POCS AFP

5.0(1)

Card Sorting

1/46

Earn XP

Description and Tags

Last updated 2:10 AM on 12/6/22

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

47 Terms

1

New cards

What does POCs stand for

Porous organic cages

2

New cards

generally what type of material are POCs

a type of crystalline microporous materials

3

New cards

What are the desirable properties of POCs

uniform micropores, high surface areas, and thermal and chemical stability

4

New cards

What differentiates POCs from other conventional porous materials, such as zeolites, metal organic frameworks, porous polymers, and carbon molecular sieves.

The unique structure of POCs and their distinctive solid state molecular packing

5

New cards

generally, what do POCs consist of and what can they do

They consist of covalently bonded organic cages that can assemble into crystalline microporous materials displaying three-dimensional connectivity and uniform pore size.

6

New cards

What are the general characteristics of POCS

Discrete organic building blocks

Intrinsic cavities

Extrinsic voids

Imine linked tetrahedral structure

Intrinsic cavities

Extrinsic voids

Imine linked tetrahedral structure

7

New cards

What are the general advantages of POCs

Dissolvable in common organic solvents

Thermal stability

Chemical stability

High surface areas (~40-800 m2/g)

Thermal stability

Chemical stability

High surface areas (~40-800 m2/g)

8

New cards

How are POCs typically synthesized

via [4+6] cycloimination reactions. Depending

on the amine and trialdehyde employed different cages can be formed.

on the amine and trialdehyde employed different cages can be formed.

9

New cards

what is the most studied prototypical type of POC.

CC3

10

New cards

How is CC3 formed

by the coordination of 1,3,5-triformylbenzene with trans-1,2-diaminocyclohexane,

11

New cards

What is the limiting pore size (window diameter) of CCS

~3.6 Ǻ

12

New cards

What has CC3 been used fo r

- to separate mesitylene from 4-ethyl toluene,

- separation of rare gases, including Xe and Kr ,

- sulfur hexafluoride separation

- gas chromatography separations involving chiral alcohols

- as membrane for the separation of several binary gases (ideal selectivites)

- as proton conductor

- as a noble metal catalytic support.

- separation of rare gases, including Xe and Kr ,

- sulfur hexafluoride separation

- gas chromatography separations involving chiral alcohols

- as membrane for the separation of several binary gases (ideal selectivites)

- as proton conductor

- as a noble metal catalytic support.

13

New cards

What in the XRD indicates a decrease in the

interplanar spacing.

interplanar spacing.

displacement to higher 2 theta angles

14

New cards

What may be related to small changes in the unit cell volume of CC3

the displacement of XRD peaks as a function of synthesis time

15

New cards

What suggest different degrees of packing of CC3 as well a contraction-expansion within this POC

The flexible nature of the CC3 crystals together with these changes in interplanar spacings

16

New cards

How many growth regimes are there for the crystal size of CC3

Three main growth regimes observed

17

New cards

When does the first regime occur

from 8hr to 18hr

18

New cards

what happens in the first regime

rapid crystal growth

amorphous agglomerates densify and transform into larger irregular crystals

amorphous agglomerates densify and transform into larger irregular crystals

19

New cards

when does the second regime happen

from 18 hr to 60 hr

20

New cards

what happens during the second regime

there is an intermediate stage in which crystal size decreases gradually with time

21

New cards

what might be causing the crystal size to decrease in the second growth regime

crystal fragmentation (most likely based on SEM)

crystal dissolution,

crystal dissolution,

crystal dissolution,

crystal dissolution,

22

New cards

When does the last regime take place

60 hr to 360 hr

23

New cards

what happens during the last regime

there is a regrowth stage

a progressive increase in crystals size as a function of synthesis time

a progressive increase in crystals size as a function of synthesis time

24

New cards

What is likely responsible for the continuous crystal growth in the final regime

Ostwald ripening mechanism in which small crystals disappear at expense of growing larger crystals which are favored energetically

25

New cards

What happens during the fragmentation event

crystals detach from larger crystals

26

New cards

When regarding crystal fragmentation what may explain the decrease in crystal size

The regular hexagonal voids left by fragmented crystals with comparable sizes of those crystals synthesized at 30 h

27

New cards

What is CO2 uptake highly dependent on from CC3

crystal size

28

New cards

How does the concentration of solute change for the stirring and non-stirring case

in the non-stirring case the concentration of solutes is high, and gradually decreases

in the stirring case, this concentration rapidly decreases and become steady.

in the stirring case, this concentration rapidly decreases and become steady.

