Prosth 2: Provisional Crowns & Acrylic use

1/34

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

35 Terms

a temporary crown

(temporary restoration)

a provisional is aka as

Provisional restoration

Fixed or removable prosthesis designed to enhance esthetics, stabilization, and/or function for a limited period of time before being replaced by a definitive prosthesis

- often used while it is determined what tx the pt will receive (definitive prosthesis)

Thermal

caries

periodontal

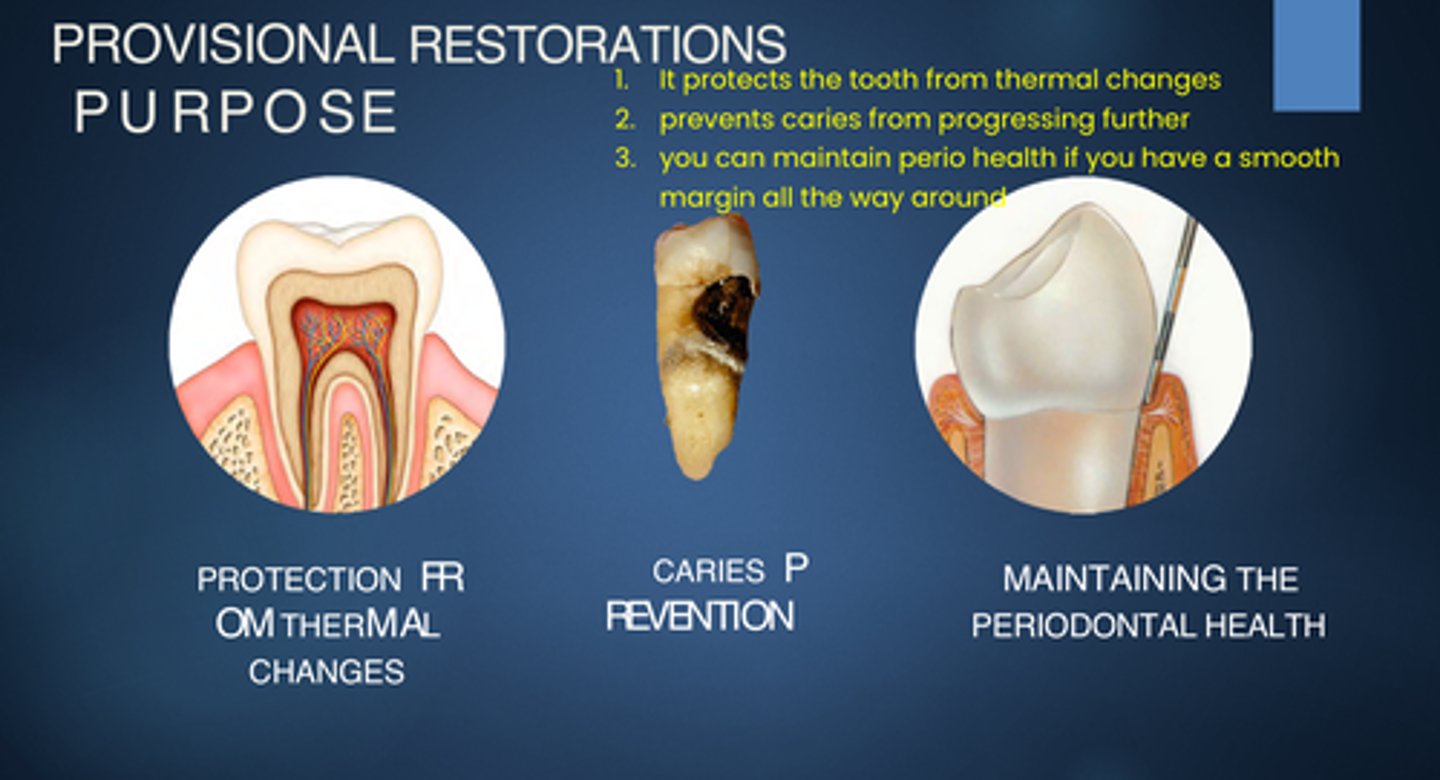

(Purpose of) Provisional restorations:

protect the tooth from _________ changes

prevent ________ from progressing further

and help to maintain __________ health

(why a smooth margin all the way around it important)

Maxillomandibular

(relationship btw max & mand during occlusion)

position

(helps teeth on either side of a missing tooth nor shift inwards)

Blueprint

(Purpose of) Provisional restorations:

