07 Plastics

1/58

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

59 Terms

Historical examples of plastics (2)

Goodyear (1839) and the rubbern (vulcanized caoutchouc)

Celluloid

Def: plastics

Materials whose components consist of such macromolecular organic compounds that are formed synthetically or by transformation of natural products

Plastically moldable under heat and pressure conditions

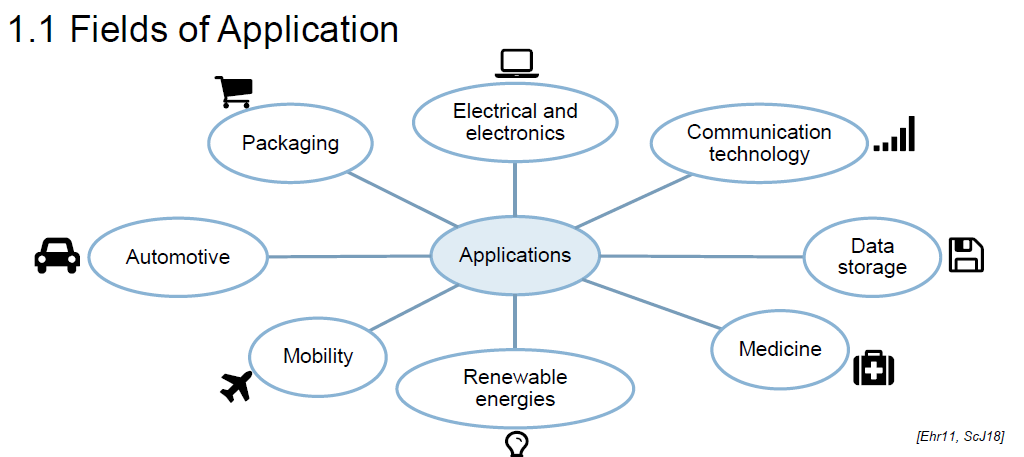

Name the fields of application of Plastics (8)

Packaging

Electrical and electronics

Communication technology

Automotive

Data storage

Mobility

Renewable energies

Medicine

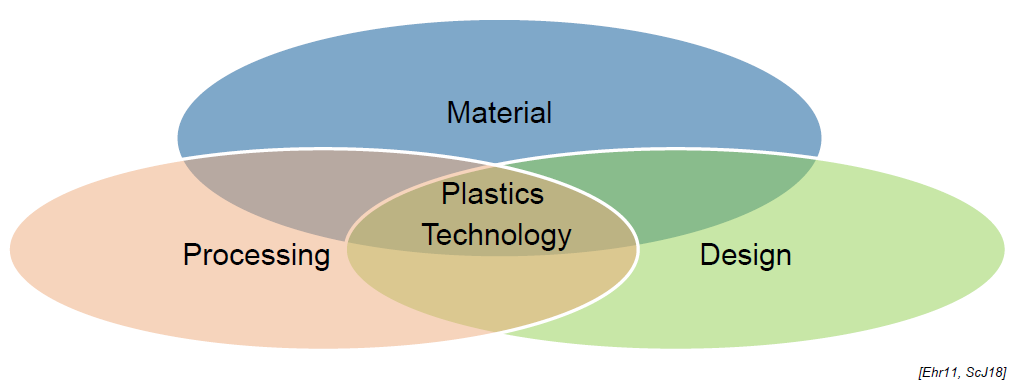

What aspects are related to Plastics Technology? (3)

Material

Processing

Design

What does Plastic Processing depend on? (5 + Ex)

Design requirements

Material properties

Quantity

Reinforcements?

Tool mold or production options

Ex: Vessels

It is not the same a HP vessel made to withstand up to 700 bar

than a tupper (also a vessel) to store food

What is comprised within Plastic Design? (5 + Ex)

Processing

Material

Function

Service requirements (mechanical, chemical and physical reqs.)

Installation space

Ex: Vessels

Pressure vessel carbon winding with different winding methods (polar, helical, hoop)

Injection molding rule (draft angles for demolding)

Organize following materials as a function of their density: Al, Fe, Ceramics, Plastics, Ti

