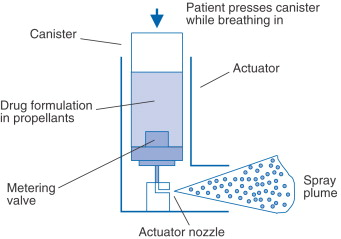

P2 PMDIs: pressurised metered dose inhalers

1/18

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

19 Terms

What is PMDI

compact pressurised aerosol dispenser

most common

25ug-5mg

advantage of pmdi

Large dose range

several hundred accurately metered measured doses

•Many doses

•Compact

•Consistent delivery

•Relatively cheap

•Sealed canister protects drug

•Lower capital costs for market entry

disadvantage pmdi

•Patient co-ordination and force required to actuate

•“Cold Freon Effect”

•Tail off at the end of a can

•Force of aerosol spray

•Varying deposition pattern in airways

•Minimum IP protection for pharmaceutical industry

Propellant

Gas compressed to 300-500 kPa

Converts to liquid

Liquid rapidly boils to form a gas

Leaving behind an aerosol of drug particles

Made from hydrofluroalkanes used to be CFC as they destroy ozone layer

Metering valve

At rest

Start of actuation

Dose release

How is the spray formed

Ligaments shear

Particles released are slightly too large but they evaporate decreasing their size

Actuator

it is the component in any machine that enables movement.

Describe the types of drug particles used in pMDIs

If drug is insoluble like solid particles suspended in solution= suspension

The more soluble the drug the more drug in each droplet = larger particle size

Add another non-volatile (non-evaporating) liquid e.g. glycerine when the particle is too small

Advantages/ Disadvantages of suspension formulation

Deliver high powder doses

Disadvantages:

Requires milling or micro ionised

Requires drug to be insoluble other leads to changes in particle size going to other parts of the body

Requires drug to be freely dispersed

Homogeneity + physical stability as particles disperse = shake vigorously

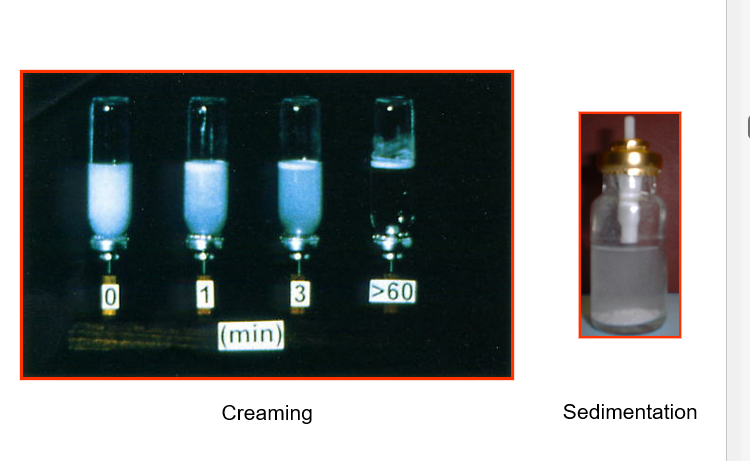

List and define 5 types of physical instability

•Rapid Flocculation - Loose Agglomerates (Interparticulate Forces)

•Bulk Separation - Creaming or Sedimentation (Density, Particle Size). Creaming = rise to the top. Sedimentation= sink to the bottom. Drug at the top is not delivered

•Irreversible Aggregation - Ostwald Ripening, Crystal Growth and Caking (Solubility)

•Crystal Structure Instability - Polymorphic interconversion (different crystal structure)

•Adhesion to the canister – inside surface often coated, e.g. PTFE

Flocculation

Clumping/ aggregation of particles that don’t break when shaken

So important to shake to remove clumps and create uniform suspension

What is the purpose of excipients

Enhance physical stability of a drug

Allows dispersing + redispersion + homogenous distribution

Prevents segregation

Examples: Oleic acid, Magnesium Stearate, PEG

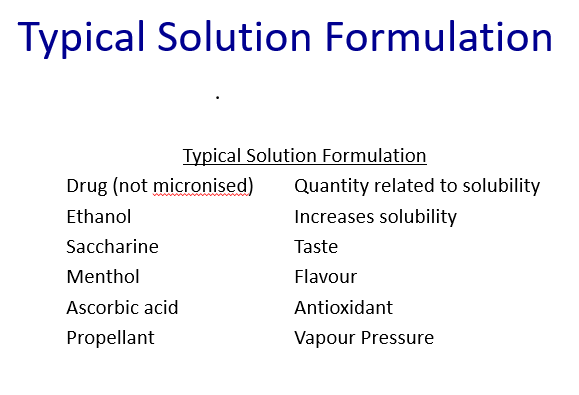

Solution based formulation

Only used if solubility and stability is adequate as it can lead to chemical reactions may lead to crystallisation during shelf life

MORE DRUG DISSOLVED = HIGHER DOSE OUT

Requires co-solvent e.g. ethanol

Solution disadvantages

•Co-solvent can cause corrosion of aluminium canister

•Drugs can be relatively unstable.

•Co-solvent lowers the internal propellant pressure, thus, atomisation is less effective.

•Modification of drug chemical structure

How to test pMDI formulation

•Sedimentation rates

•Particle size changes

•Microscopy

•Dose uniformity measurements

•Ultimate test – uniformity in the aerosol dose

•Need a consistent dose

•Particle size distribution must be consistent

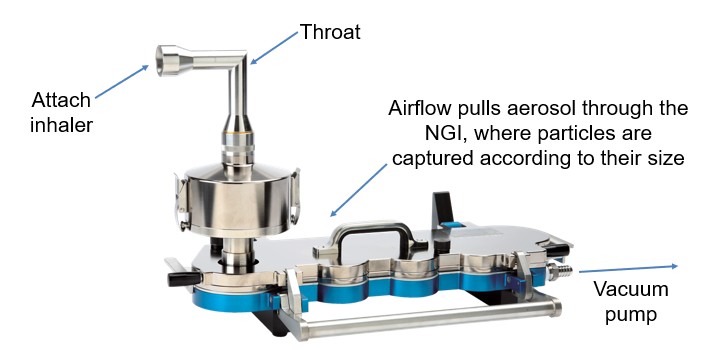

How do we measure particle size in aerosol dose

Use an impactor

Spray inhaler

Into throat mimetic

particles into collecting pan with different hole sizes

smaller and smaller particles collected

Divides aerosol cloud into 8 different compartments

Wash the pans, dissolve into solvent and can measure concentration and dose distributed into lungs

ensures same particle size distribution over time/ shelf-life and over each compartment = same performance

PMDI technique

•Shake before use.

•Breath out as far as comfortably possible away from the inhaler

•Place inhaler in mouth, inhale slowly while simultaneously pressing the canister.

•Continue to inhale slowly until lungs full

•Hold breath for around 10 seconds

•Only 20-25% of patients perform these

essential instructions.

•More can follow DPI instructions.

List some patient problems with PMDIs

Incorrect use e.g. not removing cap, don’t shake, forget to inhale, don’t hold breath, don’t exhale slowly

Actuation at start inhalation leads to poorly controlled asthma

Comorbidities e.g. arthritis find it difficult to press

Examples of training devices

In-check dial

Vitalograph AIM

Dose counters