Stabilize the ____________ relationship

maintain tooth __________

and act as a ______________ for final restorations

Provisional Restoration

- prov crown

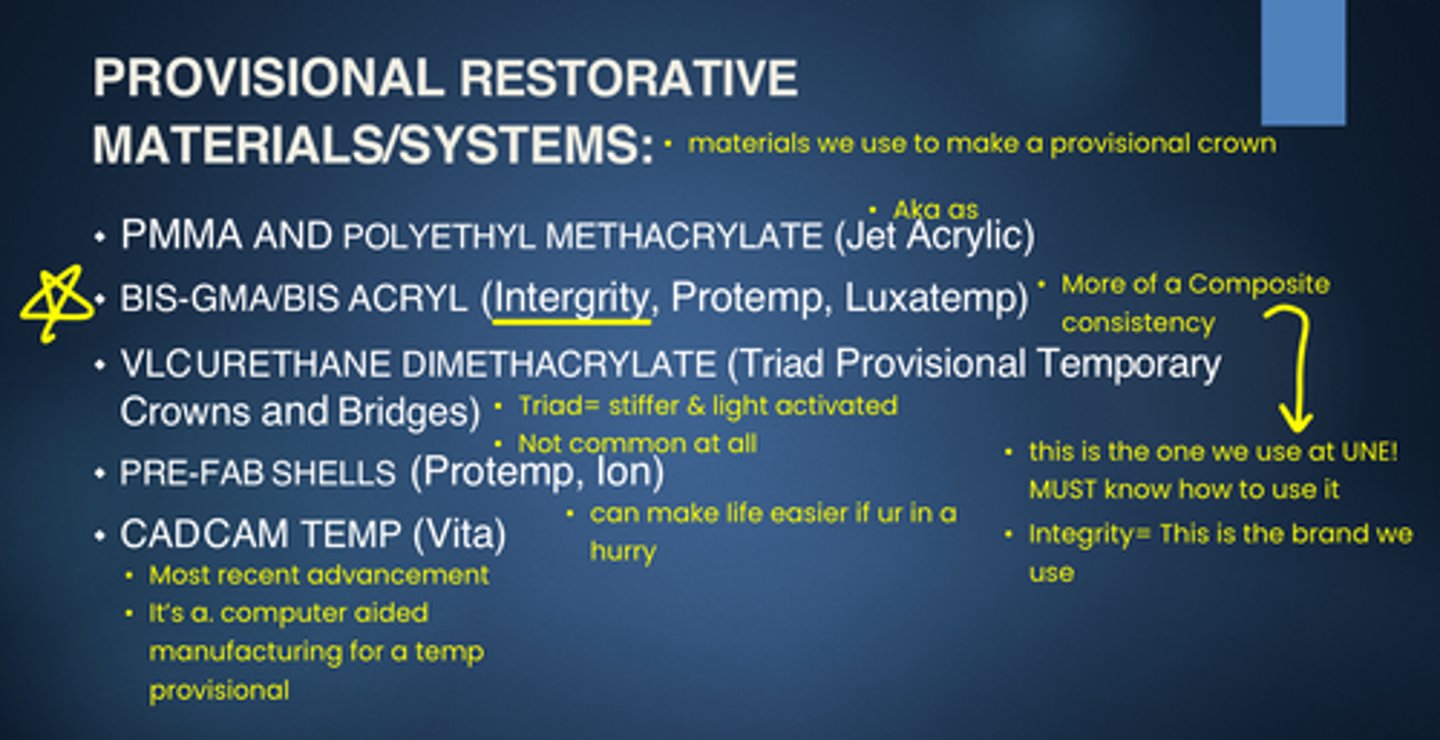

These are all the materials we can use to make a

PMMA & Polyethyl Methacrylate (Jet acrylic)

BIS-GMA/BIS ACryl (Integrity)

VLC Urethane Dimethylacrylate (Triad, Provisional temporary)

Pre-Fab Shells (Protemp. Ion)

CADCAM Temp (Vita)

BIS-GMA/BIS ACryl (Integrity)

- more of a composite consistency

Provisional material we use at UNE

- name & brand

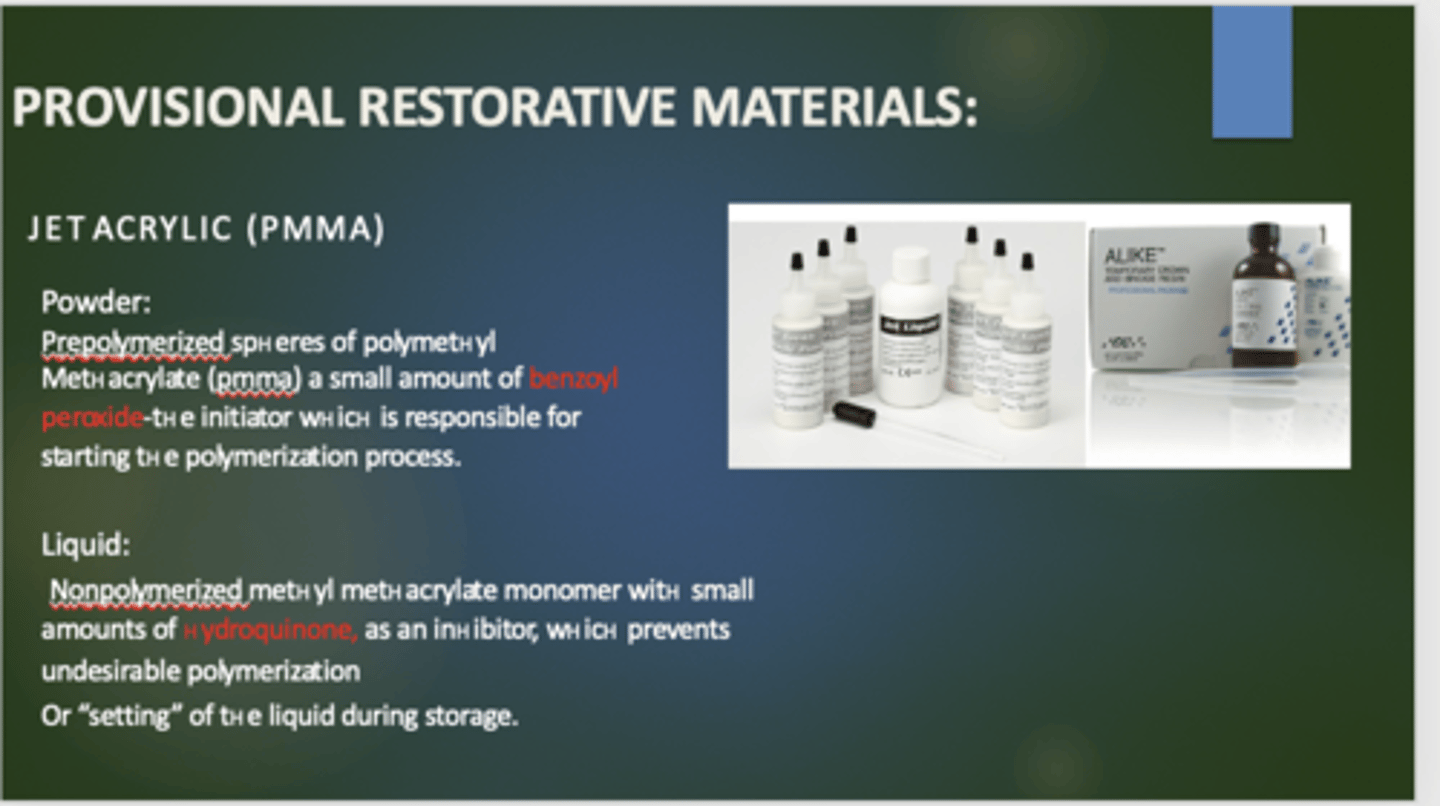

PMMA (Jet acrylic)