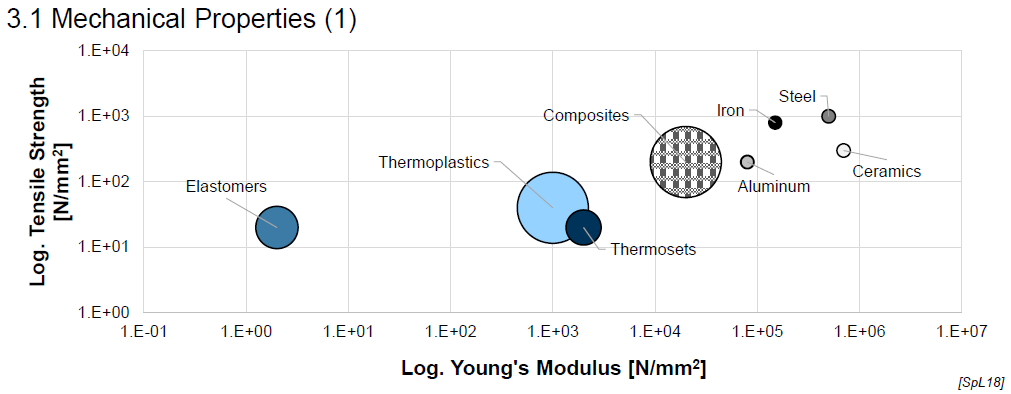

Plastics (0.8 - 2.2 g cm-3) < Al < Ti < Fe < Ceramics

Characterize Plastics (10)

Adjustable spectrum of mechanical properties

Economic

Low processing temperatures

Good thermal insulation

Good electrical insulation

Variety of colors

High chemical resistance

Permeable

Recyclable

Lightweight

What is retardation when talking about polymers?

Analogous to the creep for solid materials

How is visco-elastic behavior described?

Mathematically through Maxwell’s spring-damper model for e.g. polymer melt

Through Kelvin’s mode

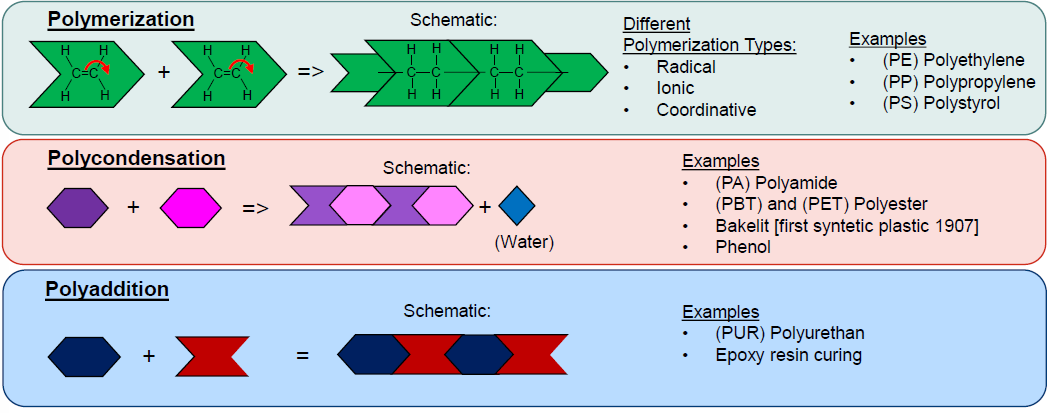

What are the main mechanisms of Polymer Synthesis? (3)

Polymerization

Polycondensation

Polyaddition

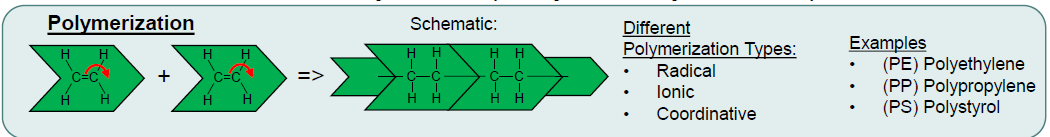

What is Polymerization? (2 + Ex)

Formation of polymers by linking monomers

Can be radiacal, ionic or coordinative

Ex:

Polyehtylene (PE)

Polypropylene (PP)

Polystyrene (PS)

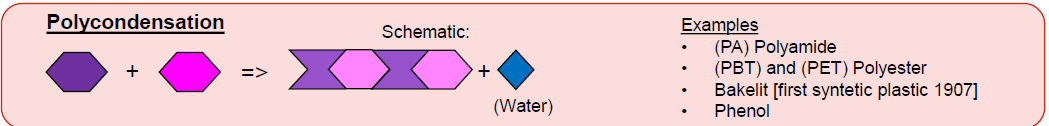

What is Polycondensation? (1 + Ex)

Reaction of monomers + release of small molecules

Ex:

Polyamide

Polyester (Polyethylene Terephthalate = PET)

PBT

Bakelite

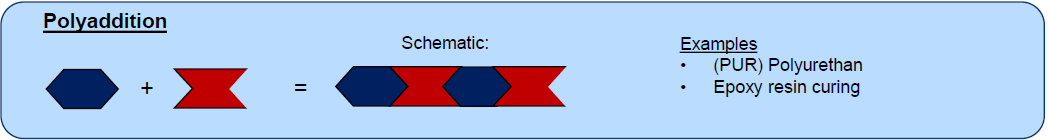

What is Polyaddition? (1 + Ex)

Monomer combination without by-product

Ex:

Polyurethane (PUR)