29

New cards

What should affect the overall crystallization process affecting the resultant crystal size, shape, and distribution

The kinetics of the stirring/non-stirring concentration gradient

30

New cards

In principle what is the most thermodynamically stable and simplest form that a colloidal particle can adopt in solution during nucleation and growth

spherical

31

New cards

Why is the spherical shape likely preferred in the non-stirring case

the higher concentration of solutes leads to:

faster supersaturation (solute concentration/solubility ratio)

lower local thermal energy associated to the stagnant solution (non-stirred case) leading to the lowest energy spherical shape configuration.

faster supersaturation (solute concentration/solubility ratio)

lower local thermal energy associated to the stagnant solution (non-stirred case) leading to the lowest energy spherical shape configuration.

32

New cards

What are the different formation stages for different crystal formation stages for CC3

rapid crystal growth stage

intermediate stage in which crystal size decreased with time.

regrowth stage leading to a continuous crystal size increase.

intermediate stage in which crystal size decreased with time.

regrowth stage leading to a continuous crystal size increase.

33

New cards

Adsorption properties of the resultant CC3 phases for CO2 and N2 were highly dependent on what

synthesis time.

34

New cards

What are the advantages of the microwave synthesis of POCs

• Narrow size distribution of crystals

• Higher heating rates vs conventional heating

• No contact between energy source and chemicals

• No wall or heat diffusion effects

• Selectively heats

• No “hotspots”

• Higher heating rates vs conventional heating

• No contact between energy source and chemicals

• No wall or heat diffusion effects

• Selectively heats

• No “hotspots”

35

New cards

What were the conclusions of the microwave synthesis of POCs

• Microwave irradiation greatly reduced crystallization time for two prototypical POCs: CC3 and CC2.

• Size control of CC3α achieved

• Highly crystalline at short times!

• Typical reported surface areas obtained

• Microporous topology maintained

• Size control of CC3α achieved

• Highly crystalline at short times!

• Typical reported surface areas obtained

• Microporous topology maintained

36

New cards

What the proposed steps for the formation of CC3 via EISA

initial homogenous solution on Al foil.

homogenous solution on Al Foil. High RH

MSE

Flexible State

POC Nanocrystalline islands

homogenous solution on Al Foil. High RH

MSE

Flexible State

POC Nanocrystalline islands

37

New cards

What were the conclusions of CC3 formed by EISA

- The solvent diffusion rate was controlled by the relative humidity in the system.

- Novel synthetic method for the formation of a prototypical type of porous organic cage denoted as CC3.

- The formation of CC3 crystals was promoted via EISA approach which relies on the gradual evaporation of dichloromethane from a diluted concentration of CC3 precursors deposited on

aluminum foil.

- The slow solvent evaporation allowed enough time for the organization and formation of CC3 porous organic cage.

- HRTEM, SAED, SEM, and XRD patterns were used as key techniques to follow the formation of this porous organic cage.

- Novel synthetic method for the formation of a prototypical type of porous organic cage denoted as CC3.

- The formation of CC3 crystals was promoted via EISA approach which relies on the gradual evaporation of dichloromethane from a diluted concentration of CC3 precursors deposited on

aluminum foil.

- The slow solvent evaporation allowed enough time for the organization and formation of CC3 porous organic cage.

- HRTEM, SAED, SEM, and XRD patterns were used as key techniques to follow the formation of this porous organic cage.

38

New cards

What are the uses of high purity Xe

Buildings - Commercial lighting

Automotive – Head lights

Space Industry – Propellant

Medical – Anesthesia, Imaging

Science – NMR

Automotive – Head lights

Space Industry – Propellant

Medical – Anesthesia, Imaging

Science – NMR

39

New cards

What are the advantages of membranes

Low energy consumption

Continuous process

No phase changes

No chemical additives

Continuous process

No phase changes

No chemical additives

40

New cards

What is the importance of separation processes

Chemical separations account for

about half of US industrial energy

use and up to 15% of the nation’s

total energy consumption.

about half of US industrial energy

use and up to 15% of the nation’s

total energy consumption.