Powder + liquid chemically activated acrylic system used for provisional restorations (same process used to create acrylic nails)

Powder= chemical initiator= Benzyol Peroxide

Liquid= chemical initiator= Hydroquinone

powder= polymer

liquid= monomer

The powder part of Jet acrylic=

The liquid part of Jet acrylic=

- KNOW

Powder= Benzyol Peroxide

Liquid= Hydroquinone

Initiator responsible for starting the polymerization process in Jet Acrylic (PMMA)

Initiator responsible for preventing unwanted polymerization in Jet Acrylic (PMMA)

(prevents setting of liquid while in storage)

Sandy

(when u mix them tg it will be like a sandy mix)

(sand + water= dry rough mix)

Stringy

(material sicks to the fingers or instruments & will separate into strings)

Dough-Like

(this is the stage where you adapt the material into a provisional crown)

Rubbery/Plastic

(material useless @ this stage)

Stiff/Set

5 stages that happen while mixing Jet Acrylic (PMMA)

- Mixing/setting stages of Acrylic

Dough-like stage

stage where you adapt the material into a provisional crown

Sandy stage of mixing Jet Acrylic

the powder is wetted by the liquid and resembles wet sand at the beach

Stringy stage of mixing Jet Acrylic

the material sticks to the fingers or instruments used and will separate into strings when manipulated

Dough-Like stage of mixing Jet Acrylic

the material separates easily from the side of the mixing jar without forming strings

- (this is the stage where you adapt the material into a provisional crown)

Rubbery/Plastic stage of mixing Jet Acrylic

the material has elastic memory and no longer can be manipulated easily

Stiff/Set stage of mixing Jet Acrylic

Chemically-activated acrylic resins will reach a hard set after 6-12 minutes

- The acrylic will be hard to the touch and no longer release heat

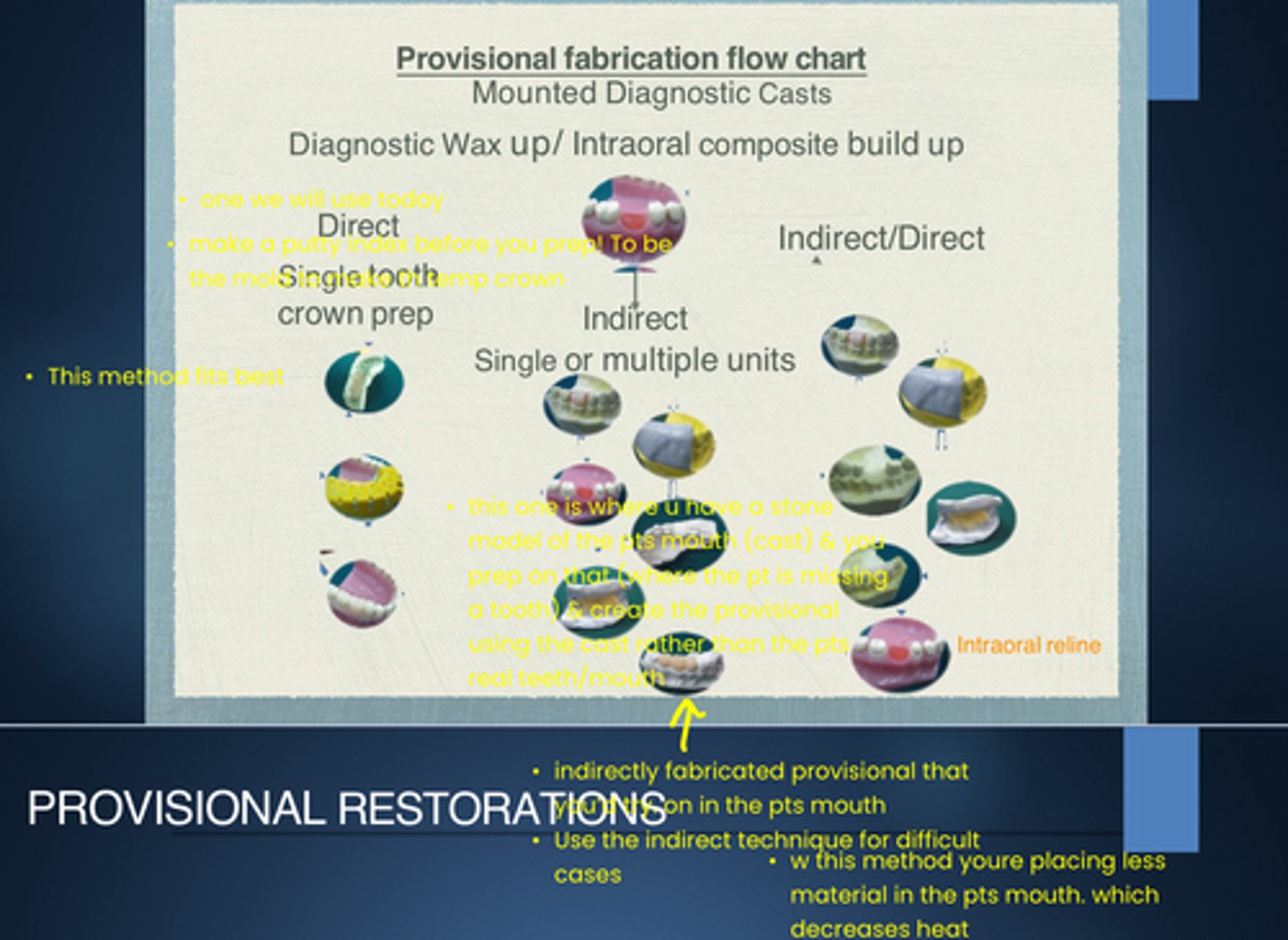

Direct

- this is the one we used

- make putty index before you prep so you can refer to it

Indirect (single or multiple units)