Epoxy resins

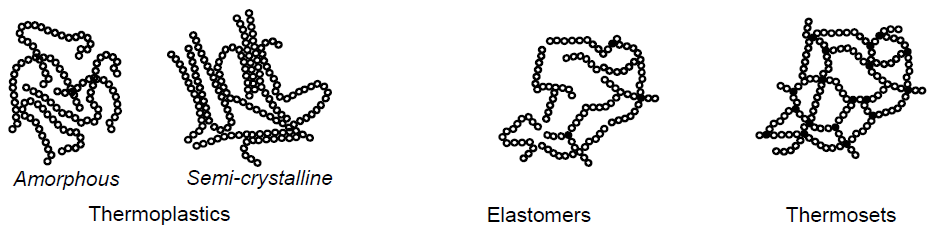

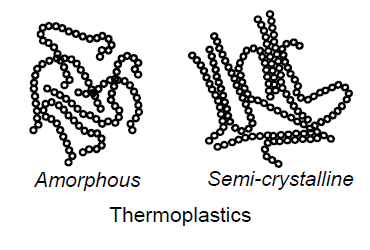

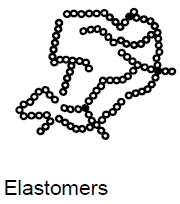

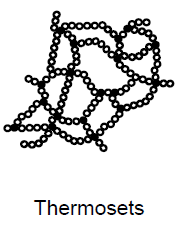

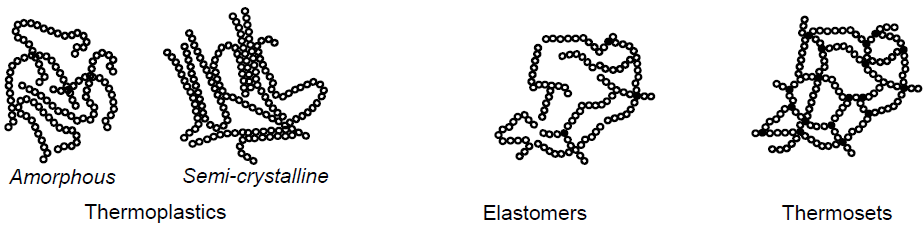

In which groups are plastics divided?

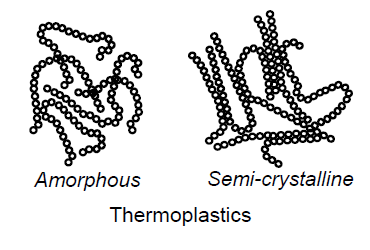

Thermoplastics: Amorphous and Semi-Crystalline

Elastomers

Thermosets

What are thermoplastics? (4)

Plastics with linear ore branched molecules, with almost no crosslinking

Amorphous: generally transparent

Semicrystalline: more visco-plastic

Can be melted as oft as desired

What are elastomers? (4)

Syn: rubber

Low degree of crosslinking

Cannot be melted without undergoing breakdown processes

Usually vulcanized

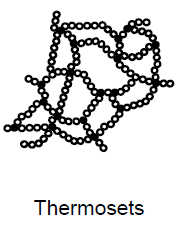

What are thermosets? (4)

Cured plasticas

Cannot be melted without undergoing breakdown processes

Syn: duromers

Constant material properties up to breakdown

Order the plastic types as a function of the degree of crosslinking of their molecules

Thermoplastics < Elastomers < Thermosets

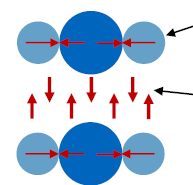

Which kind of intermolecular forces are present in plastics? (3)

Keesom-Forces (dipole-dipole force between permanent dipoles)

Debye-Forces (permanent dipole to induced dipole)

Van-der-Waals-Forces (induced dipole to induced dipole (between non-polar molecules))

Hydrogen bonds (stronger than Van-der-Waals)

What defines a meltable substance?

Intramolecular forces > Intermolecular forces (able to change state before decomposing in its constituent elements)

