast growth, metabolism and viability during fermentation and improves resistance to stress

What is an example of an easily assimilable form of nutrients for yeast?

Yeast ghosts or hulls

What are some critical factors for inoculation?

temp of water/juice at rehydration can be detrimental to viability

yeast physiological restrictions and nutritional requirements must be respected

addition of complex nutrients

always follow manufacturers recommendations

winery hygiene, microbial/chemical control

forward planning essential

Lower temperature rehydration

need to respect manufacturers instruction

some non sacch need lower temp e.g., 25 degrees

lower temp rehydration protection products can be used (e.g., Lallemand Go Ferm Sterol Flash)

What is critical to the success of a ferment?

Initial nutrient concentration and aeration

fermentation conditions need to support 4-6 yeast generations

completion of fermentation requires yeast numbers of 1 × 10^8 cells/mL

What needs to be done in terms of inoculation if you need to run a quick ferment?

Higher inoculation rate is important

What is assimilable nitrogen in terms of yeast nutrients? And in what form can be added?

It is the second most important macronutrient after carbon

required for amino acid synthesis - proteins

DAP or DIAMMONIUM PHOSPHATE is used for YAN (22% N)

What is DAP addition dependent on?

strain

oxygen availability (i.e., next limiting nutrient)

initial sugar content (i.e., how much work the yeast must do to finish fermentation)

What is the max amount of DAP you can add to a ferment?

Max DAP you can add before exceeding limit is 1700 mg/L

What is minimum N VS maximum N?

Minimum N to complete or maintain fermentation rate

or

Maximum N or Total N used when present in excess

what is the Minimum YAN requirement for low risk fermentation?

Whites – approx. 150 mg/L

Reds – approx. 100 mg/L

What is the YAN requirement for clean/fruity flavour?

Whites – approx. 250 to 350 mg/L

Reds – unknown (research in progress)

What is the Maximum YAN demand?

Mean = 400 mg/L

Range = 330 to 470 mg/L

What are the consequences of nitrogen limitation?

H2S liberated - no action, mercaptan (off aroma/flavour)

sugar transport slows or ceases

hexose permeases irreversibly inactivated

delayed additions may be slow to help

biomass formation limited

fermentation rate is a function of biomass and vitality

FERMENTATION STOPS

What are the key factors in H2S production?

yeast strain genetic propensity (sulphate reduction sequence (SRS) metabolism)

Yeast assimilable nitrogen (YAN) concentration

SO2 (exogenous or derived from the reduction of sulphate) import in yeast SRS metabolism

vitamins )thiamine, pyridoxine, biotin pantothenic acid) are important in yeast SRS metabolism

Generally speak, lower initial N concentration, higher H2S response

Nitrogen additions: how much?

varies according to strain

varies according to composition/conditions

need to know how much is in the juice

measure YAN - YAN = free amino nitrogen + ammonia

routine analysis difficult in terms of:

methodologies and constraints of vintage

easier methods = approximation

historic data helpful

Make an educated guess

Nitrogen additions: timing - earlier additions?

Earlier additions can lead to:

fermentation duration reduced

greater stimulation of fermentation rate

increased cell numbers

NUTRIENT DEMAND HIGHEST AT START OF FERMENT

Nitrogen additions: timing - later additions?

Later addition leads to:

reduced cell numbers

reduced range in fermentation rates

reduced fermentation duration BUT to less extent

Conclusions of nitrogen additions

additions helpful

need a guide - YAN vs yeast requirements, analysis, experience, history

consider timing - moderate initial dose, more later, signals of depletion - H2S, slowing of ferment

What is the average N demand of wine yeast strains?