- Create stone model of pts mouth (cast)

- Prep on the cast (rather than in the pts mouth to avoid heat)

- w this method= less heat & less material used

Indirect/Direct

- aka as Intraoral reline

3 different ways to Fabricate a Provisional Crown

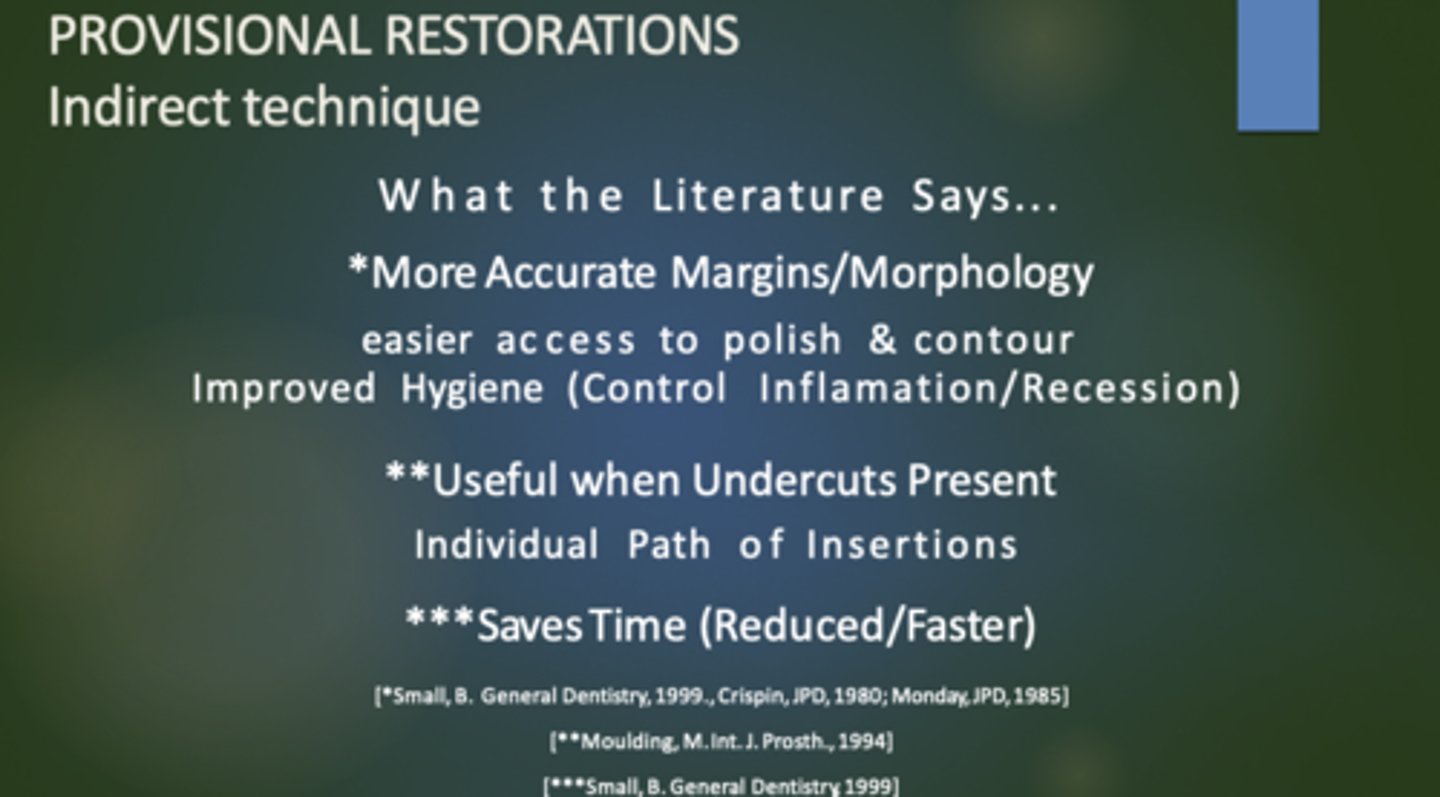

- *More accurate margins/morphology

- easier access to polish & contour

- improved hygiene

- Better control of Inflammation/Recession

- **Useful when undercuts are present

(good to see individual path of insertions)

- ***Saves time (Reduced/Faster)

3 things the literature says about using the Indirect Technique to fabricate a provisional

Indirect Technique to fabricate a provisional

- **Useful when undercuts are present

(good to see individual path of insertions)

Indirect Technique/Systems

These 3 Provisional Restoration systems are used w the

Protemp/Ion (Mass Produced Pre fabricated shells)

CAD-Temp (Fiber-FreeAcrylate Polymer)

Luxatemp (Bis-ACryl)