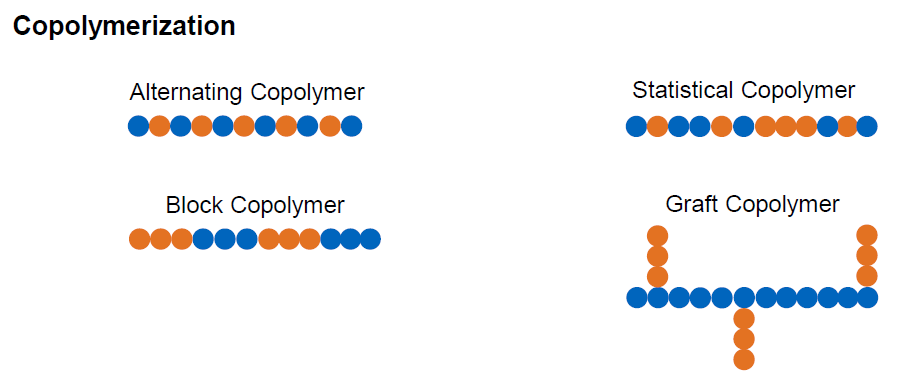

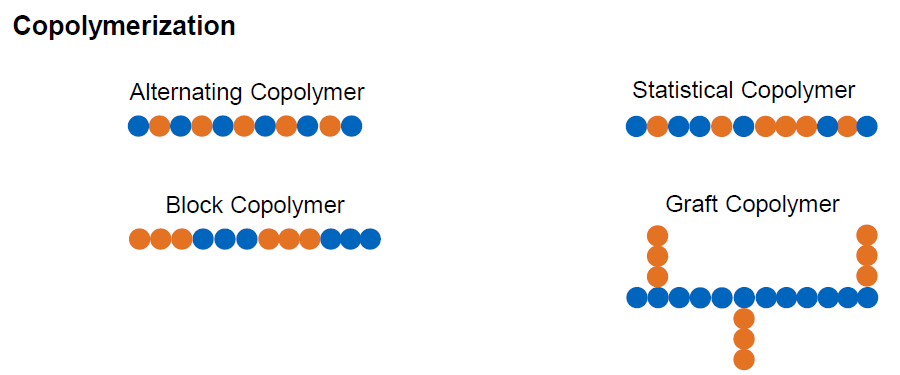

What is copolymerization?

Polymers with more than one kind of monomers

What are the types of copolymerization (4)

Alternating Copolymer

Statistical Copolymer

Block Copolymer

Graft Copolymer

What are alternating copolymer?

Two monomers alternately lined up in the chain

What are statistical copolymer?

Random arrangement of monomers

What are block copolymer?

Monomers arranged in blocks of same monomers

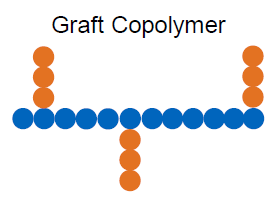

What are Graft copolymers?

2-dimensional arrangement of monomers in blocks

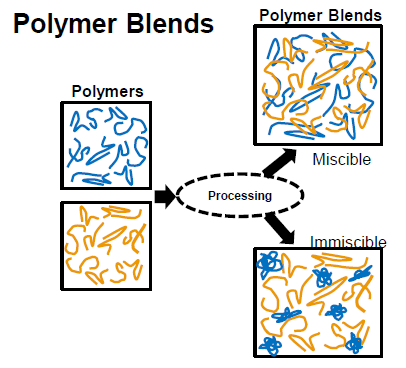

What is the difference of miscible and immiscible blends?

Miscible blends: homogeneous, single-phase, similar thermal properties

immiscible blends: heterogeneous, multi-phase, different thermal properties

What are polymer blends used for?

To tailor polymers by enhancing desired properties depending on the application

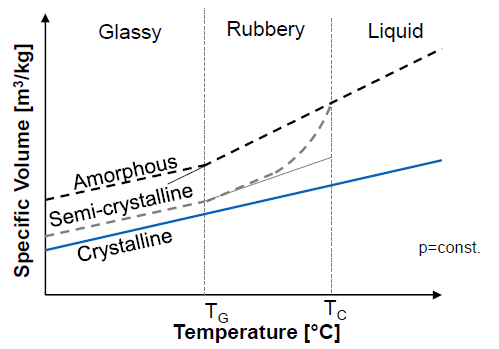

What is TG? (3)

Glass transition temperature (syn: softening temperature)

Polymer changes form flexible to glassy/brittle state

Border between rubbery and glassy

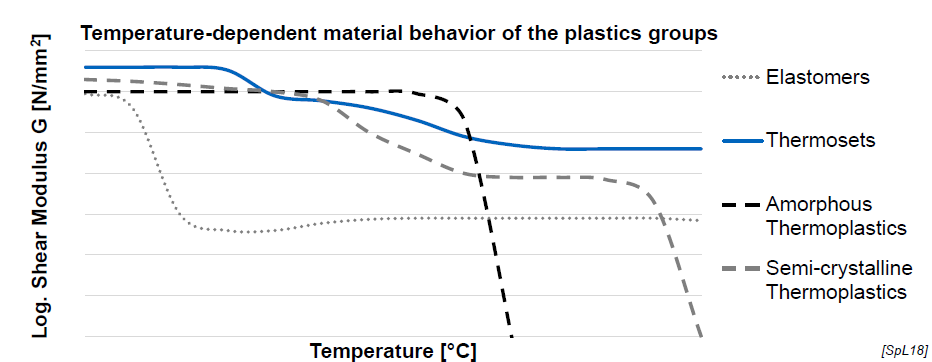

Mechanical Behavior of Plastics as a fct of Temperature (4)