41

New cards

Why would you want to use POCs as membranes

they should display the most desirable properties of polymers (facile processability and flexibility) and inorganic materials (hierarchically ordered pores with molecular sieving properties) leading to highly selective and permeable membranes

42

New cards

Why was CC3 chosen as the POC membrane for Xe separation

its limiting pore aperture is ~3.6 A can be used as a molecular sieve

Xe has a kinetic diameter ~4.1 A

He, CO2, Kr, and CH4 have kinetic

~ 2.6 Å, 3.3 Å, 3.6Å, and 3.8 Å respectively

Xe has a kinetic diameter ~4.1 A

He, CO2, Kr, and CH4 have kinetic

~ 2.6 Å, 3.3 Å, 3.6Å, and 3.8 Å respectively

43

New cards

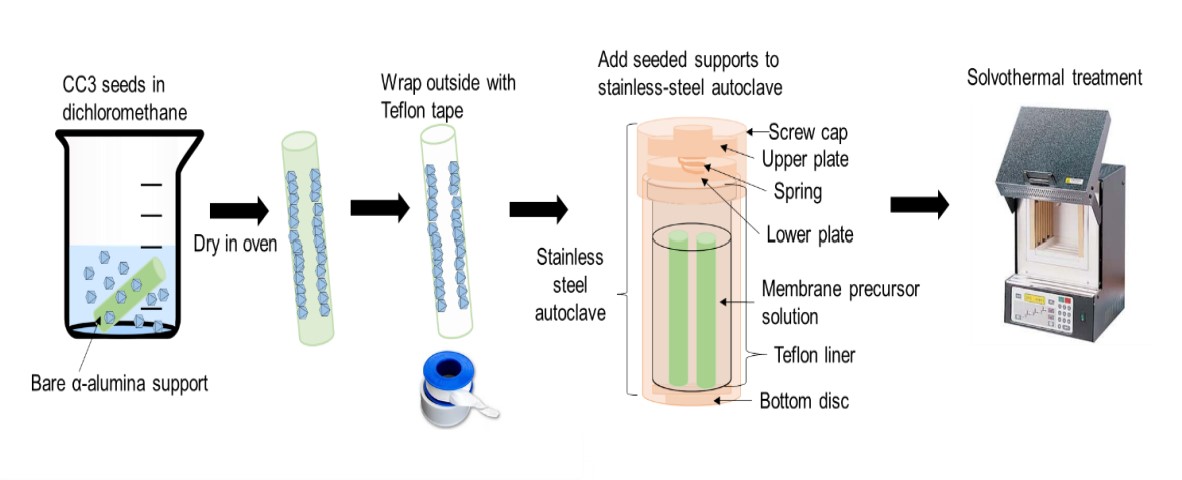

draw how CC3 membranes were made by secondary seeded growth

44

New cards

What is the key factor that leads to a higher-than-expected selectivity for Ch4/Xe

pore shape selectivity based on molecular configuration

leading potentially to entropic selectivity

leading potentially to entropic selectivity

45

New cards

What are the factors that affected the separation mechanism

molecular sieving,

adsorption,

diffusivity differences **

adsorption,

diffusivity differences **

46

New cards

What were the conclusion of CC3 as separation membranes for Xe

-The quality of the membranes was dependent on the crystal size, and size distribution of the seeds employed for membrane synthesis. Smaller CC3 seeds with narrow size distribution led to enhanced membrane separation performance.

-Mechanistically, the membranes separated He, CO2, Kr, and CH4 from Xe mainly via differences in diffusivities.

-CC3 membranes displayed low to moderate ideal selectivities of the light gas over Xenon and unprecedented high gas permeances in the 773 to 2114 GPUs range.

-These membranes may be promising for extracting Xenon from different important gas sources, including air, natural gas, and nuclear based mixtures

-Mechanistically, the membranes separated He, CO2, Kr, and CH4 from Xe mainly via differences in diffusivities.

-CC3 membranes displayed low to moderate ideal selectivities of the light gas over Xenon and unprecedented high gas permeances in the 773 to 2114 GPUs range.

-These membranes may be promising for extracting Xenon from different important gas sources, including air, natural gas, and nuclear based mixtures

47

New cards

How might POCS be used for hydrogen isotope separations

Quantum size effects are observed when the difference between the size of the molecule and pore diameter is comparable to the De Broglie wavelength.

Quantum size effects are observed when the difference between the size of the molecule and pore diameter is comparable to the De Broglie wavelength.

Quantum size effects are observed when the difference between the size of the molecule and pore diameter is comparable to the De Broglie wavelength.