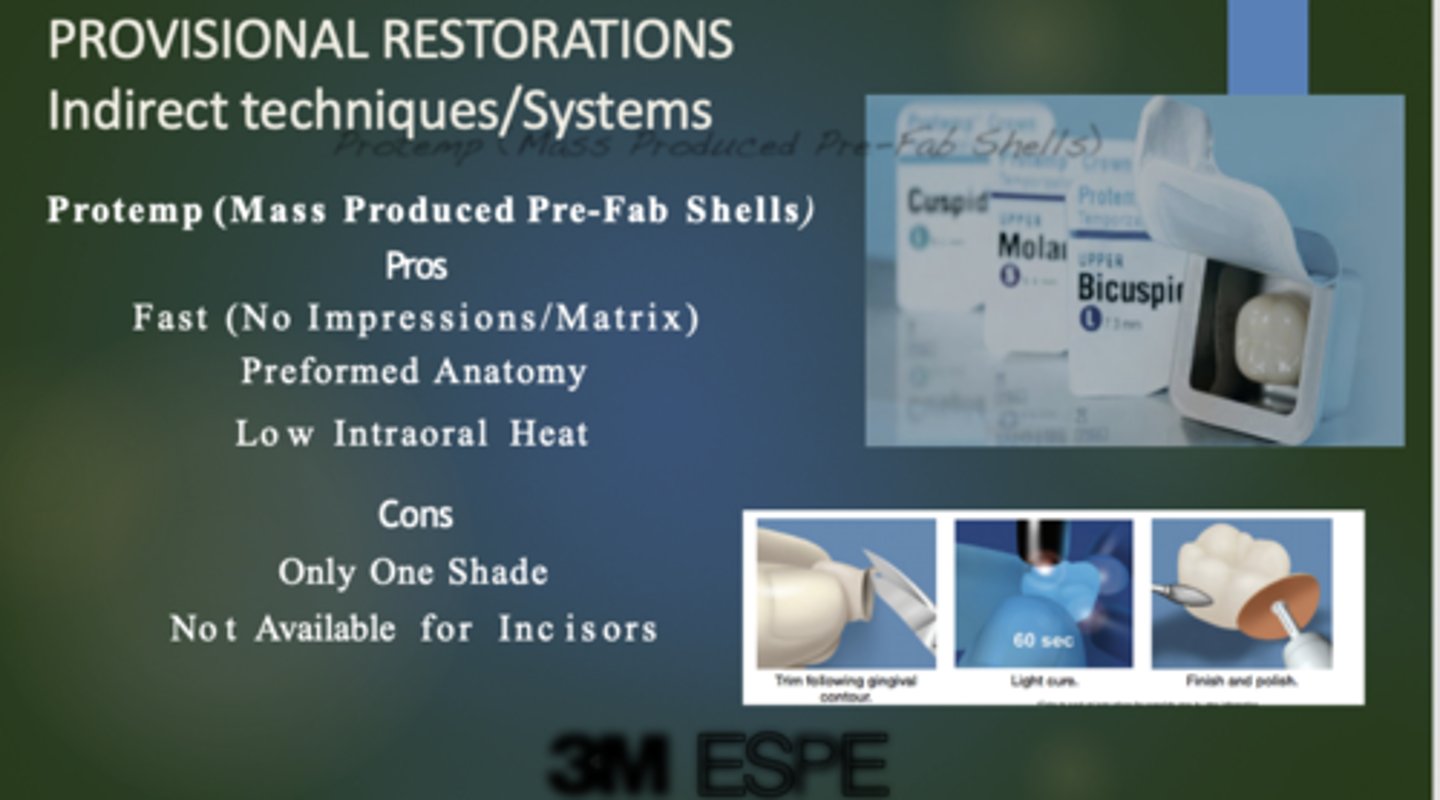

(Mass Produced Pre fabricated shells)

Indirect Technique to fabricate a provisional

Protemp/Ion is

Protemp/Ion is used for

Protemp Ion (Mass produced Pre-Fab shells)

Pros

- Fast (No impression matrix)