Elastomers: stable after certain point

Thermosets: relatively stable

Amorphous thermoplastics: abrupt drop after certain temperature

Semicrystalline thermoplastics: two quick decrease points

Mechanical Properties of Plastics (E-Modulus) (2)

Wide range of E-modulus

Tailorability

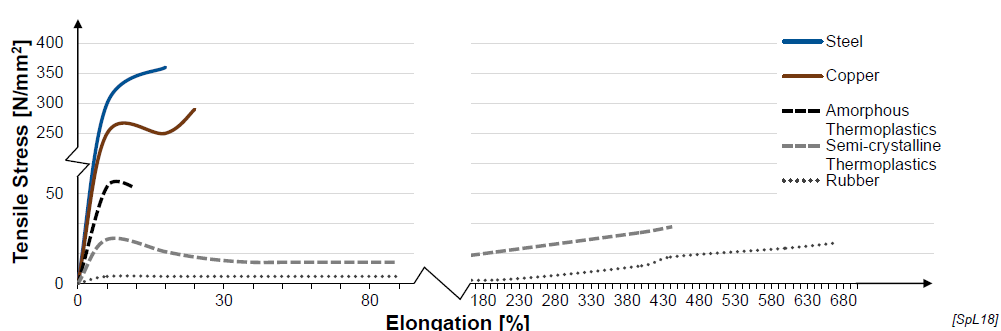

Mechanical Properties of Plastics (Stress-Strain-Diagram) (2)

Plastics are (in gneeral) extremely ductile

Amorphous Thermoplastics: brittle behavior due to random chain arrangement

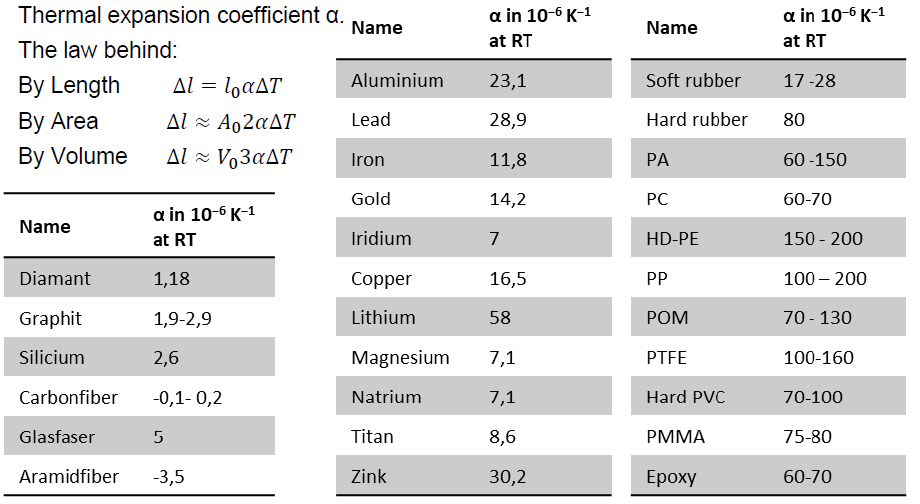

Thermal Properties of Plastics (2)

Poor thermal resistance (relative low service temperatures)

Very high thermal expansion

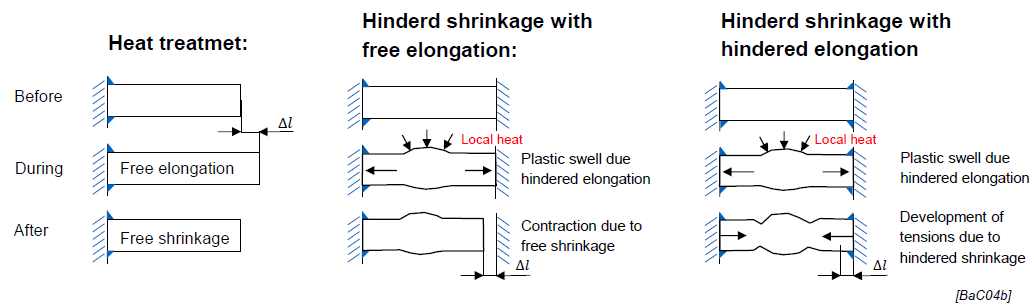

Thermal Properties of Plastics: Effects (1)