350 mg YAN/L

What are the recommendations for YAN?

yeast strain plays a critical role

Measure Yan

understand strain N demand and H2S potential

consider timing of DAP additions

DAP additions can also effect flavour outcomes

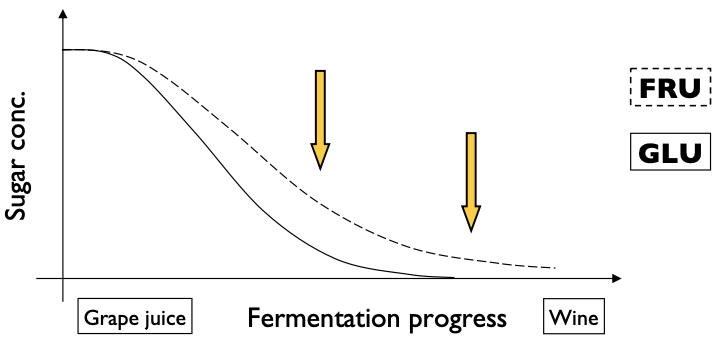

What are the major grape sugars?

Glucose and fructose

sucrose in low concentration

glu and fru are the major carbon sources utilised by yeast during fermentation

What are importation consideration when it comes to sugars and fermentation?

very high sugar concentrations (>250 g/L) cause osmotic stress - consider this impact for ferment

glucose and fructose are utilised at different rates - can be important in stuck ferments

What happens in sugar consumption during fermentation?

initially grape juice sugar composition ~ 50/50 glu/fru

during fermentation ration glu:fru decreases

if the fermentation sticks, residual sugar is mainly fru

What are the important steps needed to determine the termination of fermentation?

towards end of ferment MUST be diligent in determining end point

necessity for accurate sugar analysis, not just hydrometry

Need residual sugar analysis: enzyme G&F, rebelein etc

once completed (sugar dry <2 g/L), post fermentation processing occurs immediately

further consideration must be given to microbial stability (e.g., SO2 additions for whites, or MLF inoculation in reds)

What are some factors for sluggish or stuck ferments?

excessive clarification of juices/low solids

nutritional deficiencies in juice

strain selection

unsuccessful inoculation

initial temp too low

temp too high

temp shocks, causing cell damage/death

presence of inhibitors (e.g., ethanol, medium chain fatty acids, yeast killer toxins, bacterial contamination and pesticide residues)

During the monitoring of fermentation; what can we measure?

sugar (g & f)

YAN

temp, pH, TA, SO2 - free & total

microscopic observations, cell counts

turbidity

How can one monitor and manage yeast during fermentation? (1)

at inoculation, must/juice temps >15 degrees to minimise yeast viability losses

ferm monitored by measuring sugar content (hydrometer) 1-2x daily, and then determining rate of change in sugar concentration

Need to plot a fermentation curve - helps to manage any problems that arise

How can one monitor and manage yeast during fermentation? (2)

for whites - average 0.5-1 bé/day expected under controlled fermentation conditions

reds ferment much faster due to the presence of skins with reduction on average 1-2 bé/day preferred

cooling should be delayed until about 1 bé of sugar is fermented and avoided once ferment drops to about 2 bé

agitation of the ferment is generally required when cell vitality declines

How does yeast selection influence wine quality?

Yeast selection has several influences on wine quality including:

Aromatic profile

Different strains produce different compounds, including esters (fruity, banana, tropical fruits), higher alcohols (rose), thiols (especially in varieties like Riesling or Sauvignon Blanc)

Fermentation kinetics

Some strains ferment efficiently while others are slower and can develop more complexity

Choosing a strain that is well suited to the must’s pH and sugar is essential in ensuring a clean and complete ferment

Alcohol tolerance and glycerol production

Some strains produce more glycerol – contributing to mouth feel, softness, weight

Strains differ in tolerance to alcohol, osmotic stress, acidity

Volatile acidity and sulphide production

Stress (i.e., nutrient deficiency) can lead to excessive VA or H2S

Nutrient rich ferments or choosing low H2S producing strains can avoid these faults

Malolactic compatibility

Some strains inhibit or support MLF

Important when deciding on MLF timing – sequential or co-inoculation

Style and expression

Neutral strains allow varietal characters to dominate (e.g., EC1118)

Expressive strains can add layers of aroma, or contribute more to mouthfeel