- Preformed anatomy

- LOW intraoral heat

Cons

- Only one shade

- Not available for incisors

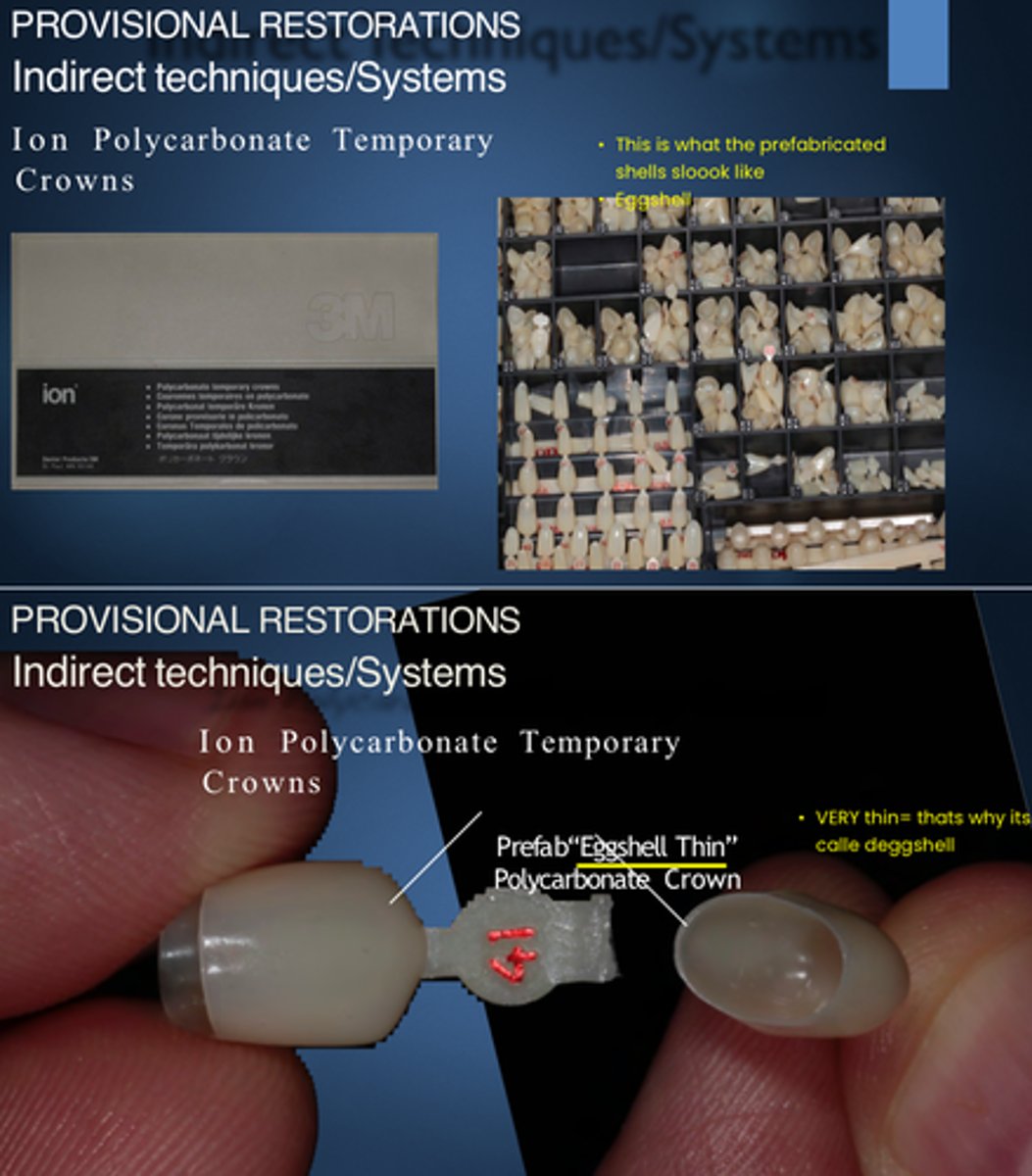

This is what Ion Polycarbonate Temporary Crowns look like

- they have a very thin shell of outer enamel (this is why we call them "eggshell"

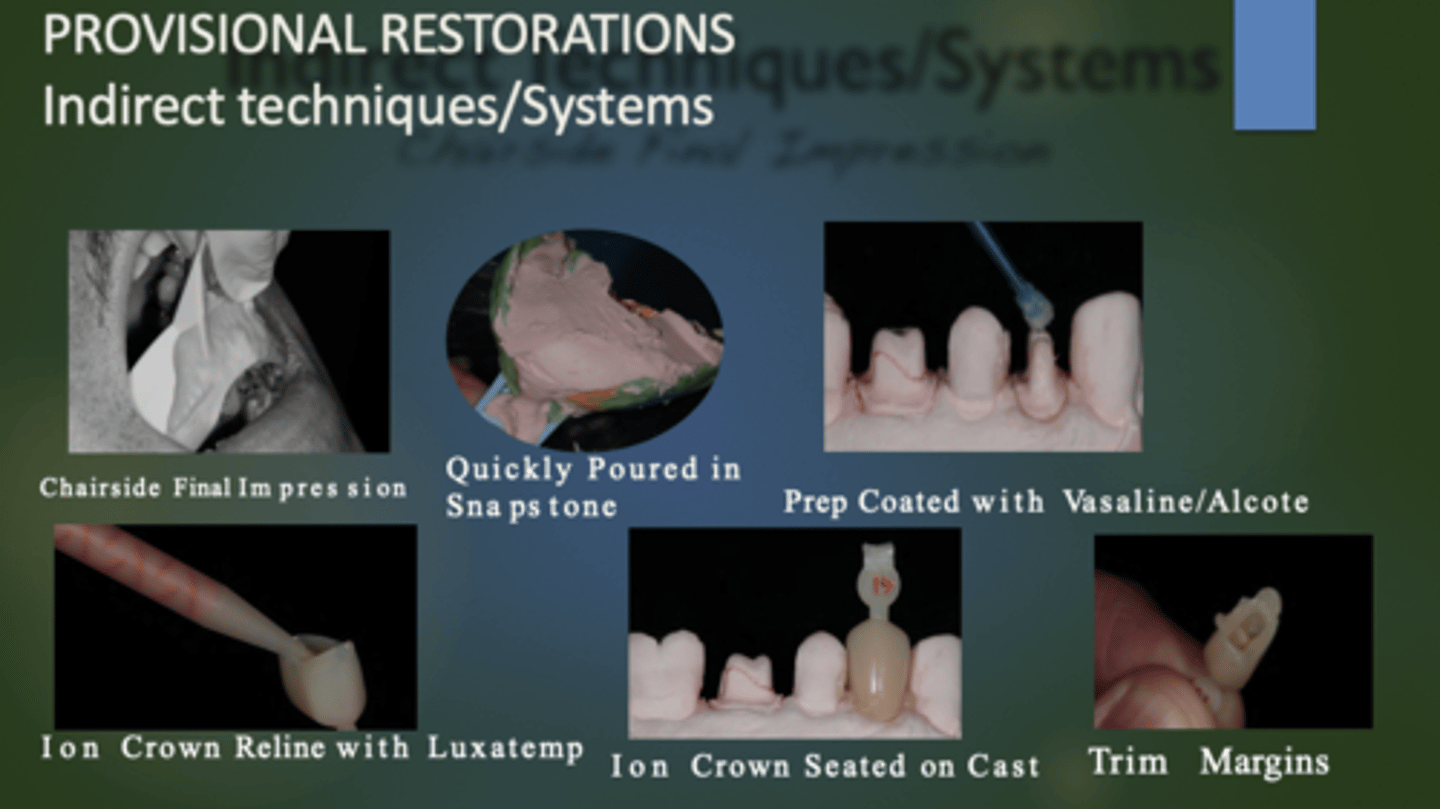

Steps for Indirect Technique Fabrication of a Provisional Crown

- chair side directions

- last pic= is what relining it= making it fit better

VITA Cad-Temp machine

(what mom uses)