Formation of huge residual stresses due to high thermal expansion

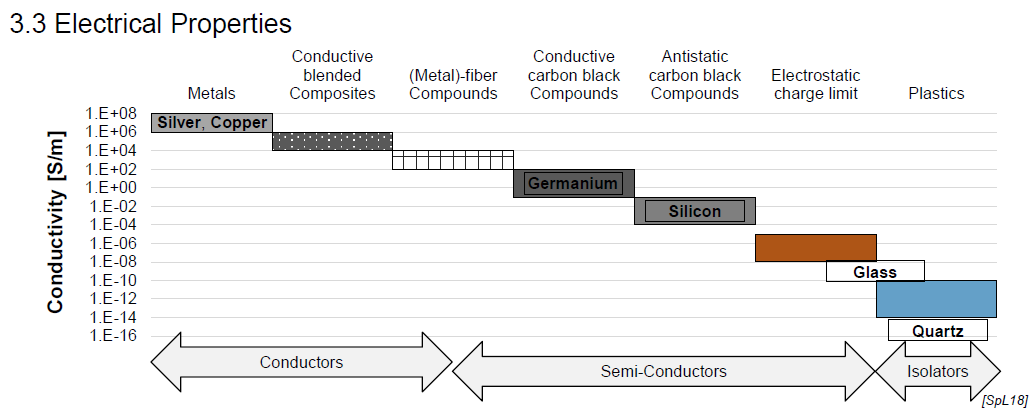

Electrical Properties of Plastics

Extremely low electrical conductivity → very good electrical insulator (e.g. good for lighting strinke protection)

How can plastics originate? (2)