Another way to create a shell temp is through using the

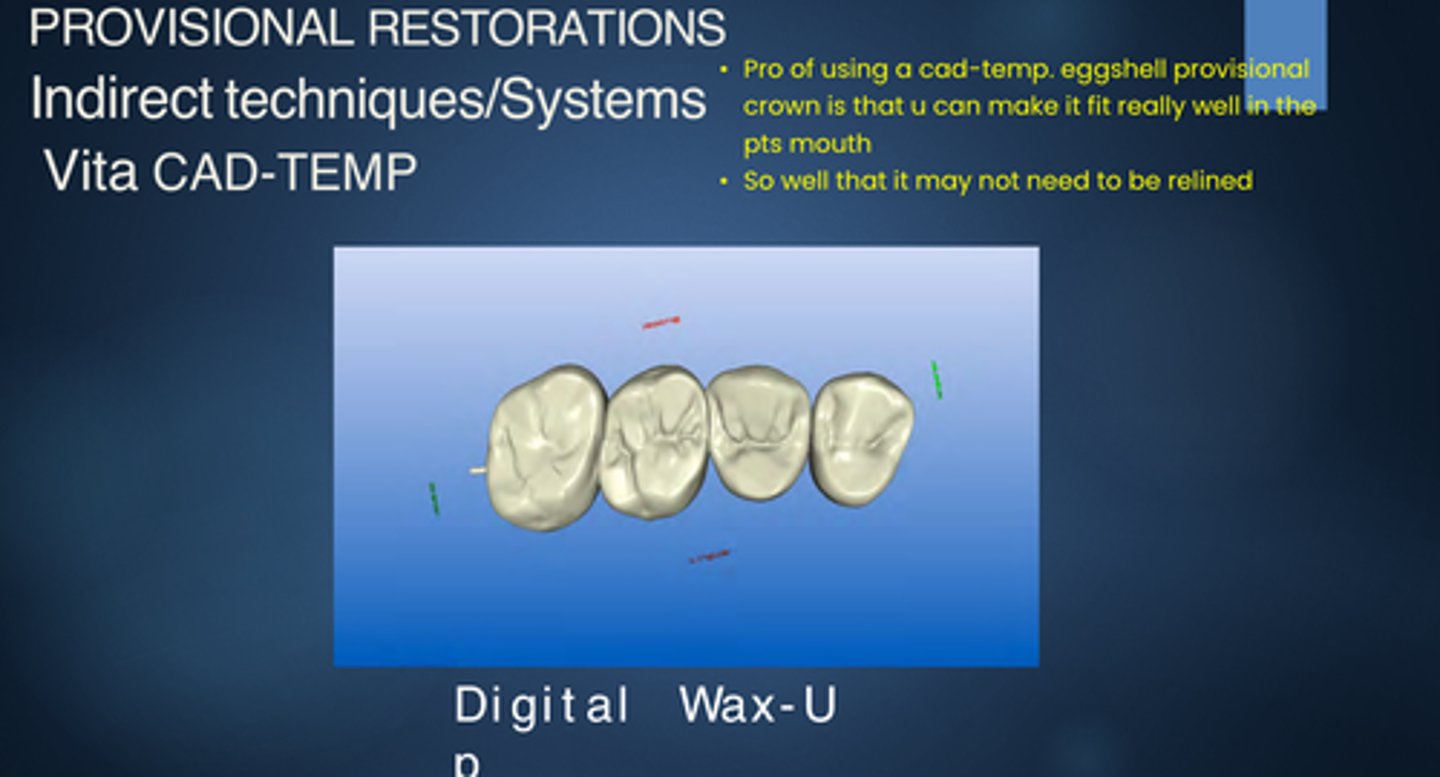

when you use this machine you can make them fir really well to each pt

- so well that they might not have to be relined after creation

1 pro of using the VITA Cad-Temp machine to fabricate a Eggshell Provisional crown

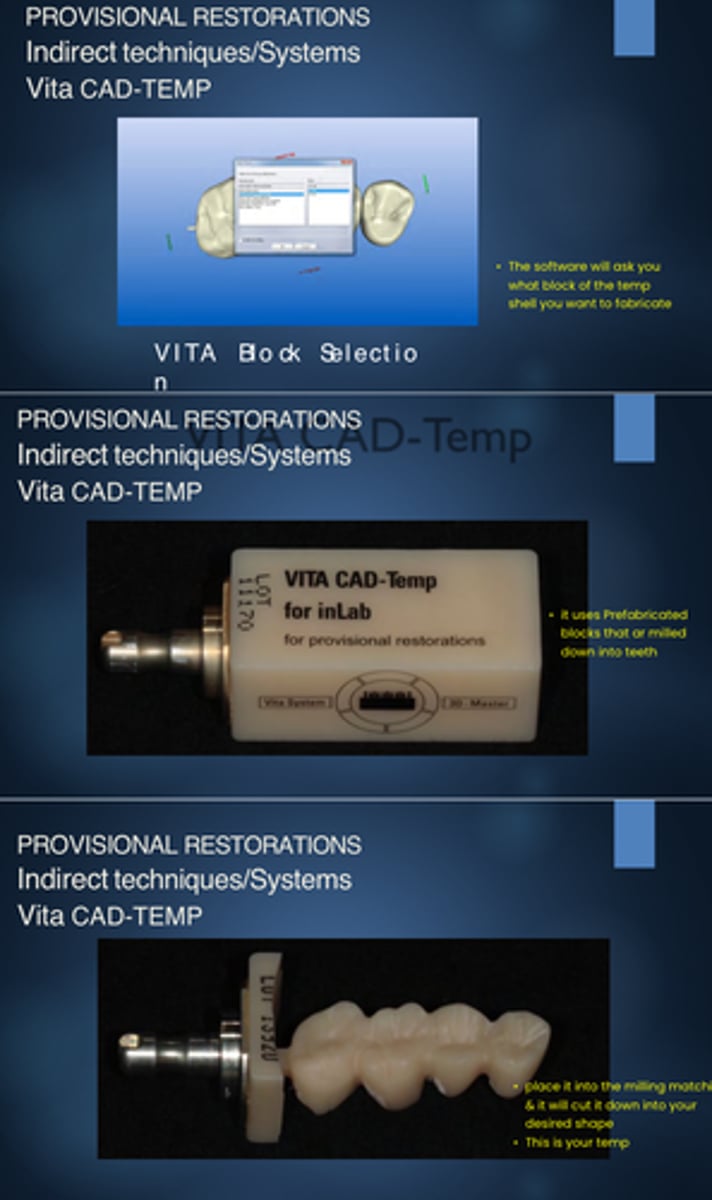

Vita CAD-Temp

These are the steps for creating a Provisional Crown using the _____ _____ _____ machine