Fossil-based

Bio-based

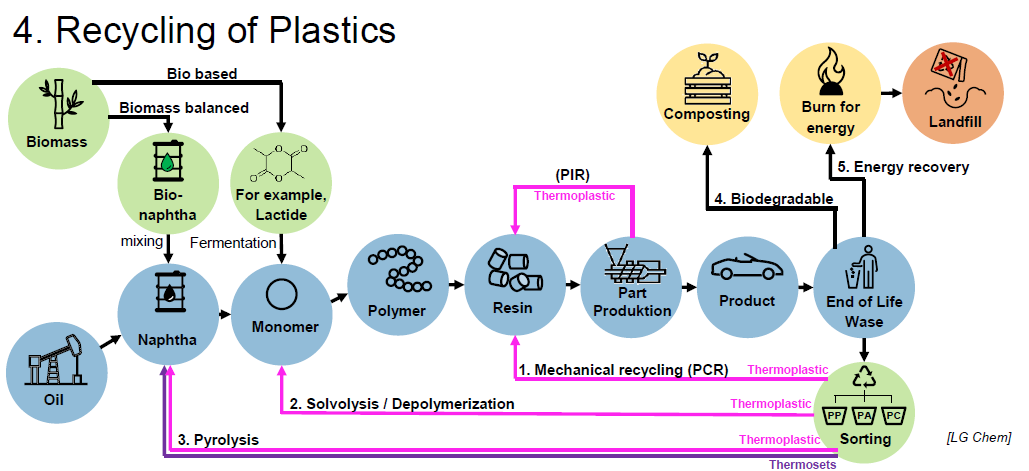

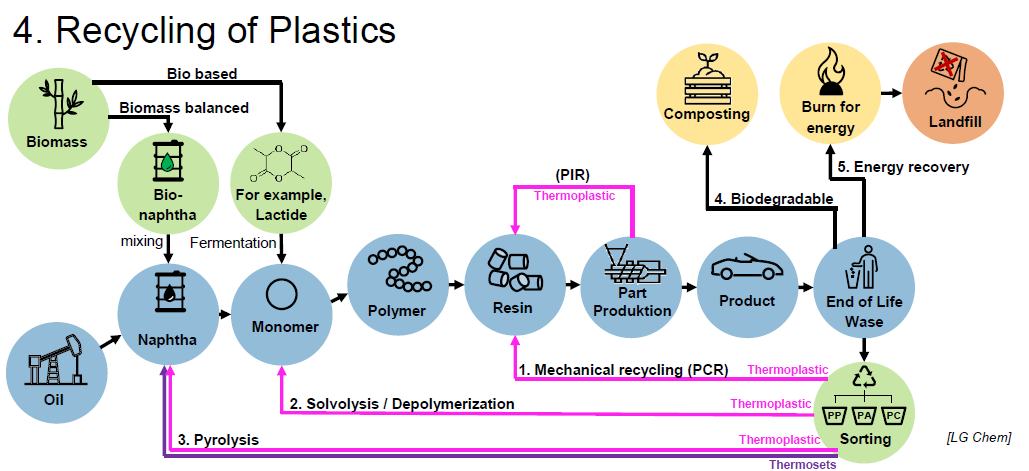

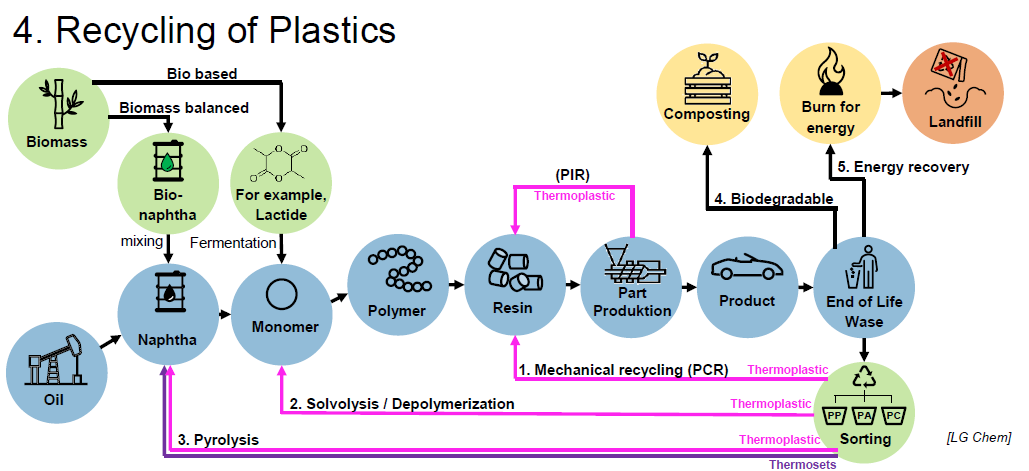

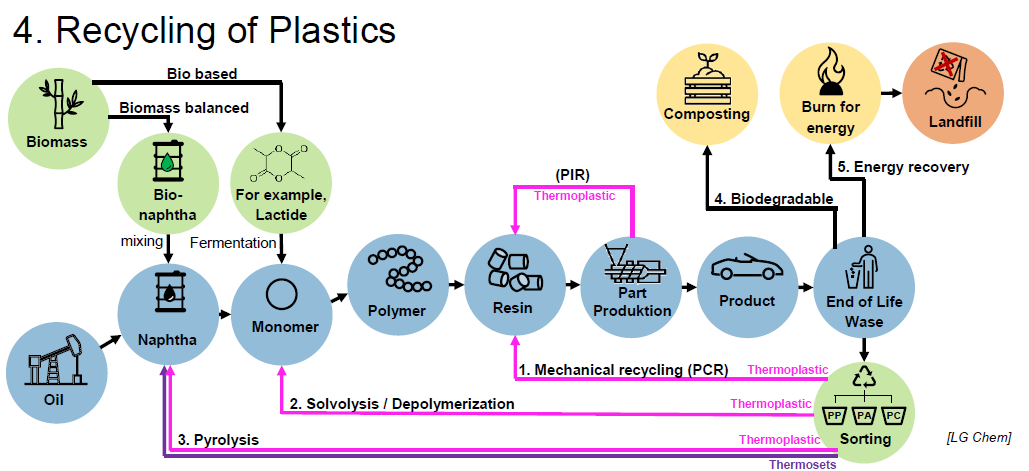

What are recycling methods suitable for plastics? (2)

Mechanical recycling (PCR) (Thermoplastic)

Depolymerization (Thermoplastic)

Pyrolisis (Thermoplasztic and Thermosets)

What End-of-Life options are there for plastics? (3)

Composting

Energy recovery (burning)

Landfill disposal

What is necessary for plastic recycling?

Sorting, at least in thermoplastics and thermosets

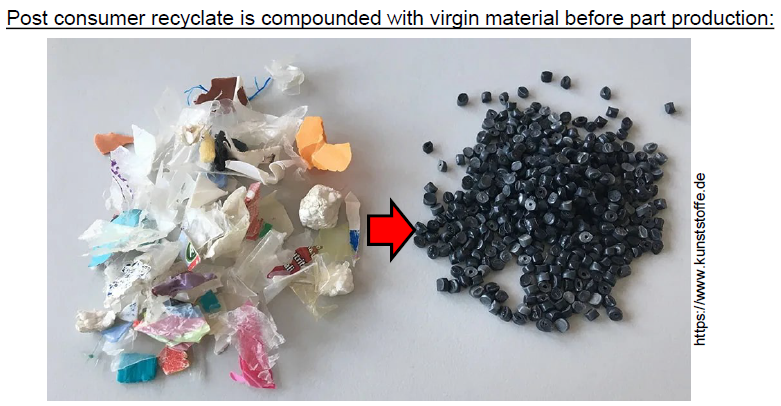

What are the steps of Mechanical Recycling? (4)

Shredding

Washing

Drying

Part Production

What is PIR? (3)

Post Industrial Recyclate

Made from rejected parts/offcuts

Low influence of quality

What is PCR? (4)

Post Consumer Recyclate

Polymer sorting

Different fabrication sources

High influence quality

What are the steps for Solvolysis/Depolymerization? (6)

Shredding

Solve

Filter

Precipitation

Drying

Monomer

For which kind of plastics is Solvolysis normally used?

Polycondensation plastics

What are the steps for Pyrolisis? (4)

Shredding

Pyrolisis

Condensation

Fractioning

Gas

Naphtha

Wax

What is Pyrolisis?

Heating up plastic past breakdown temperature in absence of oxygen to get shorter hydrocarbon chains

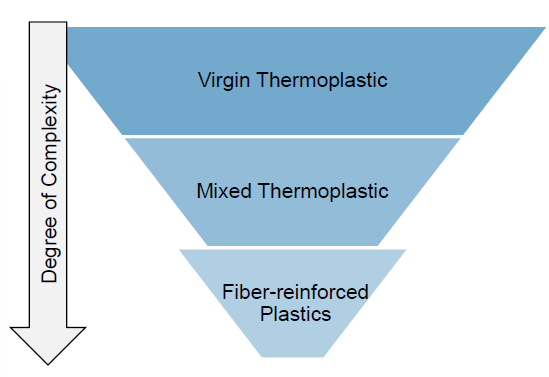

Order plastics according to their degree of complexity (3)

Vrigin Thermoplastics

Mixed Thermoplastics

FRP

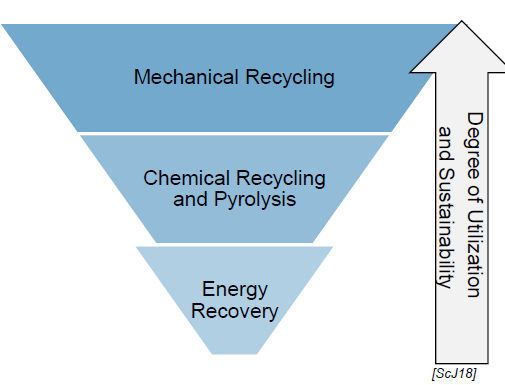

Order recycling processes according to their degree of Utilization and Sustainability (3)

Energy Recovery (not classified as recycling bc it needs high tech filters for the exhaust gases)

Chemical Recycling and Pyrolisis

Mechanical Recycling

SQ: Name the definition of plastics

Materials whose components are macromolecular organic compounds

Formed synthetically or by transformation of natural products

Plastically moldable during processing under certain heat and pressure conditions

SQ: List three field of applications for plastics and give one explicit example in each case

Packaging

Automotive: vibration damping, car interior, insulation

Mobility: FRP, leightweight construction, vibration damping

Renewable energies: connections, organic solar cells, heat exchangers

Medicine: everyday devices like contact lenses, disposable syringes, dressing materials, artifical blood vessels…

Data storage: CD, etc

Communication technology: plastic sheating for message transmision

Electrical and electronics: insulator or sheting materials for cables, organic electronics

SQ: Name five important features of plastics

Leightweight (low density)

Adjustable spectrum of mechanical properties

Economically machined

Good thermal insulator

Good electrical insulator

High chemical resistance

SQ: Name all three types of polymer synthesis and explain one in detail

Polymerization: covalent, ionic or coordination bonding between monomers e.g. Polyehtelene

Polycondensation: reaction of monomers, releasing small molecules like water e.g. Polyamide or Polyester

Polyaddition: monomer combination without by-products e.g. Epoxy Resins

SQ: List all Plastic groups and name one distinctive characteristic of each

Thermosplastics: linear or branched with very low degree of interlocking. Can be melted as oft as desired

Amorphous

Semicrystalline

Elastomers: rubber-elastic materials formed through vulcanization. Low degree of crosslinking. Breakdown before melting

Thermosets: temperature stable up to thermal breakdown, need curing, cannot be melt after curing

SQ: Distinguish Thermoplastics of Thermosets bases on polymer structure

Thermoplastics: consist of linear or branched molecules that are not covalently bonded to each other via crosslinking reactions. This allows them to melt repeatedly

Thermosets: molecular threads that are closely crosslinked. This chemical reaction during curing makes them unable to be melted afterwards

SQ: Name on major advantage and disadvantages of plastics compared to metals

Advantage: Plastics have a considerably higher elongation at break compared to metals like steel or copper

Disadvantage: lower thermal resistance, with continuous usage temperatures ending where metals do not yet show temperature-dependent properties.

SQ: Explain the influence of temperature on plastics

Transition between brittle glassy state to viscous state at glass transition temperature TG

Thermal unstable properties (in general)

Extremely high thermal expansion coefficient

SQ: Explain why it is important to consider different material properties for the design of plastic components

Plastic processing and design depend on specific requirements and material properties, meaning different applications demand specific manufacturing processes.

Design considerations for plastics must focus on processing, material properties, and functionality, including mechanical, chemical, and physical requirements.

Understanding material properties like thermal expansion is crucial, especially when combining plastics with other materials (e.g., metals), to prevent issues like residual stresses and deformation.

SQ: Explain the difference between recycling of virgin and mixed thermoplastics

?