- digital wax up (of how you want it to look)

- Vita block selection (prefabricated books that get milled down into teeth)

- Place it in the machine to be milled & cut down into the desired shape you chose

- Provisional crown created

(Scan, Design, Mill, Refine)

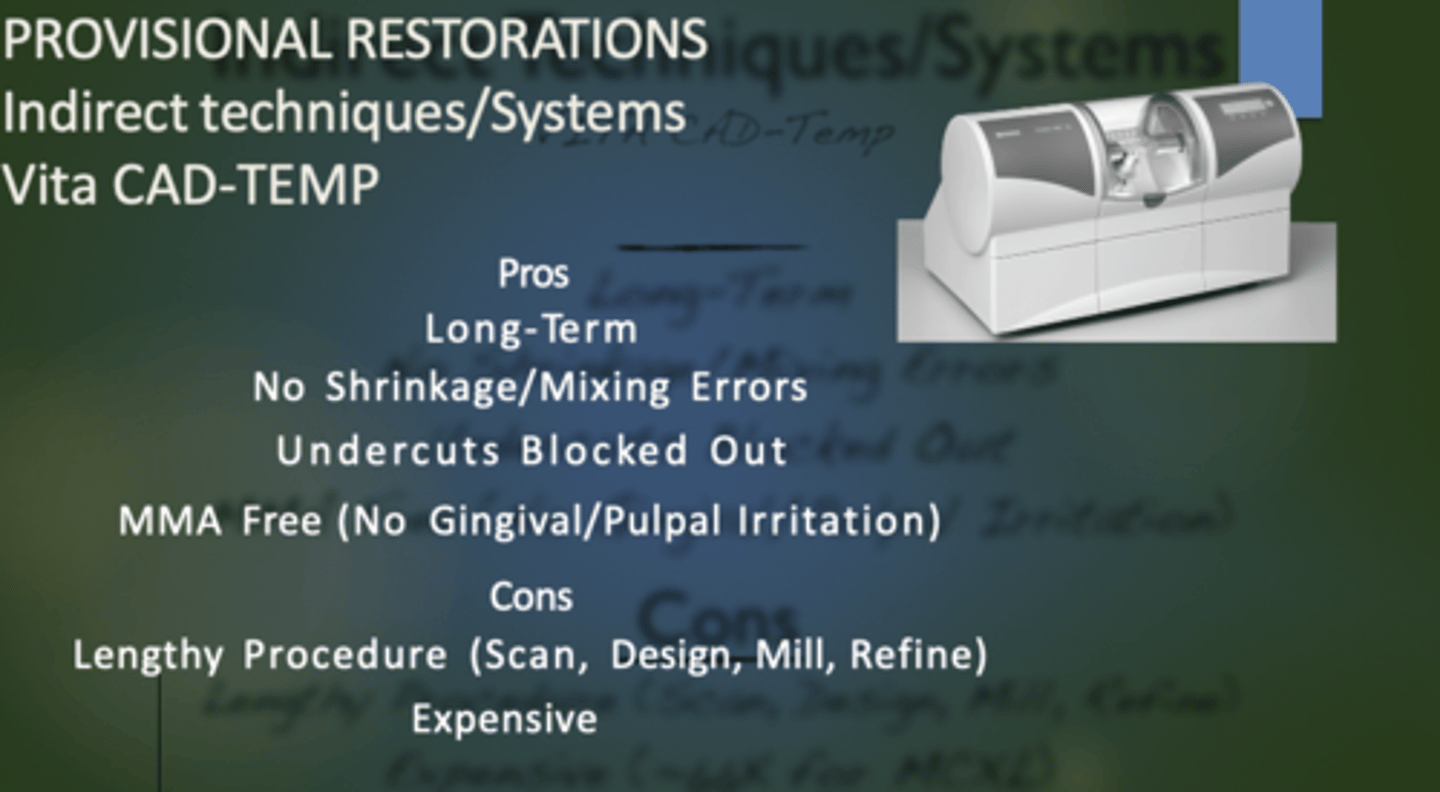

Vita CAD-Temp

- using Vita CAD-Temp for Indirect Fabrication of a Provisional Crown

Pros

- Long term (long lasting temp

(if pt moves out of state ect)

- NO shrinkage/mixing errors

(bc they are pre fabricated blocks)

(no polymerization like Jet acrylic/PMMA)

- Undercuts are blocked out

- MMA Free

(no gingival/pulpal irritation)

Cons

- Lengthy procedure

(Scan, Design, Mill, Refine)

- Expensive

MMA

Vita CAD-Temps are _____ free

Luxatemp

You can also use ______ for Indirect Fabrication of of a temp crown

- its not a pre-made shell, its a material that's squeezed out

Integrity

- using Integrity for Indirect Fabrication of a Provisional Crown

Pros

- Excellent Marginal accuracy

- Negligible Polymerization Shrinkage

- Minimally exothermic (less heat)

- Automix system (eliminates waste)

Cons

- Lack of strength (than other systems)

- Expensive ($150-300 per cartridge)

This is what we use at school!!!

strong

- lack of strength

Using Integrity for Indirect fabrication of a provisional crown is good But it is not as _______ as other systems used.

NO

- integrity wont stick to integrity

- you will have to bond & use Flowable composite to readjust/reline a provisional

After you create the Provisional crown using BIS GMA (Integrity) and it needs a reline can you just add some more integrity to make it fit better?

flowable composite

- Always use flowable composite for a reline of a Provisional made from BIS GMA!!!!!

When you use BIS GMA for a provisional & it needs a reline, you ALWAYS use _____ ____ to make any adjustments!!!

- NEVER use Integrity

- Integrity will NOT stick to integrity

True

- different for each pt

T/F: The Pre-Fabricated shells do not always have the proper/same anatomy for each pt & you may have to make some adjustments.